A corrugated box puncture tester

A corrugated box and tester technology, which is applied to the direction of testing material strength, instruments, and scientific instruments using one-time impact force. It can solve the problems of low automation, poor stability, and low detection accuracy, so as to ensure accuracy and reduce energy consumption. , The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

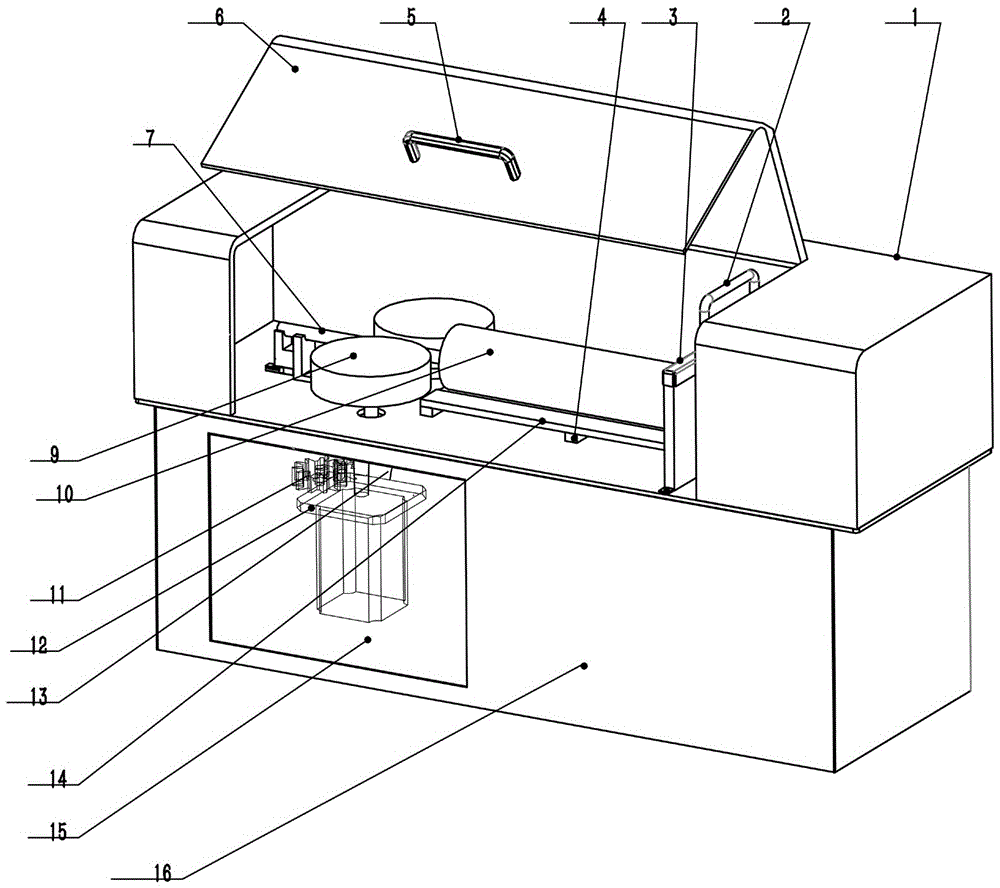

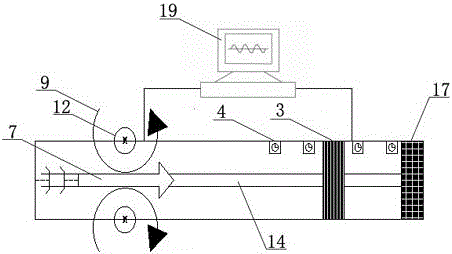

[0031] Example 1, such as figure 1 and 2 As shown, a corrugated box puncture tester, the structure includes a base 16, a control terminal 19, a pyramid 7, an acceleration mechanism that provides kinetic energy to the pyramid, and a guide rail 14 for sliding the pyramid. A top cover 1 is arranged on the base 16, and a transparent cover plate 6 is arranged on the top cover 1. The cover plate 6 and the top cover 1 are hingedly connected, and a handle 5 is arranged on the cover plate 6, which is convenient for the operator to open the cover plate 6 maintenance and operation. Wired glass observation window is installed on top cover 1 front. The top cover 1 completely seals the whole base 16, which can effectively prevent the derailment of the pyramid and injure people, and can observe the experimental conditions in the top cover 1 again. Pyramid running pipeline 10 is arranged above guide rail 14, is used for covering pyramid 7, guarantees that pyramid 7 operating environment is...

Embodiment 2

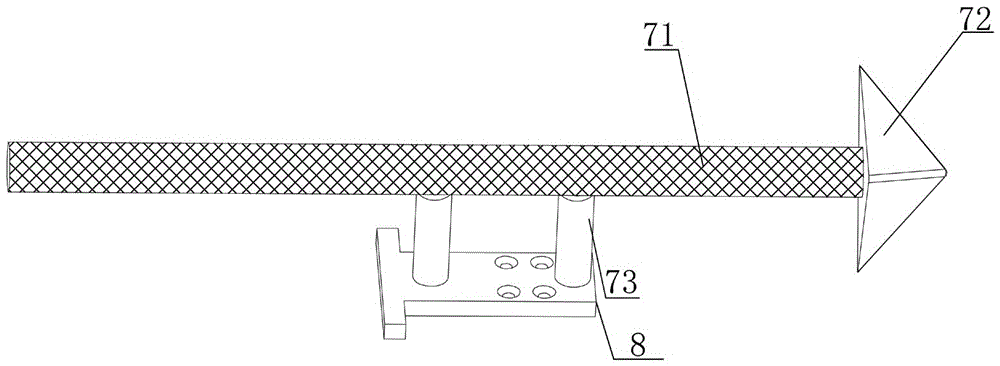

[0033] Example 2, such as Figure 5 As shown, this embodiment is based on Embodiment 1, and the boss stopper 8 is set at the bottom of the vertical mechanical fixing block 73, and the base 16 is provided with a locking connection with the boss stopper 8. The mechanical limit pin 18. A protective plate 17 is provided at one end of the guide rail 14 . The cooperation of the protective plate 17, the positioning pin 18 and the pyramid running pipeline 10 ensures that the pyramid 7 breaks away from the guide rail and hurts people, and the experimental operation is safer.

[0034] During the experiment, clamp the corrugated cardboard to be tested in the fixing clip, and then manually slide the tail of the horizontal connecting block of the pyramid into the two friction wheels, with the cone head facing the corrugated cardboard to be tested, start the control terminal, and input the experimental condition data. The rotating motor starts and the experiment starts. The control termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com