Automatic control method and automatic control device of grinding machine

An automatic control device and grinding machine technology, which is applied in the direction of grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of large workpiece accuracy errors, uneven experience, and low processing quality, so as to shorten the learning period and facilitate start-up The effect of debugging and improving the dimensional accuracy and production efficiency of the plate roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

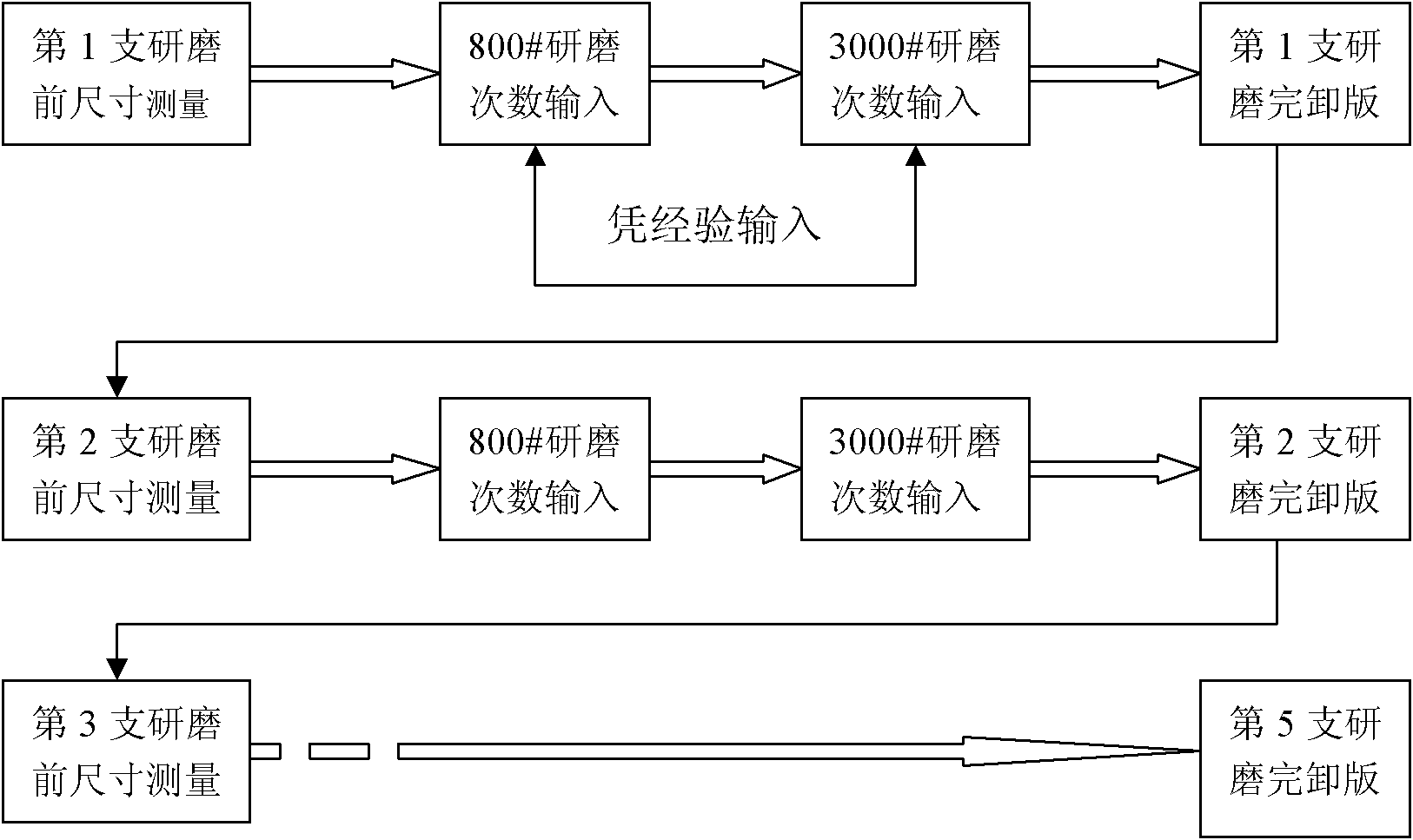

Problems solved by technology

Method used

Image

Examples

Embodiment

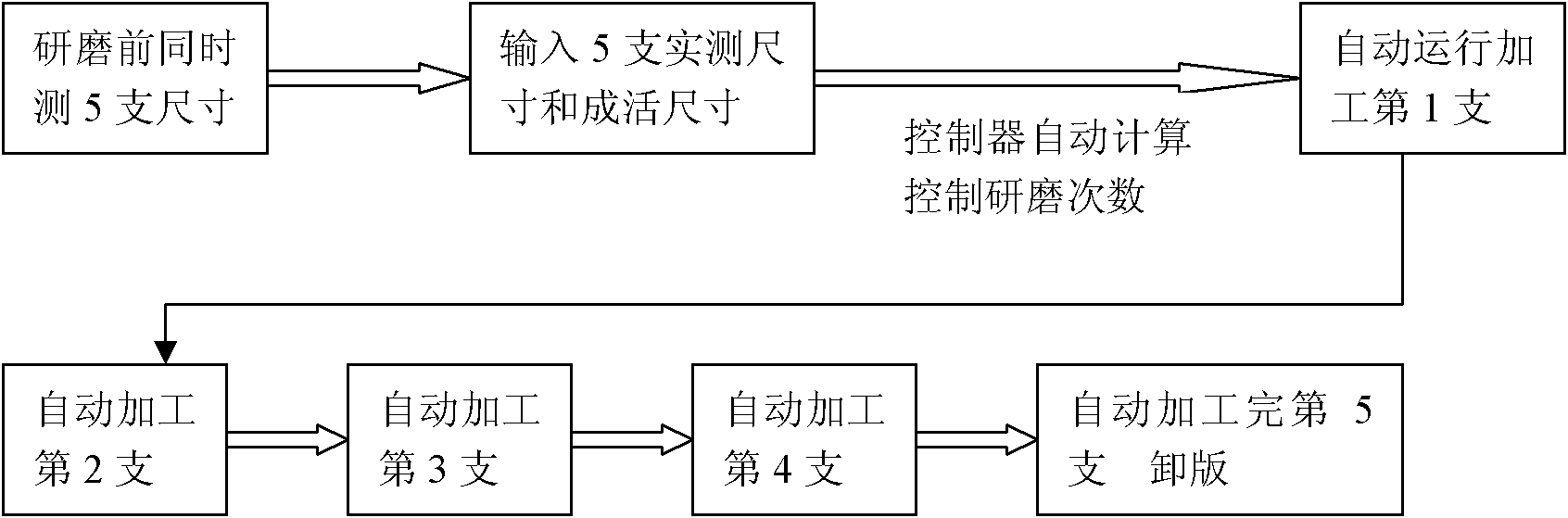

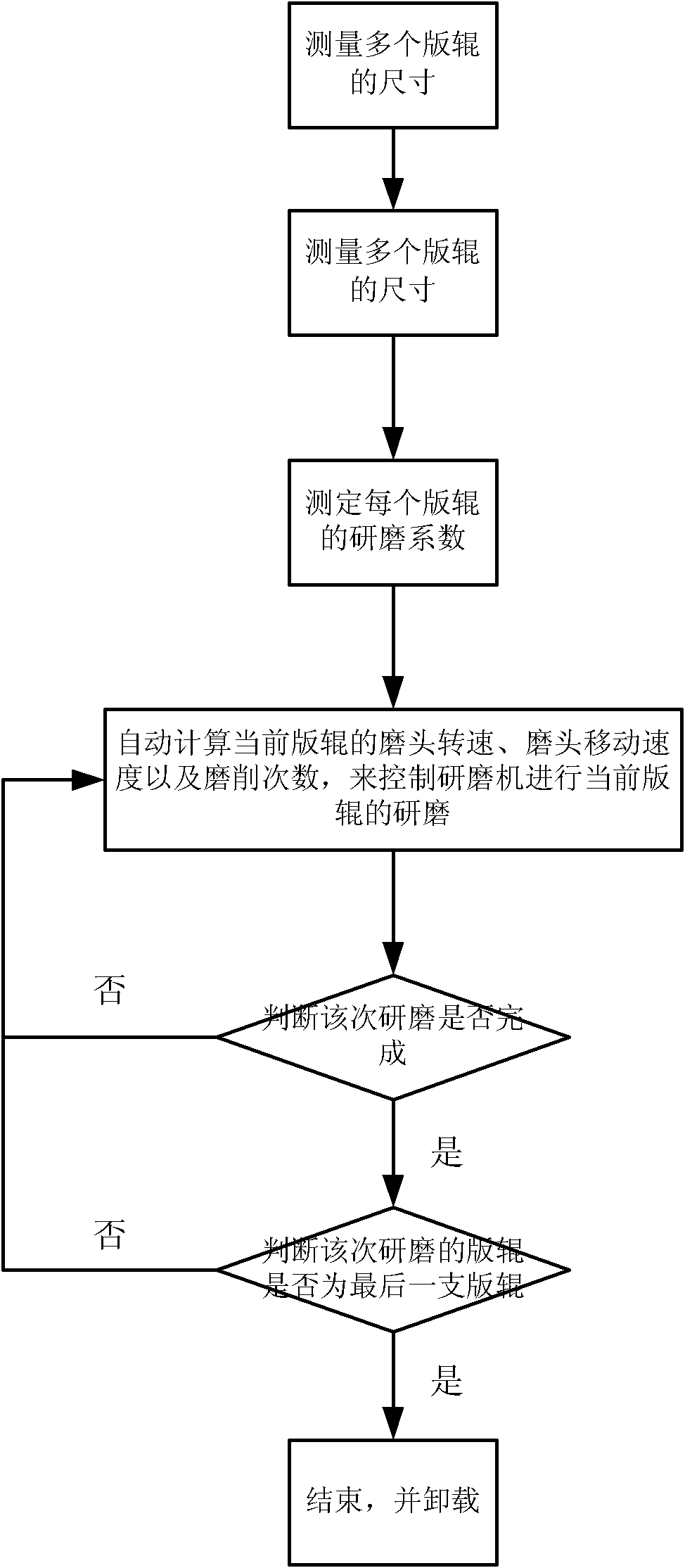

[0022] Such as image 3 , Figure 4 Shown, a kind of grinder automatic control method, comprises the following steps:

[0023] 1) Simultaneously measure the size of a plurality of version rollers, and install the plurality of version rollers on the grinder 3 at the same time after the measurement;

[0024] 2) Input the measured size and survival size information of multiple plate rollers into the controller 2 through the keyboard 1;

[0025] 3) The controller 2 determines the grinding coefficient of each version roller according to the measured size and survival size information of the version roller;

[0026] 4) The controller 2 automatically calculates the grinding head speed, the moving speed of the grinding head and the number of times of grinding of the current version roller according to the grinding coefficient of the current version roller, so as to control the grinder 3 to grind the current version roller;

[0027] 5) The controller 2 judges whether the grinding is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com