Computer control system for novel direct drive lockstitch sewing machine

A computer-controlled, direct-drive technology, applied in the field of control systems, can solve problems such as backwardness, and achieve the effects of high stitch overlap, low circuit power consumption, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

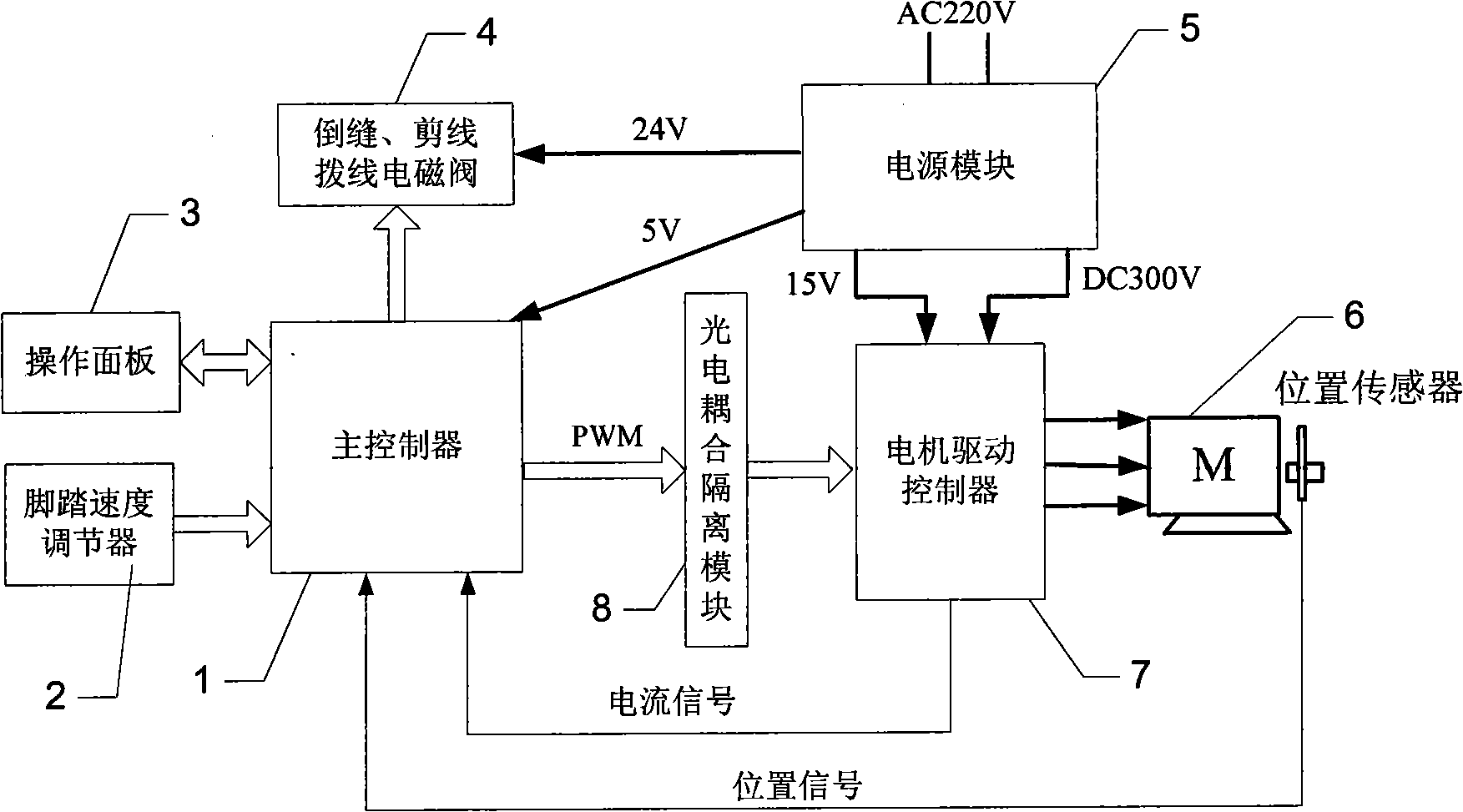

[0034] See figure 1 shown, please refer to Figure 5 , the present invention's novel direct-drive lockstitch sewing machine computer control system includes a main controller 1, a pedal speed regulator 2, an operation panel 3, a solenoid valve 4, a power supply module 5, a motor 6, a motor drive controller 7, a photoelectric coupling Isolation module 8.

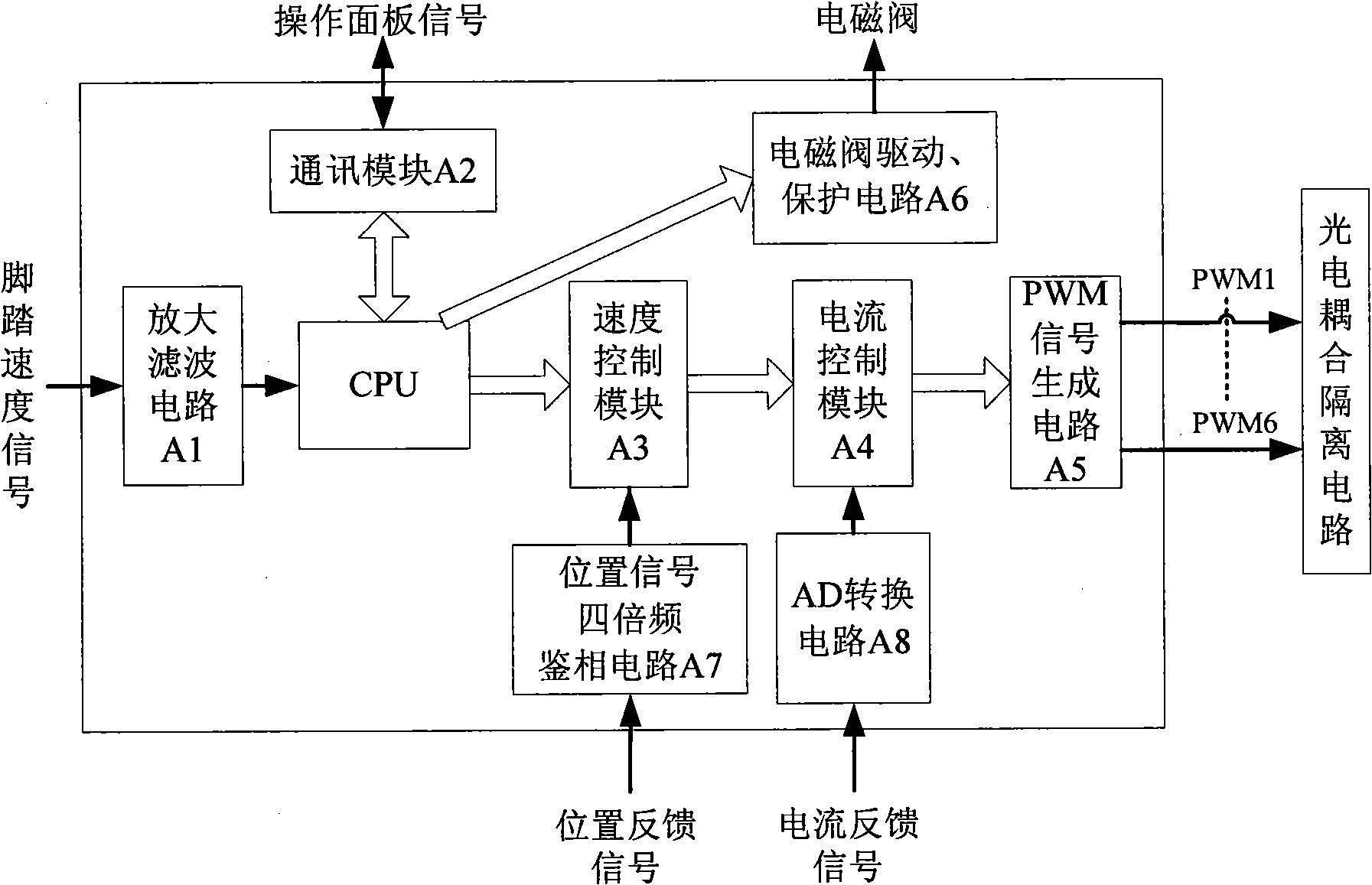

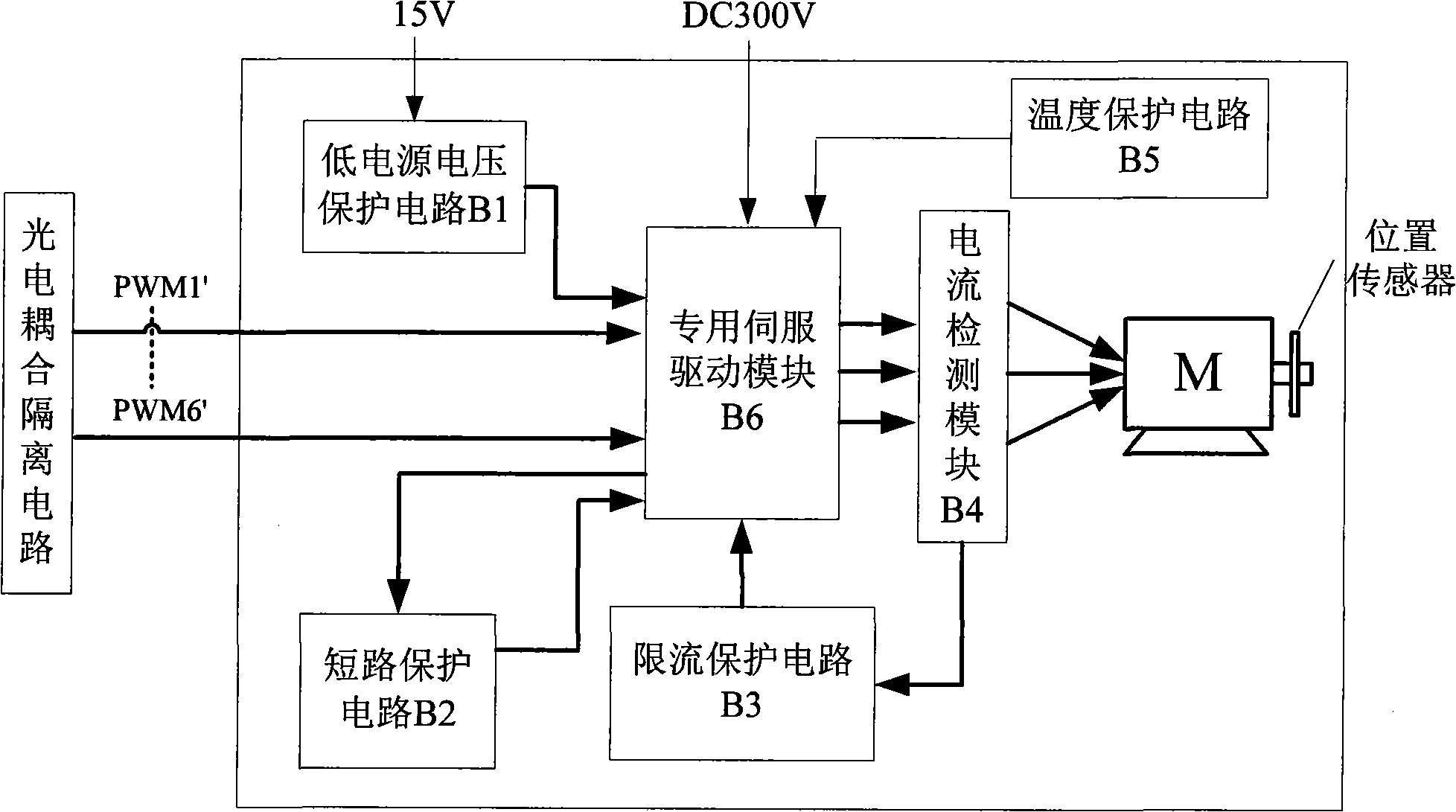

[0035] The main controller 1 is bidirectionally connected with the operation panel 3, the input end of the main controller 1 is connected with the output end of the pedal speed regulator 2, the output end of the main controller 1 is connected with the input end of the solenoid valve 4 and the photoelectric coupling isolation module 8 connection; the pedal speed regulator 2 outputs the control sewing machine speed and the operation information of each actuator; the solenoid valve 4 is used to perform reverse sewing, thread trimming, thread sweeping, and presser foot lifting; the photoelectric coupling isolation module 8 isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com