System and method for supervising gas engineering project

A technology for engineering projects and gas, which is applied in transmission systems, pipeline systems, electrical components, etc., can solve problems such as multiple specifications, quickly find the location of pipelines, and cannot be processed and corrected in time, so as to ensure the arrival rate, facilitate timely filing, Ease of statistical review

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

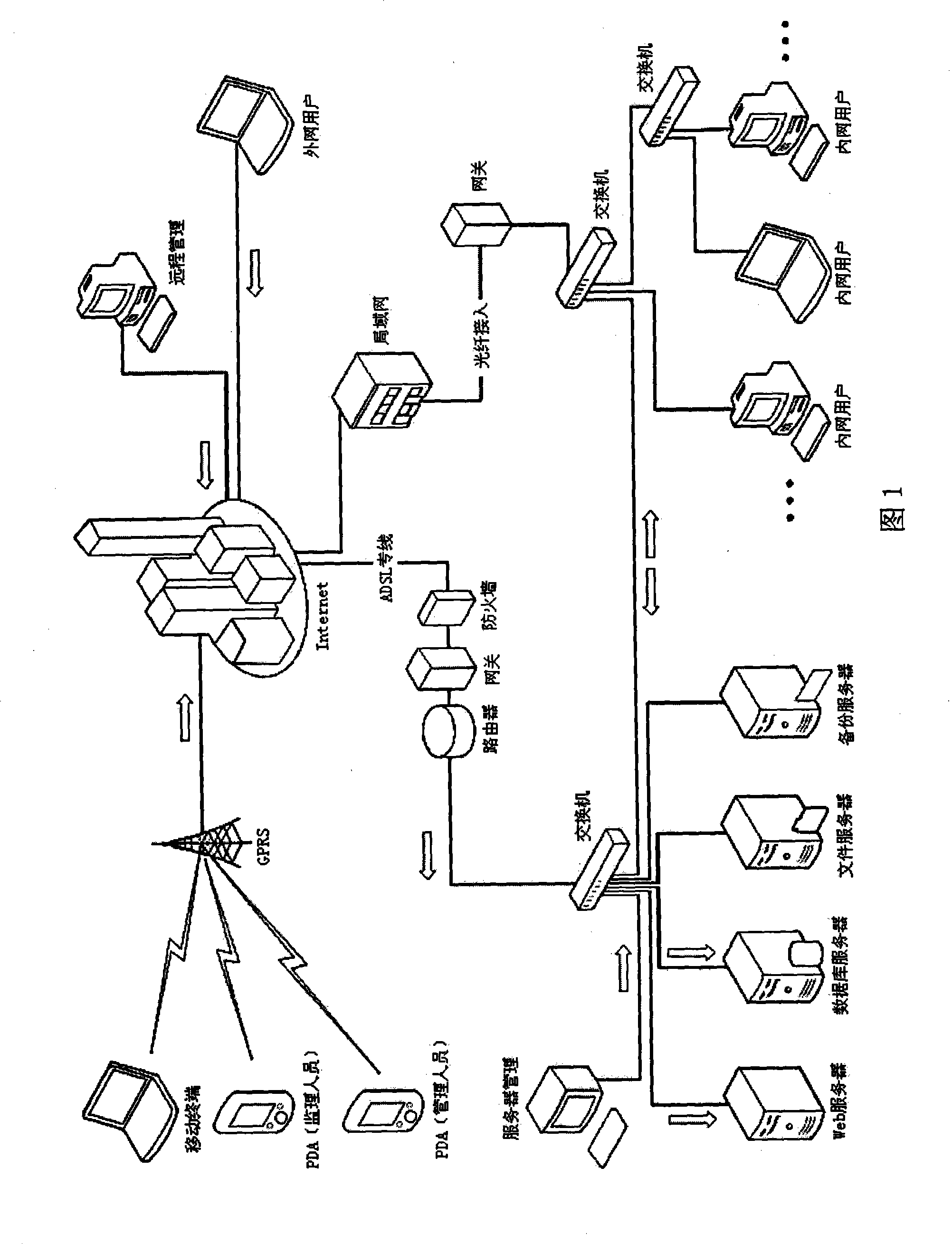

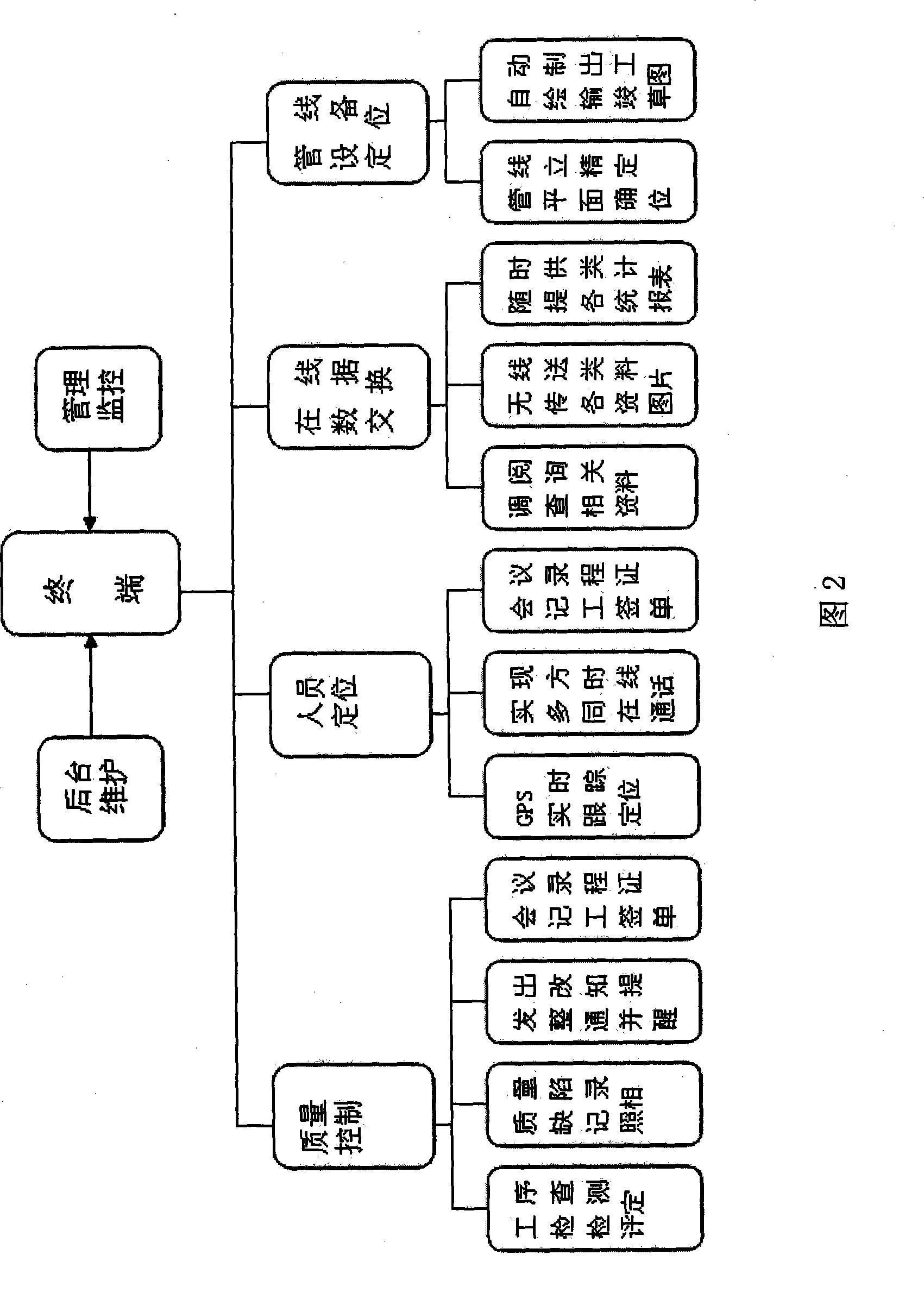

[0033]According to Fig. 1, shown in Fig. 2, the present invention comprises the server of a control center, and gas engineering project supervision module (web end) is housed in the server; A hardware firewall, is used for isolating intranet and extranet, and provides access control and Confidential service, enabling the internal network to selectively exchange information with the external network, effectively controlling the network including statistical traffic, access control, etc.; a mobile terminal, which is equipped with gas engineering project supervision software (PDA end), used for Collect on-site engineering data, and transmit the data to the server through GPRS, and at the same time locate personnel through the built-in GPS system of PDA; and GPS locator, used to collect three-dimensional coordinate information of welding joints, equipment and inflection points of the pipe network; among them, the server and The hardware firewall is connected through a network cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com