Anchor cable shed type supporting method

An anchor cable and shed-type technology, which is applied in the installation of anchor rods, earthwork drilling, shaft equipment, etc., can solve the problems of heavy workload, insufficient strength, and poor adaptability, and achieve the goals of solving on-site problems, shortening the construction period, and facilitating construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

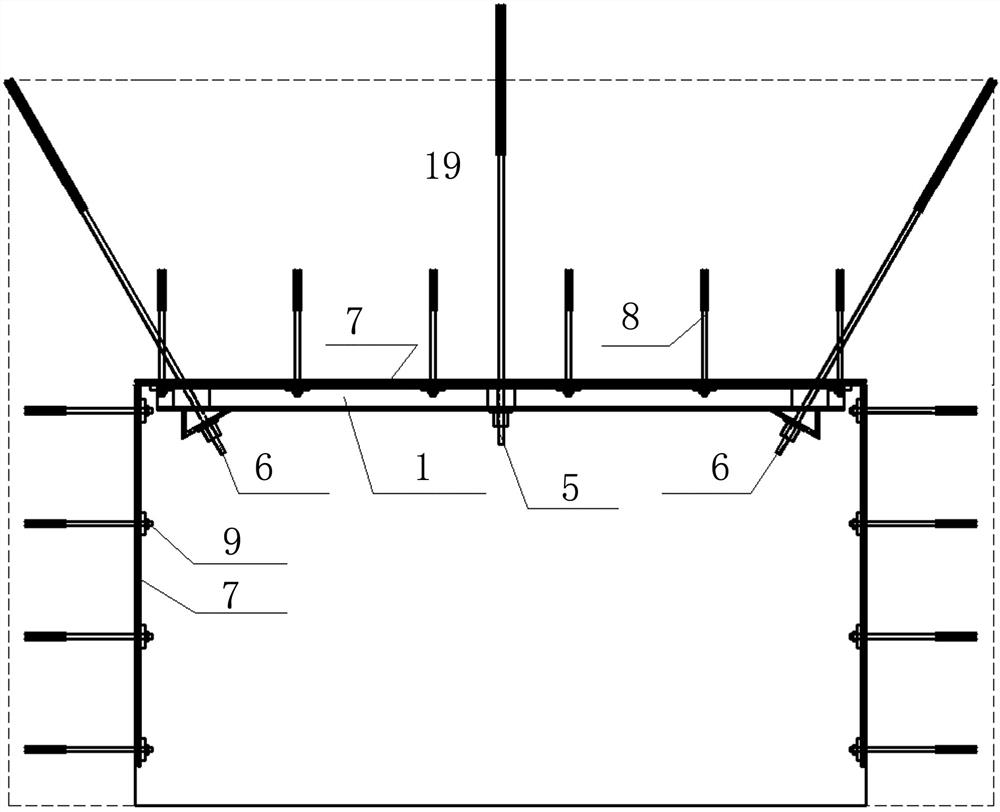

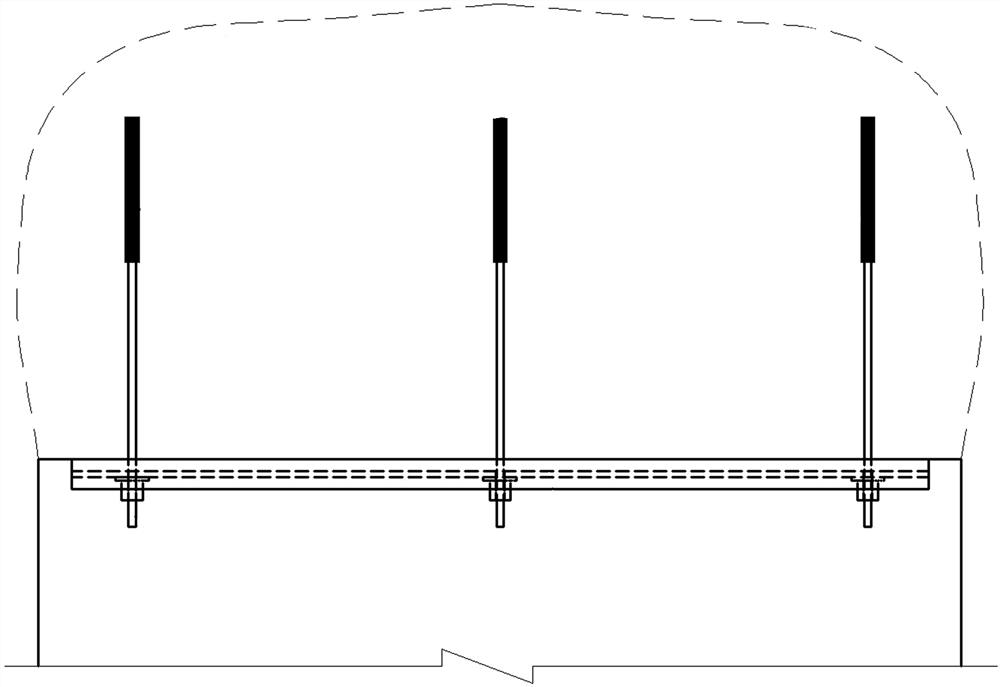

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0037] Taking the water-bearing rock layer at the top of lane 5207 of the C5# layer as an example, an anchor cable shed type supporting method designed by the present invention includes the following steps:

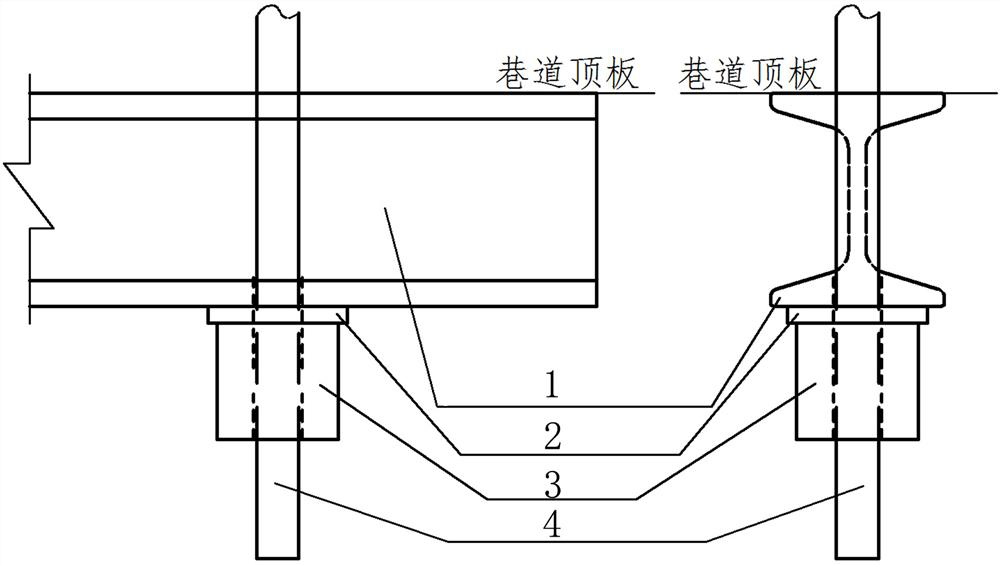

[0038] a, as figure 1 As shown, intercept 4m long 11# I-beam long beam 1, such as Image 6 As shown, the I-beam long beam 1 includes an upper flange 101, a web 102 and a lower flange 103, as shown in Figure 5 , 11 As shown, a vertical support plate 12 is welded and fixed vertically at both ends of the bottom surface of the lower flange 103. The vertical support plate 12 is 110mm long, 90mm wide and 12mm thick. The width of the vertical support plate 12 is the same as the width of the lower flange 103. Consistently, a sloped steel plate 14 is welded at a 60° angle between the bottom end of each façade support plate 12 and the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com