A grille anti-deformation device

An anti-deformation and grille technology, applied in the field of monitoring, can solve the problems of reducing downtime of equipment failure, achieve the effect of reducing downtime of equipment failure, solving on-site problems, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

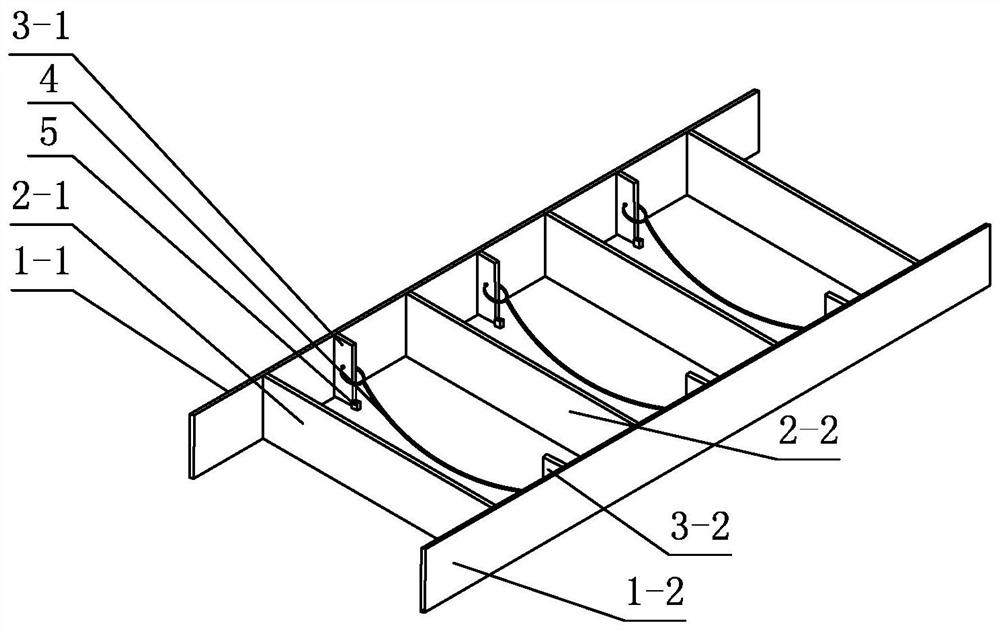

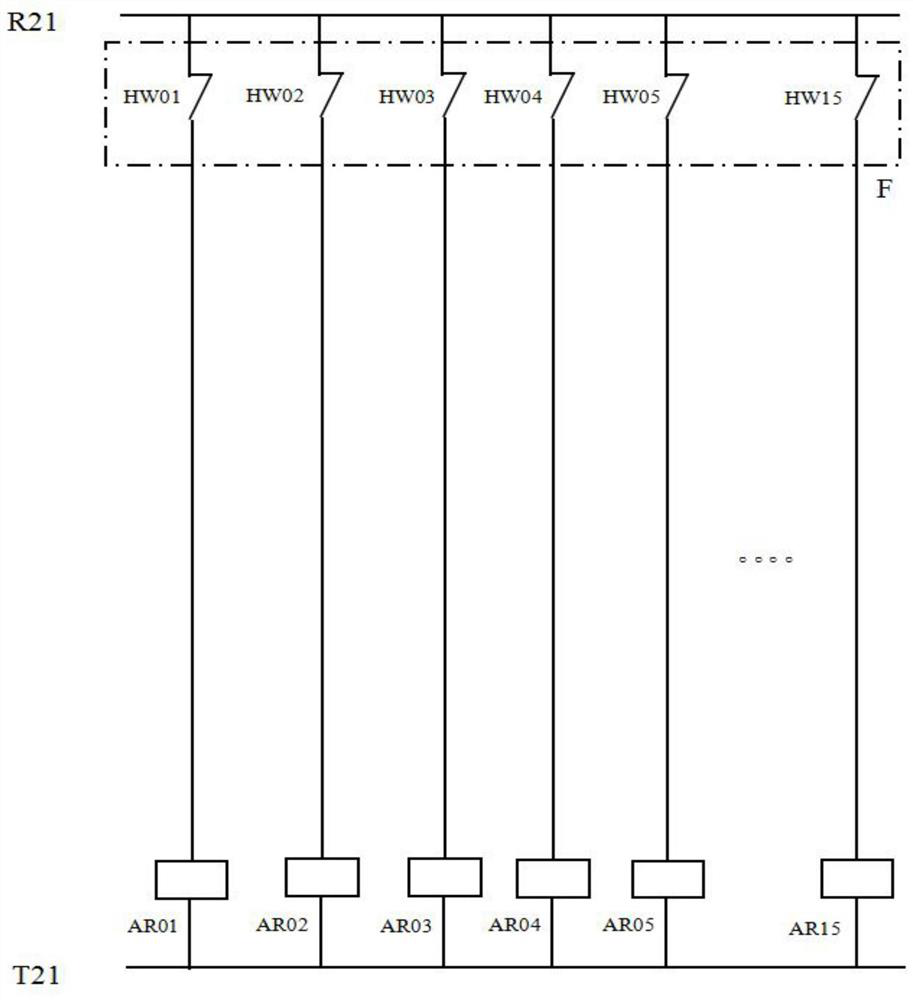

[0050] The silo has a total of 15 positions, and the grille deformation prevention device described in this technical solution is installed on the blanking ports of the 15 positions of the silo, using a combined installation method of spring wire rope and grid plate.

[0051]After on-site measurement, the distance between two adjacent grilles is 400mm, and the overall dimensions of each grille are 650*150*10mm in length*width*height.

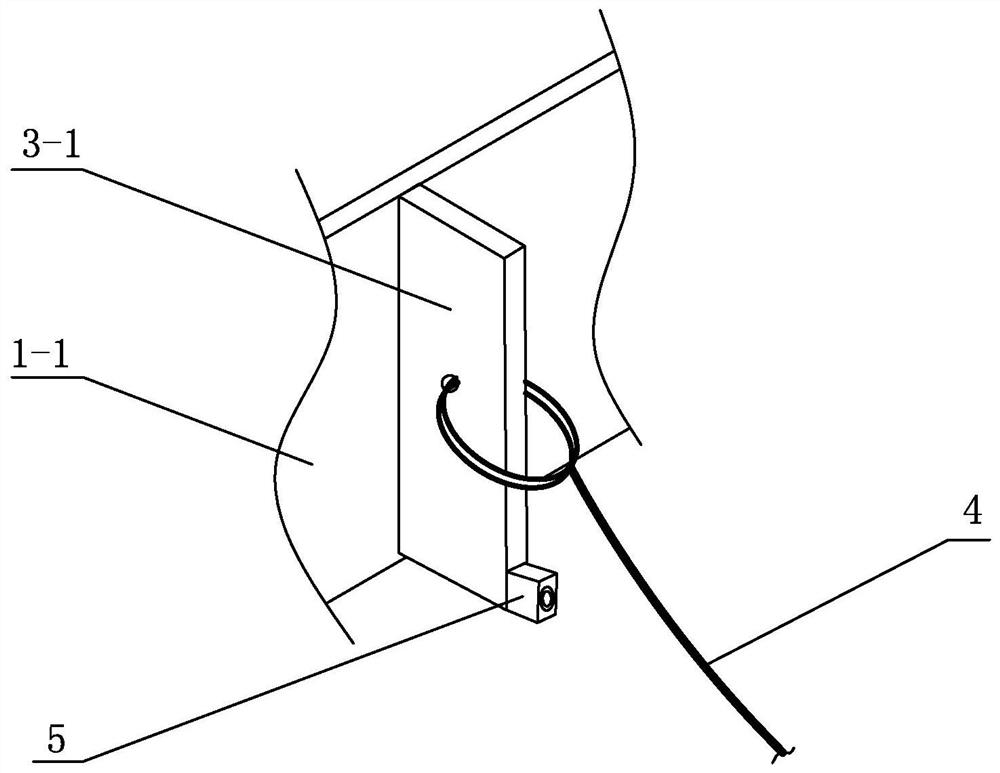

[0052] Along the length of the grille, on the side panel between two adjacent grilles, fix and install an 8mm spring wire rope.

[0053] The horizontal axis of the spring wire rope is parallel to the longitudinal axis of the two adjacent grids.

[0054] In other words, the spring wire ropes are arranged between two adjacent grids, and when viewed from above the grids, the wire ropes are arranged between the two adjacent grids parallel to the grids.

[0055] The two ends of the elastic wire rope are fixed on the side panels between two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com