A method for evaluating wheelset repair of rail transit vehicles

A rail transit vehicle and wheel technology, applied in instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of accelerated wheel wear, lack of practical operation feasibility, and long time-consuming wheel repairing, etc., to achieve significant economy value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention will be described in further detail below in conjunction with the drawings, taking a high-speed EMU as an example.

[0025]Establish the correspondence between the order of the wheel polygon and the frequency in the noise spectrum in the car;

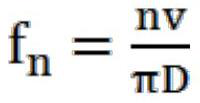

[0026]

[0027]In the formula, n is the non-circular order of the wheel; v is the running speed of the train in m / s; D is the wheel diameter in m. fnIs the excitation frequency corresponding to the wheel's n-th order non-circle, in Hz;

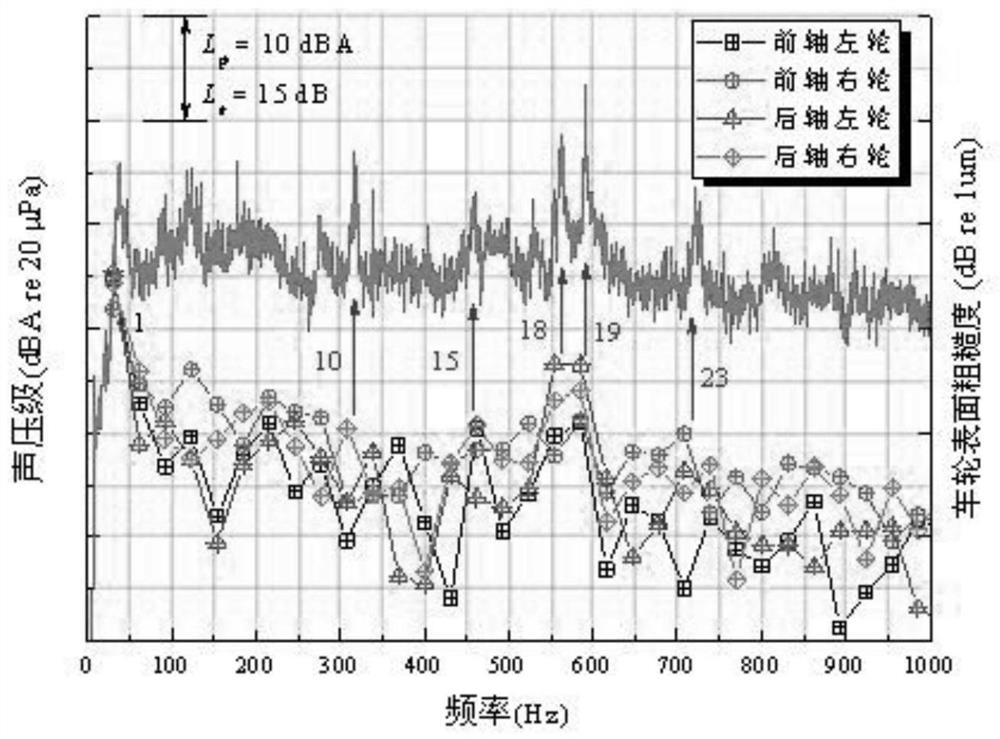

[0028]When the train speed is 300km / h, the wheel diameter is 0.86m, and the order n is 1, f1The corresponding frequency is 30.8 Hz, which corresponds to the wheel rotation excitation frequency caused by the first-order eccentricity of the wheel. If the order n is 19, f19The corresponding frequency is 586.0 Hz, which corresponds to the wheel-rail excitation frequency caused by the non-circular wheel of the 19th wheel;

[0029]A bogie corresponds to four wheels. When a certain wheel has obvious non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com