Control method for stirring rod of rod mill

A control method and rod mill technology, applied in the direction of grain processing, etc., can solve the problems that the system cannot obtain the design requirements, cannot meet the requirements of the rod mill material crushing operation, etc., so as to promote safe production and increase production capacity, The effect of solving on-site problems and avoiding tape damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

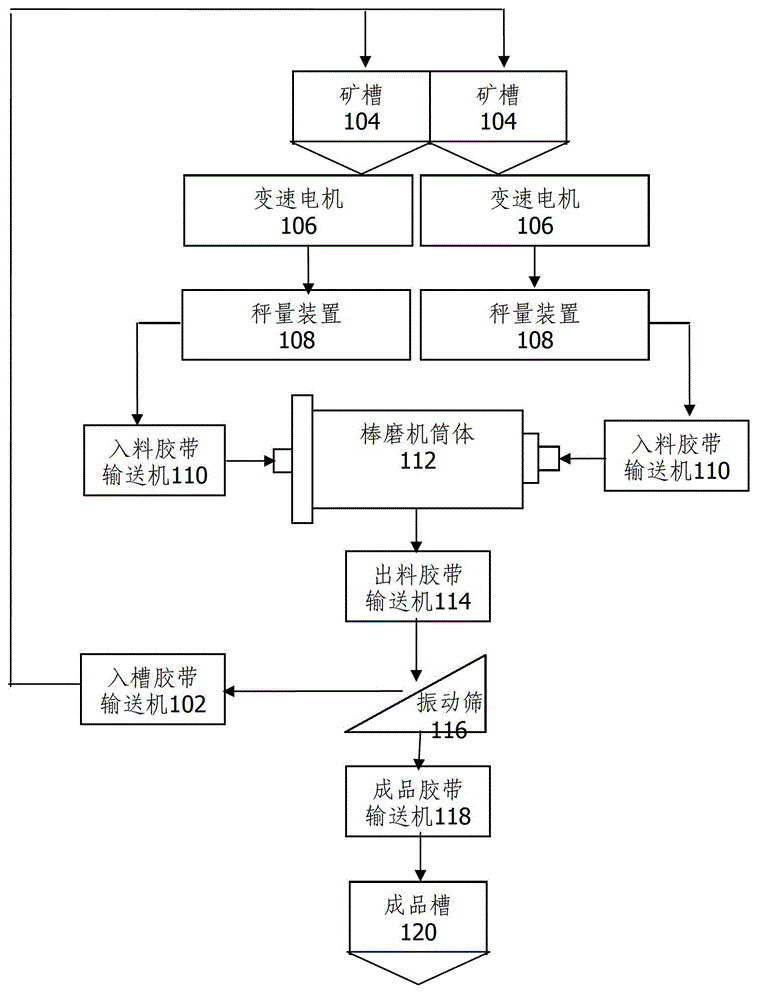

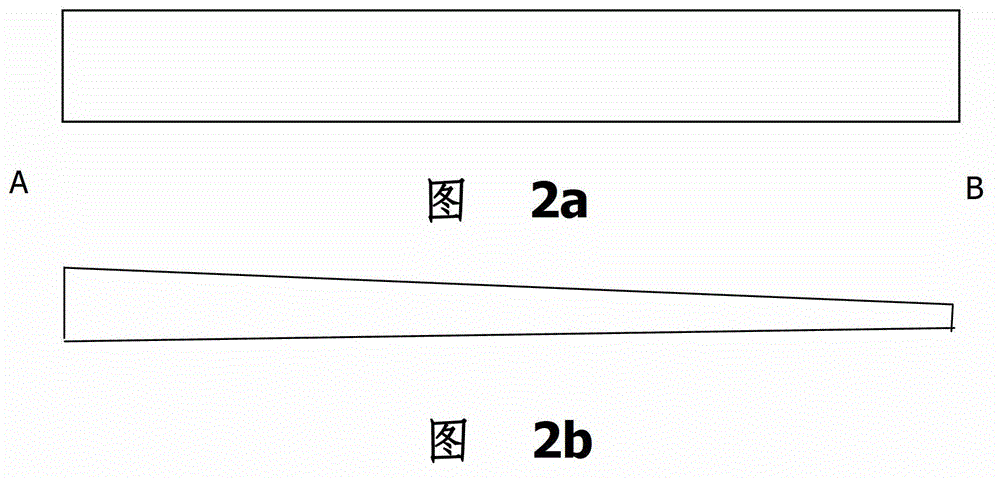

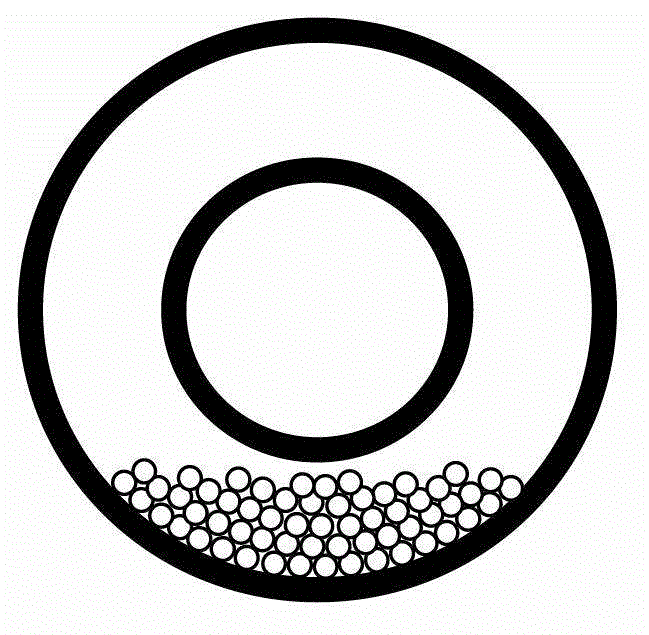

[0047] The purpose of the present invention is to control the accuracy of the flow rate of materials on both sides entering the cylinder of the rod mill, the accurate control system, and the adoption of a suitable material supply balance, and to make a logical judgment on the actual situation displayed by the electronic scale flow rate of the belt conveyor on both sides of the rod mill , Automatically adjust the speed of the variable speed motor. The purpose of this invention is to immediately detect and automatically adjust the speed of the variable speed motor when the flow of materials entering the cylinder on both sides of the rod mill deviates, so as to achieve the balance of the materials entering the cylinder on both sides of the rod mill and prevent the imbalance of materials entering the cylinder Unbalanced steel rod wear and wedge-shaped steel rod wear. Realize the small wedge-shaped phenomenon of the steel rod of the rod mill, and avoid the occurrence of the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com