Fully-automatic hard alloy spherical-teeth robot

A technology of cemented carbide and robots, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as edge drop, corner drop, manpower consumption, and waste products, so as to improve dustproof ability, enrich built-in commands, and operate interface human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

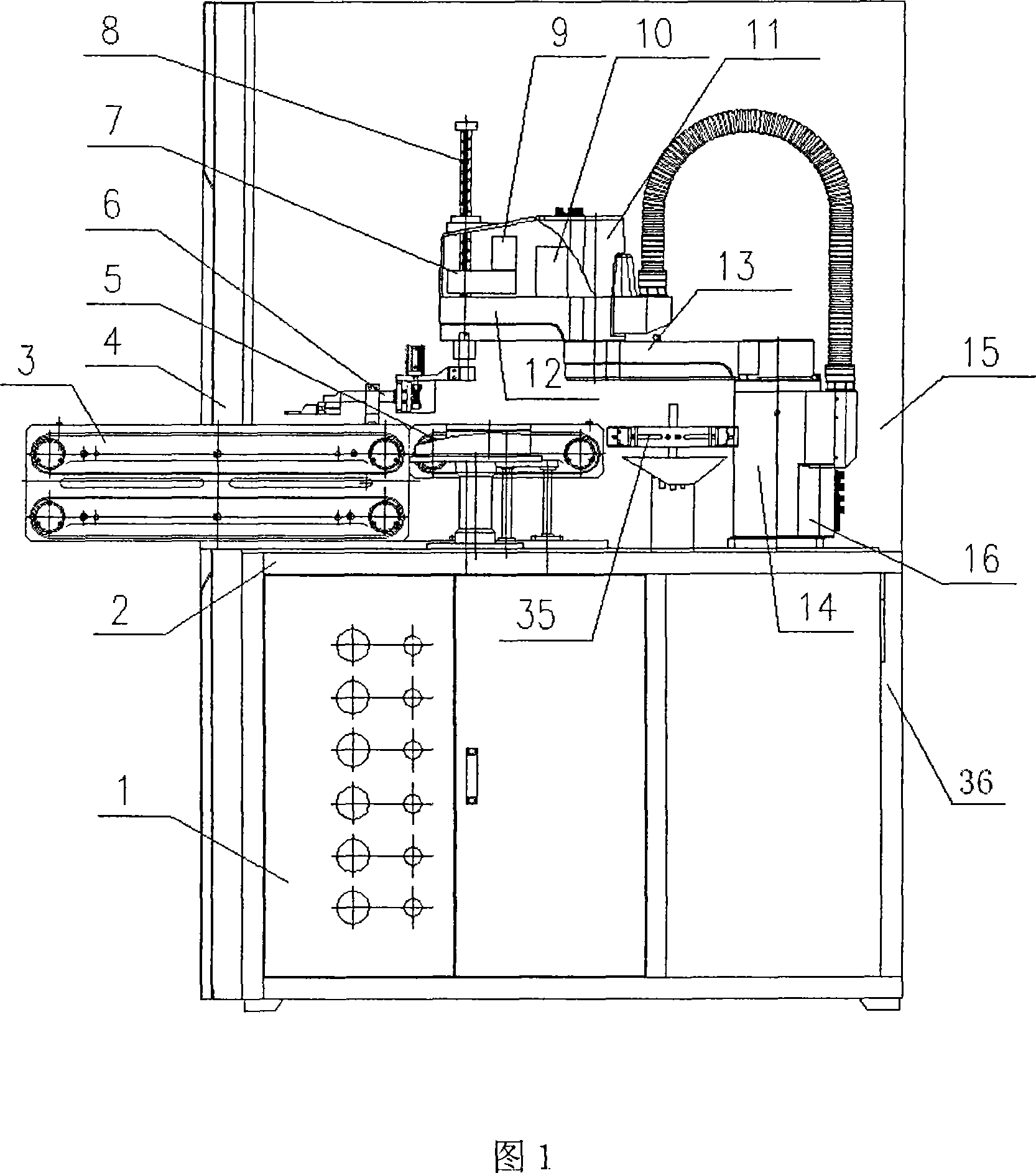

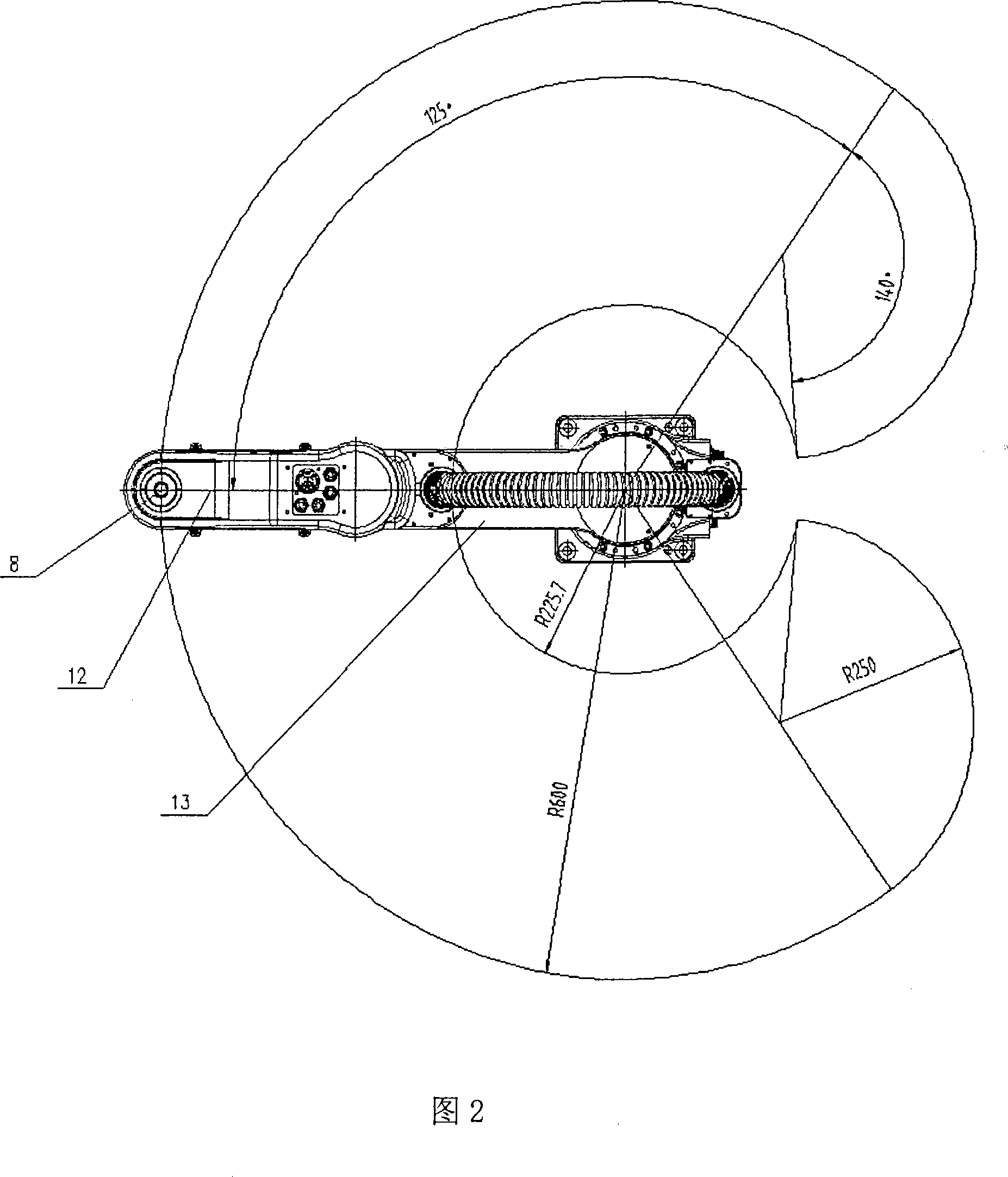

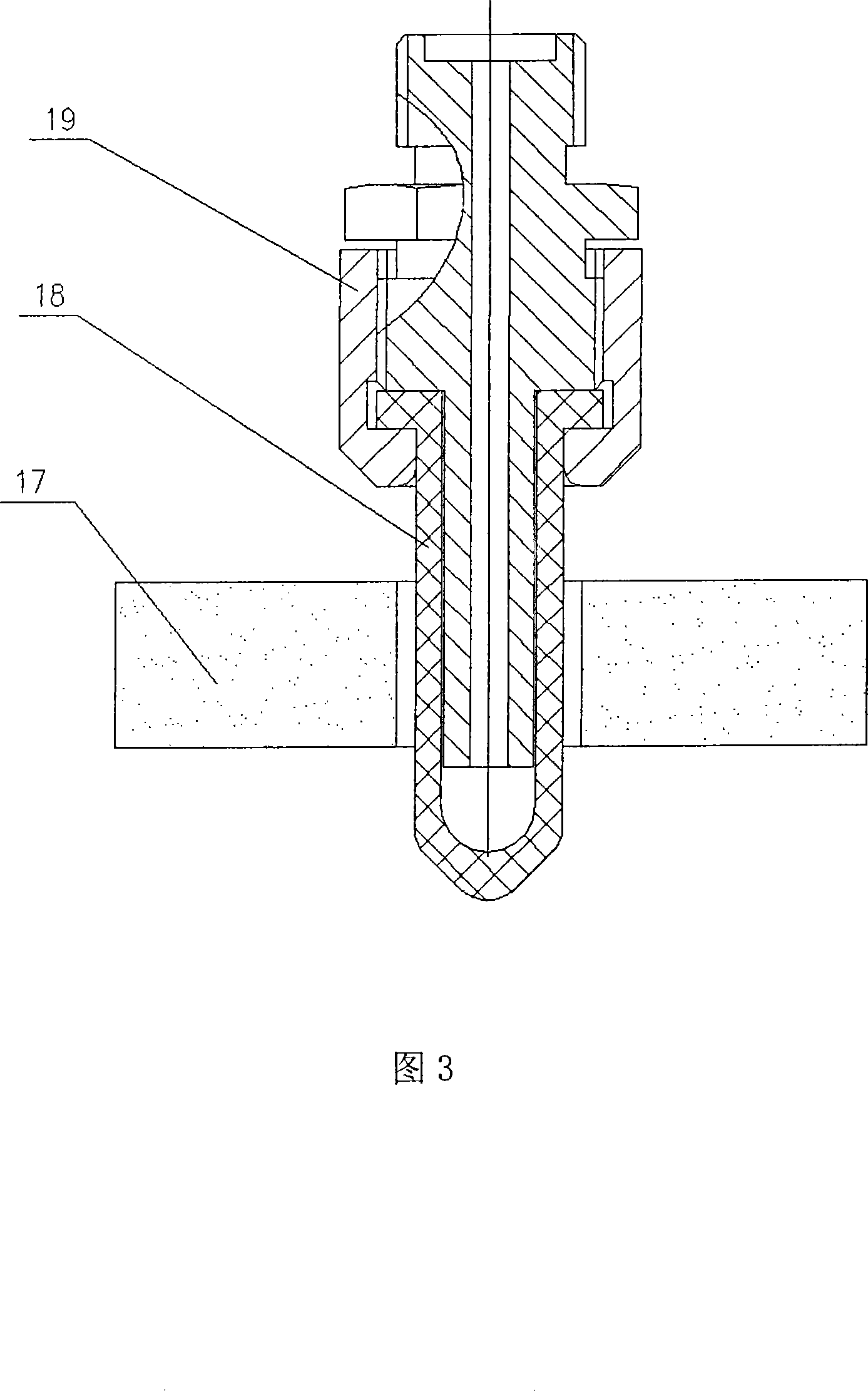

[0031] With reference to accompanying drawing 1~8, the structure of full-automatic cemented carbide ball tooth robot comprises frame (36), deburring mechanism (35), electronic balance (5), multi-joint robot, automatic plate changing mechanism (3). Frame (36) is equipped with frame panel (2), operation panel (4), electric control box, pneumatic control box (1), protective cover (15). The multi-joint robot, the electronic balance (5), and the automatic plate changing mechanism (3) are installed on the frame panel (2), and the multi-joint robot includes a base (16), three horizontal joints, a Z-axis motion mechanism, and a grabbing mechanism ( 6). The three horizontal joints include A-axis horizontal joints, B-axis horizontal joints, and W-axis horizontal joints. A-axis horizontal joints have arm A (13), rotation axis A, servo motor A (14), and B-axis horizontal joints have arm B ( 12), the rotary shaft B, the servo motor B (11), the W-axis horizontal joint has the rotary shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com