Bus bridge and bus phase modulation method

A technology of busbar bridge and busbar, which is applied in the direction of busbar/line arrangement, fully enclosed busbar device, etc., and can solve the problems of phase sequence mismatch and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

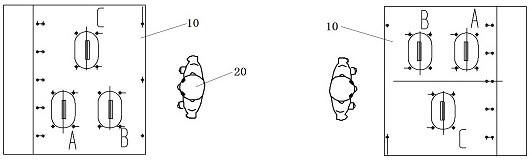

[0056] Embodiment 1 of the bus bridge: The bus bridge is used to connect two switch cabinets. The switch cabinets in this embodiment are arranged in a "face-to-face" manner. Font layout. When arranged in a "face-to-face" manner, the three-phase busbar terminal will appear figure 1 situation shown in . When the bus bridge in this embodiment connects two switch cabinets, A, B, and C of the two switch cabinets are connected in three phases through the connecting bus inside the bus bridge.

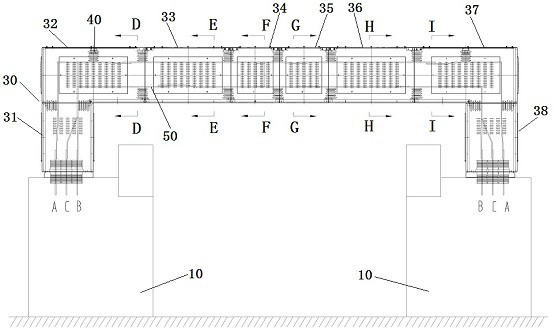

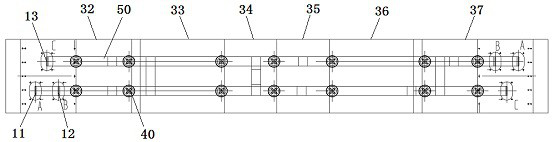

[0057] Such as figure 2 As shown, the bus bridge 30 is U-shaped as a whole, and its two ends are respectively connected to the tops of the two switch cabinets 10 . The busbar bridge 30 includes an axle housing. The inner wall of the axle housing is connected with an insulating support 40 as a supporting body by bolts. The insulating support 40 is a common insulating component in the prior art. The end is provided with a conductor and the surrounding surface is provided with an umbrella ski...

Embodiment 2

[0070] Such as Figure 10 and Figure 11 As shown, it is Embodiment 2 of the bus bridge in the present invention: the difference from the above-mentioned embodiments is that the type of switchgear to be adapted is different, and the arrangement of the supporting body in the axle housing of the bus bridge will also change accordingly. Such as Figure 13 As shown, in this embodiment, the switchgear is arranged in a "face-to-face" manner, and the top of the switchgear is provided with an A-phase bus terminal 11, a B-phase bus terminal 12, and a C-phase bus terminal 13. arranged in a manner.

[0071] The busbar bridge in this embodiment is U-shaped as a whole, and its two ends are respectively connected to the tops of the two switch cabinets. The busbar bridge includes an axle housing, and the inner wall of the axle housing is connected with an insulating support as a supporting body by bolts. The insulating support is a common insulating component in the prior art, with a cond...

Embodiment 3

[0084] Embodiment 3 of the busbar bridge in the present invention: the difference from the above embodiment is that in this embodiment, two sets of support bodies are connected to the bottom wall or top of the axle housing at the same time, and the support heights of the two sets of support bodies are different, so that The corresponding three-phase connection buses are staggered in the vertical direction, thereby being divided into two layers in the vertical direction.

[0085] Embodiment 4 of the busbar bridge in the present invention: the difference from the above embodiment is that in this embodiment, two sets of support bodies are arranged and connected on the left inner wall and the right inner wall of the axle housing, and each support body is L-shaped , so that the three-phase connecting bus is still divided into upper and lower layers in the axle housing.

[0086] Embodiment 5 of the bus bridge in the present invention: the difference from the above embodiments is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com