Active rotating steel collar

A steel ring and active technology, applied in the direction of textiles and papermaking, etc., can solve the problems of cumbersome installation and maintenance, unsuitable for promotion and use, and short service life, and achieve simple and effective structure, increased output per spindle, and reduced yarn damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

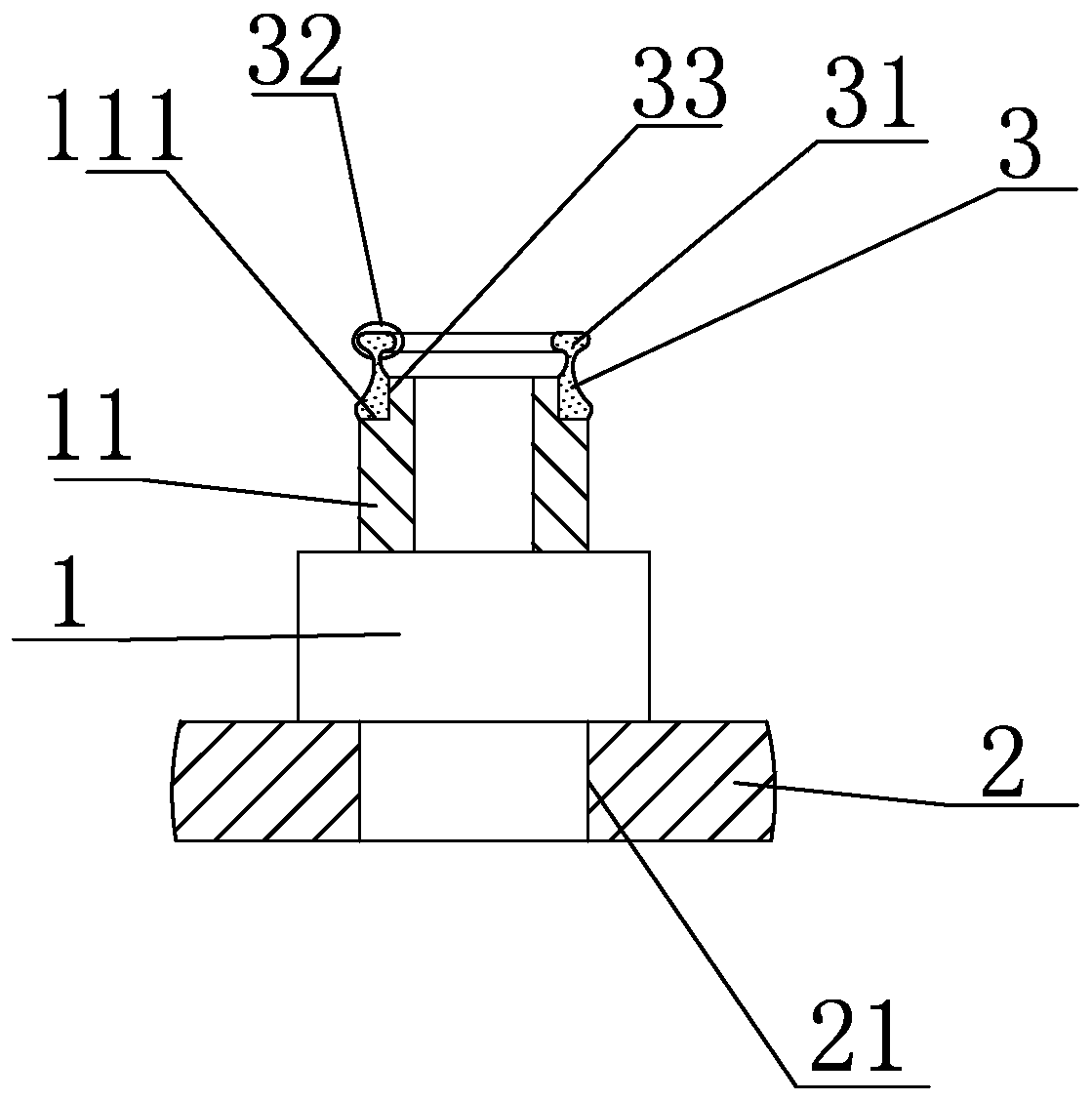

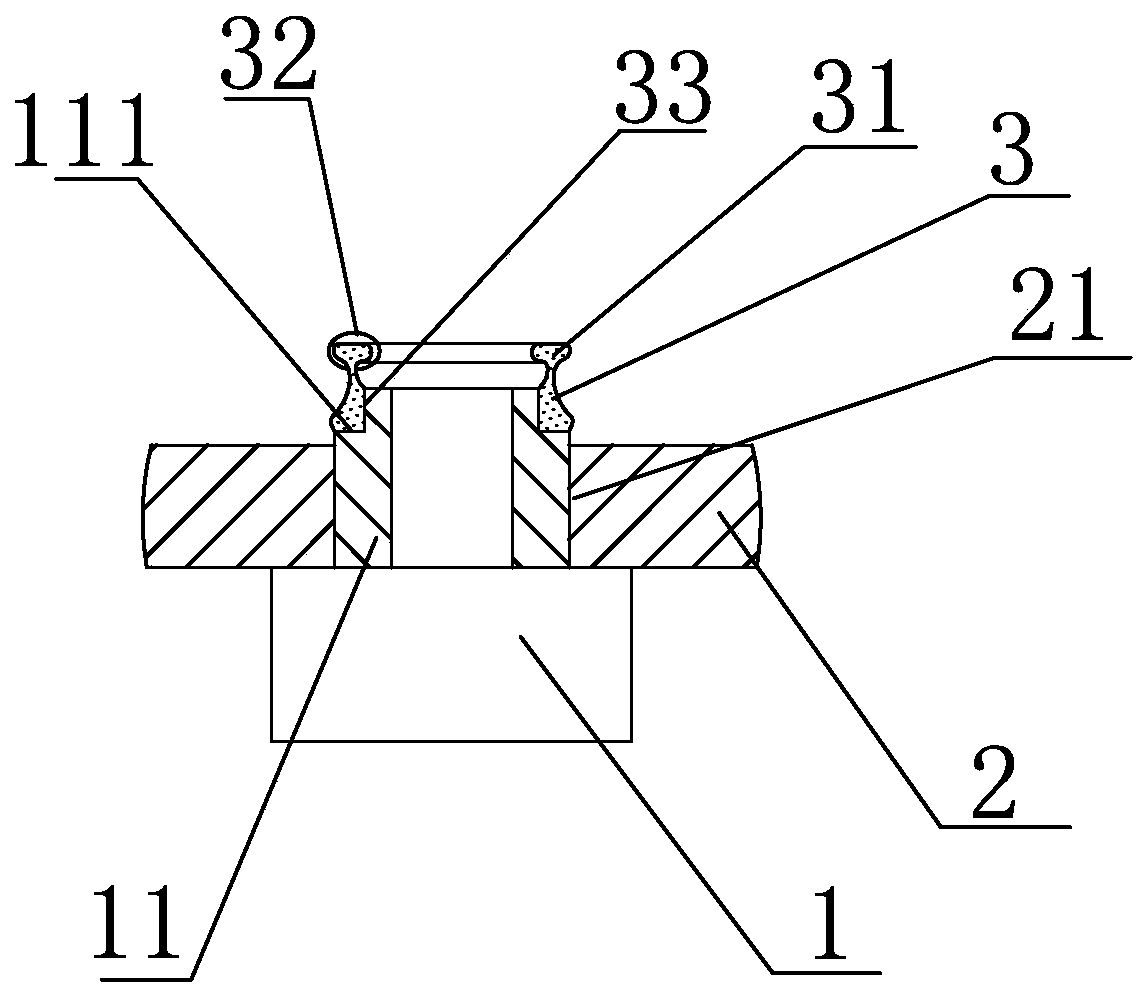

[0017] Such as figure 1 , figure 2 As shown, the structure of the active rotary ring includes a hollow shaft motor 1 and a ring body 3, wherein the hollow shaft motor 1 is fixedly connected with the ring plate 2, and the ring plate 2 has a through hole 21, and the hollow shaft motor 1 The central axis of the hollow rotating shaft 11 passes through the center of the through hole 21, and the steel ring body 3 is fixedly connected with the outer end of the hollow rotating shaft 11. The ring body 3 is provided with a raceway 31, and the raceway 31 is provided with a traveler 32.

[0018] The outer edge of the outer end of the hollow rotating shaft 11 is provided with a circle of steps 111 along the outer circumferential direction, and the outer edge of the bottom end of the steel ring body 3 is provided with a circle of mounting surface 33 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com