Transmission mechanism and rotary engine thereof

A technology of rotating engines and transmission mechanisms, which is applied in the direction of machines/engines, engine components, combustion engines, etc. It can solve the problems of increased gas blow-by between the mixed gas studios, short service life, and long combustion lines, so as to increase work reliability. , short service life, large emission pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

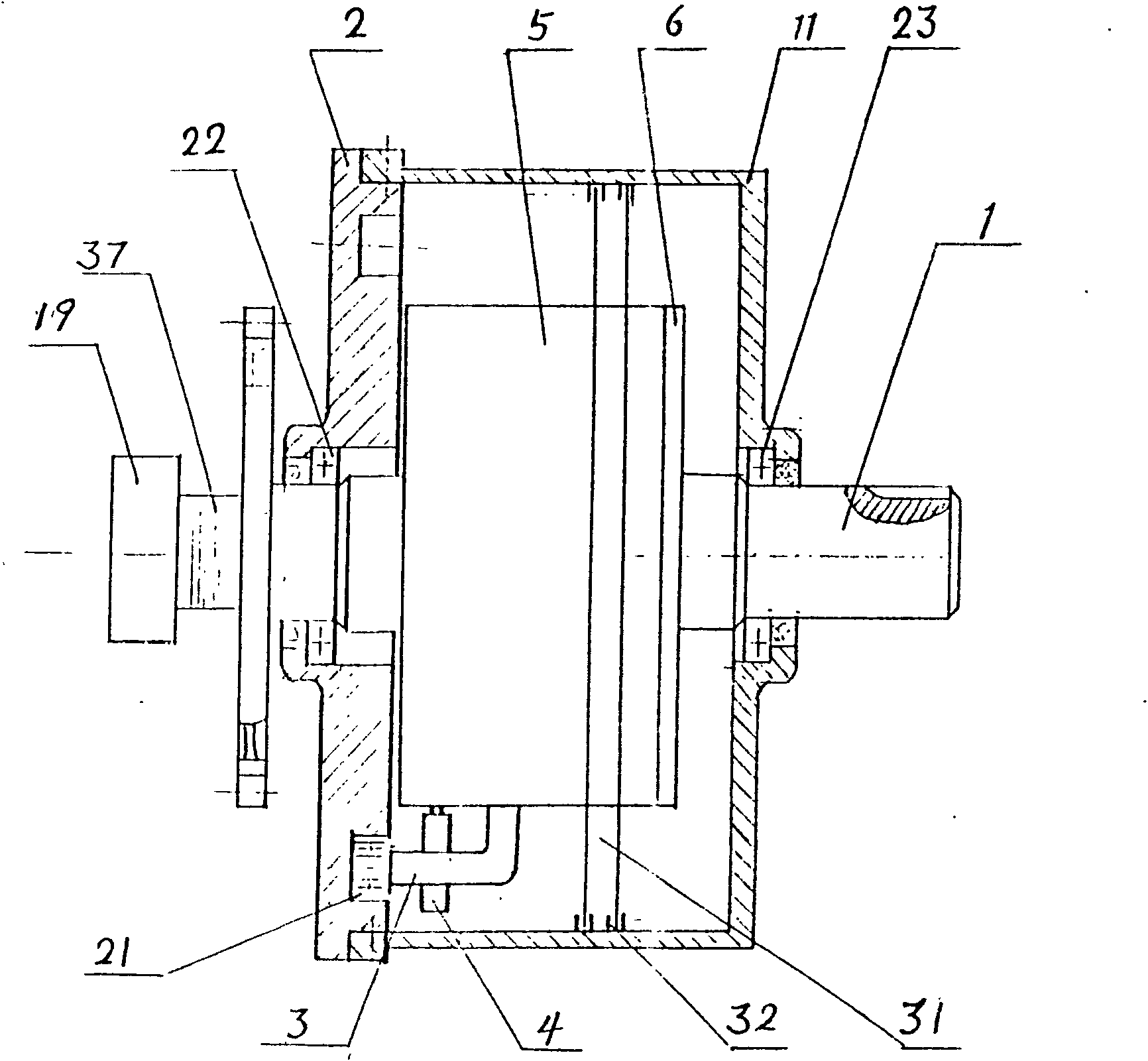

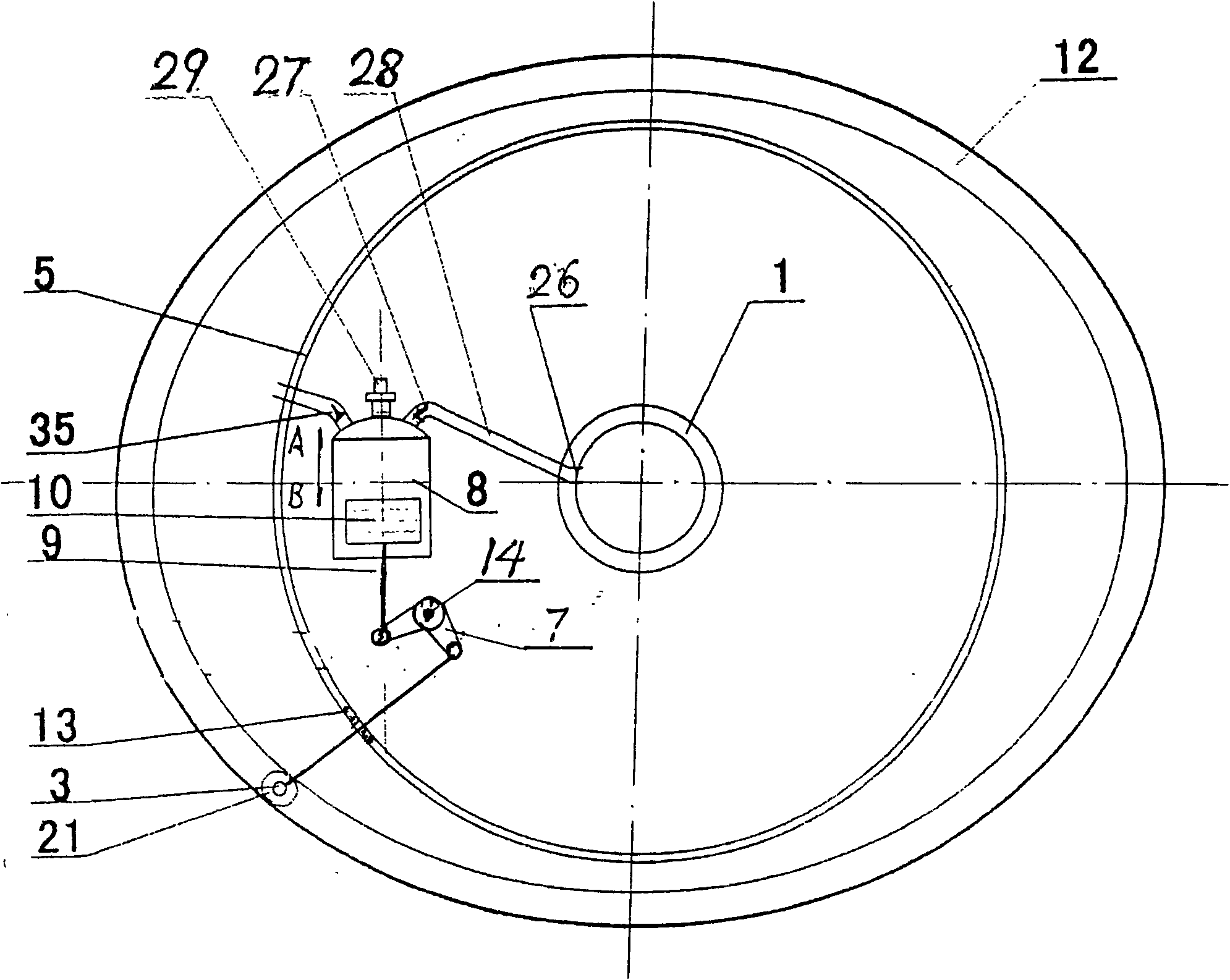

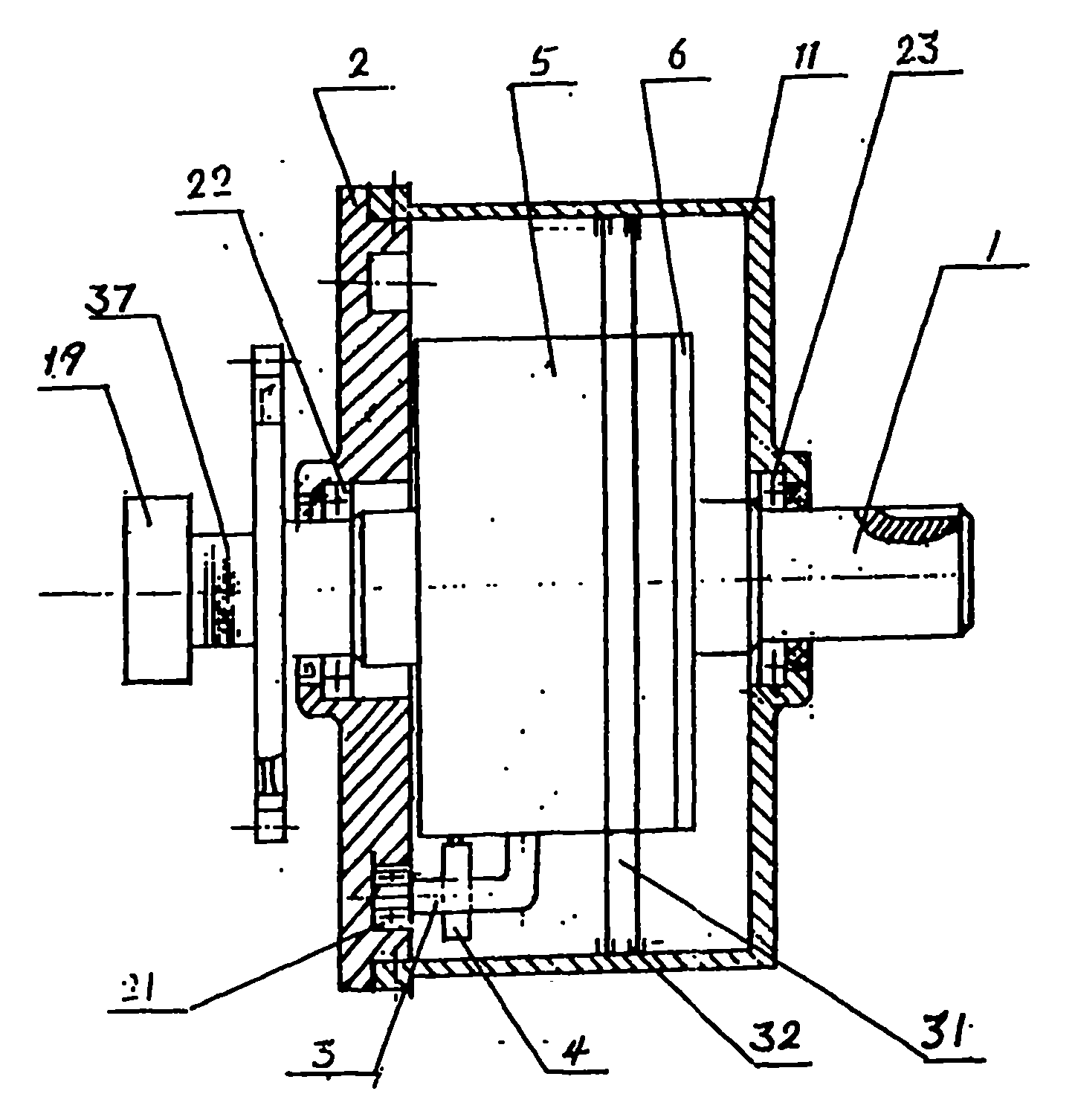

[0030] see figure 1 figure 2A transmission mechanism and its rotary engine of the present invention include a main shaft (1); an elliptical track groove disc body (2); a transmission connecting rod (3); a positioning U-shaped fork (4); a cylindrical rotating cylinder body (5) ;Cylinder end cover (6); Reversing lever (7); Machine head (8); Piston rod (9); Piston (10); Cylindrical casing (1D; Elliptical track groove (12); Seal (13); Reversing lever shaft (14); Head intake oil valve (27); Oil supply manifold (28); Spark plug (29); Exhaust valve (30); Exhaust runner ring (31 ); exhaust runner sealing ring (32); exhaust pipe (33), and corresponding supporting electronic actuators, control units, electronic circuits, etc.

[0031] Design elliptical track groove (major axis - short axis) ÷ 2 = piston stroke S

[0032] Assume that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com