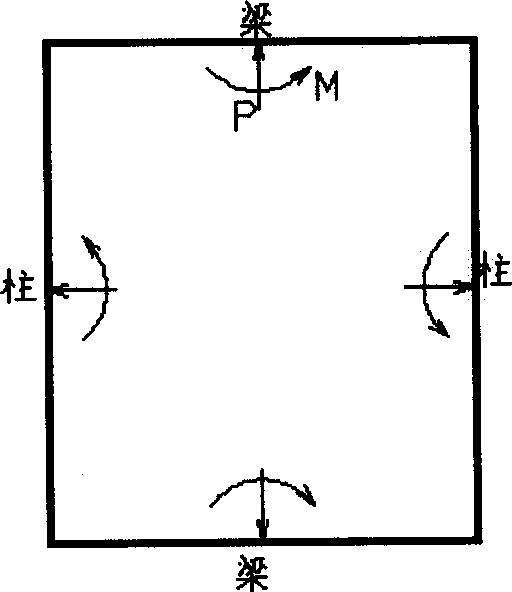

Closed type three poles framework for support

A bearing machine and closed technology, applied in the direction of metal rolling frame, press machine, metal rolling mill stand, etc., can solve the problem that the four-bar frame cannot effectively use the space, the four-bar system frame is not suitable, and the material utilization rate Low and other problems, to achieve the effect of improving rack space utilization, simple structure, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

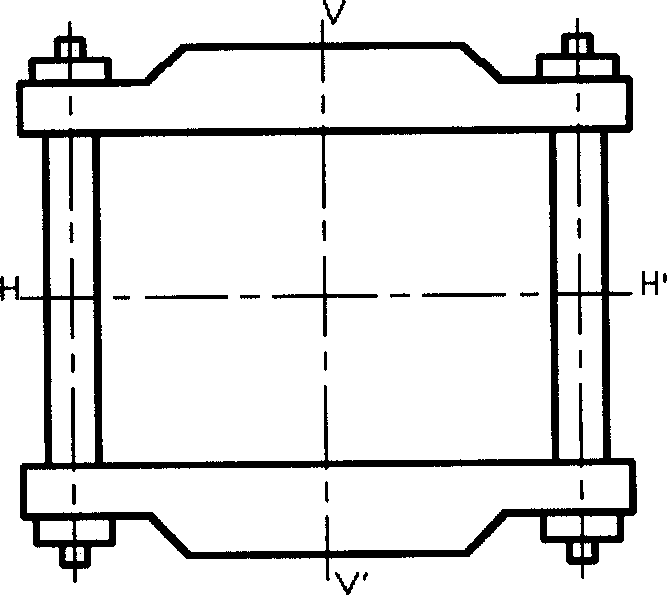

Embodiment 1

[0040] Example 1: Frame design of 6000 ton open die forging press

[0041] As mentioned above, the single cylinder 6000 ton free forging hydraulic press frame L M =4.6m, L C=1.7m, λ = 4.6 1.7 = 2.7 , Therefore, it is more appropriate to design a three-bar rack.

[0042] Figure 14 Among them, a, c and e form a three-bar rack with parallel local axes. b, d and f are the transition blocks added for connecting the bar system, K 1 、K 2 、K 3 、K 4 、K 5 and K 6 It is the joint surface of the hurdle, and 2 is the pre-tightened steel wire layer. The frame can withstand a working load of 6,000 tons and weighs only 400 tons, while the frame of a traditional 6,000-ton free forging press weighs at least 800 tons.

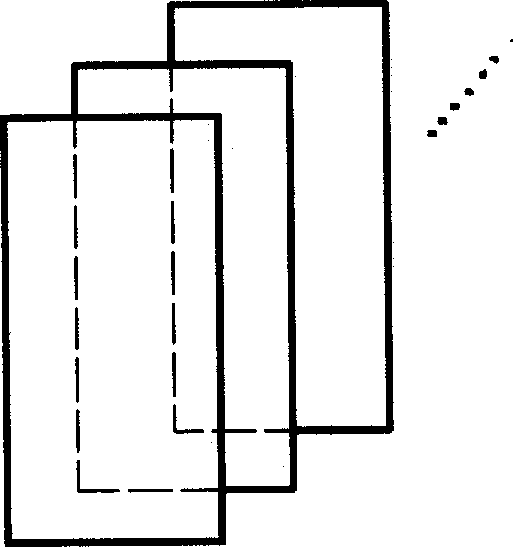

Embodiment 2

[0043] Example 2: 1250-ton press frame design

[0044] The four-column frame of the 1250-ton open-die forging press adopts a design of 330kg / cm 2 Working oil pressure, the working outer diameter of a single master cylinder is Φ820mm, namely L c =820mm, while the forging space scale is 1940mm, L M =1940mm

[0045] λ = L M L C = 1940 820 = 2.36

[0046] Therefore, it is more reasonable to design the frame of the 1250-ton free forging hydraulic press as a three-bar frame, which is 40 tons lighter than the four-bar frame. Figure 15a For a traditional four-post rack, Figure 15b It is a three-bar rack with the same drawing scale. The former has 4 columns of Φ300; the latter is only designed with two hollow columns, the upper beam is greatly reduced, and the movable beam and lower beam are sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com