Device for measuring current density of arc column of welding arc

A measuring device and technology for current density, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large error in calculation results, accumulation of errors, and difficulty in arc cross-section, etc., and achieve high accuracy and good insulation effect. , The intuitive effect of the measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

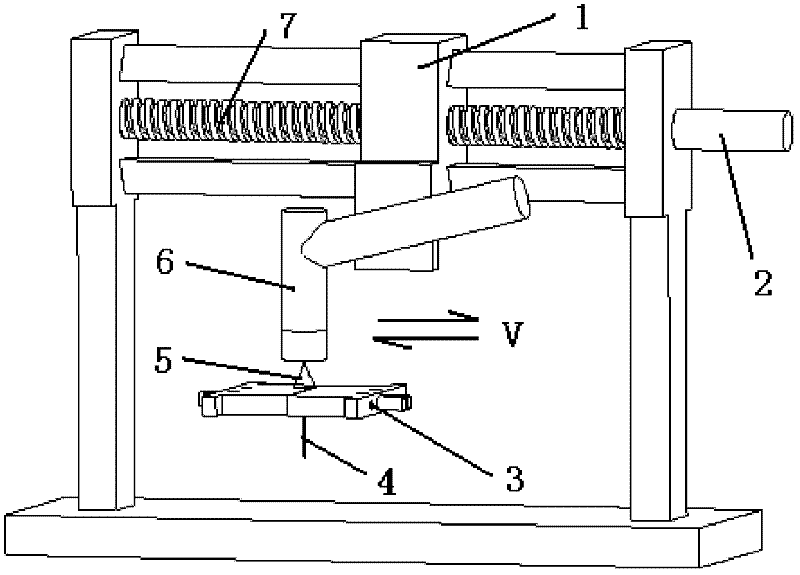

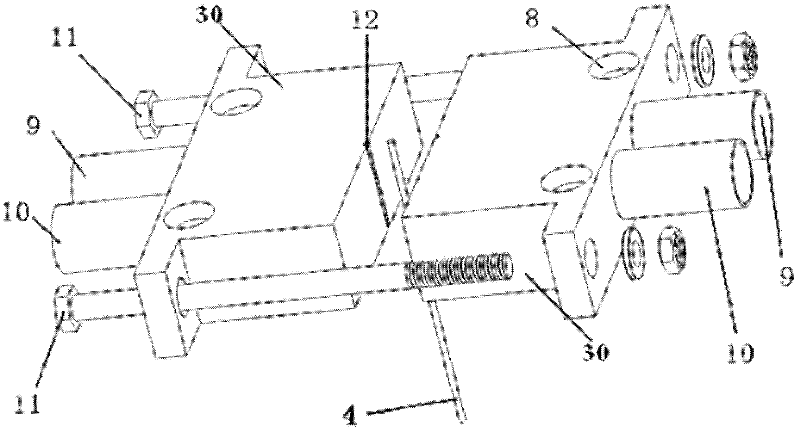

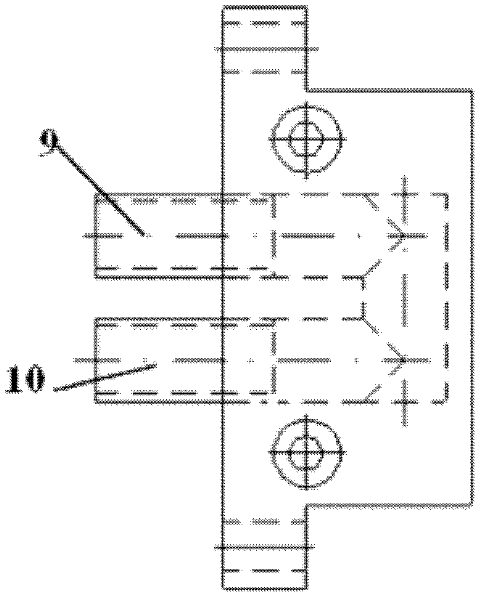

[0026] see Figure 1 to Figure 6 As shown, the welding arc column current density measuring device 3 of the present invention comprises two separated anode plates 30, digs U-shaped holes (cooling water channels) in the two anode plates 30, and passes through the two anode plates 30. Flowing water is used to cool the anode plate 30 and the tungsten probe 4 . At the butt joints of the two anode plates 30, semi-cylindrical grooves 12 are set up respectively, and a layer of Al is sprayed on the inner diameter of the groove 12 by plasma spraying. 2 o 3 Coating for insulation. The tungsten probe 4 is clamped in two grooves 12, and is clamped by two fastening bolts 11 of the copper anode plate 30, so that the tungsten probe 4 can be connected with the Al on the anode plate 30. 2 o 3 Coatings are in close contact to achieve better cooling effect. Leads are drawn from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com