Test piece component and test method of brittle material I-III mixed mode fracture toughness test

A fracture toughness, brittle material technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, analyzing materials, etc., can solve problems such as difficulty in application, and achieve easy Simple processing, loading method and testing process, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

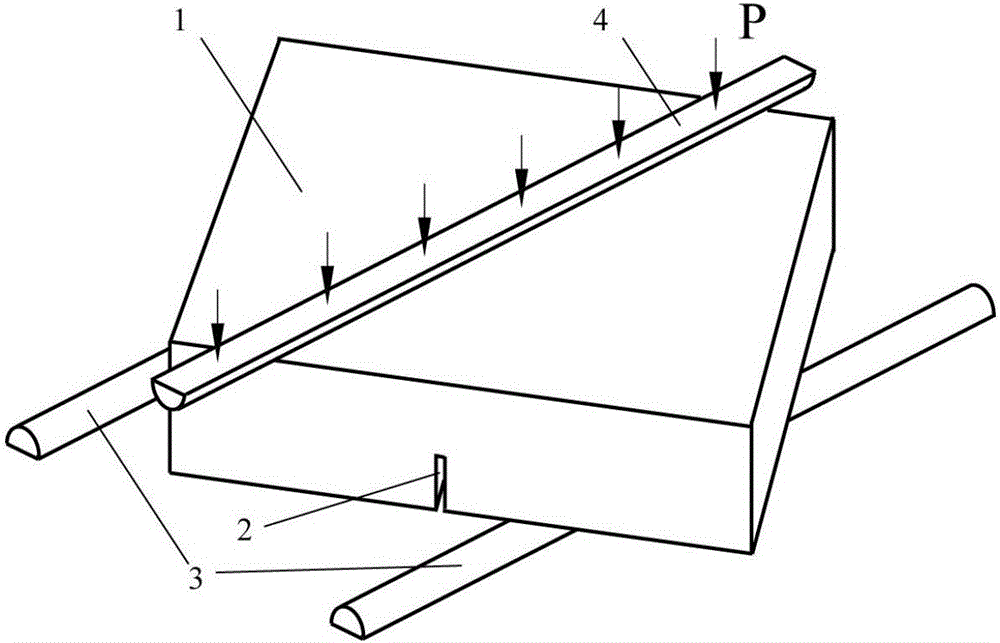

[0038] In the present embodiment, the structural representation of the specimen assembly used for the composite fracture toughness test of brittle materials I-III is as follows Figure 1~3 As shown, the body of the test piece is made by cutting a concrete block with a diamond slicer.

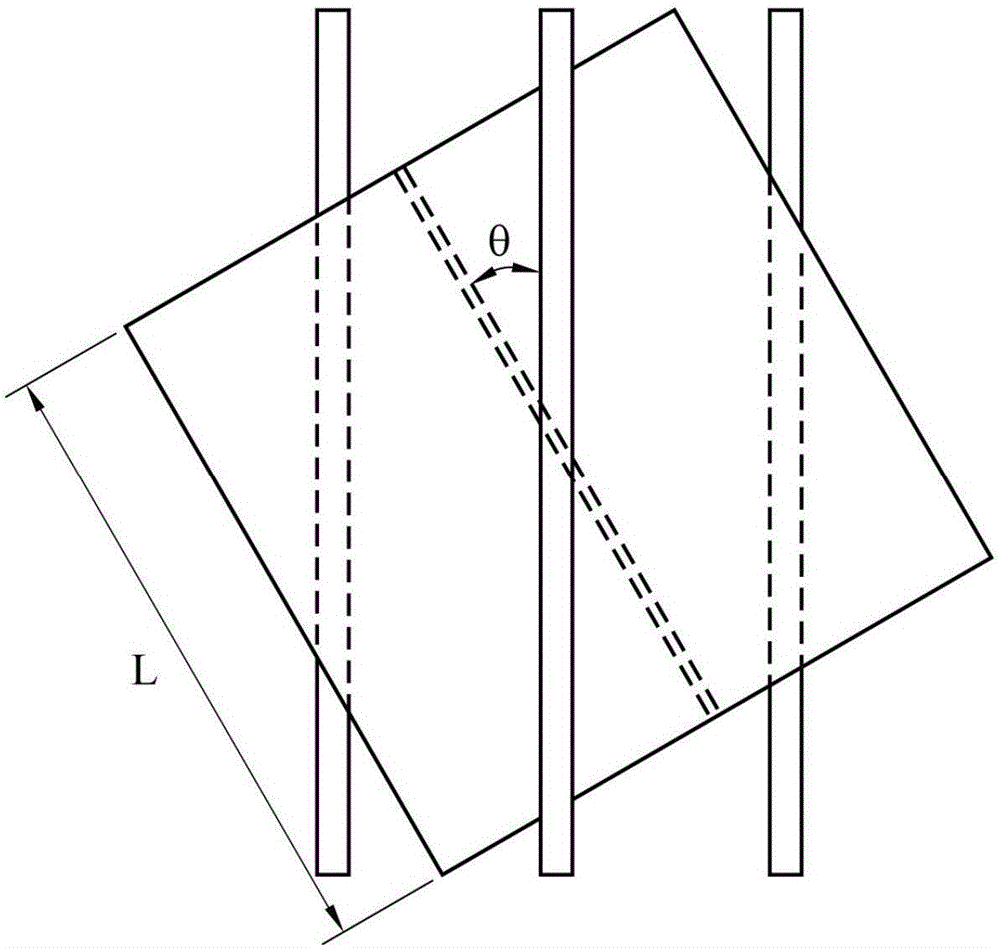

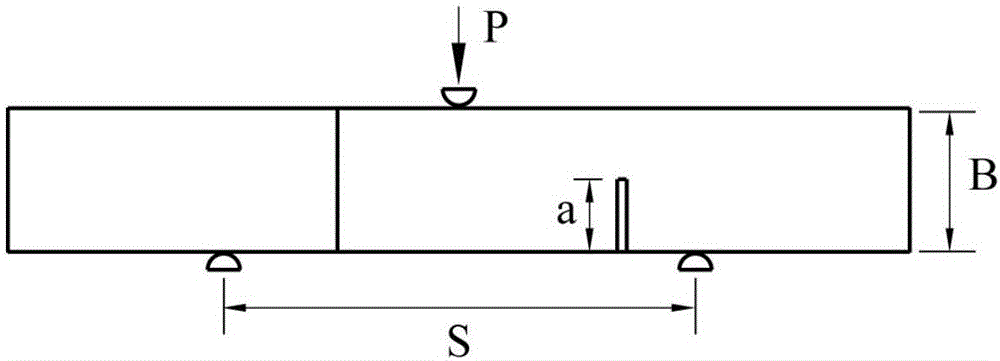

[0039] The specimen assembly for the composite fracture toughness test of brittle materials I-III consists of a specimen body 1 with a notch 2 and columns for supporting the compression specimen body, and the specimen body is a square flat plate The plate on the surface, the thickness of the plate is B=25mm, the side length of the plate surface is L=100mm, the groove passes through the center of the plate surface of the specimen body and the groove surface of the groove is parallel to the left and right sides of the specimen body, and the groove runs through the specimen On the front and rear sides of the body, the depth a of the groove is a=10mm, and the width of the groove is 1mm; the columns ...

Embodiment 2

[0041] In the present embodiment, the structural representation of the specimen assembly used for the composite fracture toughness test of brittle materials I-III is as follows Figure 1~3 As shown, the body of the specimen is made of rock blocks cut by a diamond slicer.

[0042] The specimen assembly for the composite fracture toughness test of brittle materials I-III consists of a specimen body 1 with a notch 2 and columns for supporting the compression specimen body, and the specimen body is a square flat plate The plate on the surface, the thickness of the plate is B=75mm, the side length of the plate surface is L=150mm, the groove passes through the center of the plate surface of the specimen body and the groove surface of the groove is parallel to the left and right sides of the specimen body, and the groove runs through the specimen On the front and rear sides of the body, the depth of the groove is a=45mm, and the width of the groove is 1mm; the columns include two sup...

Embodiment 3

[0044] In the present embodiment, the structural schematic diagram of the specimen assembly for brittle material I-III composite fracture toughness test is similar to Figure 1~3 , the body of the specimen is made of rock blocks cut by a diamond slicer.

[0045] The specimen assembly for the composite fracture toughness test of brittle materials I-III consists of a specimen body 1 with a notch 2 and columns for supporting the compression specimen body, and the specimen body is a square flat plate The plate on the surface, the thickness of the plate is B=40mm, and the side length of the plate surface is L=200mm. On the front and rear sides of the body, the depth of the groove is a=12mm, and the width of the groove is 0.8mm; the columns include two supporting columns 3 between the plate surface where the groove of the test piece body is located and the working platform of the universal testing machine and a pressing column 4 located between the other side of the test piece body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com