Method for designing high-enthalpy arc heater with fixed arc length

A technology of arc heater and design method, which is applied in the direction of heating by discharge, electric heating device, electrical components, etc., can solve inconvenient maintenance, lack of mature design technology of laminated arc heater, complex structure of laminated arc heater, etc. problems, to achieve the effect of simplified structure, simple and convenient operation and maintenance, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

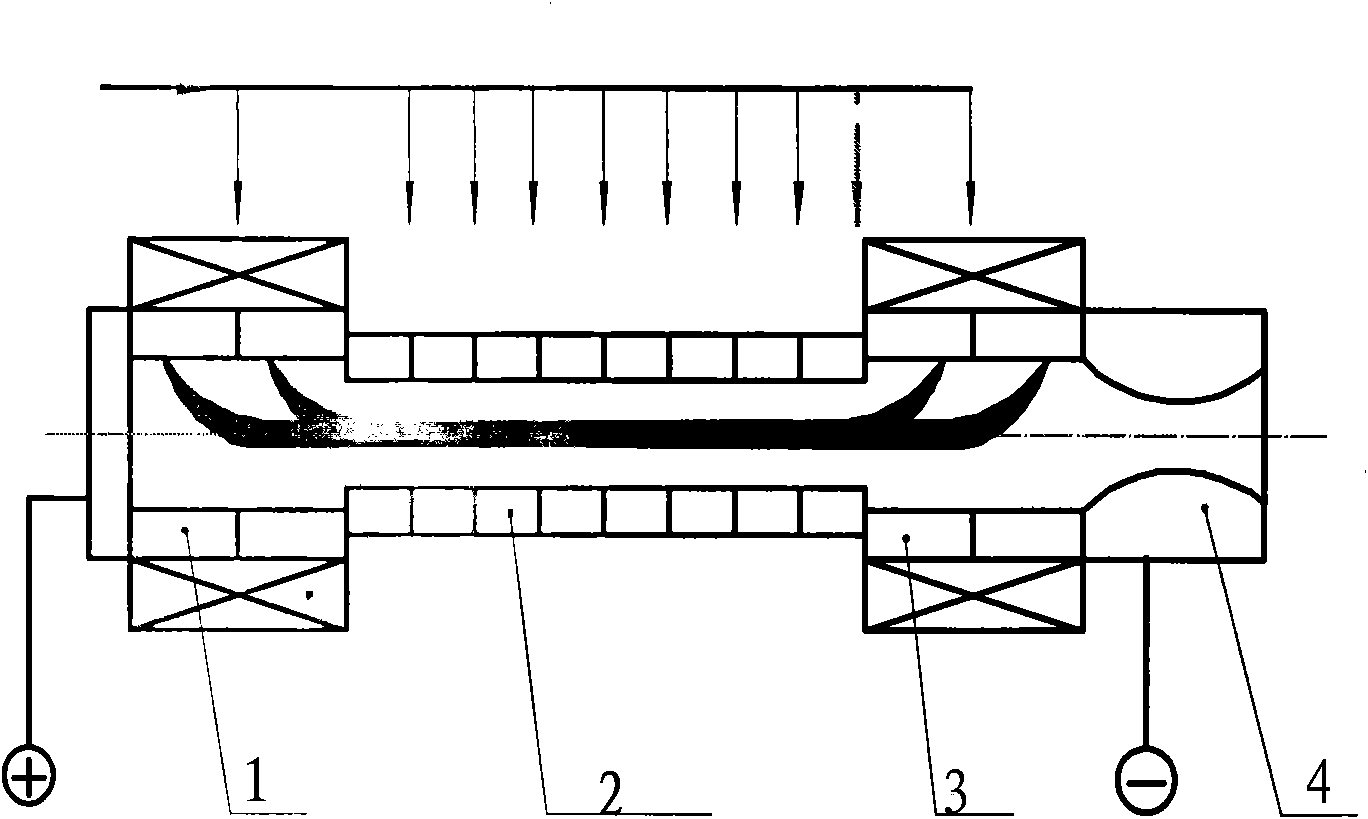

[0014] As shown in Figure 1, the present invention is composed of a positive electrode 1, a compression channel 2, a negative electrode 3, and a nozzle 4. The connection sequence is followed by a positive electrode 1, a compression channel 2, a negative electrode 3, and a nozzle 4. The structure of the positive electrode 1 is as follows: The outer jacket has a water-cooled sandwich structure, the inner jacket is made of red copper, and the outer jacket is made of metal or insulating non-metallic materials. The positive electrode 1 and the negative electrode 3 can be made into a single electrode form or a segmented multi-electrode form. A magnetic field coil is wound around the outside of the positive and negative electrodes. After the magnetic field coil is energized, the electromagnetic force generated at the arc root can accelerate the Rotate to reduce electrode burnout. When the multi-electrode form is adopted, it can effectively reduce the electrode burnout, which is helpf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com