Disc-type gyromagnetic transverse blowing vacuum arc extinguish chamber

A vacuum interrupter and disc-type technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems such as arc voltage and arc energy increase, recovery voltage re-ignition, and breaking capacity limitations, etc., to achieve The effect of reducing the arc temperature, reducing the burning time, and reducing the thickness of the melting zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

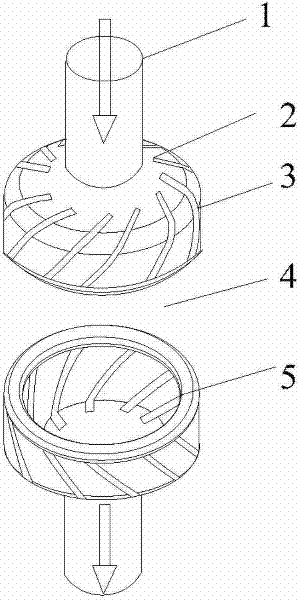

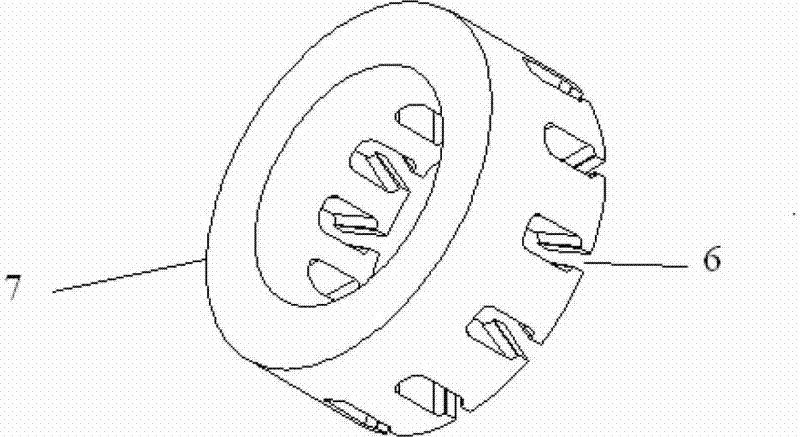

[0021] As shown in the figure, the disk-type gyromagnetic horizontal blowing vacuum interrupter includes a conductive rod 1, a contact cup bottom 2, an iron core 7 and a contact cup 3; the contact cup bottom 2 and the contact cup 3 are connected to the conductive The rods 1 are fixedly matched in turn; the contact cup 3 is equally divided into a circulation groove; the deflection angle between the circulation groove and the longitudinal axis of the conductive rod 1 is 30°; the iron core 7 is placed in the contact cup 3 Inside; winding slots 6 are opened in equal parts on the iron core 7 ; coil windings 8 are embedded in the winding slots 6 .

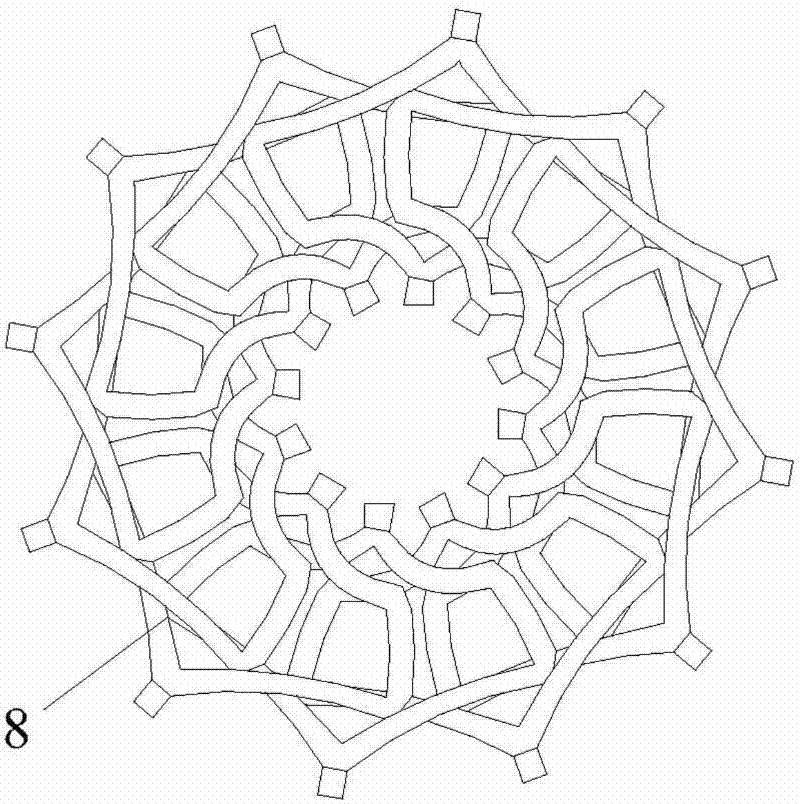

[0022] The number of winding slots 6 in the present invention is 12-30. The slot width of the winding slot 6 in the present invention is 2.5-3mm. The coil windings 8 of the present invention are radially distributed in a disc structure. In order to protect the coil winding 8 in the contact, the present invention fixes a contact piece 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com