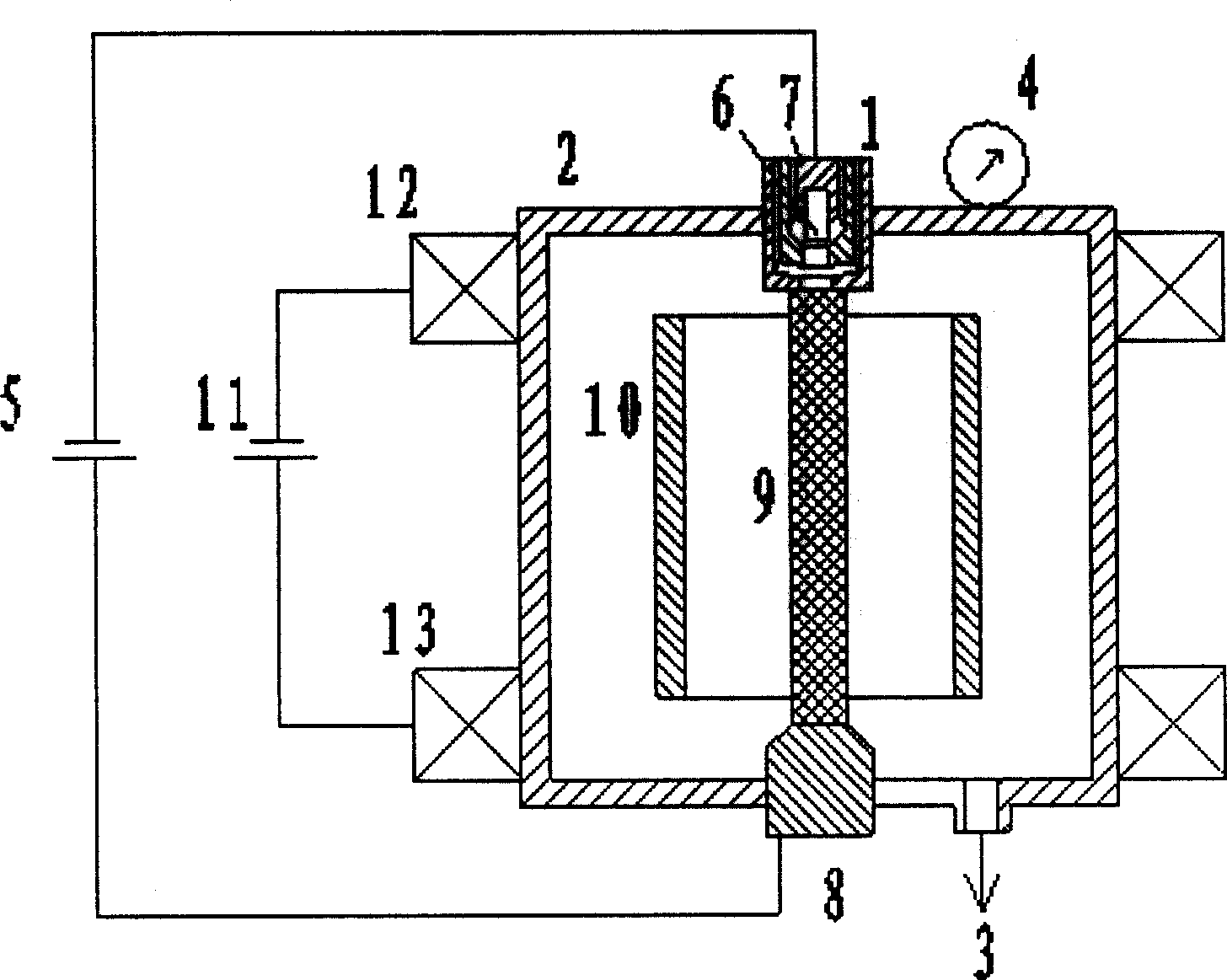

DC electric arc plasma chemical vapor deposition apparatus and diamond coating method

A chemical vapor deposition, DC arc technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve technical difficulties and other problems, achieve stability improvement, life and structural stability improvement, quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

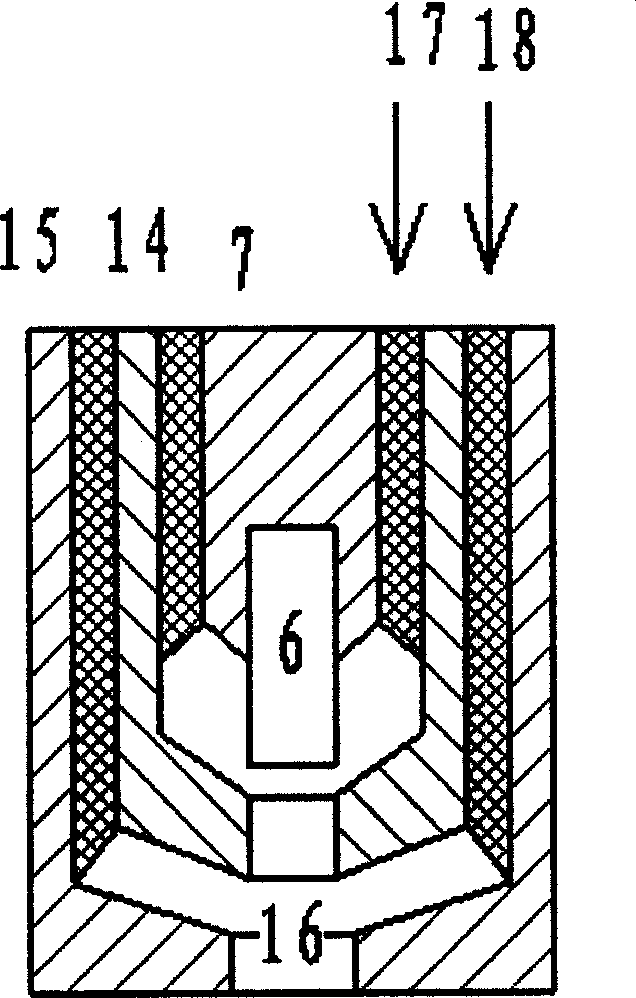

Method used

Image

Examples

Embodiment 1

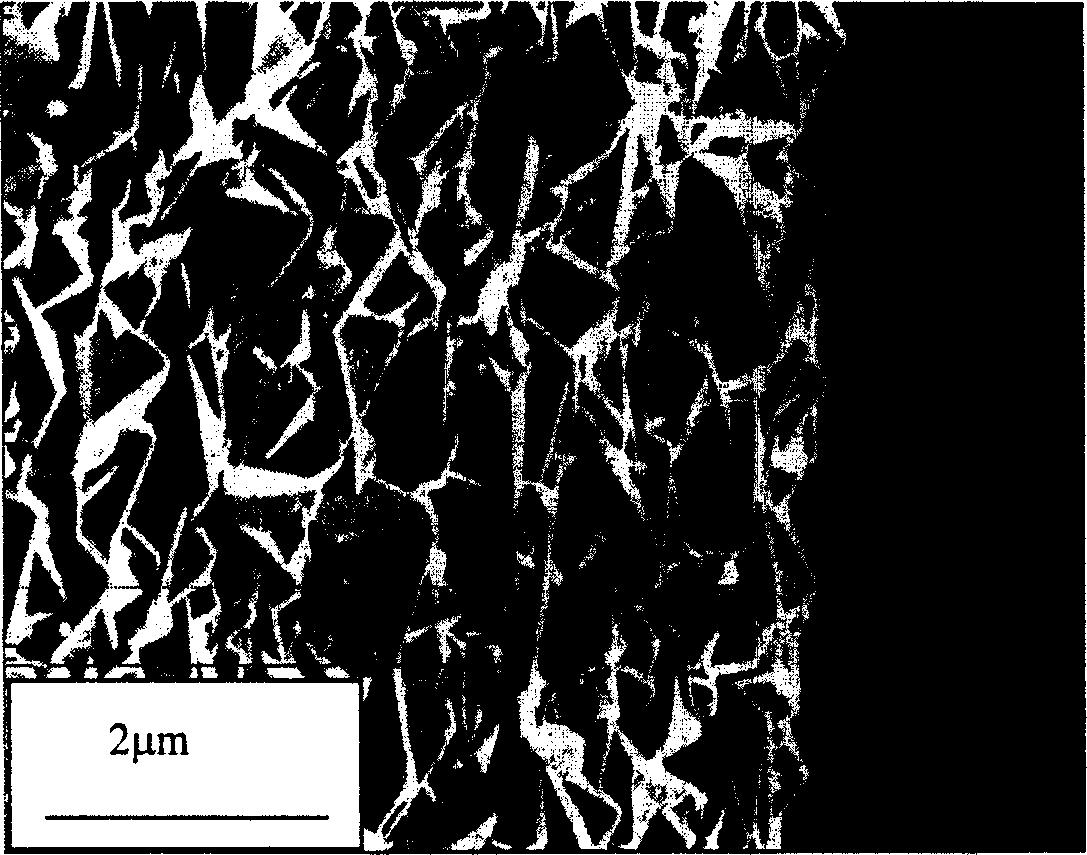

[0023] The product to be coated with diamond coating is placed on the product rack, and it is diamond-coated using the process conditions listed in Table 1:

[0024] Argon gas flow(L / min)

[0025] Among them, argon is the protective gas used, while hydrogen and methane are the necessary reaction gases for depositing diamond. Adjust the pressure in the vacuum chamber, DC discharge voltage, and current to 1kPa, 120V, and 150A, respectively, and the surface temperature of the product to be coated is 900°C. Treat the product coating for 6 hours to obtain such as image 3 Diamond coating shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com