A Cathode Structure of a Laminar Arc Plasma Generator

A technology of arc plasma and cathode structure, applied in the direction of plasma, electrical components, etc., can solve the problems of short cathode life, high cost, difficulty in meeting the stability requirements of laminar plasma arc, etc., and achieve extended working life and extended life , Accelerate the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

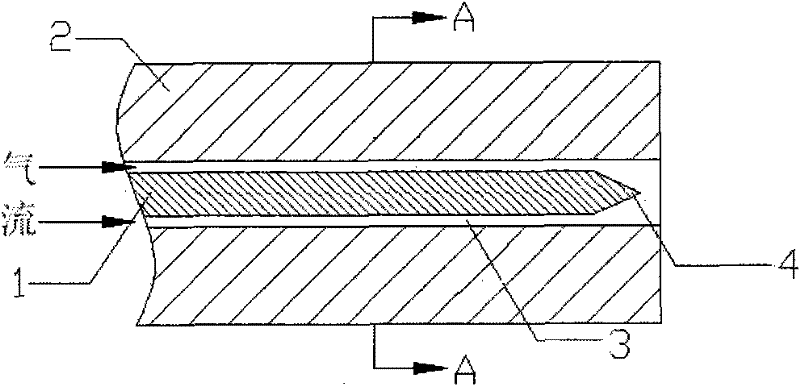

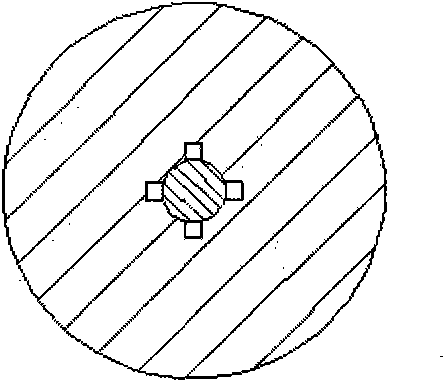

[0017] Implementation example 1: figure 1 The cathode column [1] in is made of tungsten alloy and connected to the cathode. The cathode cover [2] is made of red copper with good electrical and thermal conductivity. There is a clearance fit between the cathode column [1] and the cathode cover [2], and the inner wall of the cathode cover [2] has uniformly distributed teeth in the axial direction. Groove, as the airflow channel of the working gas [3]. This implementation example is applied to a 40-kilowatt nitrogen laminar arc plasma generator, which can produce a stable beam-like (length-to-diameter ratio greater than 100) laminar hot plasma jet, and the cathode column [1] can work continuously for more than 500 hours.

Embodiment 2

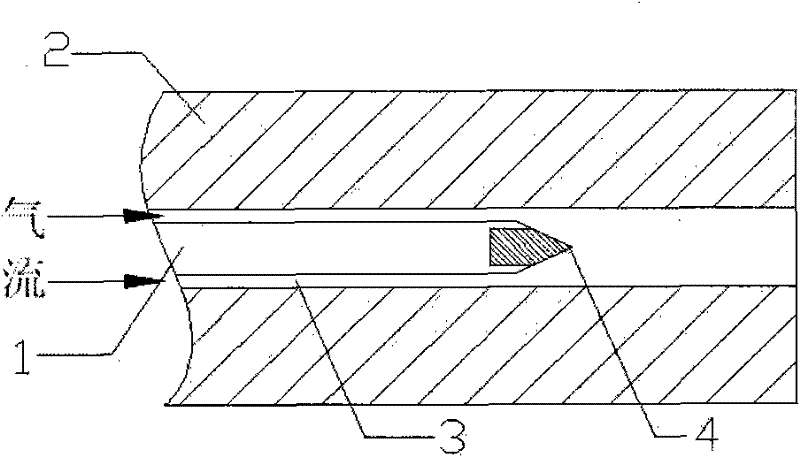

[0018] Implementation example 2: such as image 3 As shown, except that the cathode column [1] is made of red copper, and the top is embedded with tungsten or tungsten alloy, other structures and processes are exactly the same as those in Example 1.

Embodiment 3

[0019] Implementation example 3: such as Figure 4 As shown, the outer wall of the cathode column [1] is grooved as an air flow channel, and the inner wall of the cathode cover [2] is smooth. Other structures and processes are exactly the same as those in Examples 1 and 2, and the inner tube of the cathode column [1] can be passed into the cooling liquid. , to facilitate the heat dissipation of the cathode column [1] and prolong its life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com