Wood hanger processing method

A processing method and technology for hangers, which are applied in the manufacture of wood processing appliances, hangers, veneer chips, etc., can solve the problems of complex production process of wooden hangers, low processing efficiency and high labor intensity, achieve excellent color and luster, and improve production. Efficiency and machining accuracy, excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

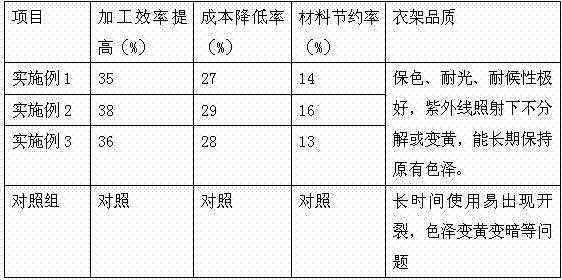

Examples

Embodiment 1

[0016] A processing method of a wooden hanger, comprising the following steps:

[0017] (1) Divide the cylindrical wood used to make clothes hangers, take the cylinder as the base, take a square inscribed on its cross section, and cut the cylinder axially along the side of the square to obtain 4 cross sections. An arc column with an arc angle of 90 degrees and a straight line and a rectangular parallelepiped with a square cross section are used as the central skeleton of the connecting position between the right shoulder and the left shoulder of the hanger, and the rectangular parallelepiped is sliced into thicknesses of 2 mm flakes, drying the cut material separately;

[0018] (2) Apply a layer of pressure-sensitive adhesive evenly on one side of the dried sheet, centering on the arc column, neatly stack the sheet coated with pressure-sensitive adhesive on the arc column, and use the mold for hot pressing Forming, the pressure-sensitive adhesive is made of the following co...

Embodiment 2

[0024] A processing method of a wooden hanger, comprising the following steps:

[0025] (1) Divide the cylindrical wood used to make clothes hangers, take the cylinder as the base, take a square inscribed on its cross section, and cut the cylinder axially along the side of the square to obtain 4 cross sections. An arc column with an arc angle of 90 degrees and a straight line and a rectangular parallelepiped with a square cross section are used as the central skeleton of the connecting position between the right shoulder and the left shoulder of the hanger, and the rectangular parallelepiped is sliced into thicknesses of 3 mm flakes, drying the cut material separately;

[0026] (2) Apply a layer of pressure-sensitive adhesive evenly on one side of the dried sheet, centering on the arc column, neatly stack the sheet coated with pressure-sensitive adhesive on the arc column, and use the mold for hot pressing Forming, the pressure-sensitive adhesive is made of the following co...

Embodiment 3

[0032] A processing method of a wooden hanger, comprising the following steps:

[0033] (1) Divide the cylindrical wood used to make clothes hangers, take the cylinder as the base, take a square inscribed on its cross section, and cut the cylinder axially along the side of the square to obtain 4 cross sections. An arc column with an arc angle of 90 degrees and a straight line and a rectangular parallelepiped with a square cross section are used as the central skeleton of the connecting position between the right shoulder and the left shoulder of the hanger, and the rectangular parallelepiped is sliced into thicknesses of 4 mm flakes, drying the cut material separately;

[0034] (2) Apply a layer of pressure-sensitive adhesive evenly on one side of the dried sheet, centering on the arc column, neatly stack the sheet coated with pressure-sensitive adhesive on the arc column, and use the mold for hot pressing Molding, the pressure sensitive adhesive is made of the following co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com