Optical film

A technology of optical film and optical surface, which is applied in the field of optical film and can solve problems such as poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0065] The preparation of preparation example 1 resin formula A

[0066] Take a 250 ml glass bottle, and add solvent: 40 grams of toluene into the glass bottle. Add acrylate monomers sequentially under high-speed stirring: 10 grams of dipentaerythritol hexaacrylate, 2 grams of trimethylolpropane triacrylate, 14 grams of pentaerythritol triacrylate, oligomer: 28 grams of aliphatic aminomethyl Ester hexaacrylate [Etercure 6145-100, Eternal Company], photoinitiator: 6 grams of 1-hydroxycyclohexyl phenyl ketone, and finally foamed into a resin formula A with a solid content of about 60% and a total weight of about 100 grams.

preparation example 2

[0067] Preparation Example 2 Mold Roller Engraving

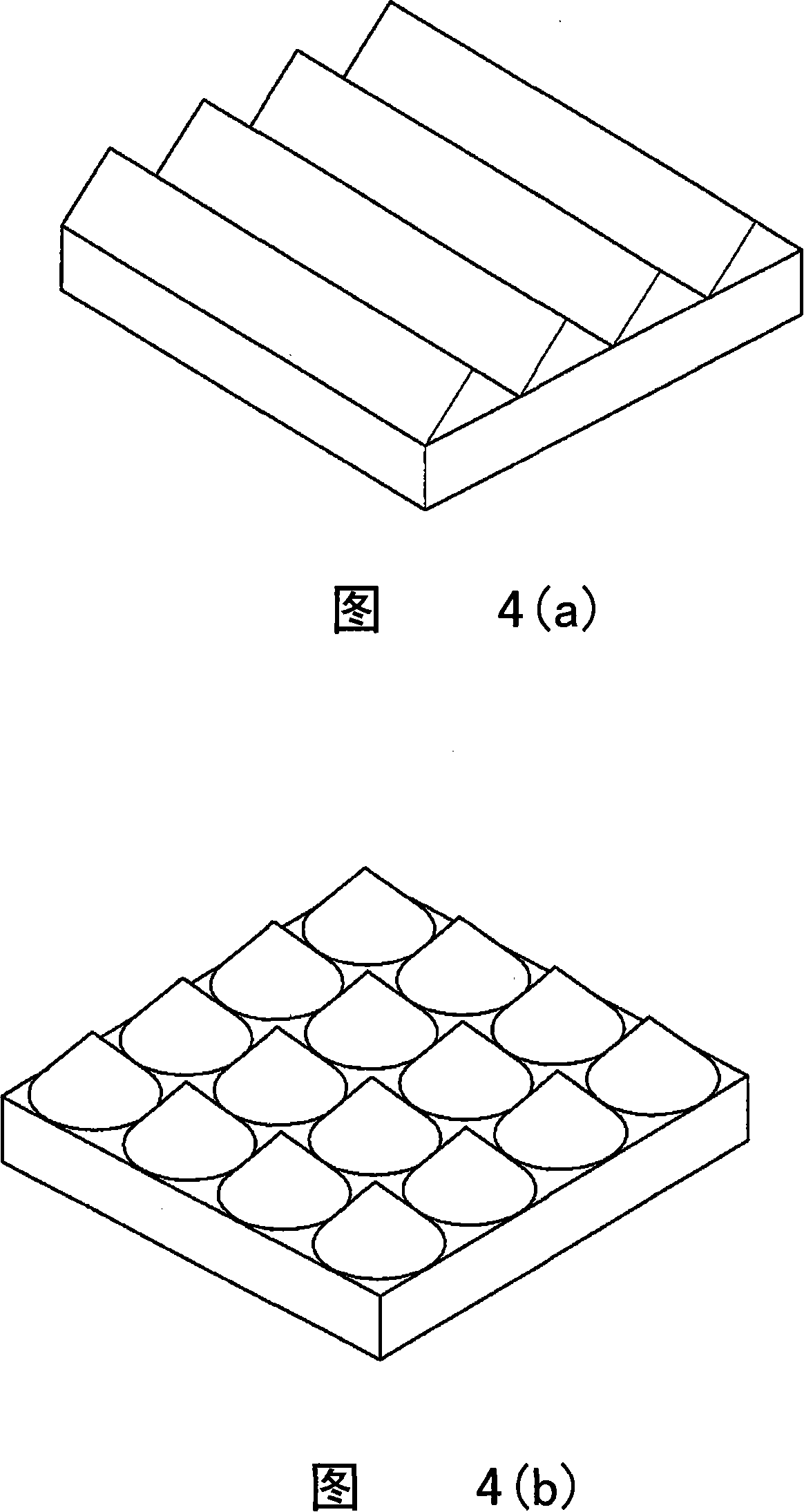

[0068] The surface of the precision roller is electroplated with electroless nickel or oxygen-free copper, using a CNC precision lathe and a single crystal diamond cutter, the lathe speed is below 500rpm, the upper limit of the feed is 0.015 mm, and the numerical control (NC) program is written according to the set pattern Process and prepare the desired microstructure grooves on the surface of the roller as a mold for subsequent processing.

Embodiment 1

[0070] Preparation of microstructure layer

[0071] 60 g of EM210 (2-phenoxyethyl acrylate, sold by Eternal Company) and 60 grams of 624-100 (epoxy acrylate, sold by Eternal Company) mixes, then adds 5 grams of Chivacure BP was used as a photoinitiator (benzophenone, provided by Double Bond Chemicals) and stirred at 50° C. and a rotation speed of 1,000 rpm to form a colloidal coating composition.

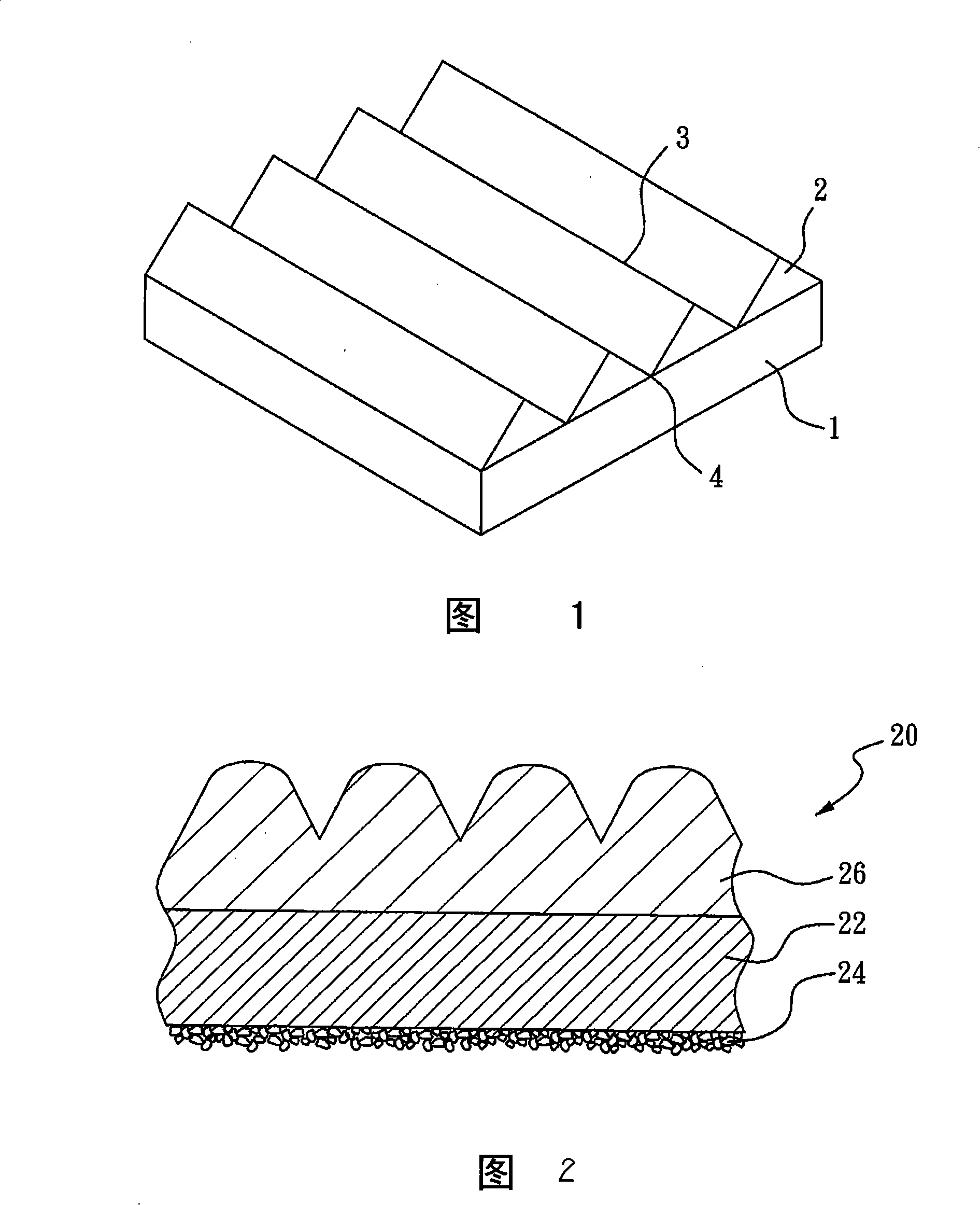

[0072] This colloidal coating composition is coated on a polyethylene phthalate (PET) substrate (U34 , produced by TORAY Company) to form a coating, and then use the roller with microstructure grooves obtained in Preparation Example 2 to form a structured surface on the coating in an embossing manner. Then, at room temperature, with energy rays (200-400nm UV lamp, intensity: 150-300mJ / cm 2 , time: 2 to 15 seconds) to irradiate the coating to cure it. 10 is an image of the microstructure layer of the optical film of Example 1 produced by a scanning electron microscope (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com