DPF regeneration device for mixing two-phase flow mediums and exhaust air temperature increment strategy of DPF regeneration device

A technology of exhaust temperature and regeneration device, which is applied in the direction of exhaust treatment, muffler, exhaust device, etc. It can solve the problems of affecting DPF regeneration, affecting ignition characteristics and combustion speed, fuel residue in nozzles, etc., and achieves ignition and ignition performance Good combustion performance, improved ignition conditions and combustion conditions, good reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

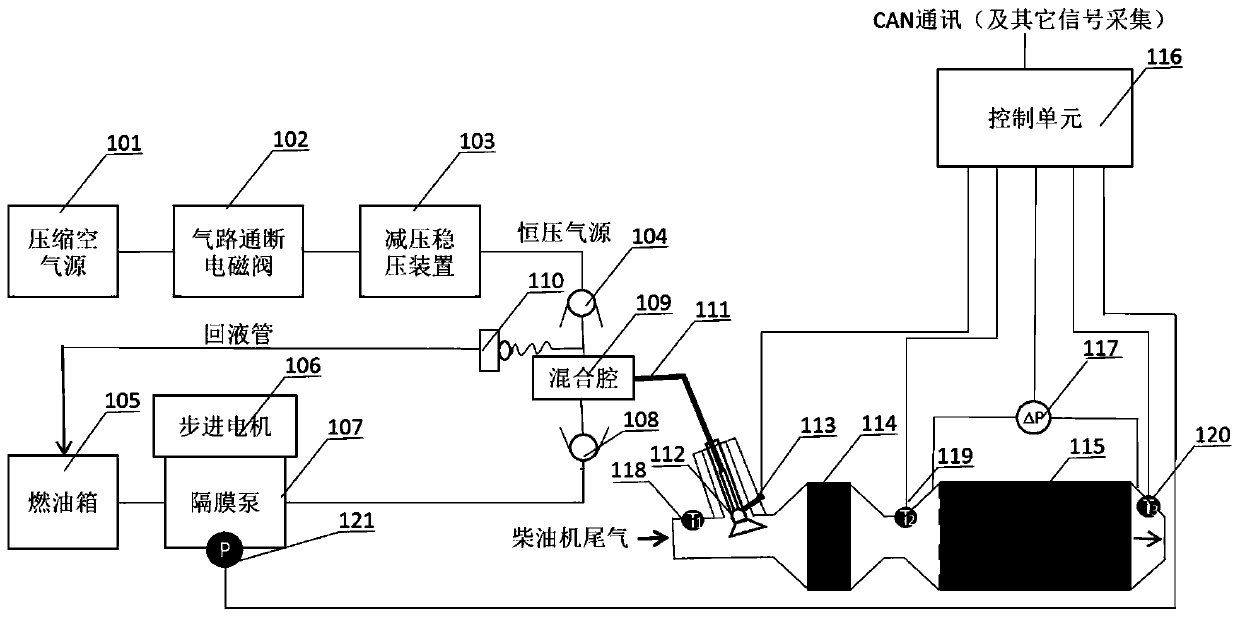

[0060] Such as figure 1 As shown, in the two-phase flow medium mixing DPF regeneration device of the present invention, the exhaust pipe inlet is provided with a nozzle 112, and the exhaust pipe is provided with an oxidation catalyst DOC114 and a particle trap DPF115, including two-phase flow Medium mixing device and control system; the two-phase flow medium mixing device is used to provide the two-phase flow medium mixed by the nozzle 112;

[0061] The two-phase flow medium mixing device includes a mixing chamber 109, a gas supply system, and a liquid supply system; the gas supply system and the liquid supply system are respectively connected to the mixing chamber 109 for mixing two-phase flow medium; the mixing chamber 109 and The nozzle 112 is connected through a mixed oil and gas delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com