Treating system, separating apparatus and treating method for oily sludge

A technology for separating equipment and sludge, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of difficult production, secondary pollution, high cost, and achieve Avoid uneven mixing, expand application range, and meet emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

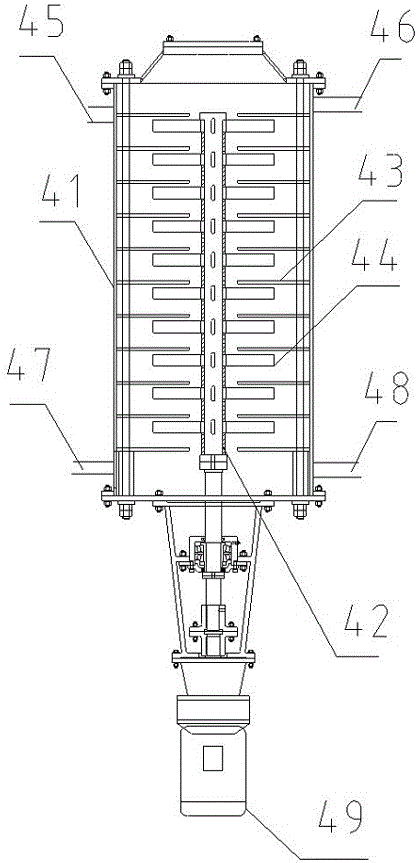

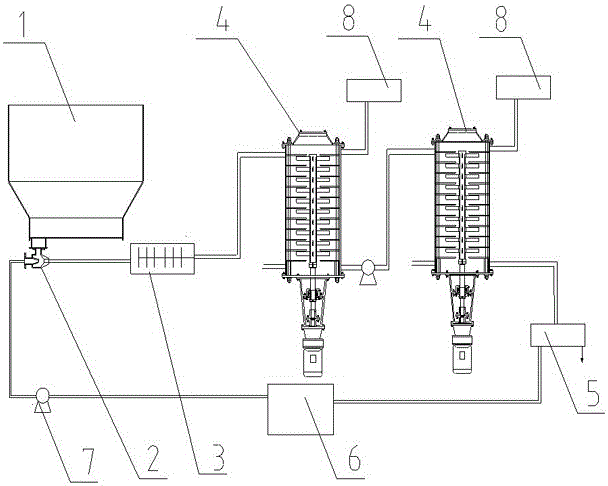

[0063] Reference Figure 1-2 The present invention is further illustrated through the following examples.

[0064] Take the oil sludge at the bottom of an oil tank (the sludge contains 30 wt% oil, 35 wt% water, and the rest is solid matter) as an example to illustrate specific embodiments of the present invention.

[0065] (1) The treatment method also includes the step of pretreatment of oily sludge. The pretreatment step includes: removing impurities in the oily sludge, then crushing and mixing with water to make a mud-water mixture, and then transporting it to the sludge Storage device 1.

[0066] (2) The jet 2 sucks out the sludge and sprays it into the high-speed crushing device 3 for impact crushing and high-speed shredding. The water source of the jet 2 uses the water in the water storage device 6 (temperature 80℃), and the high-speed crushing device 3 The sludge particles are further broken by high-speed rotation, so that the sludge is completely broken, and the particle si...

Embodiment 2

[0071] As another embodiment of the present invention, it is basically the same as the processing method of embodiment 1, but the difference is: in step (3), an extractant is introduced into the feed port 47 at the bottom of the separation device, and the extractant is toluene. The amount of extractant is 0.5wt% of oily sludge. The final oil recovery rate was 98.3%, and the residual oil rate was 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com