Coal-fired boiler combustion system with participant mixture of drainage gas and ventilation gas

A technology for extracting gas and coal-fired boilers, which is applied in the direction of combustion methods, combustion control, and combustion equipment. It can solve the problems of no way to use gas, poor coal quality, and failure to maximize the combustion status of boilers, etc., and achieve improvement. Boiler combustion conditions, improving economic and social benefits, and increasing the effect of gangue utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

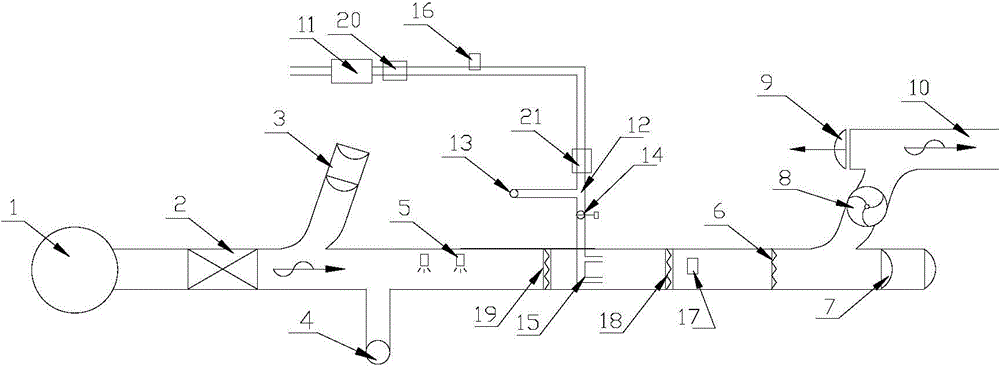

[0023] In the following, the same reference numerals refer to the same elements.

[0024] The present invention considers that the extracted gas is mixed into the exhaust air flow of the mine that participates in the combustion of the thermal power plant boiler through the pipeline, so as to participate in the combustion. In this way, while making full use of the exhaust air flow in the mine, the high-concentration extraction gas is diluted to below the safe value and utilized, which improves the gas utilization rate and improves the coal-fired combustion performance of the power plant boiler.

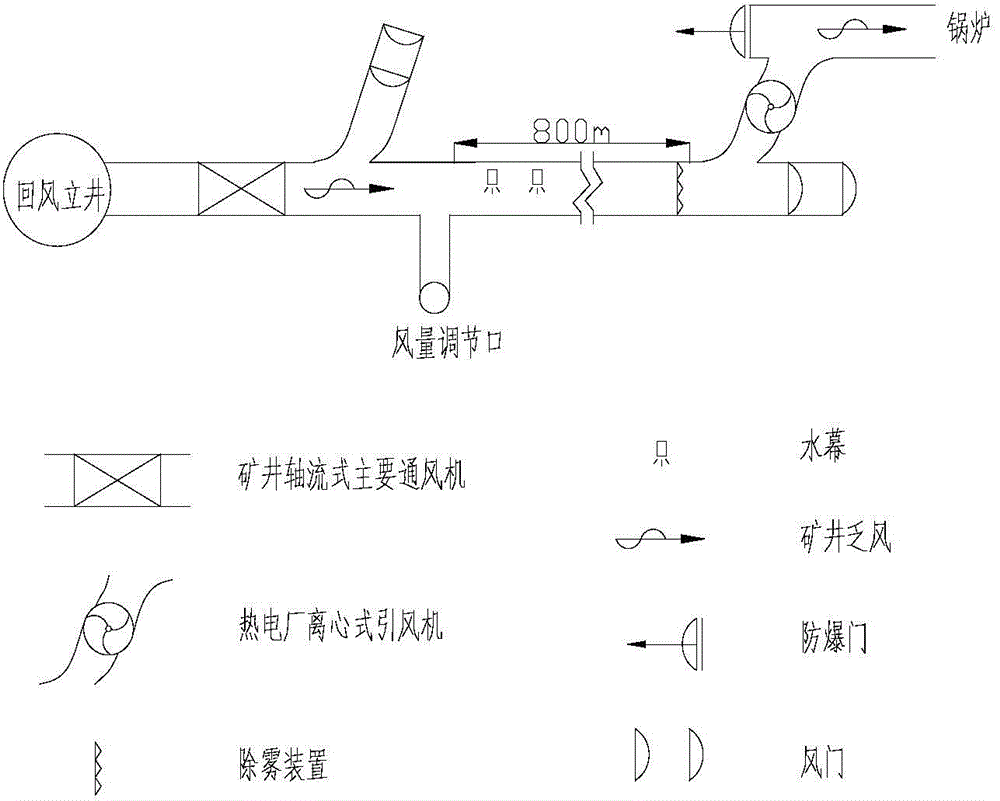

[0025] figure 2 It shows a system in which extraction gas is mixed with exhaust gas to participate in combustion of a coal-fired boiler according to the present invention. Such as figure 2 As shown, the exhaust air flow generated in the mine return air shaft 1 enters the induced draft fan 8 near the coal-fired power plant along the exhaust air flow channel under the pumping of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com