Copper-cerium solid solution catalyst for methane catalytic combustion, and preparation method thereof

A methane catalytic combustion and catalyst technology, which is applied in the direction of fuel, gas fuel, petroleum industry, etc., achieves the effects of simple preparation method, easy operation of preparation method and good stability

Inactive Publication Date: 2010-08-25

EAST CHINA UNIV OF SCI & TECH

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

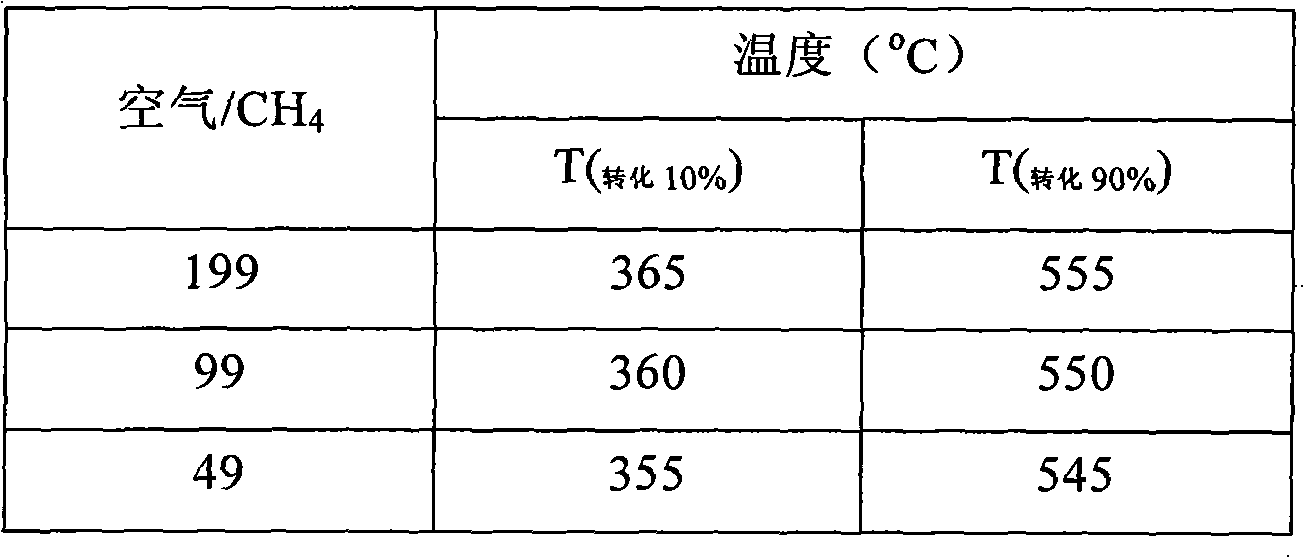

The invention aims to provide an effective copper-cerium solid solution catalyst for methane catalytic combustion, and a preparation method thereof. A preparation process of the catalyst comprises the following steps: weighing Ce(NO3)3.6H2O and Cu(NO3)2.3H2O according to a general formula CuxCe1-xO2, wherein x is between 0.1 and 0.9; dissolving Ce(NO3)3.6H2O and Cu(NO3)2.3H2O in deionized water to ensure that the total concentration of metal ions is 1 mol / L; adding citric acid in the same weight with the metal ions; stirring uniformly; standing the obtained product for 3 to 12 hours; slowly heating the obtained product in an oil bath at 50 to 80 DEG C to form gel; drying the obtained product for 12 hours at 110 to 150 DEG C; and roasting the obtained product for 4 to 12 hours in an air atmosphere at 500 to 800 DEG C to obtain a finished product of the catalyst. When the catalyst is used for methane catalytic combustion reaction, air is adopted as oxidant, so the combustion reaction is low in light-off temperature, low in complete combustion temperature and capable of ensuring the complete combustion of methane at 550 DEG C. The catalyst is a solid solution catalyst taking copper oxide or cerium oxide as active components, thereby having high content of active components and low price. The catalyst is prepared by a citric acid complexing sol-gel method, and has the advantages of easily operated preparation method, uniformly dispersed active components and good stability.

Description

technical field The invention relates to a catalyst for methane low-temperature catalytic combustion and a preparation method thereof. Background technique Due to its inherent advantages in cleanliness, economy, convenience, versatility and high efficiency, natural gas has replaced coal or petroleum in more and more fields, and has become a clean energy that improves the quality of human life and promotes economic development. The main component of natural gas is methane. The traditional combustion method has a high combustion temperature (1600°C), which not only produces a large amount of NO x , and incomplete combustion of methane, resulting in environmental pollution. Catalytic combustion is being widely studied as a method of energy utilization. Catalytic combustion is a kind of flameless combustion, which has high combustion efficiency and energy utilization rate, and the working temperature is low, thus greatly suppressing NO x The formation of unburned substances i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/83C10L3/00

Inventor 杨伟领李到王幸宜

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com