Cobalt oxide and cerium oxide catalyst for purifying particulate emission of diesel engine and preparation method

A technology of soot particles and cerium oxide, which is applied in the field of catalyst technology and environmental protection, can solve the problems that the catalytic performance cannot fully meet the requirements of diesel vehicle exhaust purification, limited application, high cost, etc., and is suitable for large-scale industrial production , The preparation method is simple and easy, and the effect of reducing the cost of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

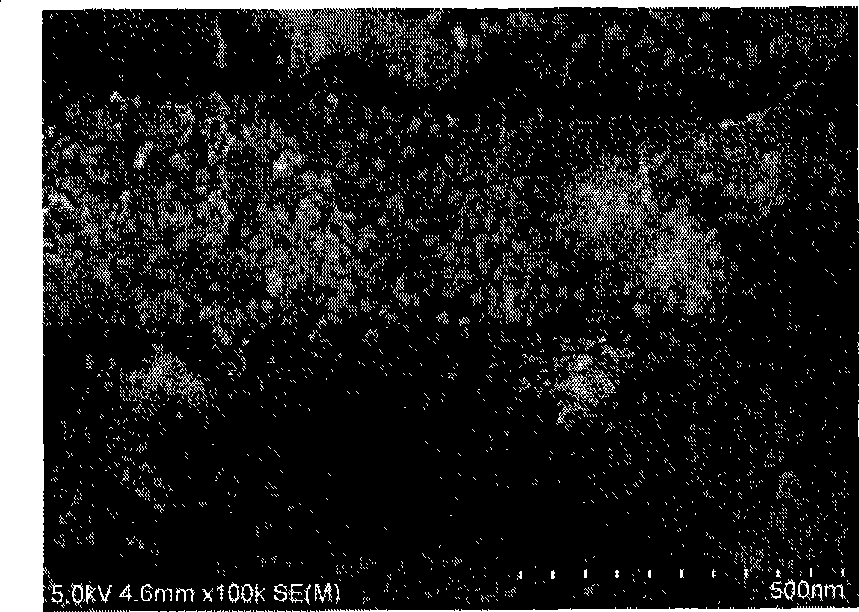

[0033] 2.9107 g Co(NO 3 ) 2 ·6H 2 O and 2.1040 grams of citric acid powder were dissolved in 20 milliliters of deionized water to prepare a cobalt nitrate impregnation solution, 17.2120 grams of nano-cerium dioxide powder was placed in the impregnation solution, stirred for about 15 minutes, and further utilized ultrasonic dispersion for about 30 minutes, After drying in static air at 100°C for about 16 hours, it was moved into a muffle furnace and calcined in an air atmosphere at 600°C for about 4 hours to obtain the catalyst Co 0.10 / CeO 2 , the atomic molar ratio of Co and Ce in the catalyst is about 0.1.

Embodiment 2

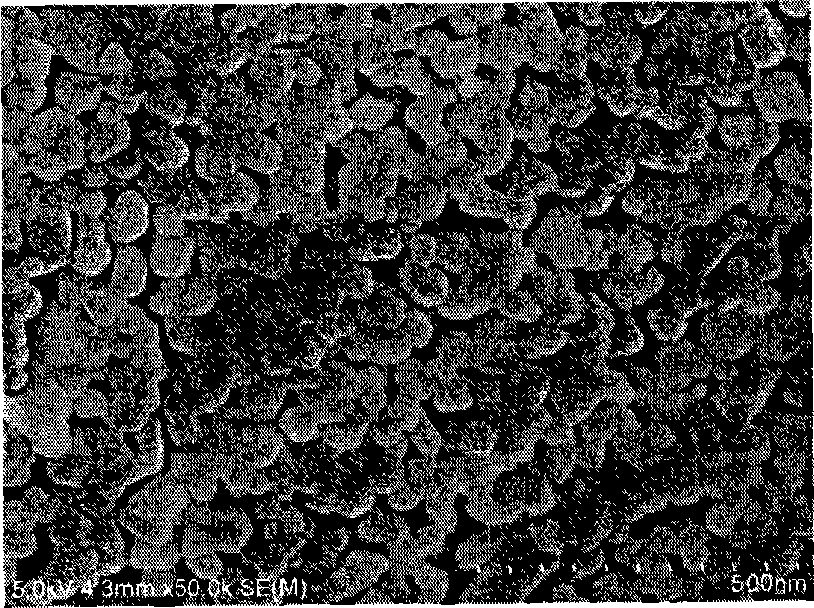

[0035] 2.9107 g Co(NO 3 ) 2 ·6H 2 O, 43.4230 g Ce(NO 3 ) 3 ·6H 2 O and 23.1440 grams of citric acid powder were dissolved in 50 ml of deionized water, stirred vigorously to mix evenly, heated and evaporated to dryness on a 2KW electric furnace, and spontaneously ignited, accompanied by the release of a large amount of reddish-brown gas and white smoke, spontaneously ignited After completion, a black solid powder was obtained, which was transferred into a muffle furnace and calcined in an air atmosphere at 600°C for 4 hours to obtain a catalyst Co 0.10 CeO 2 , the atomic molar ratio of Co and Ce in the catalyst is 0.1.

Embodiment 3

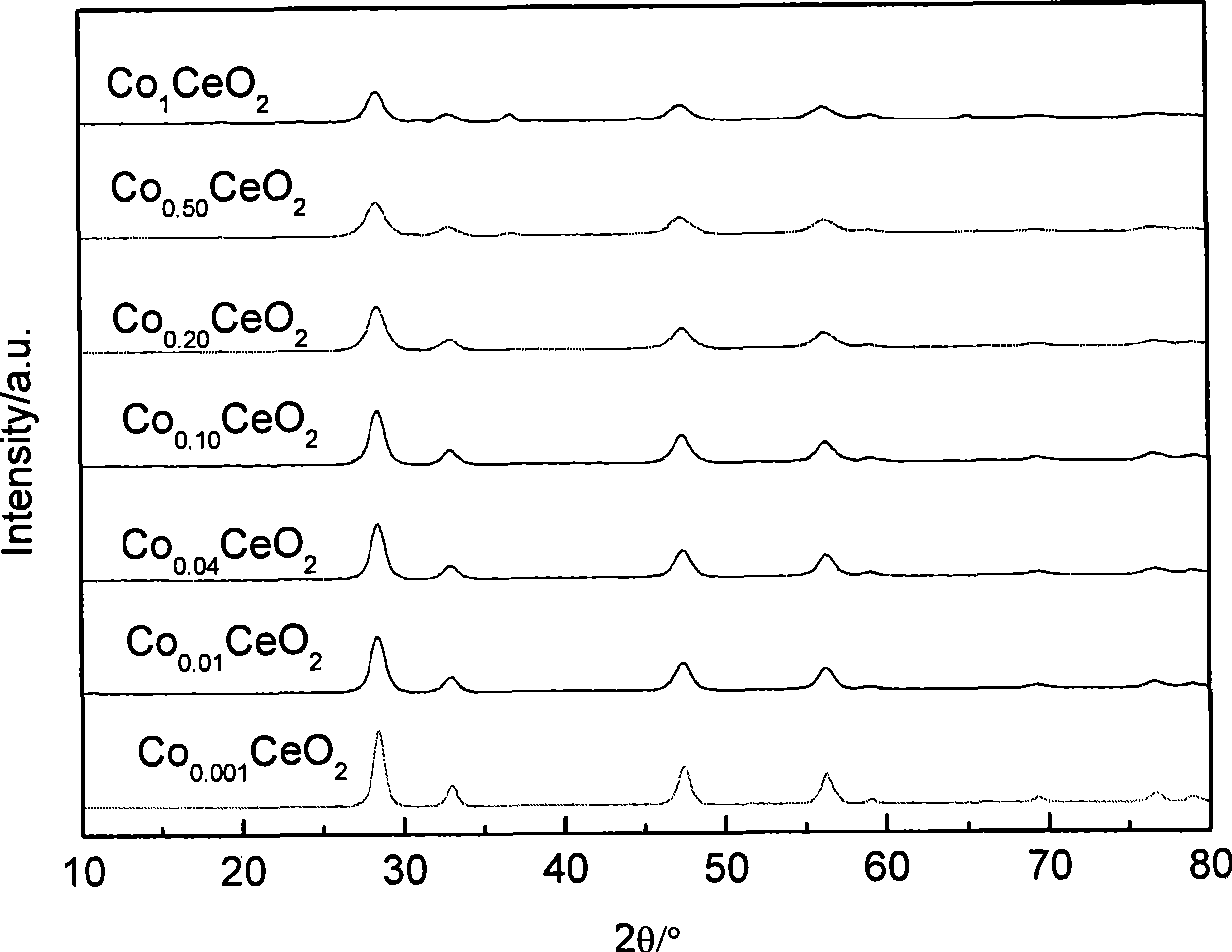

[0037] The preparation method is the same as in Example 1, except that the loading of cobalt is changed so that the loading of Co on the catalyst (in terms of the atomic molar ratio of Co and Ce) is 0.001, 0.01, 0.04, 0.1, 0.2, 0.5, 1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com