Three-dimensional ordered macroporous oxide catalyst for diesel soot purification and preparation method thereof

A technology for oxidizing catalysts and oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of obtaining composite metal oxides, Consistent metal molar ratio of composite metal oxides and other issues to achieve the effects of easy control of the reaction process, simple and easy preparation process, and reduced diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13D

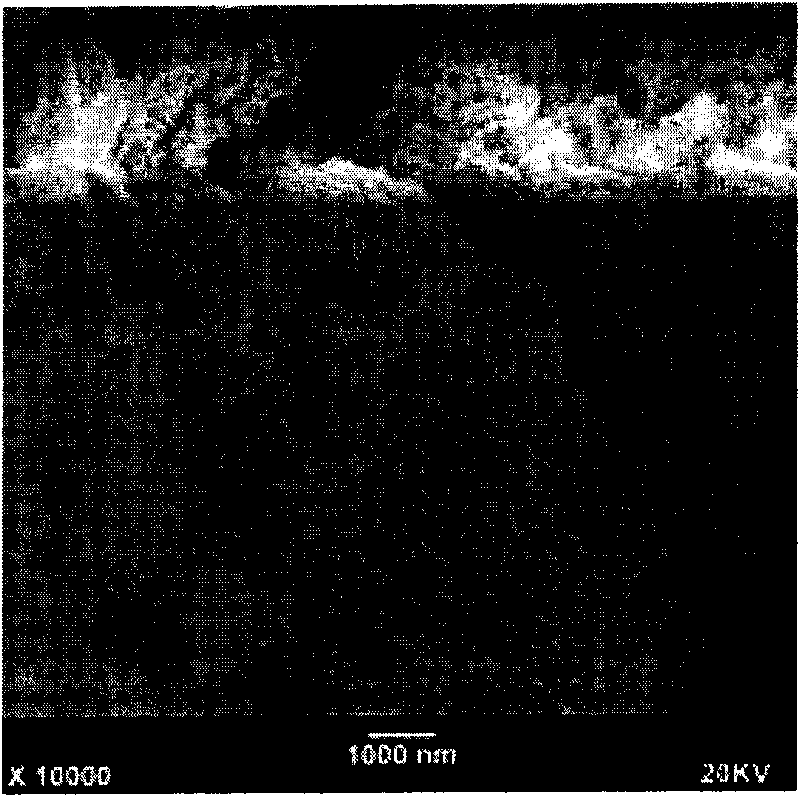

[0064] Example 13 DOM CeO 2 simple metal oxides

[0065] Take a small amount of polymethyl methacrylate microsphere emulsion with a particle size of 446nm, centrifuge at a speed of 3000rpm for 10h to obtain a PMMA colloidal crystal template, and dry naturally;

[0066] Weigh a certain amount of cerium nitrate, dissolve it in ethylene glycol, transfer the resulting solution to a volumetric flask, and constant volume with methanol (methanol volume fraction is 5-50%), the concentration of metal ions in the prepared solution is 2.0mol / L, to get 3DOM CeO 2 The precursor solution;

[0067] Add 3DOM CeO dropwise to the dried PMMA colloidal crystal template 2 Precursor solution until the solution is immersed in the PMMA template. After the impregnation is complete, remove the excess solution by suction filtration to obtain the precursor / PMMA composite, dry it naturally, and then place it in a tube furnace at a heating rate of ≤2°C / min Raise the temperature to 500°C and roast (kee...

Embodiment 23D

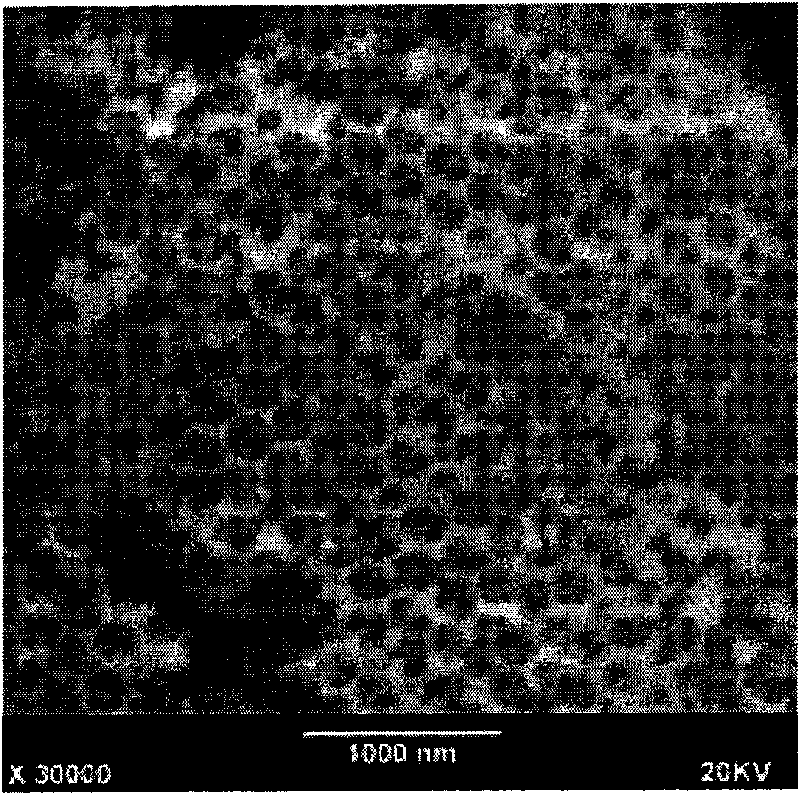

[0077] Example 23 DOM LaFeO 3 composite metal oxide

[0078] Take a small amount of polystyrene microsphere emulsion with a particle size of 367nm, centrifuge at a speed of 3000rpm for 20h to obtain a PS colloidal crystal template, and dry naturally;

[0079] Weigh lanthanum nitrate and ferric nitrate according to the stoichiometric ratio (molar ratio 1:1), add ethylene glycol therein, magnetically stir for 2 h, transfer the resulting solution to a volumetric flask, and dilute to volume with methanol (the volume fraction of methanol is 30%), the concentration of metal ions in the prepared solution is 1.5mol / L, and 3DOM LaFeO 3 The precursor solution, this solution is 3DOM LaFeO 3 The precursor solution of composite metal oxide catalyst;

[0080] 3DOM LaFeO 3 The precursor solution was added dropwise to the dry PS colloidal crystal template until the solution submerged the PS template. After the impregnation was complete, the excess solution was removed by suction filtratio...

Embodiment 33

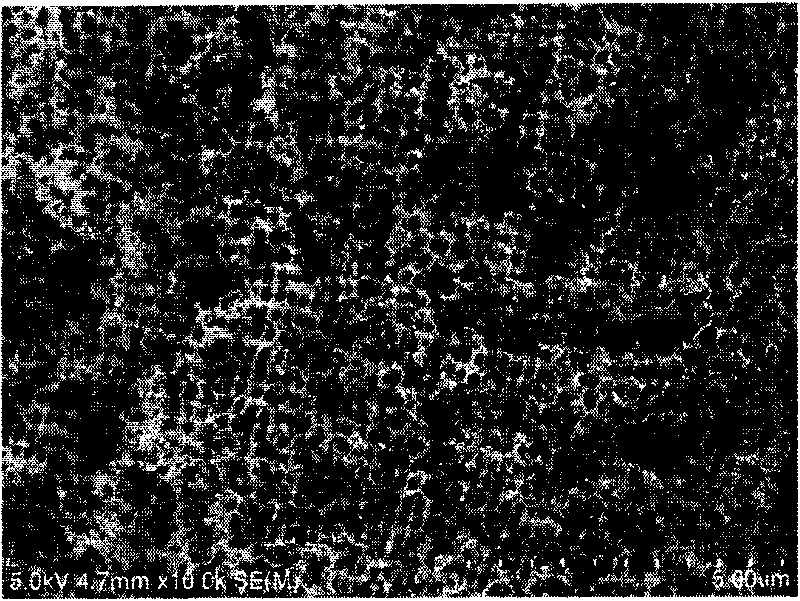

[0091] Example 33 DOMLa 0.9 K 0.1 FeO 3 composite metal oxide

[0092] Take a small amount of polymethyl methacrylate microsphere emulsion with a particle size of 487nm, centrifuge at a speed of 2000rpm for 15h, discard the supernatant to obtain a PMMA colloidal crystal template, and dry naturally;

[0093] Weigh lanthanum nitrate, potassium nitrate and ferric nitrate according to the stoichiometric ratio (9:1:10 in molar ratio), add ethylene glycol therein, stir magnetically for 2 hours, transfer the resulting solution to a volumetric flask, and dilute to volume with methanol (methanol volume fraction is 40%), metal ion concentration is 2.0mol / L in the prepared solution, obtains 3DOMLa 0.9 K 0.1 FeO 3 The precursor solution, this solution is 3DOM La 0.9 K 0.1 FeO 3 The precursor solution of composite metal oxide catalyst;

[0094] Add 3DOM La dropwise to the dried PS colloidal crystal mold 0.9 K 0.1 FeO 3 Precursor solution until the solution is immersed in the PM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com