Macroporous composite metal oxide catalyst for purifying soot of diesel and preparation method thereof

A technology for oxidation catalysts and composite metals, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. High combustion temperature, small catalyst pores and other problems, to achieve the effect of improving catalytic activation efficiency, lowering combustion temperature and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Large Pore La 0.9 K 0.1 FeO 3 Perovskite composite oxide catalyst

[0054] Weigh lanthanum nitrate, potassium nitrate and ferric nitrate according to the stoichiometric ratio, dissolve them in ethylene glycol, add an appropriate amount of methanol (the volume fraction of methanol is 5-50%) to obtain a mixed solution, wherein the total amount of metal ions in the mixed solution The concentration is 0.5-3.0mol / L, after reaction, the macroporous composite metal oxide catalyst La 0.9 K 0.1 FeO 3 precursor solution. Take a small amount of the precursor solution in a crucible, directly place the crucible in a muffle furnace and bake at 650°C for 5 hours to obtain La 0.9 K 0.1 FeO 3 Perovskite type composite metal oxide, cooled for standby.

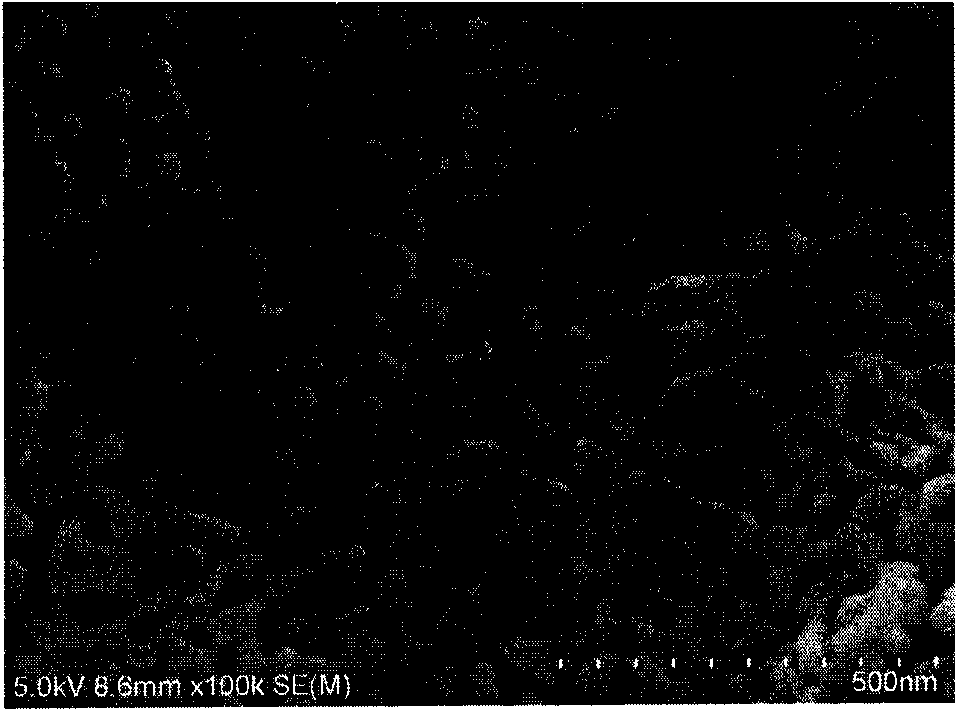

[0055] Figure 1a and Figure 1b Respectively La prepared in this example 0.9 K 0.1 FeO 3 Scanning electron microscope (SEM) photographs of different magnifications. It can be seen from the figure that La 0.9 K 0...

Embodiment 2

[0061] Example 2 Large Pore La 0.9 K 0.1 CoO 3 Perovskite composite oxide catalyst

[0062] Weigh lanthanum nitrate, potassium nitrate, and cobalt nitrate according to the stoichiometric ratio, dissolve them in ethylene glycol, add an appropriate amount of methanol (the volume fraction of methanol is 5-50%) to obtain a mixed solution, wherein the total amount of metal ions in the mixed solution Concentration is 1.0mol / L, after reaction, macroporous composite metal oxide catalyst La 0.9 K 0.1 CoO 3 precursor solution. Take a small amount of the precursor solution in a crucible, directly place the crucible in a muffle furnace and bake at 600°C for 5 hours to obtain La 0.9 K 0.1 CoO 3 Perovskite type composite metal oxide, cooled for standby.

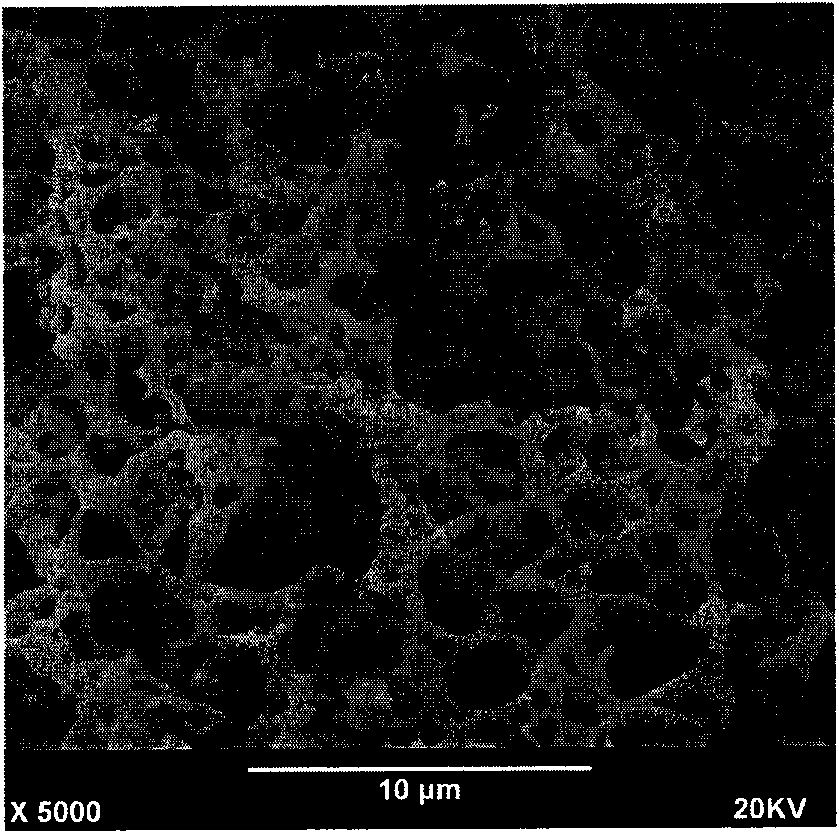

[0063] figure 2 La prepared for this example 0.9 K 0.1 CoO 3 The scanning electron microscope picture, as can be seen from the figure, La 0.9 K 0.1 CoO 3 Has a honeycomb macroporous structure. Figure 7 La prepared for th...

Embodiment 3

[0069] Example 3 Macroporous LaCo 0.9 Fe 0.1 o 3 Perovskite composite oxide catalyst

[0070] Weigh lanthanum nitrate, cobalt nitrate, and iron nitrate according to the stoichiometric ratio, dissolve them in ethylene glycol, add an appropriate amount of methanol (the volume fraction of methanol is 5-50%) to obtain a mixed solution, wherein the total amount of metal ions in the mixed solution The concentration is 2.0 mol / L, and the precursor solution of the macroporous composite metal oxide catalyst is obtained through the reaction. Take a small amount of the precursor solution in a crucible, directly place the crucible in a muffle furnace and bake at 600°C for 5 hours to obtain LaCo 0.9 Fe 0.1 o 3 Perovskite type composite metal oxide, cooled for standby.

[0071] image 3 LaCo prepared for this example 0.9 Fe 0.1 o 3 The scanning electron microscope photo, as can be seen from the figure, LaCo 0.9 Fe 0.1 o 3 Has a macroporous honeycomb structure. Figure 7 LaCo p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com