Three-dimensional ordered porous-mesoporous iron-based perovskite oxide catalyst and preparation method thereof

A technology of perovskite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The problems of complex oxides and complex structures in the pore channel structure can improve the catalytic activity, reduce the combustion temperature, and reduce the diffusion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of embodiment 1 colloidal crystal template

[0044] In this example, the colloidal crystal template was prepared according to the following method:

[0045] (1) Prepare monodisperse c-PMMA microspheres by improved soap-free emulsion polymerization

[0046] Add 50ml of acetone and 150ml of deionized water to a tank equipped with a stirrer, reflux condenser, thermometer and N 2 In a 1000ml four-necked flask with a trachea, pass N 2 Vacuumize, add MMA and AA with a volume ratio of 25:1 (both monomers are purified by distillation under reduced pressure), and heat to 70°C. At the same time, 0.27g of KPS and 0.45g of AIBN were weighed and dissolved in 150ml of water, heated to 70°C and added to a four-necked flask. N 2 After reacting for 2 h under protection, it was naturally cooled to room temperature under stirring, ultrasonically treated for 0.5 h, and c-PMMA polymer microspheres were obtained by suction filtration.

[0047] (2) Preparation of c...

Embodiment 23D

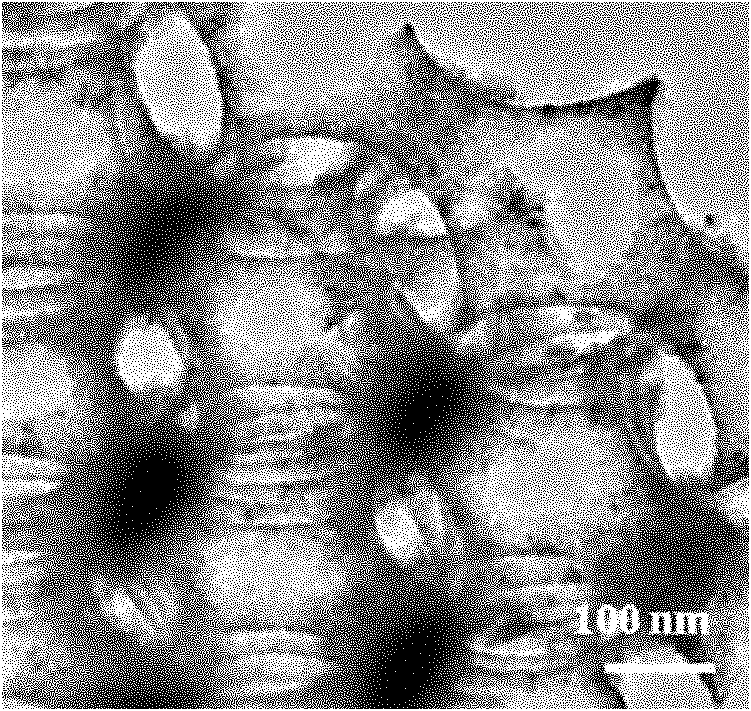

[0049] Example 23 DOM / m LaFeO 3 oxide catalyst

[0050] Weigh 16.24g La(NO 3 ) 3 ·6H 2 O and 15.15g Fe(NO 3 ) 2 9H 2 O, dissolved in 10ml of ethylene glycol, and magnetically stirred for 2 hours to obtain a homogeneous transparent solution, that is, to obtain a catalyst precursor solution. At the same time, 0.25g of Brij-56 was dissolved in 5ml of hydrochloric acid solution, magnetically stirred for 2h, then added to the precursor solution, and transferred to a 25ml volumetric flask, and the total volume of the solution was 25ml with ethylene glycol. The solution was used to impregnate 3 g of the dried c-PMMA colloidal crystal template for 10 h. After the impregnation was complete, the excess precursor solution was removed by suction filtration, and then the template was placed in a vacuum drying oven to dry overnight. Finally, it was first heated to 700 ° C in an argon atmosphere and roasted at a constant temperature for 4 hours. After cooling down to room temperature,...

Embodiment 3

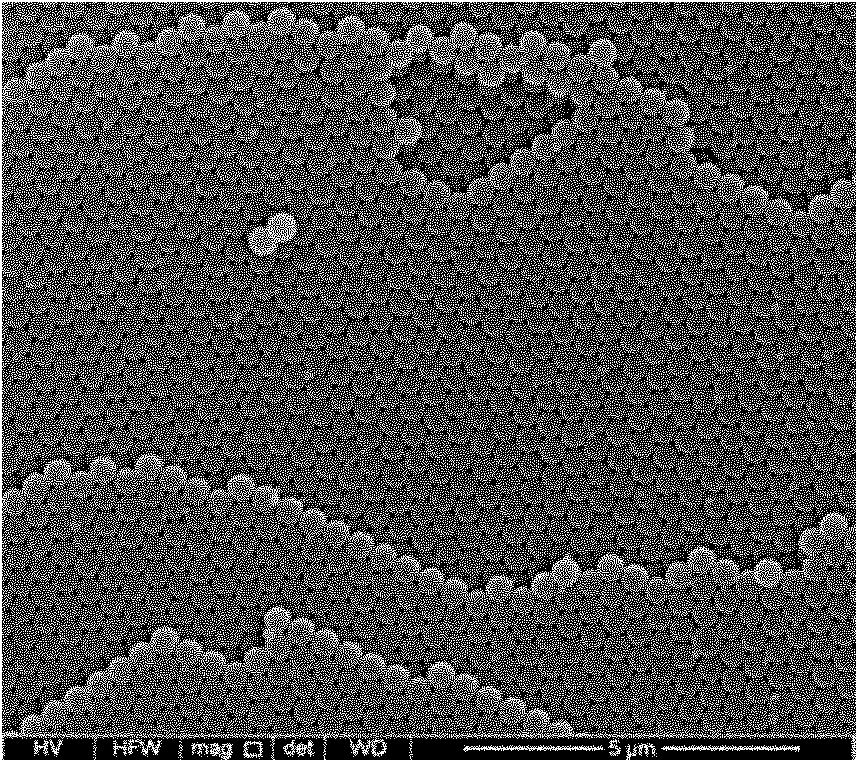

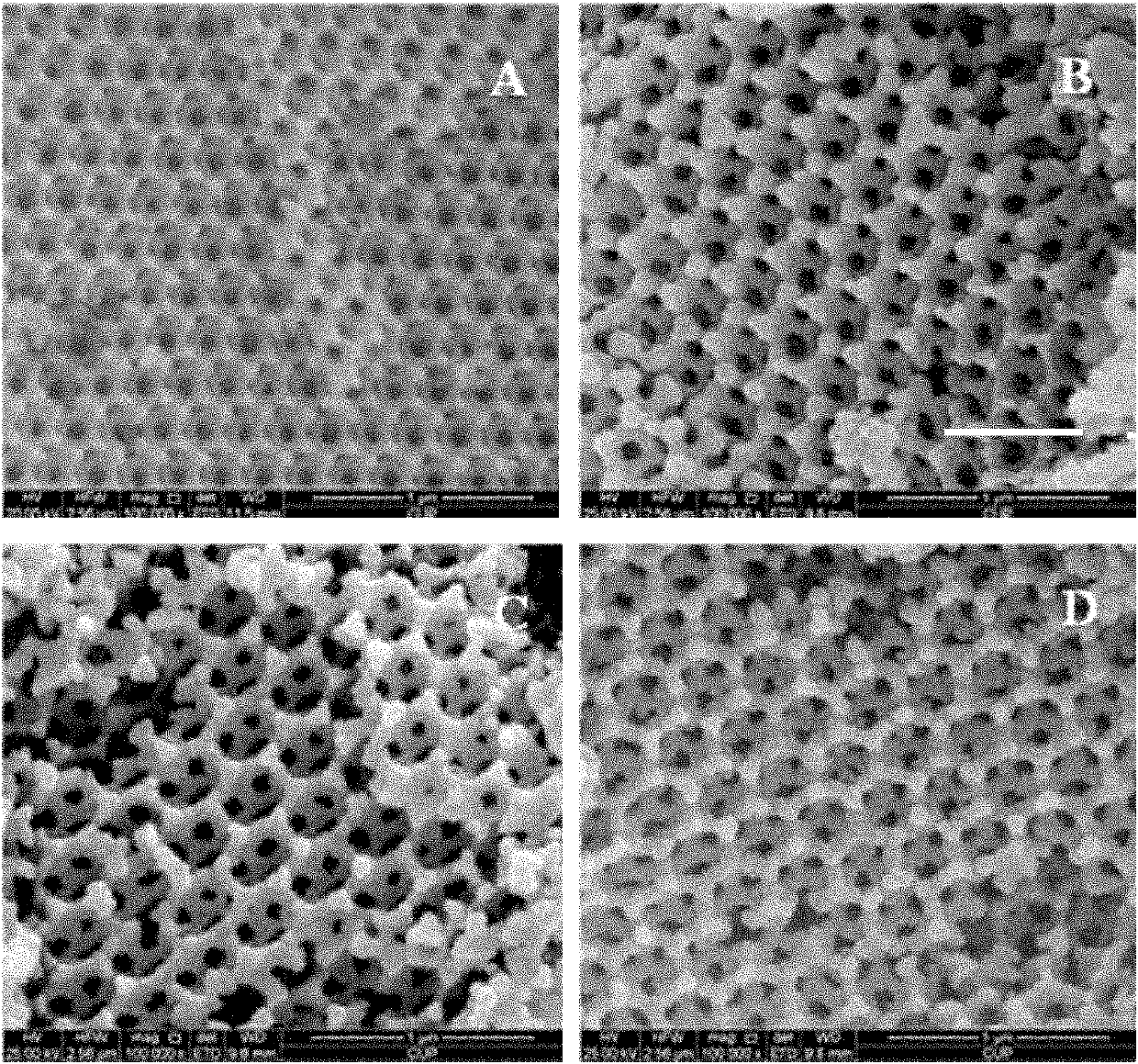

[0052] Embodiment 3 investigates the impact of different additives

[0053] The surfactant was dissolved in methanol, hydrochloric acid and nitric acid respectively, and other preparation conditions and preparation procedures were the same as in Example 2 to prepare 3DOM / m LaFeO 3 . Three kinds of catalysts prepared by the embodiment are respectively marked as S-methanol, S-hydrochloric acid and S-nitric acid, and its SEM photos are as follows: Figure 4a , Figure 4b , Figure 4c Shown, the BET specific surface area is shown in Table 1. It can be seen from the figure that when the three solvents are used as additives, regular macroporous structures can be formed. However, it can be seen from Table 1 that the specific surface area of S-methanol is the smallest (35.56m 2 / g), mainly because methanol is not conducive to the self-assembly of surfactants, so it will cause the formation of disordered mesopores, resulting in a smaller specific surface area. Among them, S-hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com