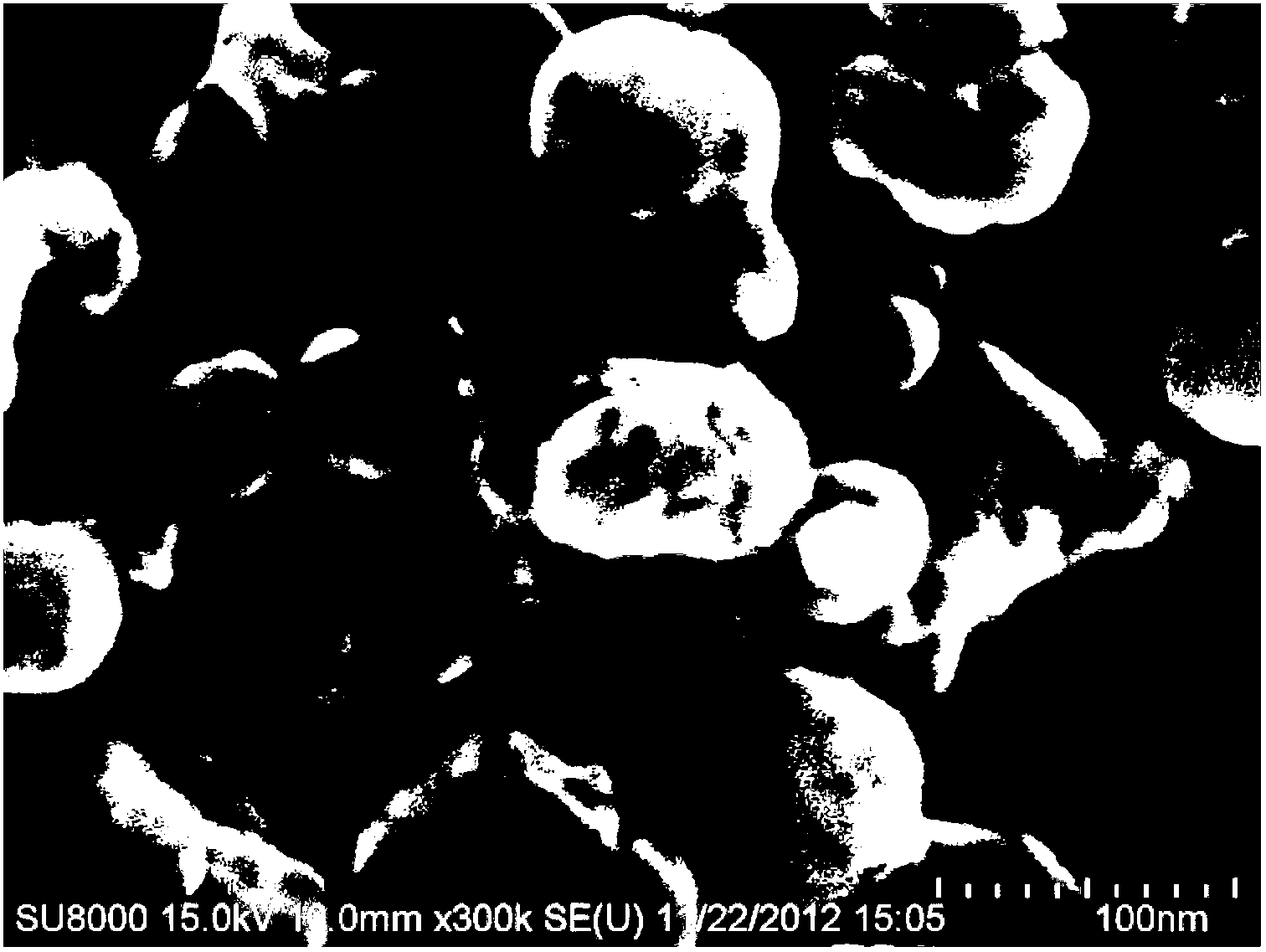

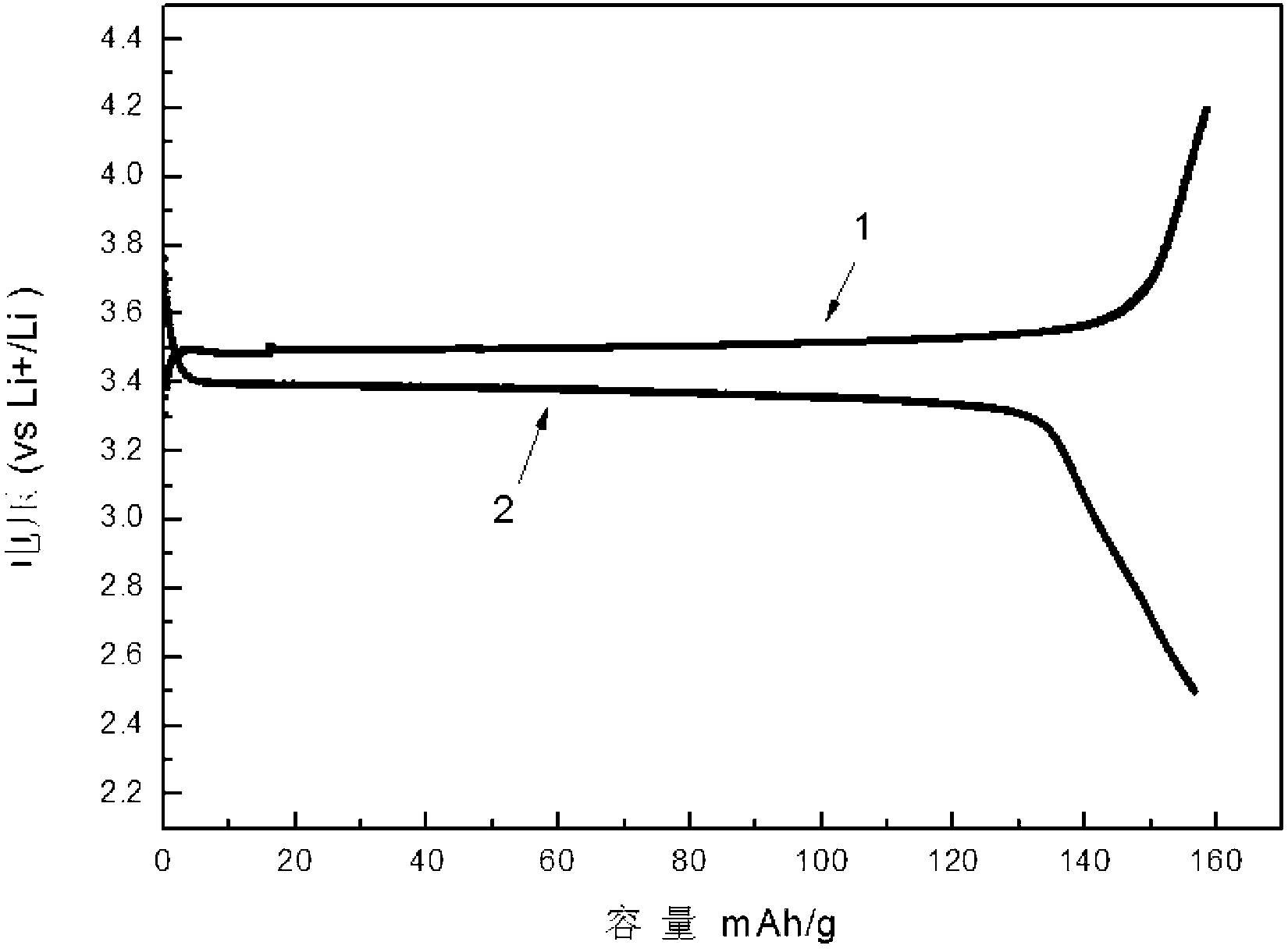

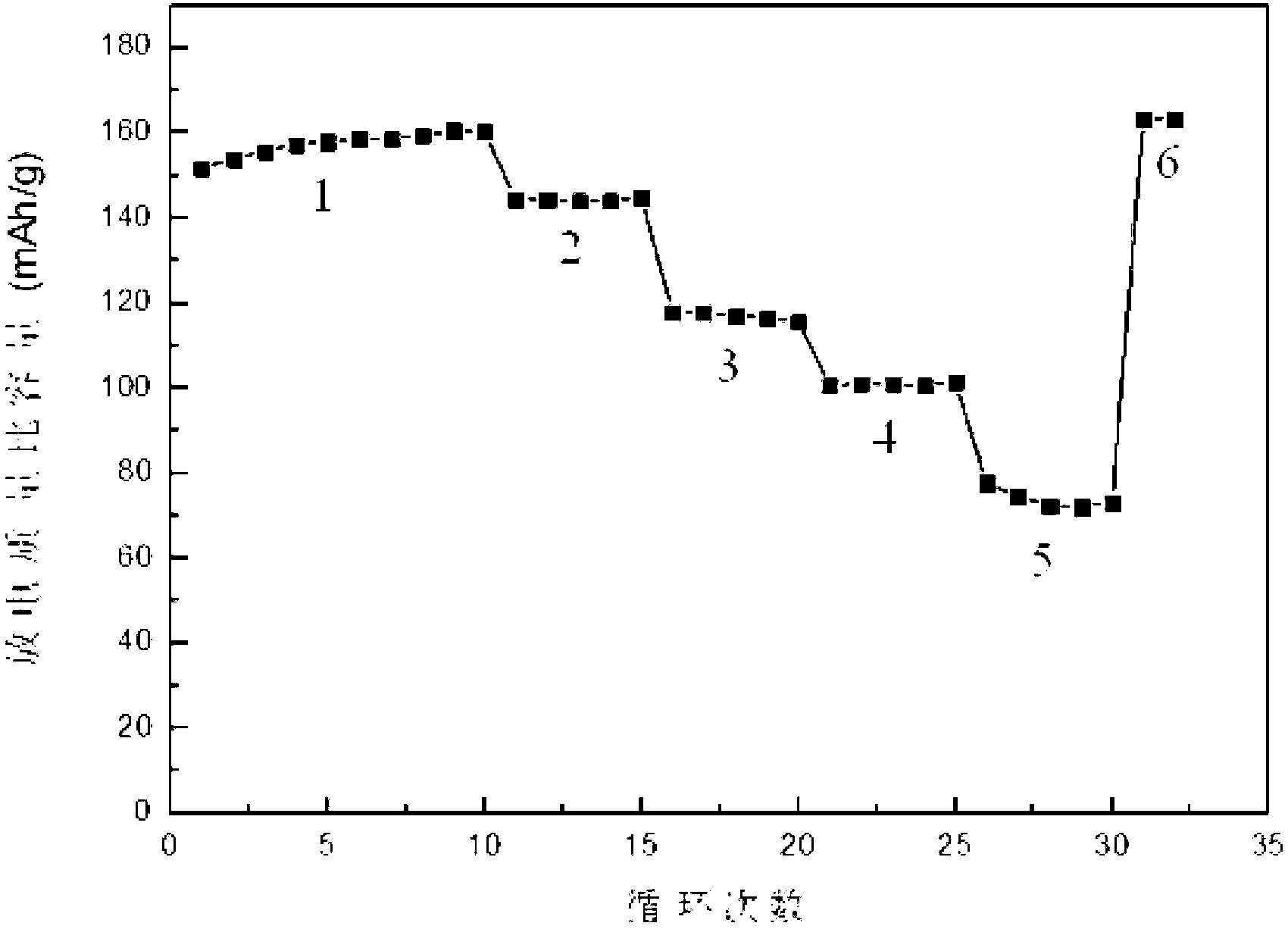

Preparation method of carbon-coated porous nano lithium iron phosphate material and lithium ion battery taking material as anode material

A porous structure, lithium iron phosphate technology, applied in the direction of battery electrodes, secondary batteries, structural parts, etc., can solve the problems of poor conductivity, poor performance, poor batch production consistency, etc., to achieve excellent consistency, short roasting time, distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: The preparation method of carbon-coated porous structure nano-lithium iron phosphate material in this embodiment is prepared according to the following steps:

[0023] 1. Weigh the ferric salt, phosphorus source compound and lithium source compound according to the ratio of the amount of Fe, P and Li as 1:1:0.9~1.1, according to the mass of organic small molecule carbon source and ferric salt The ratio is 1-11:20, and the organic small molecule carbon source is weighed;

[0024] 2. Mix the ferric salt, phosphorus source compound, lithium source compound and organic small molecule carbon source weighed in step 1 evenly to obtain a mixture, then add deionized water to the mixture, stir for 2h to 4h, and obtain a dispersion liquid, Among them, the quality of deionized water is 5 to 10 times that of the mixture;

[0025] 3. Stir the dispersion liquid obtained in step 2 at a temperature of 50°C to 100°C for 6h to 7h, and control the stirring ...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the ferric salt is ferric nitrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the phosphorus source compound in step 1 is ammonium dihydrogen phosphate or ammonium monohydrogen phosphate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Coating area density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com