Lightweight aggregate concrete and a preparation method thereof

A lightweight aggregate concrete and lightweight aggregate technology, applied in the field of concrete, can solve the problems of economic loss, frost resistance and durability of concrete structures that cannot be ignored, and the concrete structure has not reached the expected service life, so as to reduce the loss of slump , Improve the effect of frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

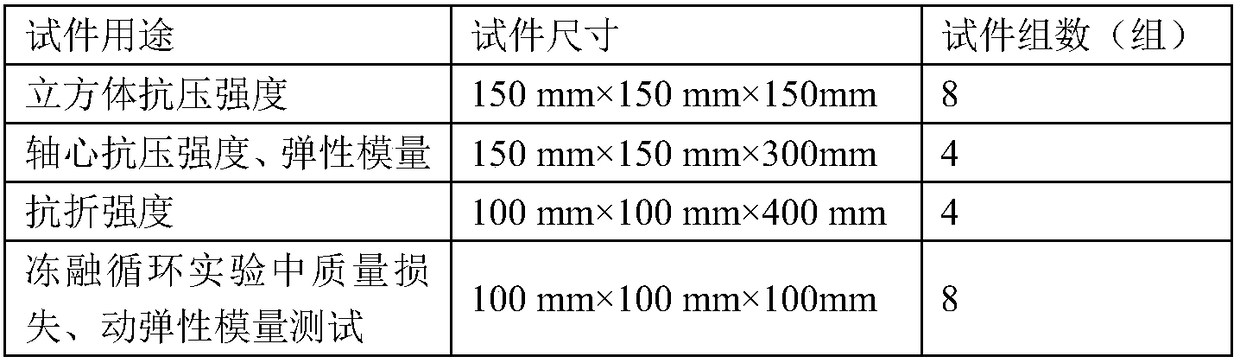

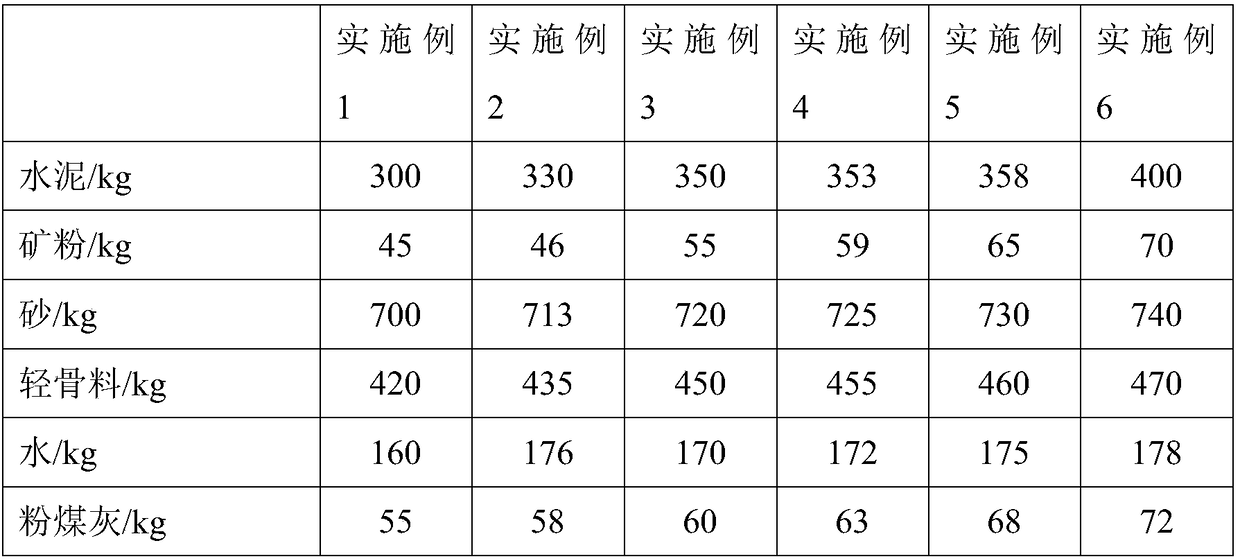

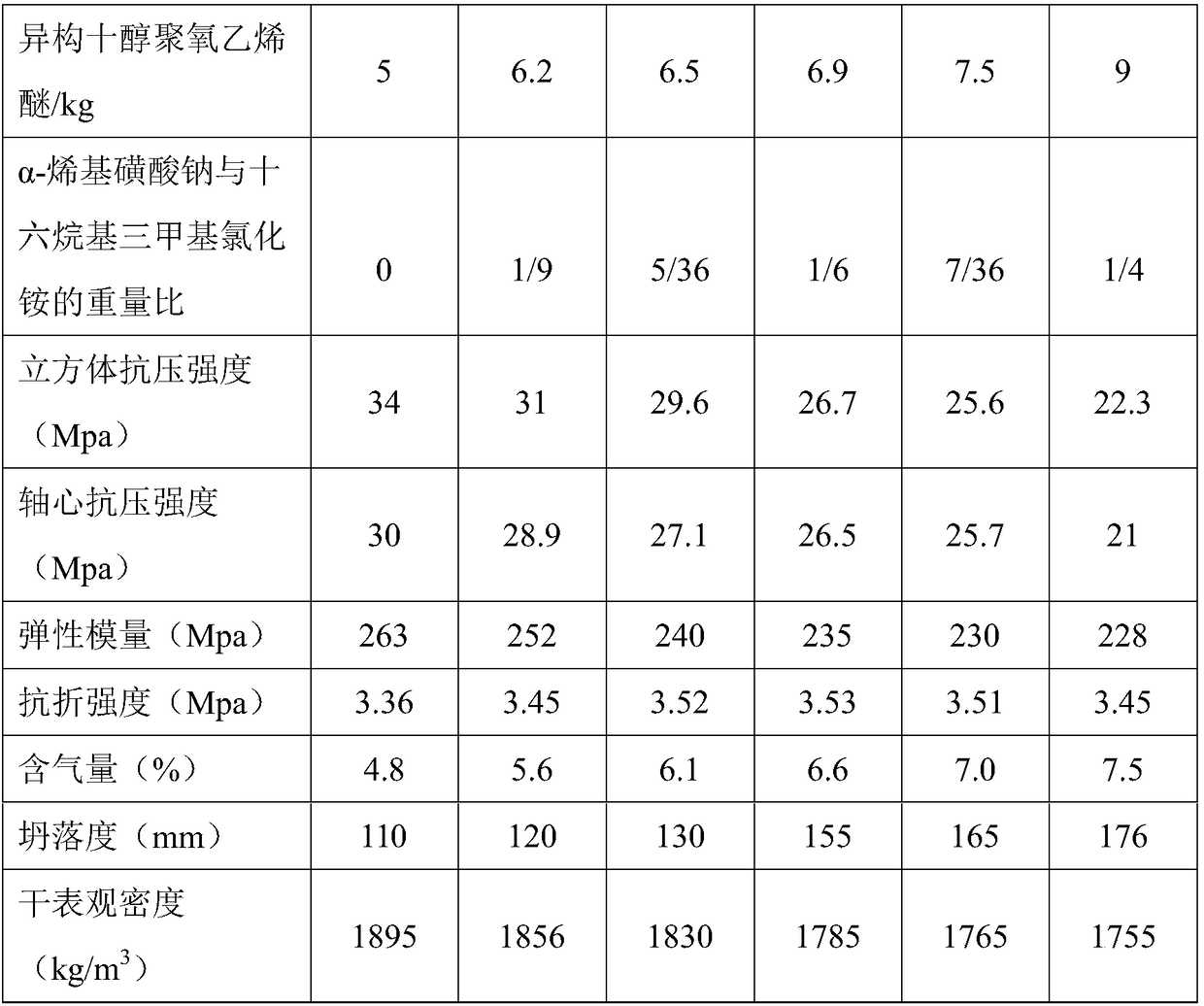

Method used

Image

Examples

Embodiment

[0026] Embodiment: select for use in the present invention the ore powder of the S95 grade that buys from Tianjin Cheng Jin company; The fly ash of F (II); From the cement of the P.O42.5 that Tangshan Jidong Sanyou buys; Hebei Zunhua Sand, fineness modulus 2.6; the air-entraining agent is a compound solution of sodium α-alkenyl sulfonate and cetyltrimethylammonium chloride, among which sodium α-alkenyl sulfonate is from Xi’an Nanfeng Daily Chemical Co., Ltd. Purchased, cetyltrimethylammonium chloride was purchased from Shanghai Chemical Reagent Company; the water reducer was: isomeric decanol polyoxyethylene ether and purchased from Hai'an Petrochemical Plant, Jiangsu Province; tap water was directly used for water.

[0027] The lightweight aggregate is 800-grade shale ceramics produced by Yichang Everbright Ceramic Products Co., Ltd., with a particle size range of 4.75-20 mm, a water absorption rate of 4.5% in 1 hour, and a saturated water absorption rate of 8.7%. The apparent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com