High power density permanent magnet synchronous motor with radiator

A permanent magnet synchronous motor, high power density technology, applied in synchronous machine parts, electrical components, electromechanical devices, etc., can solve the problems of water leakage on the water channel wall, affecting the heat dissipation of the motor, and increasing the cost, so as to reduce the weight of the motor and improve the heat dissipation. ability, the effect of high heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

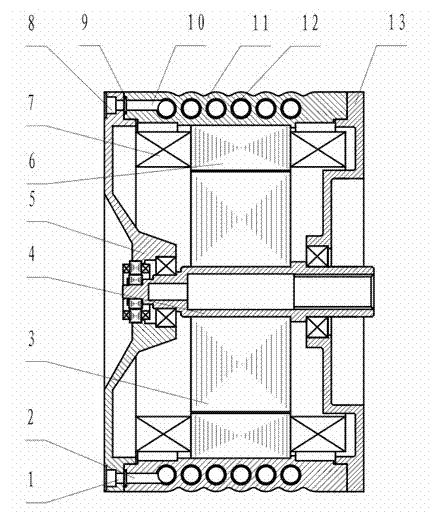

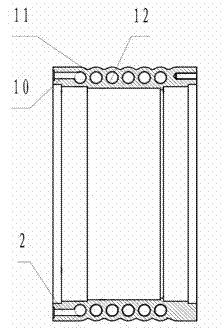

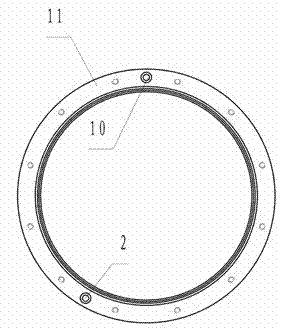

[0027] Such as Figure 1-5 As shown, a high power density permanent magnet synchronous motor with a radiator mainly includes a stator composed of a stator core 6, a stator winding 7, a casing 11, a front end cover 5, and a rear end cover 13, and a rotor core 3, a shaft 4 and other components of the rotor. It is characterized in that: the radiator of the present invention is mainly composed of a double-helical copper or aluminum alloy pipe water channel 12 installed in the wall of the casing 11 and water inlet and outlet nozzles 8 installed on the front end cover 5 , 1 composition.

[0028]The casing 11 is cylindrical with a length of 134mm, an outer diameter of 240mm, and a wall thickness of 42mm. In the middle of the wall of the cylindrical casing 11, two spiral water channels 12 rotating counterclockwise and axially separated by 15 mm are arranged. The two spiral water channels 12 are made of copper tubes with an inner diameter of 10 mm, a wall thickness of 1 mm, a pitch ...

Embodiment 2

[0031] A high power density permanent magnet synchronous motor with radiator, same as embodiment 1, wherein:

[0032] The casing 11 has a length of 280 mm, an outer diameter of 540 mm, and a wall thickness of 60 mm. The inner diameter of the water channel 12 is 15 mm, the wall thickness is 2 mm, the pitch is 50 mm, and the axial length is 180 mm. The inner diameter of the water inlet and outlet 10, 2 is 12mm. Fourteen threaded blind holes with a depth of 16 mm are evenly arranged on the front and rear end faces of the casing 11 . The depth of the frustum-shaped hole at the front end of the inlet and outlet nozzles 8 and 1 on the front cover 5 is 10 mm, and the depth of the rear-end frustum hole is 5 mm.

Embodiment 3

[0034] A high power density permanent magnet synchronous motor with radiator, same as embodiment 1, wherein:

[0035] The casing 11 has a length of 100 mm, an outer diameter of 200 mm, and a wall thickness of 30 mm. The inner diameter of the water channel 12 is 8 mm, the wall thickness is 1 mm, the pitch is 30 mm, and the axial length is 75 mm. The inner diameter of the water inlet and outlet 10, 2 is 6mm. Eight threaded blind holes with a depth of 9 mm are evenly arranged on the front and rear end faces of the casing 11 . The depth of the frustum-shaped hole at the front end of the inlet and outlet nozzles 8 and 1 on the front cover 5 is 6mm, and the depth of the frustum hole at the rear end is 4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com