Negative electrode for secondary battery

A technology of negative electrode and current collector, applied in the field of negative electrode for secondary battery, can solve the problems of deterioration of negative electrode performance, electrode corrosion, insufficient positioning of active material, etc., and achieve the effect of improving charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] Preparation of Artificial Graphite with Tuned Li-ion Diffusion Rate and Orientation Index

[0053] Coal-based pitch and petroleum-based pitch were mixed, then dissolved in THT to prepare a mixed pitch solution, and the mixed pitch solution was evaporated to prepare mixed pitch. Subsequently, the mixed pitch is calcined to prepare the average particle size (D 50 ) is a secondary particle of 19 μm, and the secondary particle is graphitized at a temperature of 2,800 ° C, thereby completing a lithium ion diffusion rate of 1.69×10 -8 cm 2 / s and the preparation of artificial graphite with an orientation index of 13.

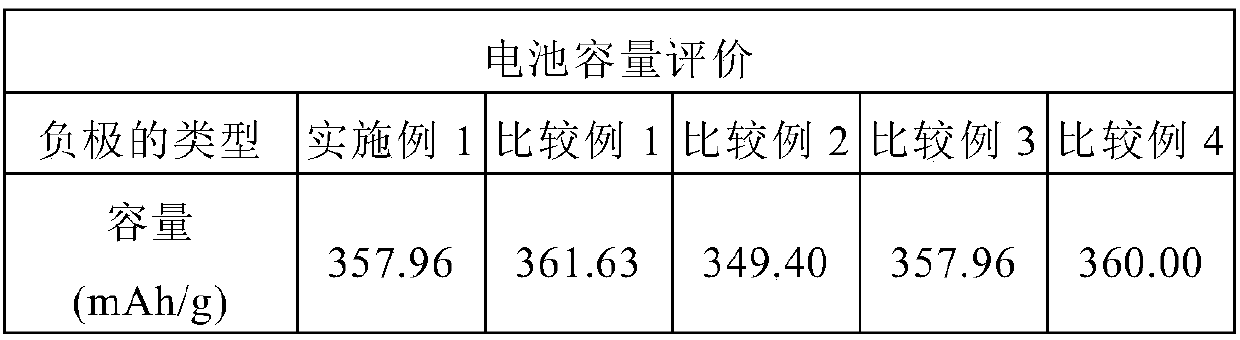

Embodiment 1 and comparative example 1 to 4

[0054] Example 1 and Comparative Examples 1 to 4: Preparation of Negative Electrodes

Embodiment 1

[0056] (1) Preparation of the first active material layer

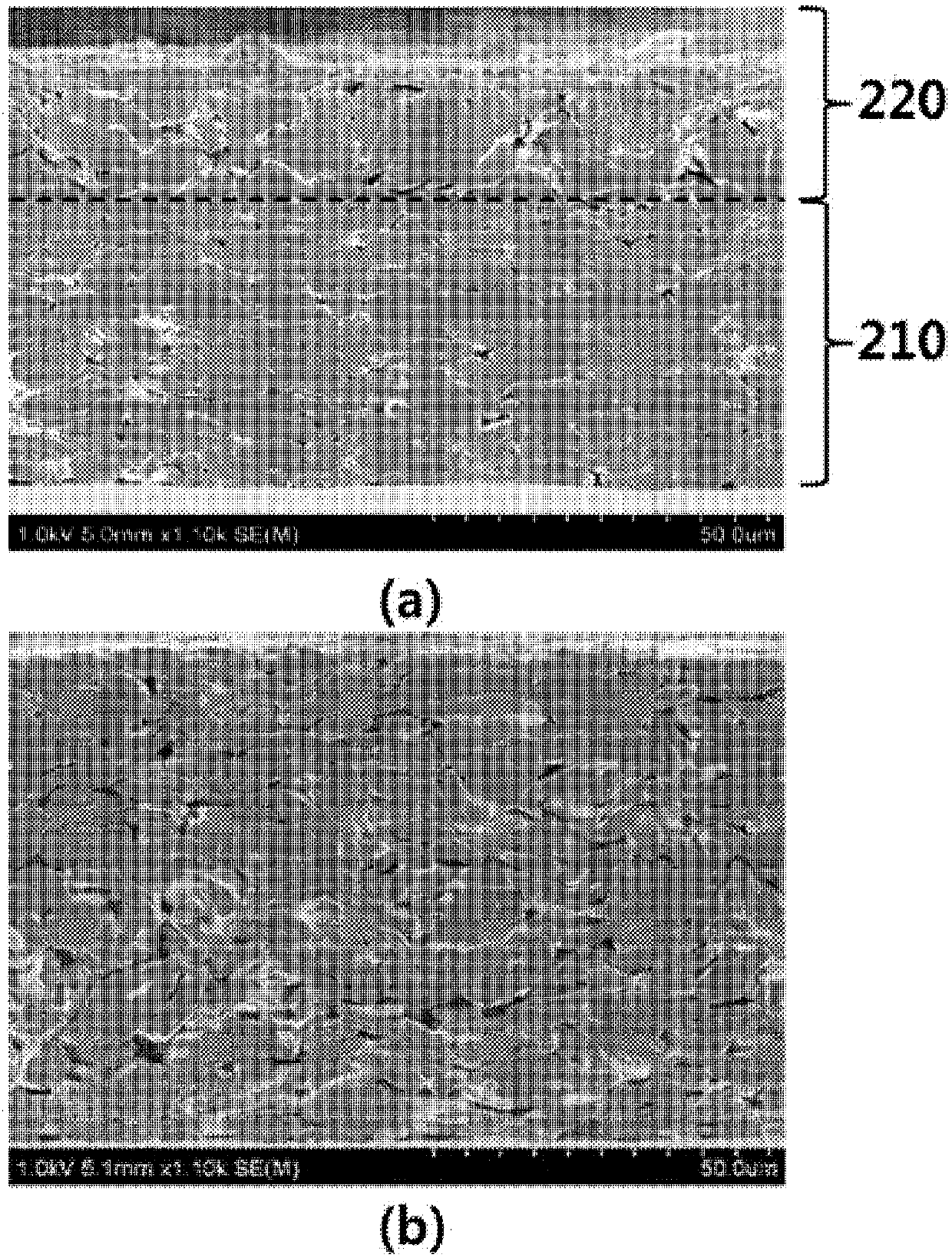

[0057] The lithium ion diffusion rate of 95.6% by weight of the first active material particles as the first active material layer is 5.88×10 -9 cm 2 / s of natural graphite, 1.0% by weight of carbon black (Super C65) as a conductive material, 2.3% by weight of SBR as a binder, and 1.1% by weight of CMC are added to distilled water to prepare for forming the first active Material layers of paste. The slurry for forming the first active material layer was applied on a copper foil with a thickness of 20 μm as a negative electrode current collector, dried and rolled, thereby completing the first active material layer with a thickness of 60 μm on the current collector. Formation of material layers (see figure 2 (a) of 210).

[0058] (2) Fabrication of the second active material layer and negative electrode

[0059] 95.6% by weight of the artificial graphite prepared according to Preparation Example 1 as the second act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com