Copper zinc catalyst and precursor, preparation and use thereof

A catalyst, copper-zinc technology, applied in the field of copper-zinc catalyst and its precursor, can solve the problems of short service life, poor thermal stability, low catalytic activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of MCM-41 Mesoporous Molecular Sieve

[0047] At room temperature, add 25L of deionized water and 5kg of structural template agent hexadecyltrimethylammonium bromide to a 100L horizontal reactor, control the stirring speed at 100rpm, and add acid dropwise to the reactor under sufficient stirring. Regulator HCl, make the pH of the system = 6, then add 3.01kg sodium silicate and 30g sodium metaaluminate into the reactor, continue to stir for 12h, then age for 45h, the obtained material is transferred to an autoclave for crystallization, crystallization The crystallization temperature is 175°C and the crystallization time is 80h. During the crystallization process, the solid content gradually increases, and the reactor needs to be stirred to make the obtained particle size more uniform, and the stirring speed is adjusted to 60rpm. The obtained liquid-solid mixture is taken out after cooling down, filtered, washed, dried and calcined to obtain a powder state me...

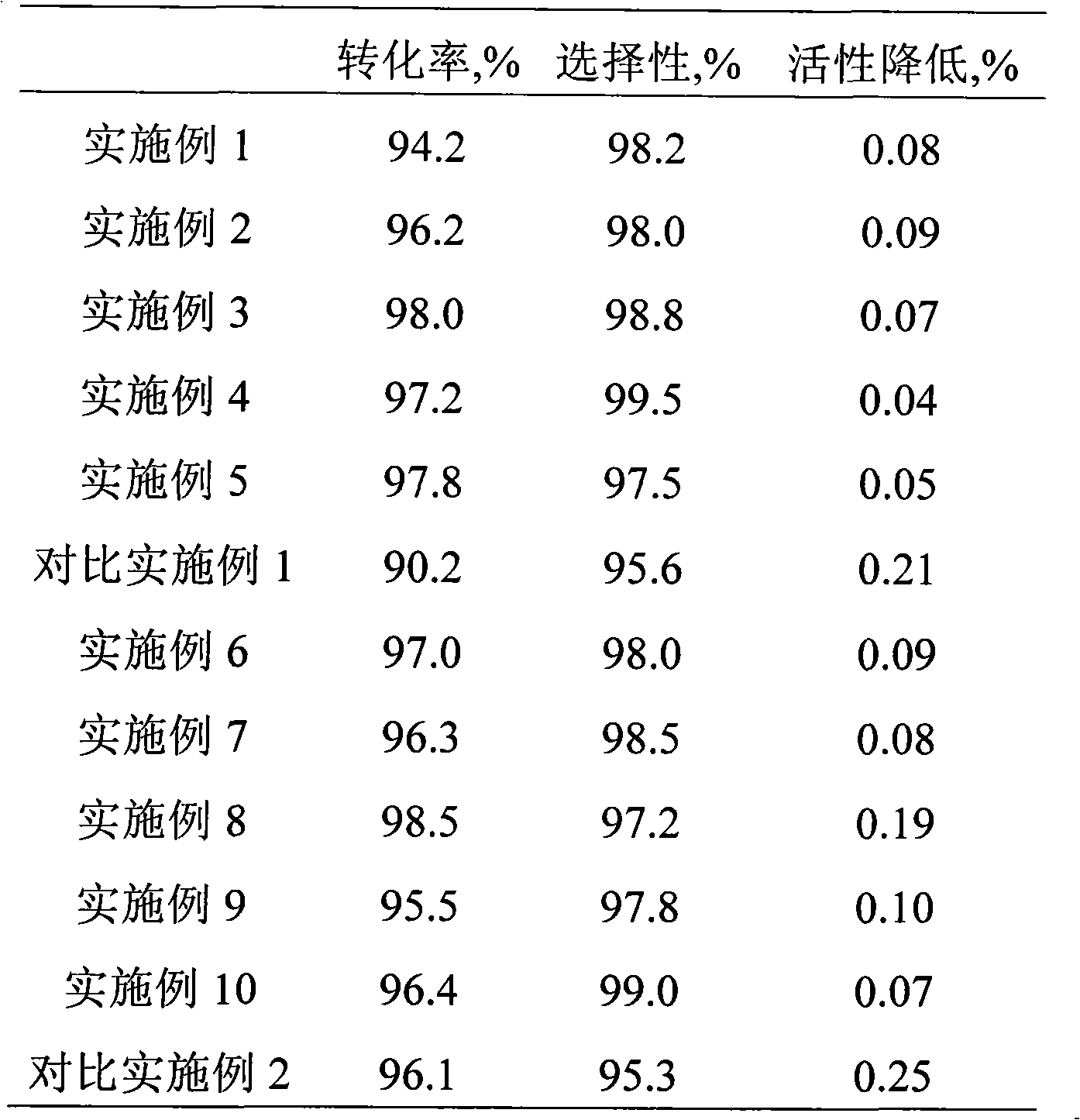

Embodiment 1

[0048] Embodiment 1 High temperature and high pressure catalytic hydrogenation

[0049] Preparation of copper-zinc molecular sieve catalyst

[0050] Add 3 kg of the powdery mesoporous molecular sieve prepared in Reference Example 1 into a horizontal reactor filled with 25 L of aqueous solution in which copper nitrate and zinc nitrate are dissolved, and impregnate. Wherein the copper ion concentration in the aqueous solution is 8.19mol / L, and the zinc ion concentration is 1.638mol / L. The above liquid-solid mixture was stirred at room temperature for 0.5 h. After the stirring was completed, the material was taken out and filtered to obtain a solid filter cake. The filter cake is mixed with the binder silica sol, and the binder hydrogenated polydextrose is also added at the same time. The amount of the binder is 0.5%wt of the filter cake, and the amount of the auxiliary binder is 10%wt of the binder. After the filter cake, binder and binder are fully mixed, a paste is obtained...

Embodiment 2

[0054] Embodiment 2 High temperature and high pressure catalytic hydrogenation

[0055] Preparation of copper-zinc molecular sieve catalyst

[0056] The powdered mesoporous molecular sieve obtained in Reference Example 1 was mixed with the binder aluminum sol, and the binder phenolic resin was added at the same time. The amount of the binder is 30%wt of the filter cake, and the amount of the auxiliary binder is 0.01%wt of the binder. After the carrier, binder and co-binder are fully mixed, the paste is obtained and finally granulated in a catalyst granulator to obtain cylindrical granules with a diameter of about 6mm and a height of about 6mm, which is the medium after granulation. Molecular sieve.

[0057] Add 12 kg of the granulated mesoporous molecular sieve into a vertical reactor containing 25 L of an aqueous solution in which cupric chloride and zinc sulfate have been dissolved for impregnation. Wherein the copper ion concentration in the aqueous solution is 6.85mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com