Positive electrode of lithium-manganese button cell and preparation method of positive electrode

A button battery, lithium-manganese technology, applied in the field of electrochemistry, can solve the problems affecting wide application and low output performance of large current, and achieve the effect of smooth diffusion process, improved discharge capacity and enhanced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a positive electrode of a lithium-manganese button cell, comprising the steps of:

[0026] S1: sintering electrolytic manganese dioxide in a sintering furnace at 350-440°C for 10-20h;

[0027] S2: fully mix the sintered manganese dioxide with graphite, acetylene black, and polytetrafluoroethylene;

[0028] S3: through dry mixing, wet mixing, tableting, granulation, tableting, drying and other processes to prepare positive electrode sheets.

[0029] The present invention adopts the above components, and according to the conventional lithium-manganese button battery positive electrode production process, through dry mixing, wet mixing, tableting, granulation, tableting, drying and other processes, the positive electrode sheet of lithium battery is prepared, and combined with the negative electrode lithium , The diaphragm is assembled into a CR2032 lithium manganese button cell.

[0030] During the experiment, the inventor unexpectedly found that t...

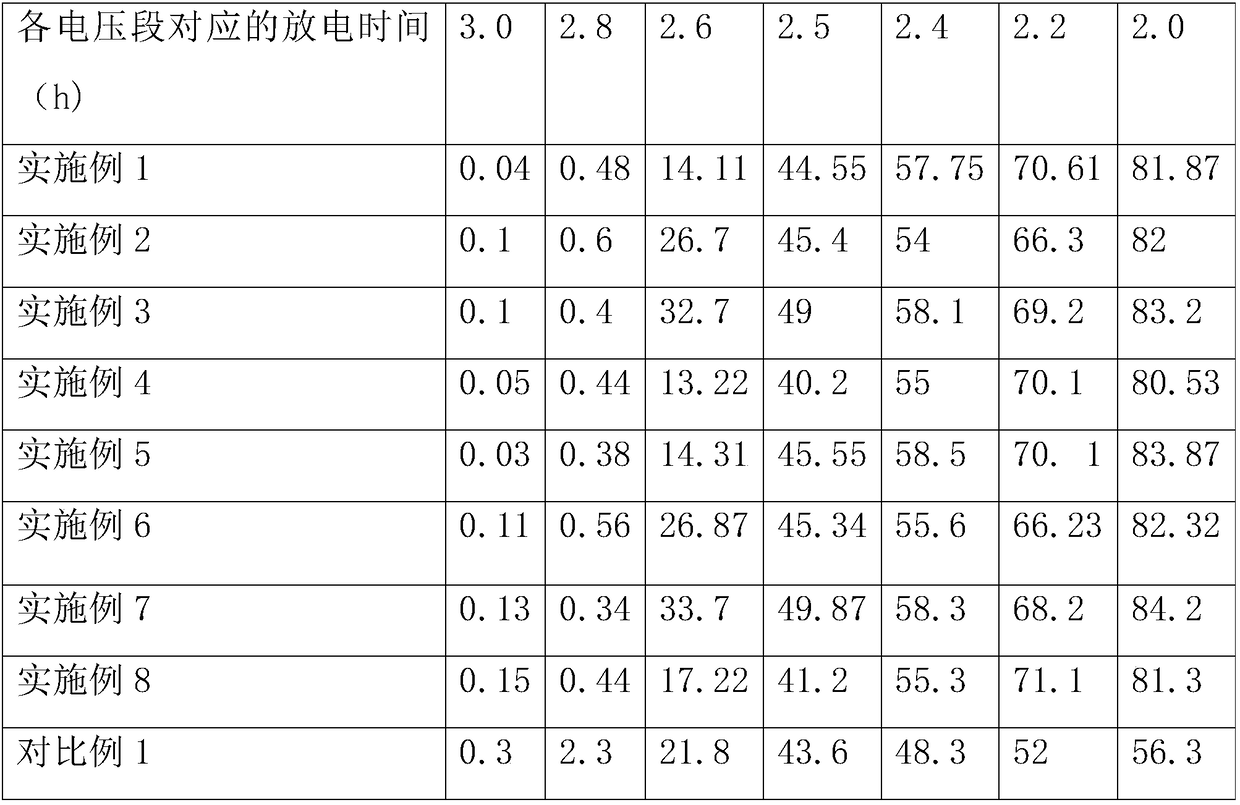

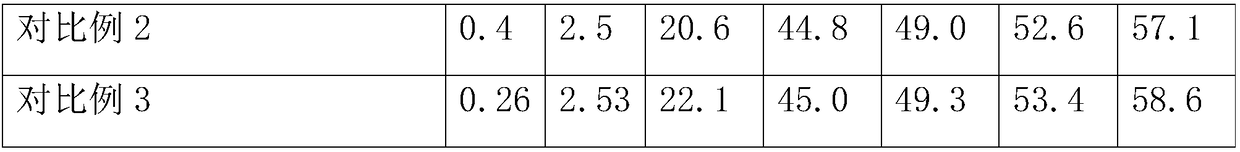

Embodiment 1

[0035] Example 1: Sinter electrolytic manganese dioxide in a sintering furnace at 375° C. for 12 hours, and mix the sintered manganese dioxide by manganese dioxide: graphite: acetylene black: polytetrafluoroethylene=92%: 4%: 2 The ratio of %: 2% is fully mixed, and prepared into a positive electrode sheet through dry mixing, wet mixing, tableting, granulation, tableting, drying, etc., with metal lithium as the negative electrode, the diaphragm is a glass fiber diaphragm, and 1mol / L high chlorine Lithium oxide (LiClO4) / propylene carbonate (PC) + ethylene glycol dimethyl ether (DME) (volume ratio 1:1) as the electrolyte, assembled into a CR2032 lithium battery in a dry room with a low dew point and -30 degrees.

Embodiment 2

[0036] Embodiment 2: Sinter electrolytic manganese dioxide in a sintering furnace at 405° C. for 16 h, and sinter the manganese dioxide by manganese dioxide: graphite: acetylene black: polytetrafluoroethylene=92%: 4%: 2 The ratio of %: 2% is fully mixed, and prepared into a positive electrode sheet through dry mixing, wet mixing, tableting, granulation, tableting, drying, etc., with metal lithium as the negative electrode, the diaphragm is a glass fiber diaphragm, and 1mol / L high chlorine Lithium oxide (LiClO4) / propylene carbonate (PC) + ethylene glycol dimethyl ether (DME) (volume ratio 1:1) as the electrolyte, assembled into a CR2032 lithium battery in a dry room with a low dew point and -30 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com