Catalyst for normal paraffin hydroisomerization reaction and preparation method as well as application thereof

A technology for hydroisomerization and normal alkanes, applied in the field of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

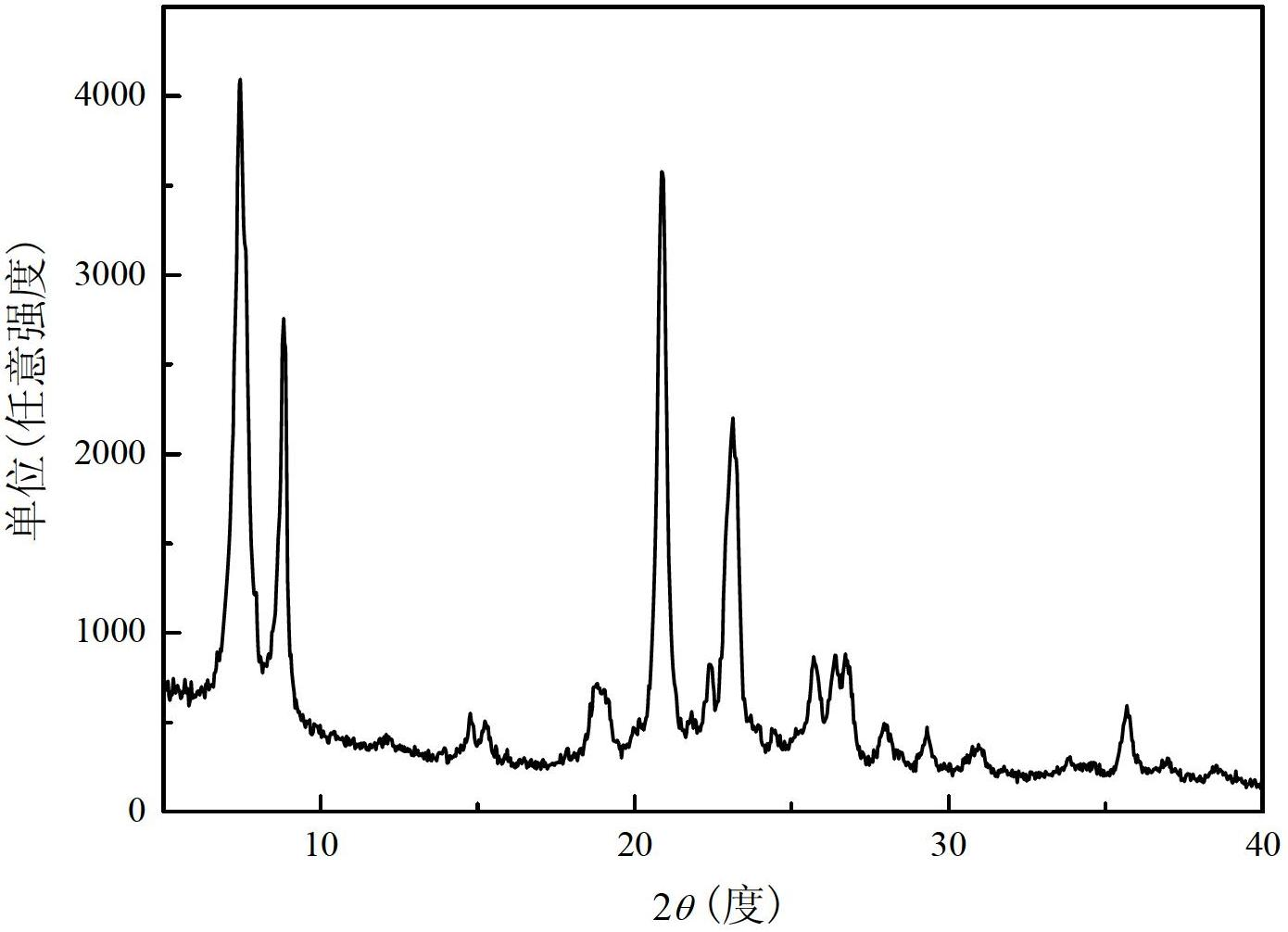

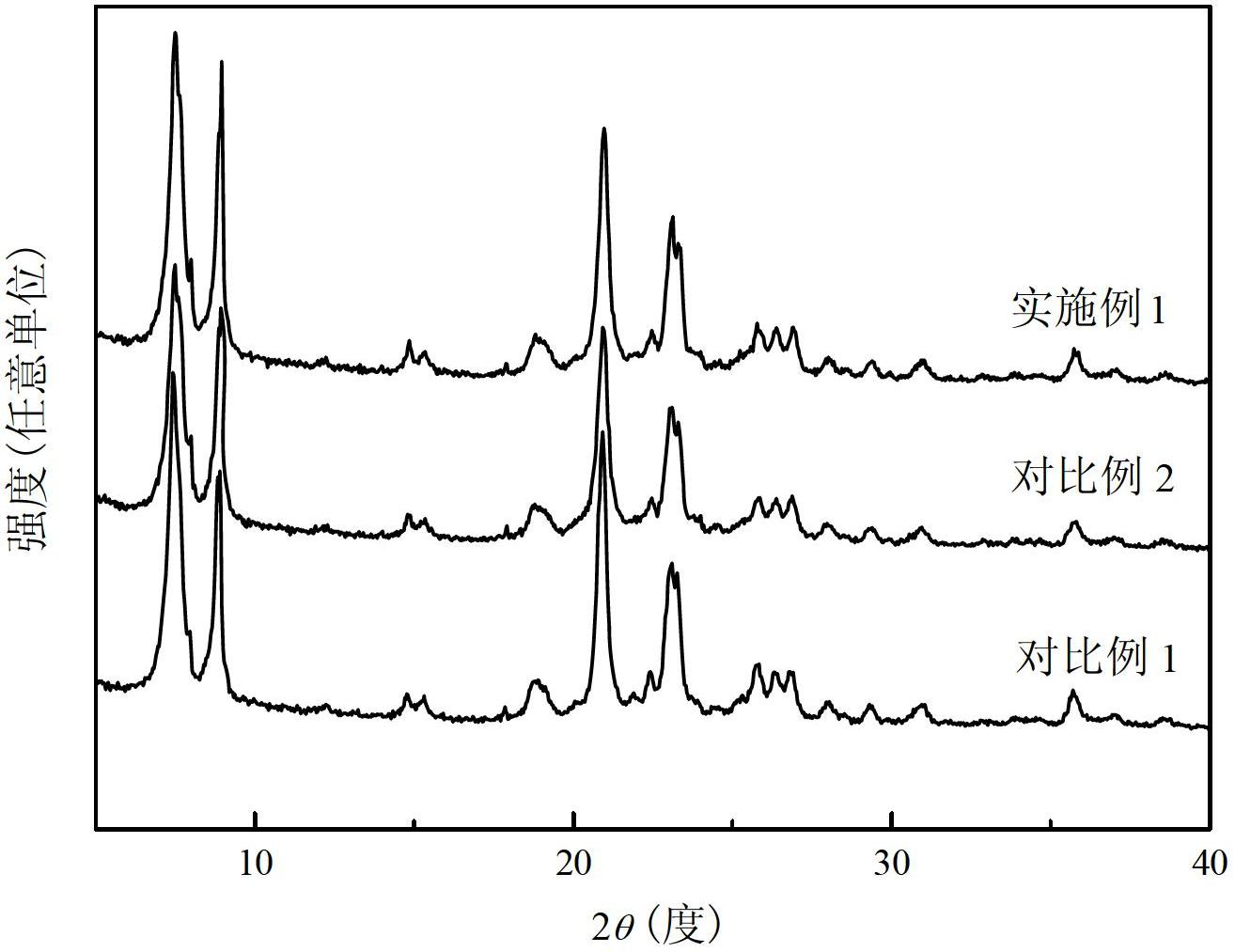

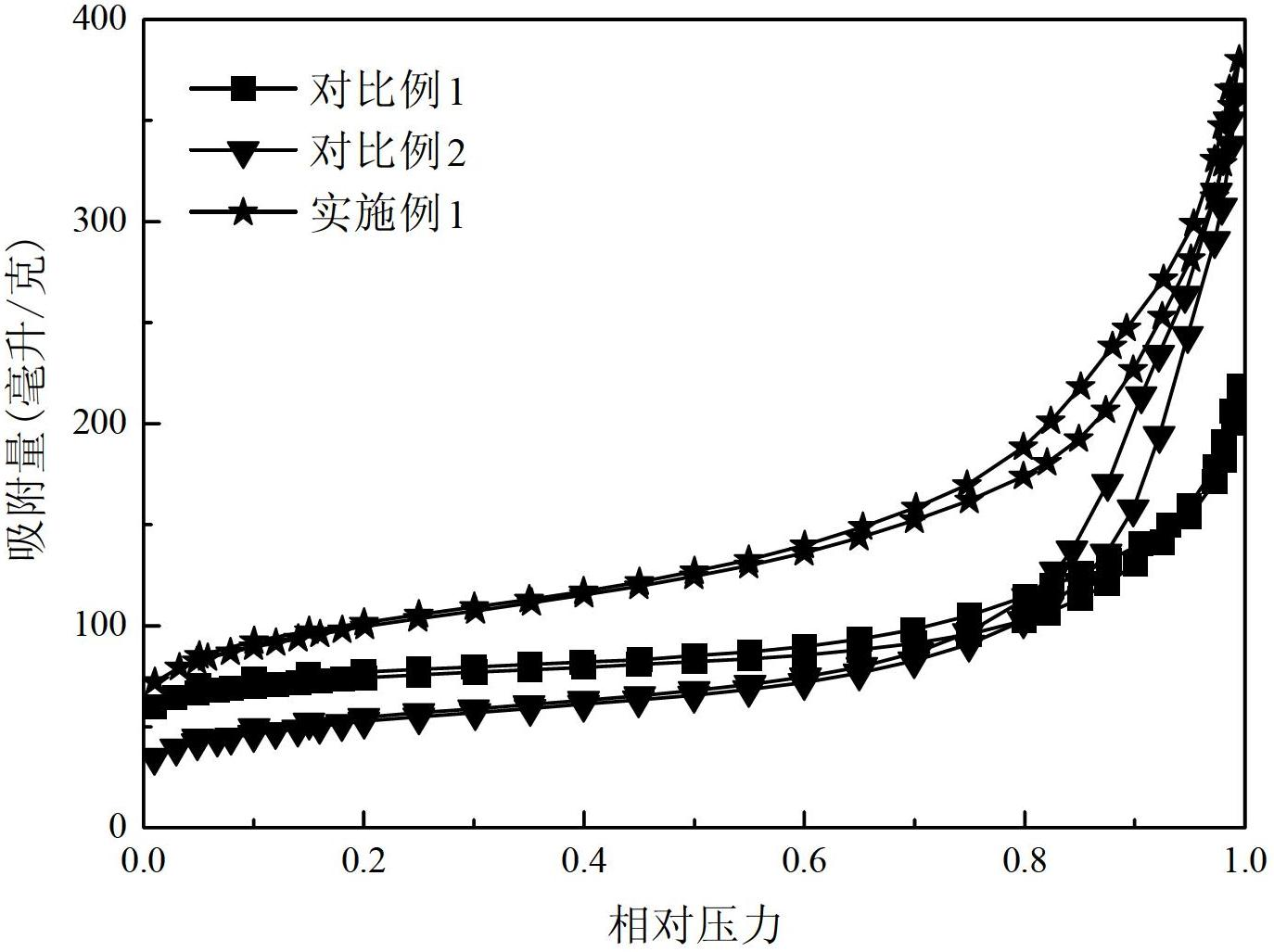

Image

Examples

Embodiment 1

[0053] Mix the ZSM-12 zeolite molecular sieve containing the template agent and the sodium hydroxide solution with a concentration of 0.2M in the ratio of zeolite molecular sieve (g): sodium hydroxide solution (g) = 1:30 in Comparative Example 1, and place in a water bath at 65°C Stir in medium temperature for 30min, filter the mixture with suction, wash the solid with deionized water until the filtrate is neutral, dry the filter cake at 110°C for 8h, and then roast the sample at 550°C in air atmosphere for 2h to obtain the modified ZSM-12 zeolite molecular sieve.

[0054] Mix the modified ZSM-12 zeolite molecular sieve obtained above with a concentration of 1.0M ammonium nitrate solution according to the ratio of zeolite molecular sieve (gram): ammonium nitrate solution (gram) = 1:20, stir in a water bath at 80°C for ionization After 2 hours of exchange, the mixture was filtered with suction to separate the sample, and the exchange was repeated three times. The filter cake w...

Embodiment 2

[0059] Carry out stability investigation experiment to catalyst of the present invention, reaction condition is identical with embodiment 1, and the relational curve of reactant conversion rate changing with time is shown in Figure 9 . Depend on Figure 9 It can be seen that the catalyst has excellent stability, and there is no sign of deactivation when used for 1200 min.

[0060] Table 1

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com