Array substrate and display device

An array substrate and substrate technology, which is applied in the direction of instruments, semiconductor devices, optics, etc., can solve the problems of uneven thickness of alignment layer, poor display, uneven diffusion of alignment liquid, etc., and achieve the effect of preventing uneven diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

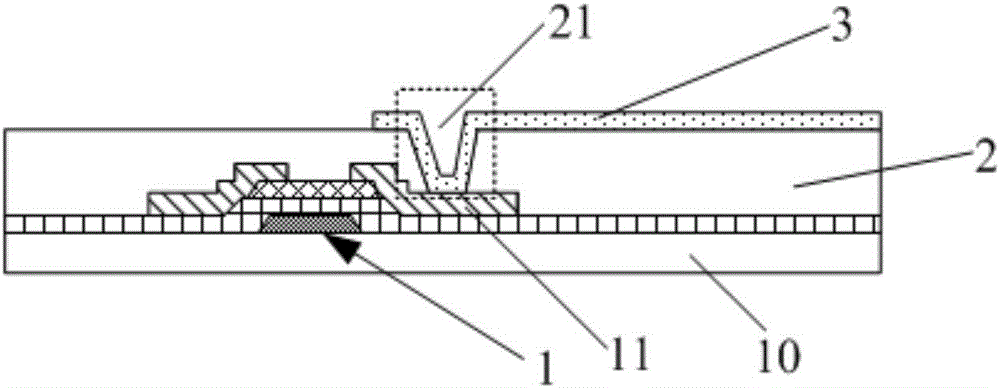

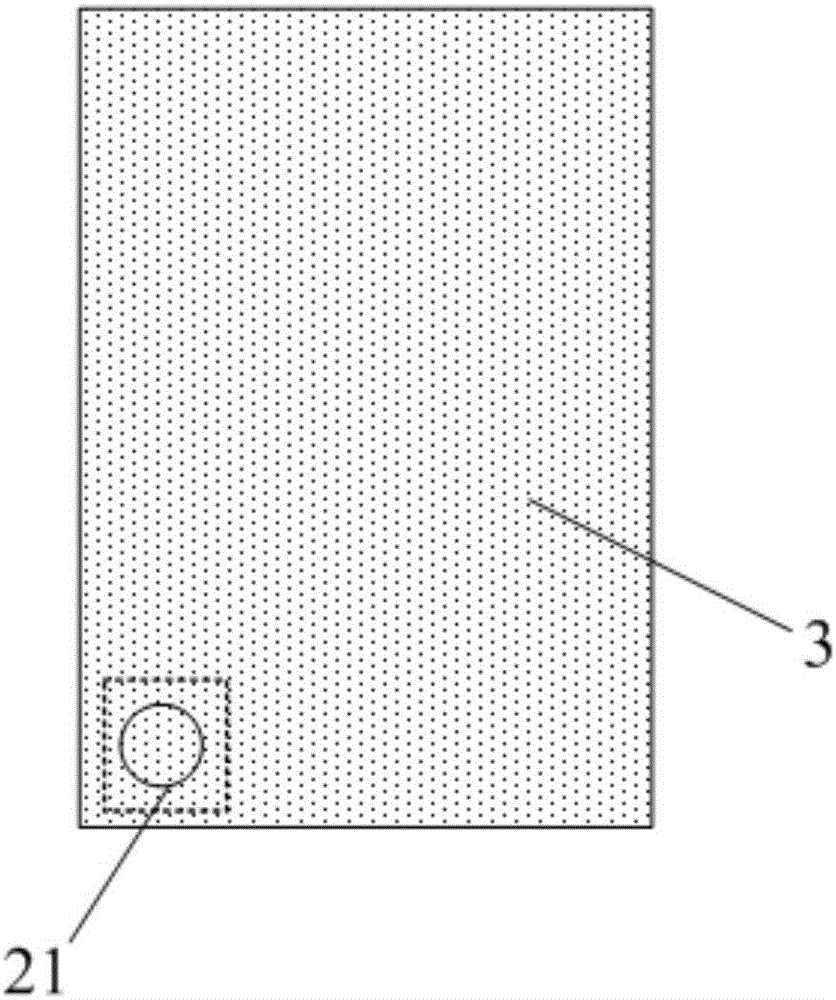

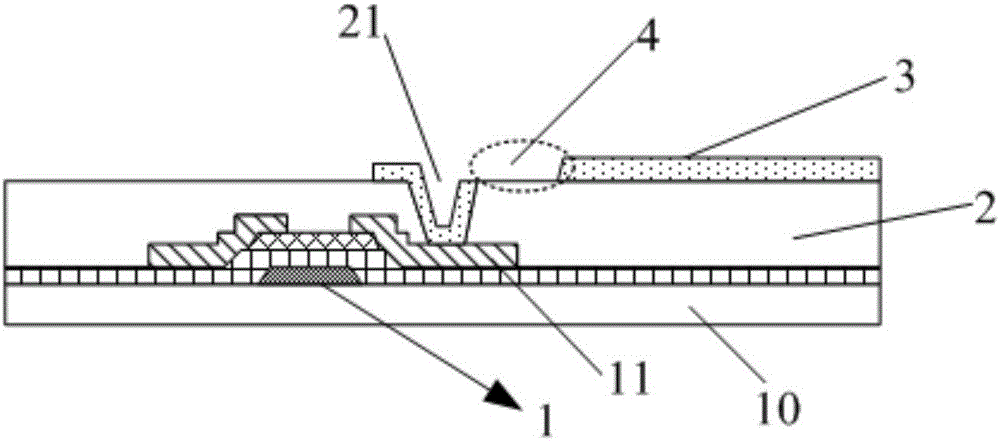

[0040] This embodiment provides an array substrate, which includes a substrate, a via hole located above the substrate, and a diffusion part; wherein, the orthographic projection of the diffusion part on the substrate is connected to the orthographic projection of the via hole on the substrate; the diffusion part is used to The alignment liquid at the position of the via hole is diffused.

[0041] The array substrate in this embodiment is provided with a diffusion part for diffusing the alignment liquid at the position of the via hole, and the orthographic projection of the diffusion part on the substrate is in contact with the orthographic projection of the via hole on the substrate. It can be seen that the concave surface corresponding to the position of the via hole on the surface of the array substrate on which the alignment liquid is not formed is excessively connected to other positions through the surface of the corresponding position of the diffusion part, and then when...

Embodiment 2

[0066] This embodiment provides a display device, which includes the array substrate in Embodiment 1. Therefore, the display device has a better display effect.

[0067] Wherein, the display device can be a liquid crystal display device or an electroluminescent display device, such as any product or component with a display function such as a liquid crystal panel, an electronic paper, a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, etc. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com