Underground heat-gas co-production gasification equipment, and coal field fire area leading edge treatment system and method

A technology of gasification equipment and underground heating, applied in lighting and heating equipment, coal gasification, fire prevention equipment, etc., can solve problems such as a drop in the bucket and unsatisfactory effects, and achieve the effect of avoiding damage and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

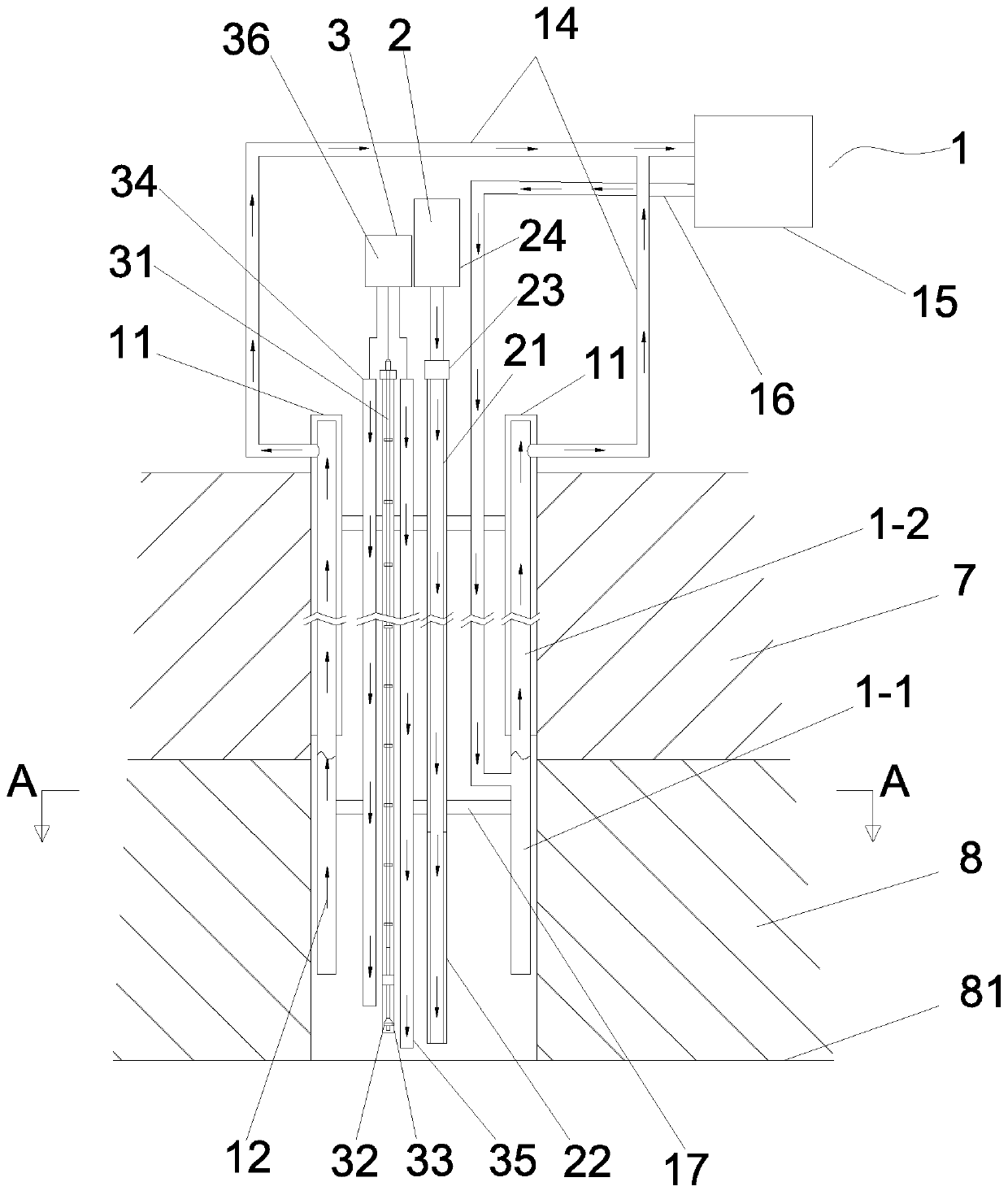

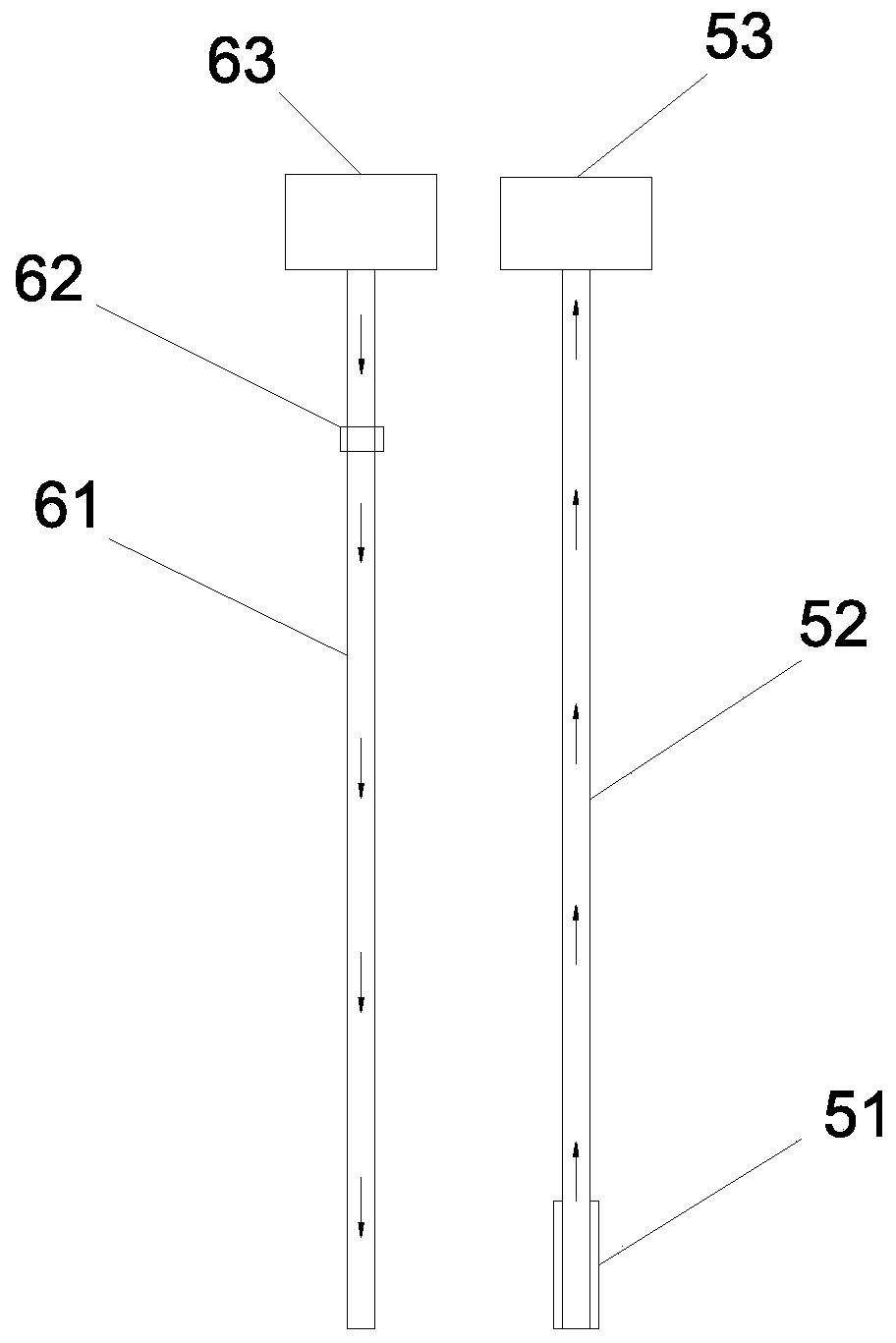

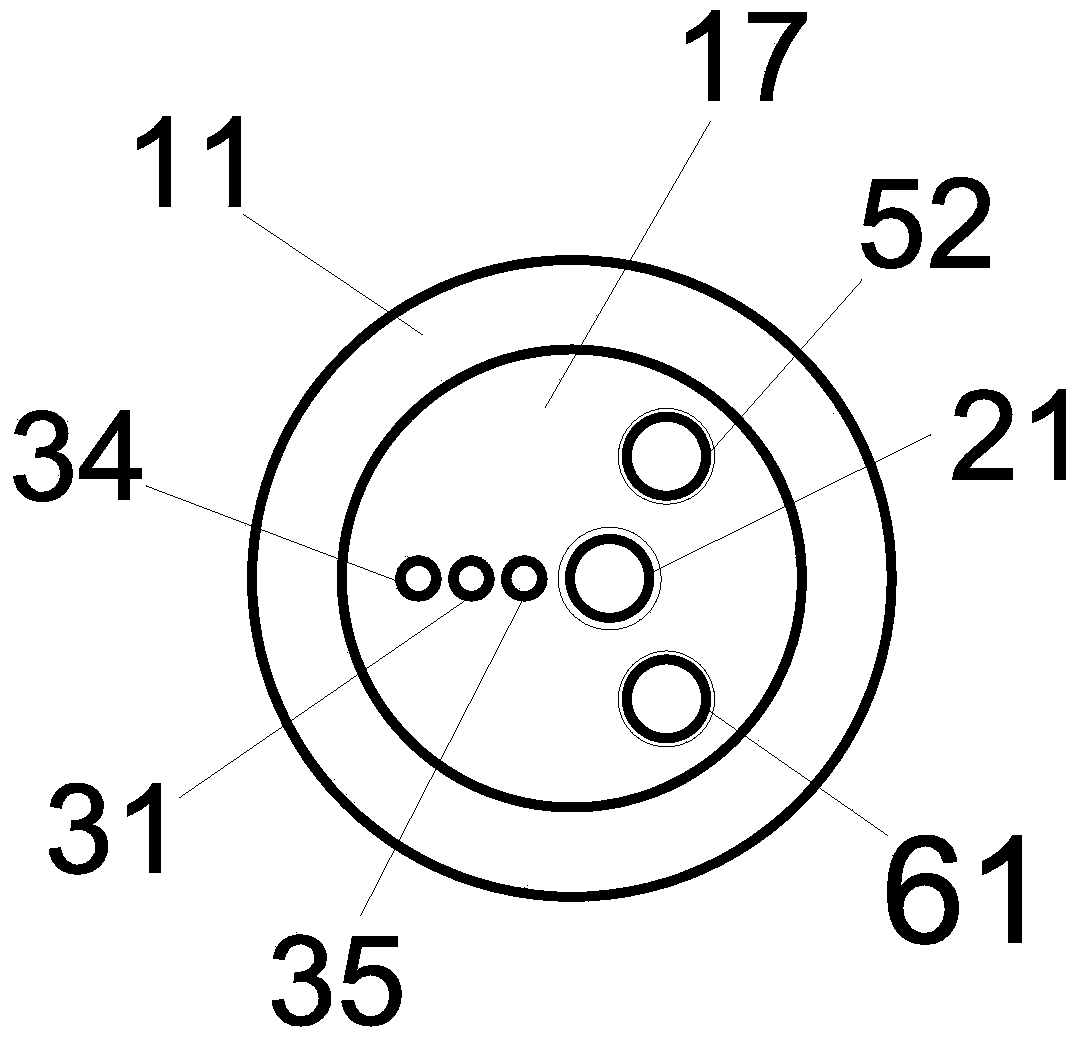

[0045] Such as Figure 1 to Figure 3 As shown, a kind of underground heat-gas cogeneration gasification equipment includes a borehole located at the boundary of the fire zone, the borehole passes through the rock formation 7 and the bottom of the borehole extends to the bottom plate 81 of the coal seam 8, and is installed in the borehole There is a heat extraction device 1, the heat extraction device 1 includes an annular super-long gravity heat pipe 11 placed in a borehole, the hollow tube wall of the annular super-long gravity heat pipe 11 is filled with a heat exchange working medium 12, and the annular super-long gravity heat pipe 11 The gravity heat pipe 11 is divided into a heat-absorbing section 11-1 and an adiabatic section 11-2 from bottom to top, and the hollow pipe wall of the annular super-long gravity heat pipe 11 exposed from the bore hole is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com