Bioactive glass ceramic material and preparation method and application thereof in oral care products

A technology of bioactive glass and ceramic materials, applied in the application field of oral care products, can solve problems such as differences in repair mechanism, and achieve the effects of promoting remineralization, simple preparation method, non-toxic and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

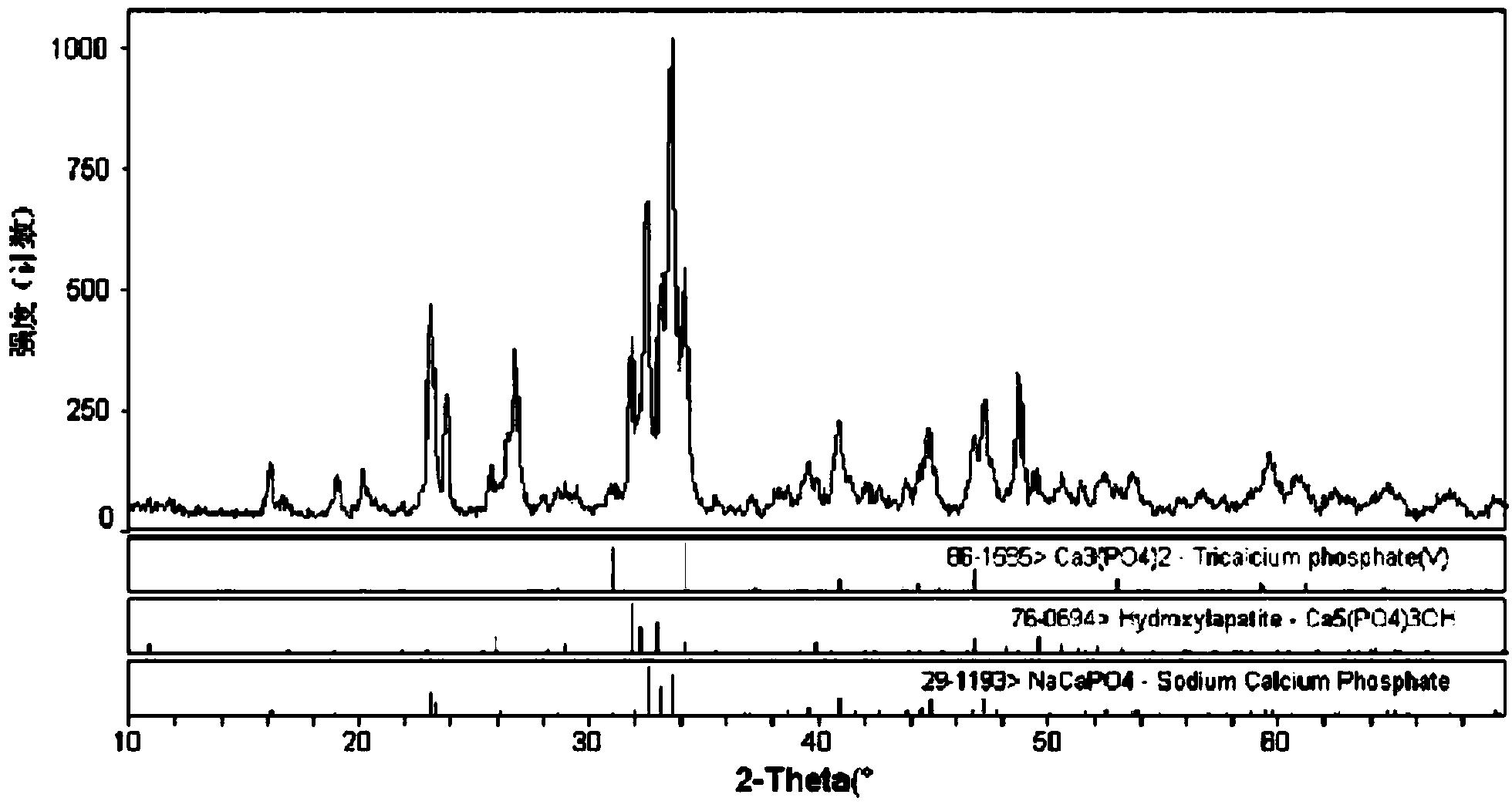

[0033] Example 1 Preparation of HX-BGC by powder calcination method

[0034] Choose SiO2 2 , CaHPO 4 2H 2 O, CaCO 3 , NaCO 3 , Sr(NO 3 ) 2 And NaF as raw material, ball mill grinding to micron-sized particles, pressing and pre-calcining, crushing to micron-sized particles, then sintering, controlling the furnace cooling process, and then crushing to micron and sub-micron-sized particles, that is, the raw material composition The ratio principle and conditions of pre-sintering, sintering, and controlled furnace cooling process are shown in Table 1.

[0035] Table 1 Experimental conditions for preparing HX-BGC by powder calcination method

[0036]

Embodiment 2

[0037] Example 2 Preparation of HX-BGC by High Temperature Melting Method

[0038] Choose SiO2 2 , CaHPO 4 2H 2 O, CaCO 3 , NaCO 3 , Sr(NO 3 ) 2 , CaF 2 It is the raw material, and the proportioning principle of each raw material is the same as that of Example 1. After ball milling and mixing uniformly, it is melted in a platinum crucible at 1400°C or 1460°C, poured into water to cool, crushed into 20-50 mesh particles, and subjected to microcrystallization treatment. Cool to room temperature, and then pulverize into micron and submicron particles.

[0039] The conditions of the microcrystallization treatment are to heat the cooled melt poured into water at a rate of 10°C / min to 600°C for nucleation for 2 hours to form crystal nuclei, and then hold at 900°C for 1 hour for crystallization treatment to form fine crystals;

[0040] Or heat up the cooled melt poured into water to 700°C for 1 hour at a rate of 20°C / min to form crystal nuclei, and then hold at 1000°C for 1 h...

Embodiment 3

[0042] Example 3 Preparation of HX-BGC by Co-precipitation Synthesis

[0043] Nano-SiO 2 Gel powder, Ca(NO 3 ) 2 4H 2 O, H 3 PO 4 , NaCO 3 , Sr(NO 3 ) 2 and NaF as raw materials; the Ca(NO 3 ) 2 4H 2 O, H 3 PO 4 , NaCO 3 , Sr(NO 3 ) 2 and NaF were prepared into 2.5mol / L, 1mol / L, 5mol / L, 2.5mol / L, and 1.5mol / L aqueous solutions with deionized water; the Ca(NO 3 ) 2 .4H 2 O, Sr(NO 3 ) 2 and NaF aqueous solution under the condition of stirring (100-300 rpm) to mix evenly, and evenly mix nano-SiO 2 Gel powder, slowly drop into H under stirring condition 3 PO 4 solution with NaCO 3 and ammonia solution to adjust the pH to 6.5-9 for co-precipitation reaction, aging for 3 days after the completion of the reaction, dehydration and draining, sintering, cooling, and then pulverizing to micron and submicron particles, that is, the ratio of raw materials and The sintering conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com