Method for preparing medium-viscosity PET slice by recycled low-viscosity polyester yarn

A technology for slicing and polyester fabrics, which is applied in the field of producing medium and high viscosity PET spinning chips, which can solve the problems of poor strength, low viscosity, and lower market value of high-viscosity PET, and achieve the effect of simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

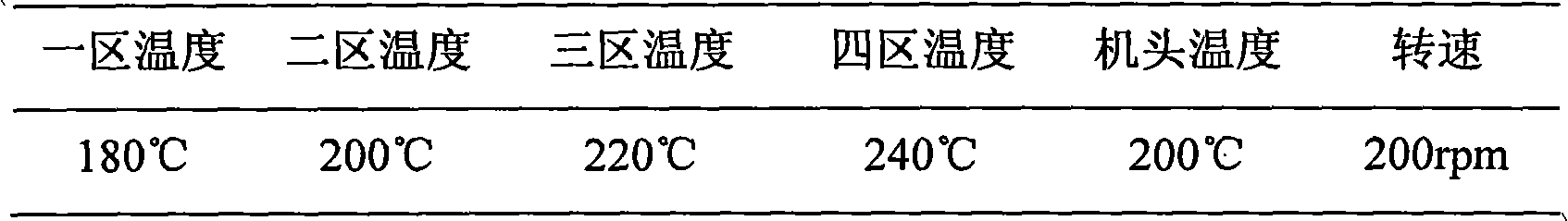

[0036] Recycled low-viscosity polyester fibers or polyester fabric fragments PET materials are sorted, cleaned, placed in a blast oven at 160°C and dried for 4 hours, then put into the hopper of the extruder and wait for extrusion. The modified MDI (containing 28wt% isocyanate) and the dried PET were fed into an extruder at a mass ratio of 1:100 for melt extrusion. Viscosity-enhancing chain-extending agent is accurately metered by metering pump. The temperature of each section of the barrel during the extrusion process is:

[0037]

[0038] After the extruded PET was cooled in a cooling water tank, it was pelletized by a pelletizer to obtain sliced samples. The result after the test is: the intrinsic viscosity is increased from 0.4dL / g of the raw material to 0.65dL / g.

Embodiment 2

[0040] Add polyethylene glycol-500 to MDI to make a viscosity-increasing chain extender with polyethylene glycol in the middle and isocyanate at both ends. Afterwards, according to the conditions of Example 1, the intrinsic viscosity of the PET chip was increased from 0.4dL / g to 0.6dL / g.

Embodiment 3

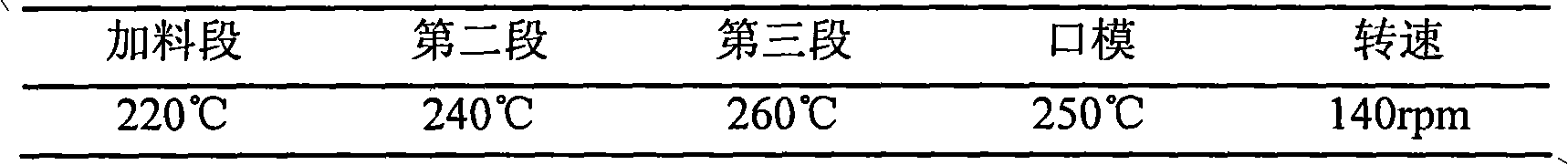

[0042] After cleaning and compacting the recovered low-viscosity polyester fiber or polyester fabric scrap PET material, PET raw material particles are obtained, and after drying in a blast oven at 130°C for 12 hours, the modified MDI containing 18wt% isocyanate is passed through a metering pump Added to the extruder at 1.2% of the PET feed. The temperature of each section of the barrel during the extrusion process is:

[0043]

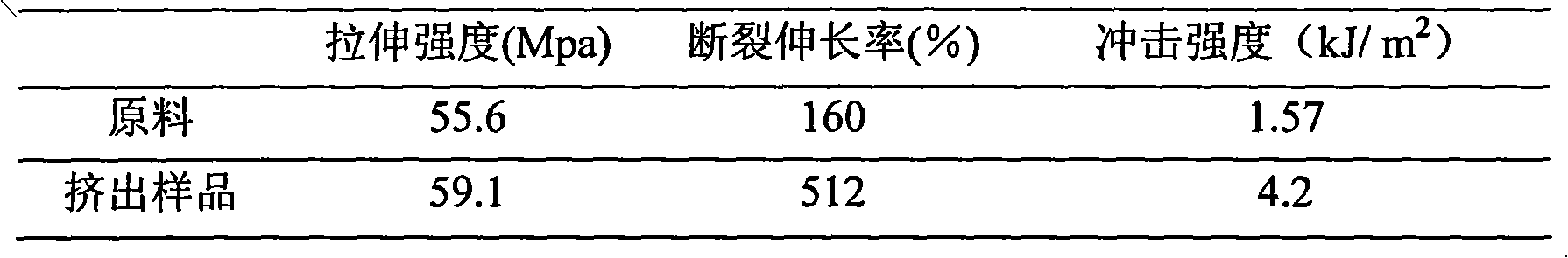

[0044] After extrusion, it is water-cooled and pelletized. After testing, the intrinsic viscosity is increased from 0.64dL / g of the raw material to 0.85dL / g. Other properties of the test are

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com