Poly-1-butene elastomer material and preparation method thereof

An elastomeric material, elastomeric technology, applied in the field of organic polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

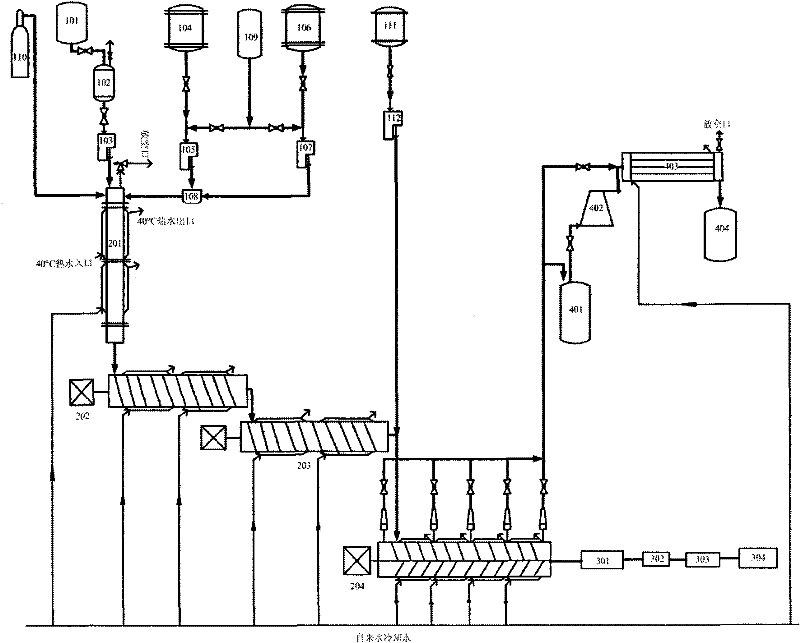

Image

Examples

Embodiment 1

[0031] Example 1. Solution Polymerization Synthesis of Poly 1-Qualitative Thermoplastic Elastomers.

[0032] 10L fully enclosed magnetic stirring stainless steel pressure polymerization kettle (double-helical stirring paddle), pumping for 2 to 3 hours, during which it was replaced several times with high-purity nitrogen. Add the 1-butene / normal hexane solution that the monomer concentration is 40% in the polymerization kettle, with Ti / Bt=2×10 -5 (molar ratio, the same below), Al / Ti=300 (molar ratio, the same below), electron donor / Ti=5 (molar ratio), under stirring, add triisobutylaluminum (Al) and supported titanium catalyst successively (Ti) and ether electron donors were polymerized at 50° C. for 5 hours, and the polymer poly-1-butene was obtained directly after drying, with a monomer conversion rate of 76% and a catalytic efficiency of 148,000 g polymer / gTi. The content of isotactic pentads was determined by NMR to be 70%, that is, the content of isotactic poly-1-butene ...

Embodiment 2

[0033] Example 2. Synthesis of 1-butene / 1-hexene copolymer saturated elastomer by solution polymerization.

[0034] 10L fully enclosed magnetic stirring stainless steel pressure polymerization kettle (double-helical stirring paddle), pumping for 2 to 3 hours, during which it was replaced several times with high-purity nitrogen. Adding monomer volume concentration in the polymerization kettle is 1-butene and 1-hexene / normal hexane solution of 30%, wherein 1-hexene content is 10% (molar ratio) of monomer total amount, with Ti / monomer =4×10 -5 , Al / Ti=300, under stirring, add triisobutylaluminum (Al) and supported titanium catalyst (Ti) sequentially, polymerize at 40° C. for 8 hours, and obtain a polymer directly after drying, with a monomer conversion rate of 65%. The glass transition temperature of the polymer as determined by DSC is -23.5 degrees, the melting point is 80.8 degrees, and the crystallinity is 9.5%. The content of the 1-hexene structural unit in the polymer was...

Embodiment 3

[0035] Example 3. Synthesis of 1-butene / non-conjugated diene copolymer unsaturated elastomer by solution polymerization.

[0036] 10L fully enclosed magnetic stirring stainless steel pressure polymerization kettle (double-helical stirring paddle), pumping for 2 to 3 hours, during which it was replaced several times with high-purity nitrogen. Adding monomer volume concentration in the polymerization kettle is 1-butene and ethylidene norbornene (ENB) / normal hexane solution of 35%, wherein ENB content is 5% of monomer total amount, with Ti / monomer=6× 10 -5 , Al / Ti=400, under stirring, triisobutylaluminum (Al) and supported titanium catalyst (Ti) were metered in sequence, polymerized at 40° C. for 8 hours, and the polymer was obtained directly after drying, and the monomer conversion rate was 42%. The ENB structural unit content in the polymer was determined to be 3% by NMR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com