Biodegradable multilayer material with adjustable gas transmission rate and preparation method and applications thereof

A gas permeability, multi-layer material technology, applied in the fields of food packaging, medical packaging, and ground covering films, which can solve the problems of decreased physical properties, poor compatibility, and confusion of right and wrong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) PBAT / PBAT-Co-PPC / PPC layer blend resin preparation in the embodiment

[0036] A. Prepare the following raw materials:

[0037] PBAT and PPC are mixed according to 10-90% of each mass percentage; the above-mentioned mixed materials are placed in a drying oven for drying, the drying temperature is 40°C-60°C, and the drying time is 2-24 hours;

[0038] B. After drying, according to 100 parts by weight of the mixed material, add 0.1 to 10 parts by weight of a chain extender (an epoxy reactive compatibilizer is used in this embodiment), and mix the raw materials in a high-speed mixer. The mixing time is 3-30 minutes;

[0039] C. Add the high-speed mixed raw materials into the twin-screw extruder. The screw diameter of the twin-screw is 45mm, the length-to-diameter ratio of the screw is 36, and the temperature of the feeding section of the twin-screw extruder is 80-120°C. The temperature of the chemical reaction section is 110-190°C, the die temperature is 130-190°C, th...

Embodiment 2-7

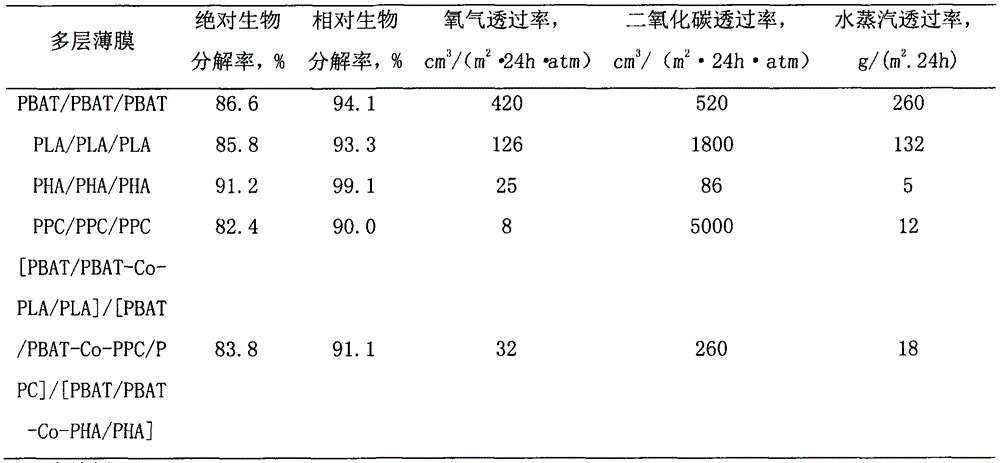

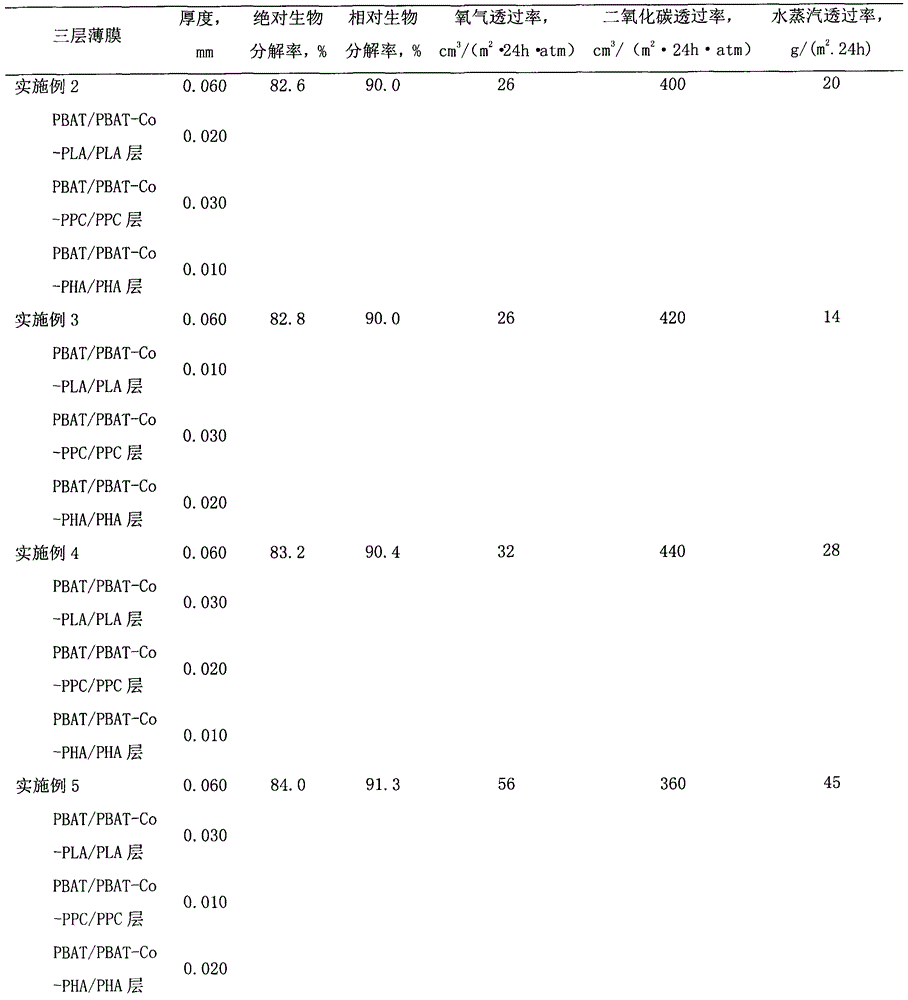

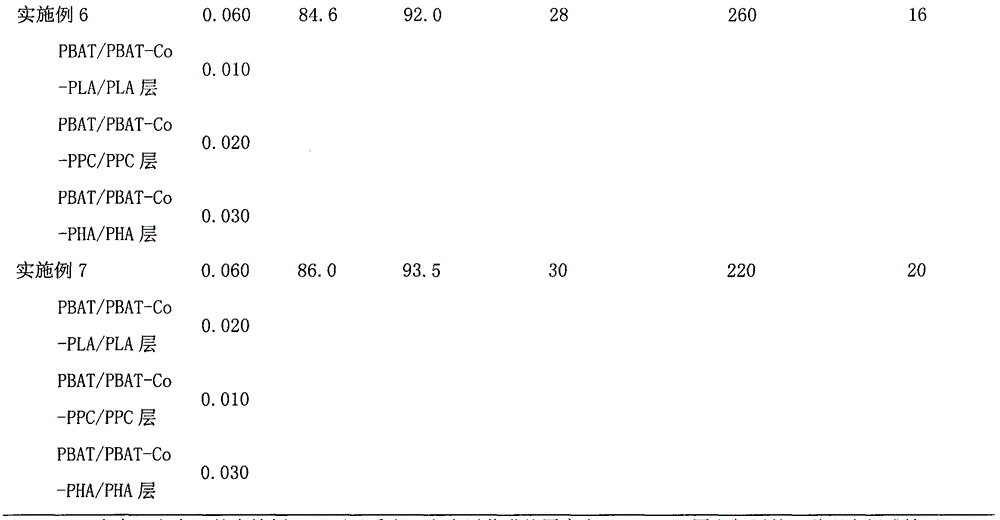

[0064] (1) Prepare [PBAT / PBAT-Co-PLA / PLA] blend layer, [PBAT / PBAT-Co-PPC / PPC] respectively according to steps (1), (2) and (3) in Example 1 Blend layer, [PBAT / PBAT-Co-PHA / PHA] blend layer, the obtained PBAT / PBAT-Co-PPC / PPC blend resin (in this example, the mass percentage of PBAT is 60%, PBAT -Co-PPC mass percentage composition is 5%, PPC mass percentage composition is 35%), the PBAT / PBAT-Co-PLA / PLA blend resin obtained (in this example, PBAT mass percentage composition is 60%, PBAT-Co-PLA mass percentage composition is 5%, and PLA mass percentage composition is 35%), the PBAT / PBAT-Co-PHA / PHA blend resin that obtains (in this example, PBAT mass percentage composition is 60% , the mass percentage of PBAT-Co-PLA is 5%, and the mass percentage of PLA is 35%);

[0065] (2) Prepare three-layer co-extruded cast film by step (4) in Example 1, measure the biodegradation rate, oxygen transmission rate, carbon dioxide gas permeation of multilayer film by step (5) in Example 1 rate, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com