Compatibilized polypropylene and polylactic acid blends and methods of making and using same

A technology of polypropylene, polylactic acid, applied in the field of polymer blends, which can solve problems such as poor mechanical and/or physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

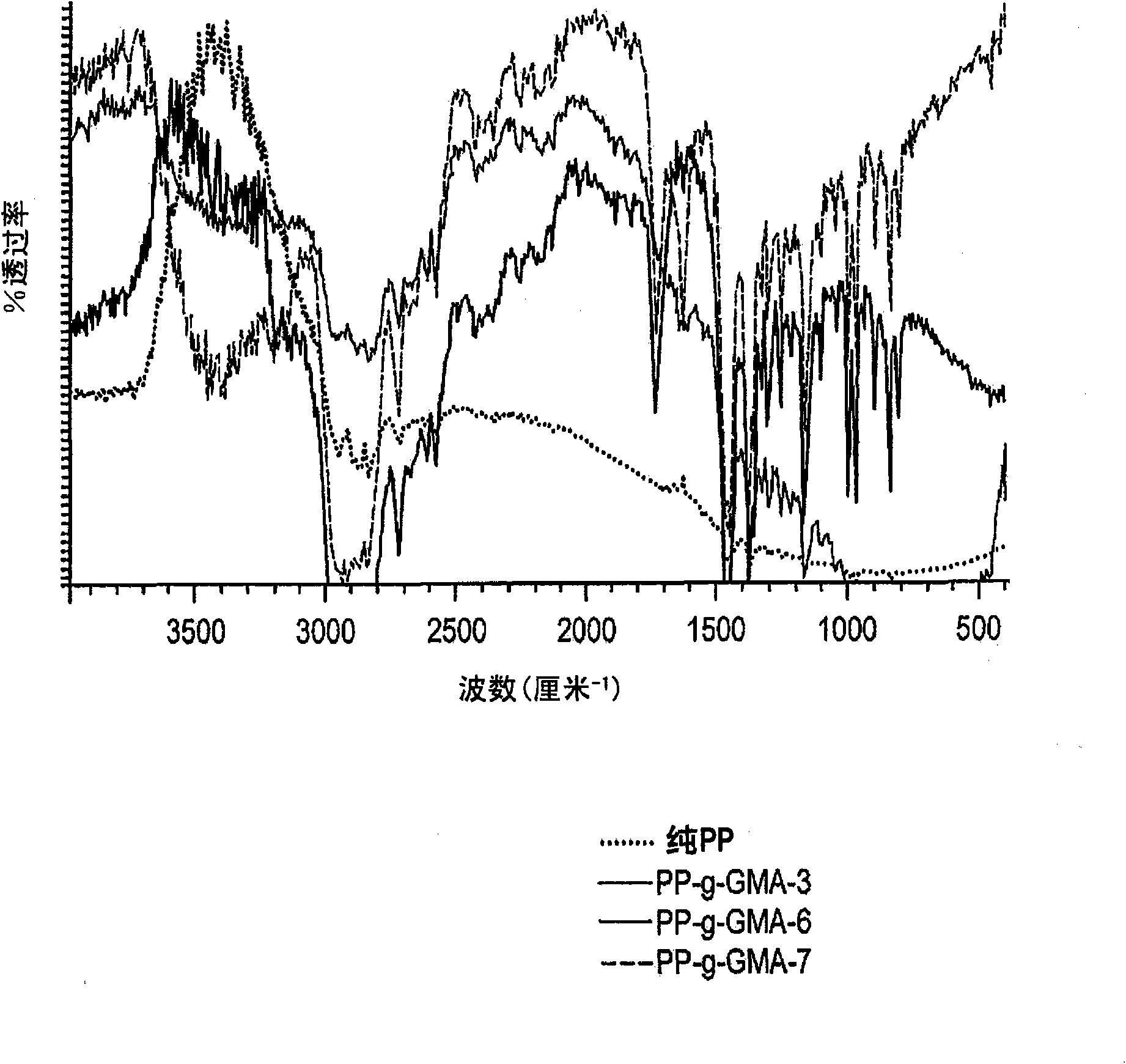

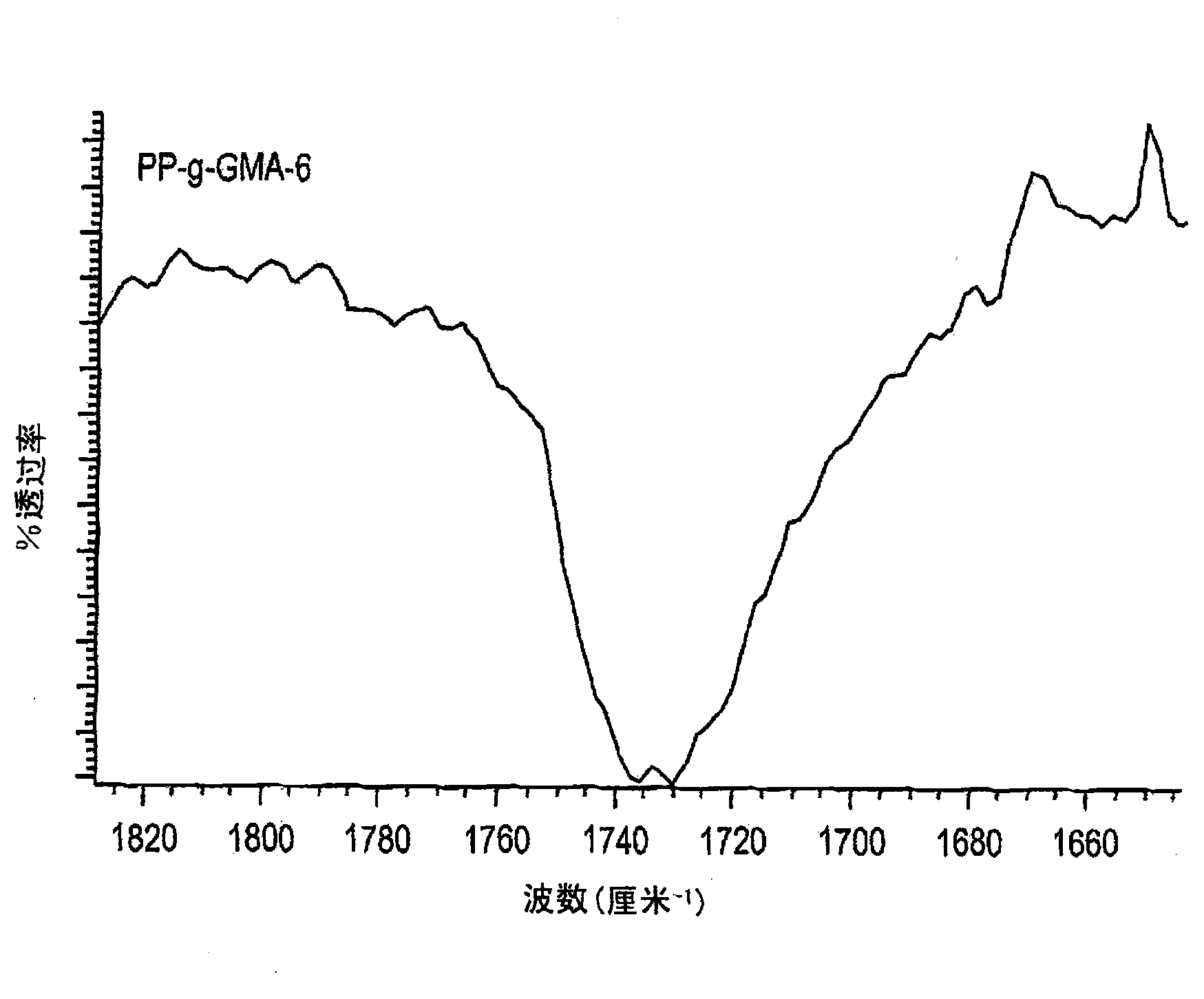

[0126] The degree of GMA grafting on polypropylene during the preparation of the reactive modifier (ie PP-g-GMA) was investigated. Base polypropylene resin 3276 (polypropylene homopolymer available from Total Petrochemicals) and GMA (flash point 85°C, viscosity 2.7 centipoise) (from Dow Chemicals) was used. ) purchased) prepared samples. The multifunctional acrylate comonomers were SR259 polyethylene glycol (200) diacrylate (25 centipoise viscosity) and SR351 trimethylolpropane triacrylate (TMTPA) (106 centipoise viscosity); they Both are commercially available from Sartomer. The initiator used was the peroxide LUPERSOL 101 (L101). The formulations listed in Table 9 are expressed in parts by weight per 100 parts of base resin (phr).

[0127] In a 50 liter mixer, a 30 pound amount of the 3277 fluff was mixed with the multifunctional acrylate comonomer (ie, GMA) and initiator. Then, under the conditions of screw speed of 100 rpm, extrusion rate of 10 lbs / hour, and vacuum devo...

Embodiment 2

[0134] The melt pressure of CB prepared from 3271 and PLA 6201D with and without various reactive modifiers was monitored during extrusion. Sample 5 is a PP / PLA blend without a reactive modifier; Sample 6 is a PP / PLA blend containing PP-g-GMA-3 as a reactive modifier; Sample 7 is a PP / PLA blend A blend containing PP-g-GMA-6 as a reactive modifier; Sample 8 is a PP / PLA blend containing LOTADER AX8840 as a reactive modifier. LOTADER AX8840 is a reactive polyethylene resin functionalized with GMA, commercially available from Arkema. PP-g-GMA-3 is a low-grafting functionalized polypropylene for the preparation of grafted PP-g-GMA containing less than 0.5% GMA, PP-g-GMA-6 is a high-grafting functionalized polypropylene , for the preparation of high grafted PP-g-GMA containing 3% GMA as described in Example 1, LOTADER AX8840 is a polyethylene functionalized resin for the preparation of high grafted PP-g-GMA containing 8% GMA GMA.

[0135] The reaction mixture formulation and the ...

Embodiment 3

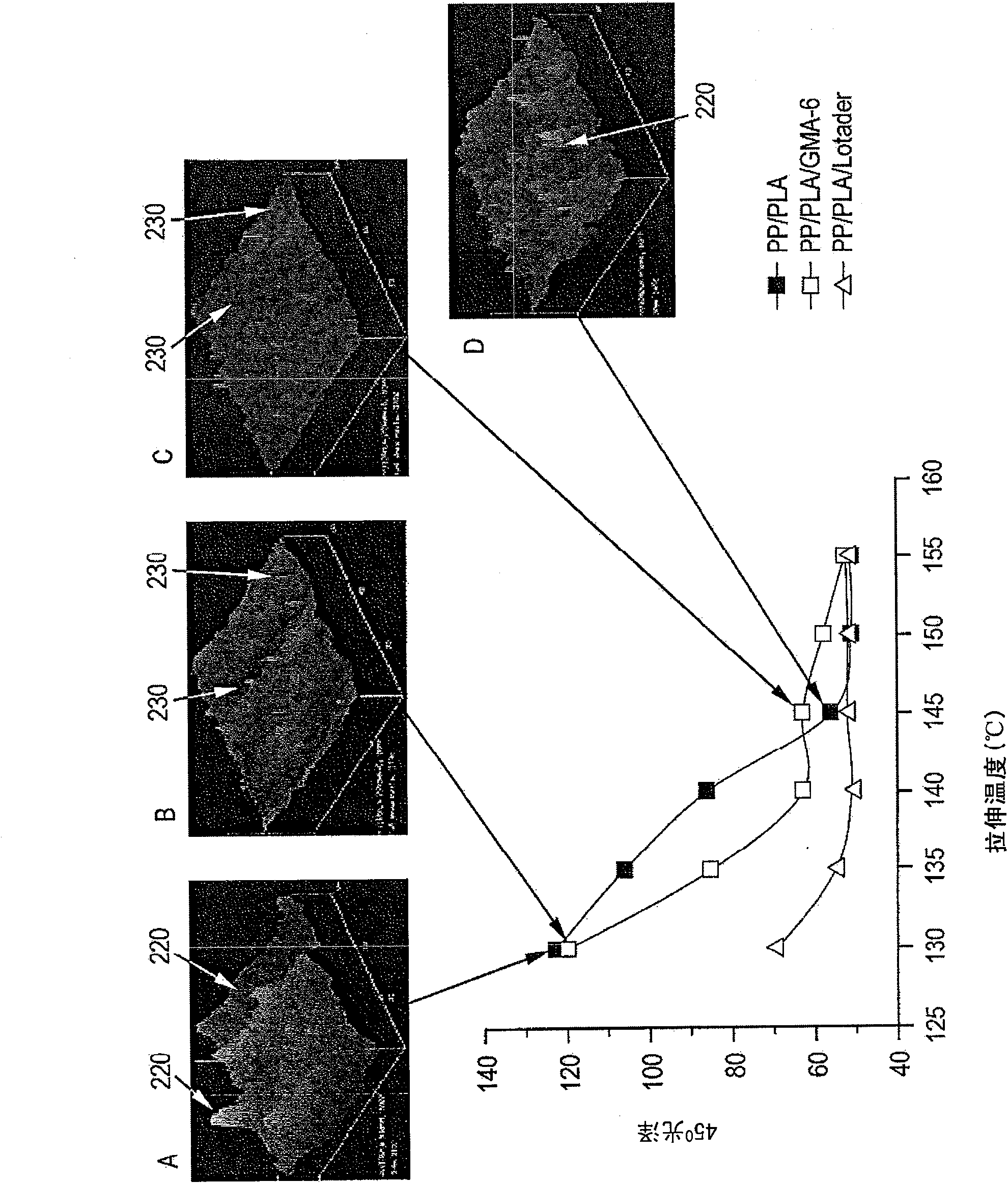

[0142] The yield strength of biaxially oriented films prepared from CB prepared with various reactive modifiers was investigated and compared to PP. Four samples, designated Samples 10-13, were prepared from the formulation listed in Table 11. The reactive modifiers are epoxy-functionalized PP (GMA-3 and GMA-6) and epoxy-functionalized PE (LOTADER) as indicated. Blends were prepared and cast into sheets of 16 mil thickness and stretched using a Brückner Karo IV. In the longitudinal and transverse directions, the area stretch ratio was 6x6, and the stretch speed was 30 m / min. The material can be stretched over a wide temperature range of 130-155°C.

[0143] Table 11:

[0144] sample

[0145] The results are shown in Table 12 and Figure 5 middle.

[0146] Table 12.

[0147] Stretch temperature

[0148] 130

[0149] Figure 5 is a graph of the longitudinal tensile yield strength as a function of stretching temperature. see Figure 5 , most o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com