Preparation method of recycled polyester chip microfilaments and usage thereof

A technology for recycling polyester and slicing, applied in the direction of single-component polyester rayon, conjugated synthetic polymer rayon, filament/thread molding, etc., to achieve high impact strength, high processing efficiency, and stable dimensions good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1. Weigh 100Kg of recycled polyester chips purchased from a professional recycling organization, vacuum-dry at 90°C for 3h, and then vacuum-dry at 110-120°C for 4h; -Diphenylmethane diisocyanate (MDI) 0.4Kg, tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester / phosphite tris(2,4-ditert Put 0.25Kg of butylphenyl) ester (3 / 1), 0.65Kg of nano-kaolin, and 1.3Kg of polyethylene glycol (6000) into the "material processing unit" together, and process at 110-180°C for 15-25min, and mix the materials evenly ;

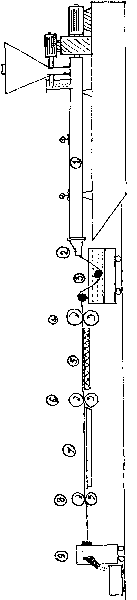

[0038] Feed the material into ( Figure 1 ) Co-rotating parallel twin-screw extruder (temperature control of each section: 90-140-220-200-240-260-250-240-260°C head 250°C), screw rotation ≥ 250rpm, extrusion strip Cooling by cold air→traction→reheating (120~160℃)→redrawing (drawing ratio 6~10 times, drawing into filaments with d≤0.3mm)→natural cooling→traction→granulation (1~10mm );

Embodiment 2

[0039] Embodiment 2. 100Kg will be weighed from the reclaimed polyester chips purchased by a professional recycling organization, vacuum-dried at 90°C for 3.5h, and then vacuum-dried at 110-120°C for 5h; then mixed with high-density polyethylene (HDPE) 20Kg, 1 4-Phenylbisoxazoline (1,4-PBO) 2.3Kg, n-octadecyl β-(4-hydroxy-3,5-di-tert-butylphenyl)propionate / dilauryl thiodipropionate Ester (4 / 1) 0.3Kg, 2,2'-methylenebis(4,6-di-tert-butylphenyl) sodium phosphate / mica (1 / 3) 4Kg, epoxy soybean oil 2.5Kg put into " In the "material handling unit", process at 110-180°C for 15-25 minutes, and mix the materials evenly;

[0040] The preparation method is the same as in Example 1.

Embodiment 3

[0041] Example 3. Weigh 100Kg of recycled polyester chips purchased from a professional recycling organization, vacuum-dry at 90°C for 5h, and then vacuum-dry at 110-120°C for 4h; Phenylisopropane dipropylene oxide phenyl ether 3.5Kg, tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester / pentaerythritol bisphosphite bis(2,4- 0.55kg of di-tert-butylphenyl) ester (3 / 1), 3.6Kg of magnesium stearate / aluminum trioxide (1 / 5), and 1Kg of polypropylene glycol are put into the "material handling unit" together, at 110~180℃ Process for 15 to 25 minutes, and mix the materials evenly;

[0042] The preparation method is the same as in Example 1.

[0043] Application result comparison:

[0044] The flexible container bag (FIBC) is made of polyolefin, mainly drawing-grade polypropylene resin, and then coated with a film as the base fabric. It has the advantages of lightness, softness, high strength, acid and alkali corrosion resistance, moisture resistance, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com