Patents

Literature

41results about How to "Drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

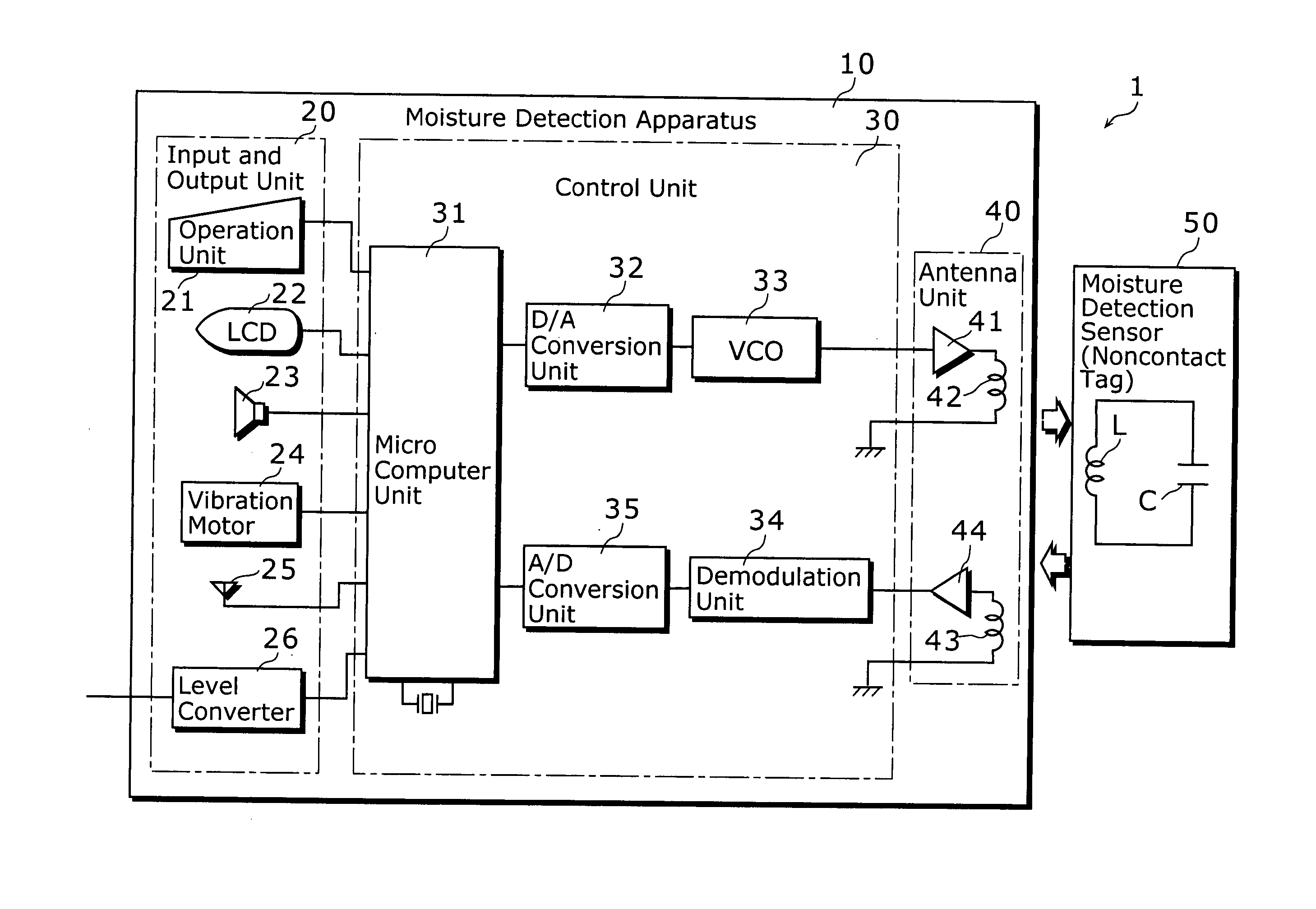

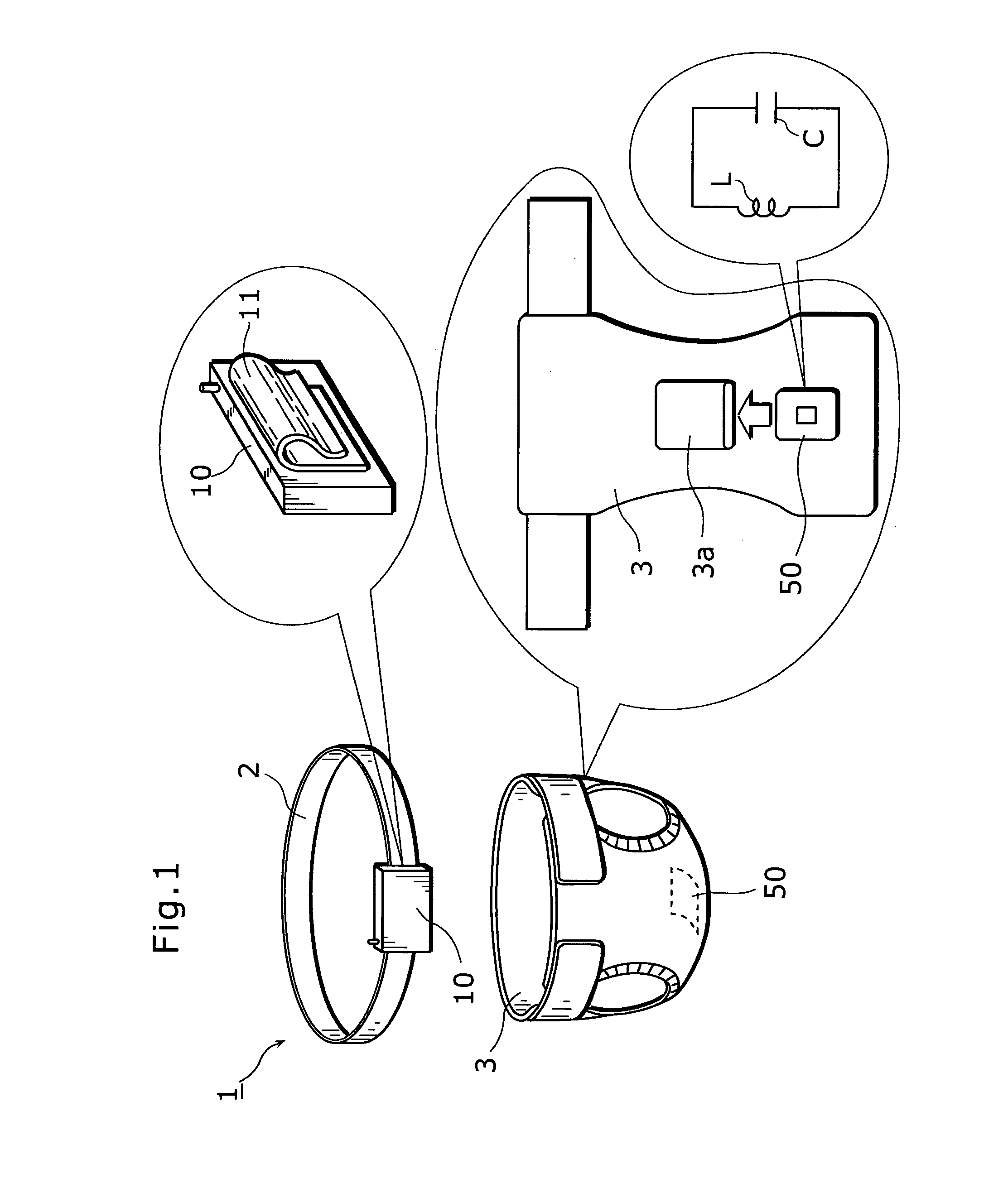

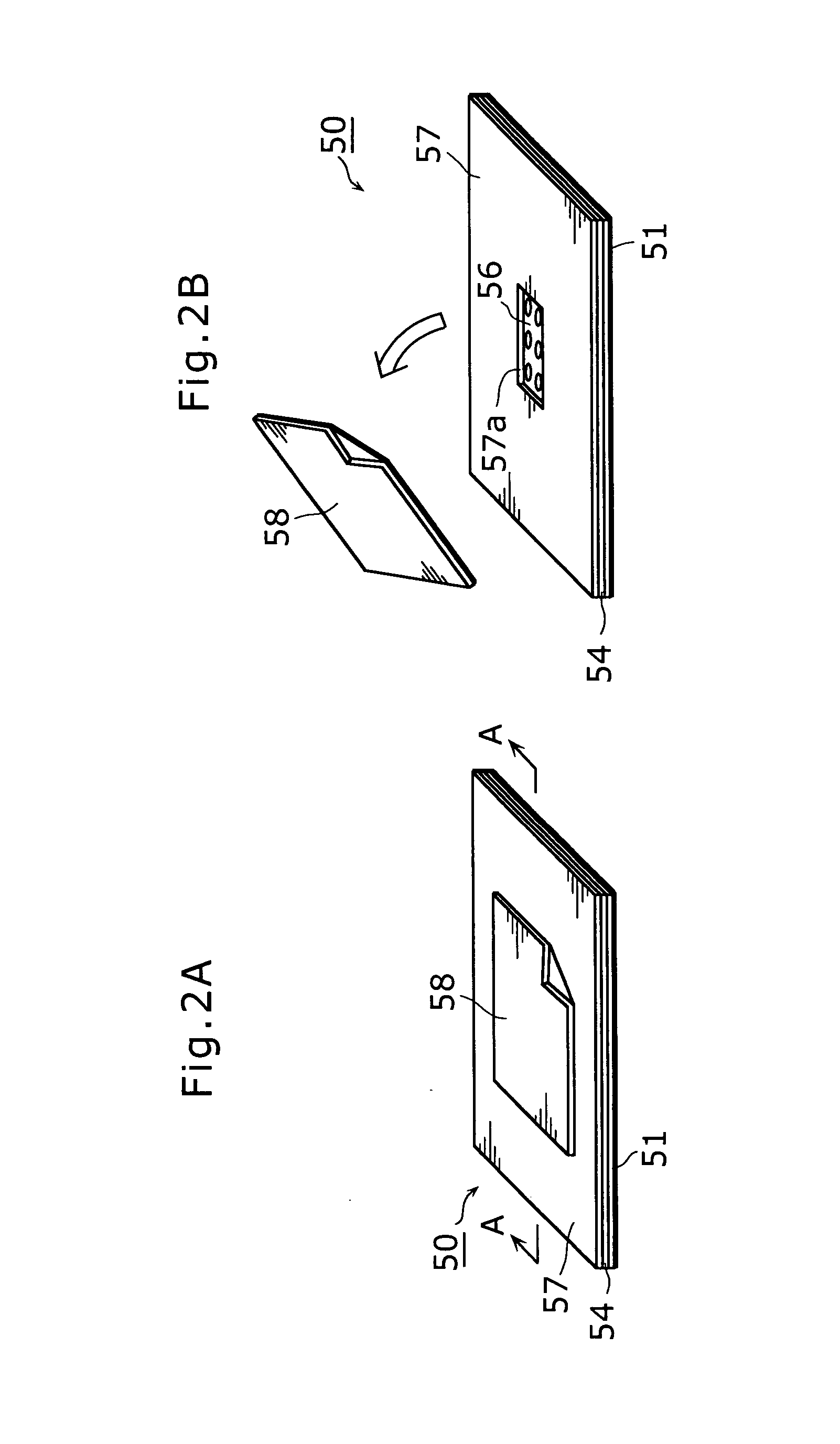

Liquid detection sensor, liquid detection apparatus and liquid detection system

InactiveUS20040036484A1Accurate detectionDrying processDetection of fluid at leakage pointResistance/reactance/impedenceEngineeringDielectric

A moisture detection sensor that detects liquid, comprising: a resonant circuit composed of an antenna coil 53 and a capacitor C; and a noncontact tag composed of covering materials 51 and 57 that cover the resonant circuit, wherein the capacitor C has a pair of electrodes 52 and 56 and a dielectric 55 interposed between the electrodes 52 and 56, and the covering material 57 contains a through hole 57a that allows the liquid to infiltrate into the dielectric 55 from an outside.

Owner:PANASONIC CORP

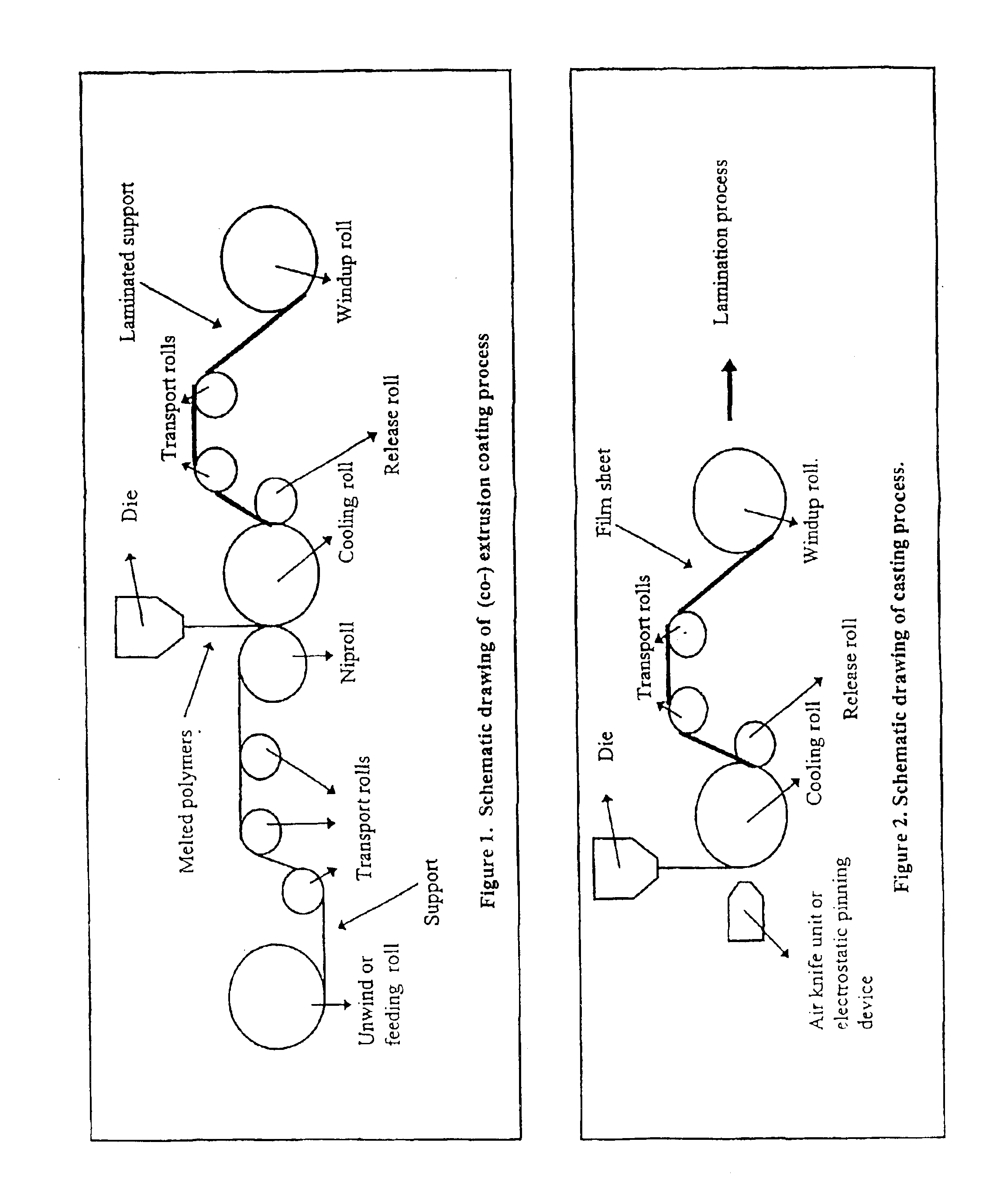

Photocatalytic sheet or film and its manufacturing process

InactiveUS6890645B2Fast productionDrying processSynthetic resin layered productsCellulosic plastic layered productsExtrusion coatingSheet material

The invention is directed to a photocatalytic sheet comprising a support, a photocalalytic layer comprising photocatalyst materials and binder, and at least one functional layer wherein said functional layer is in between said support and said photocatalytic layer, wherein said photocatalytic layer and said functional layer are brought on the support using extrusion coating technology or casting technology, as well as to a photocatalytic film sheet comprising: a photocatalytic layer comprising photocatalyst materials and binder, and at least one functional layer, wherein said film is formed by applying casting technology.

Owner:FUJIFILM MFG EURO

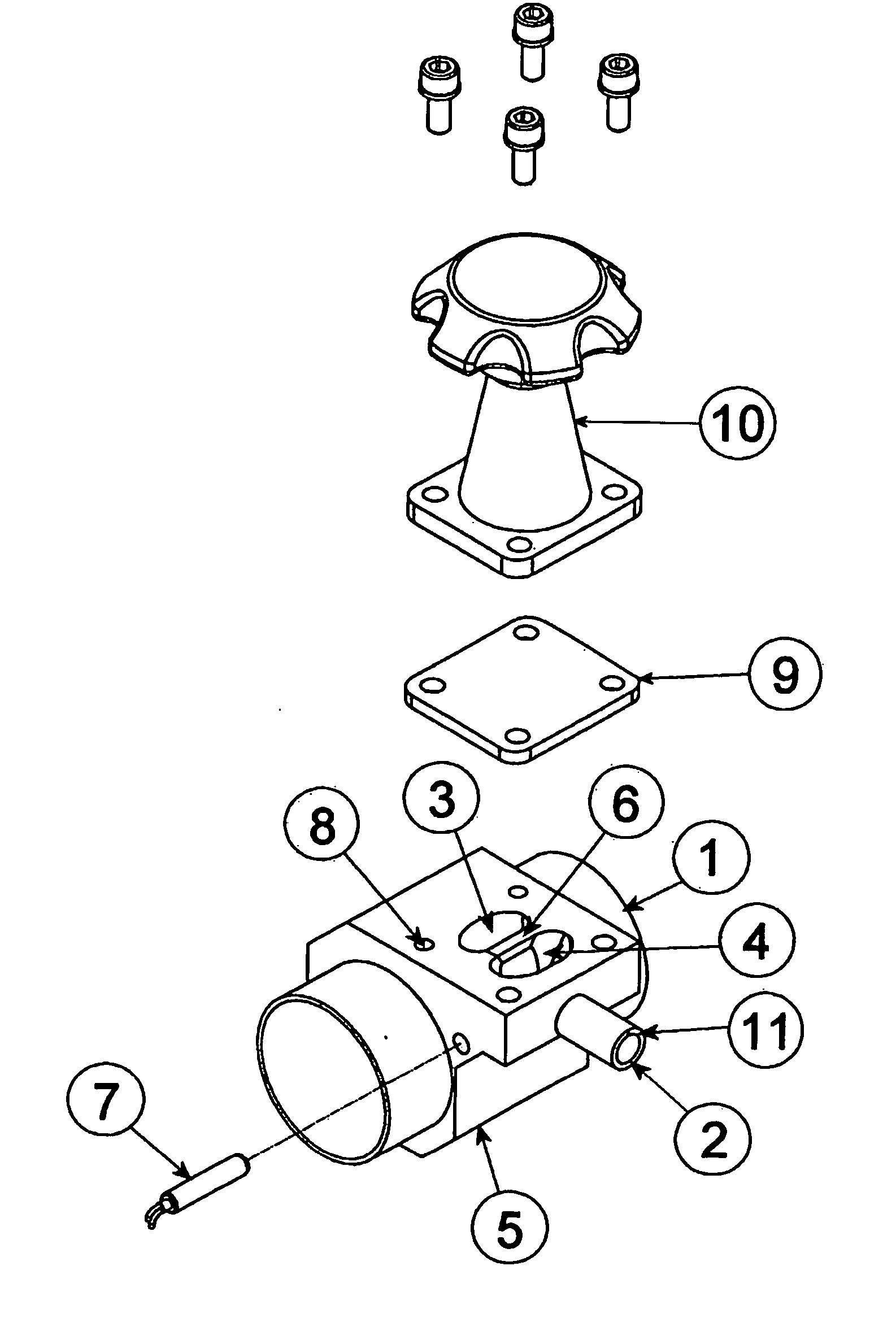

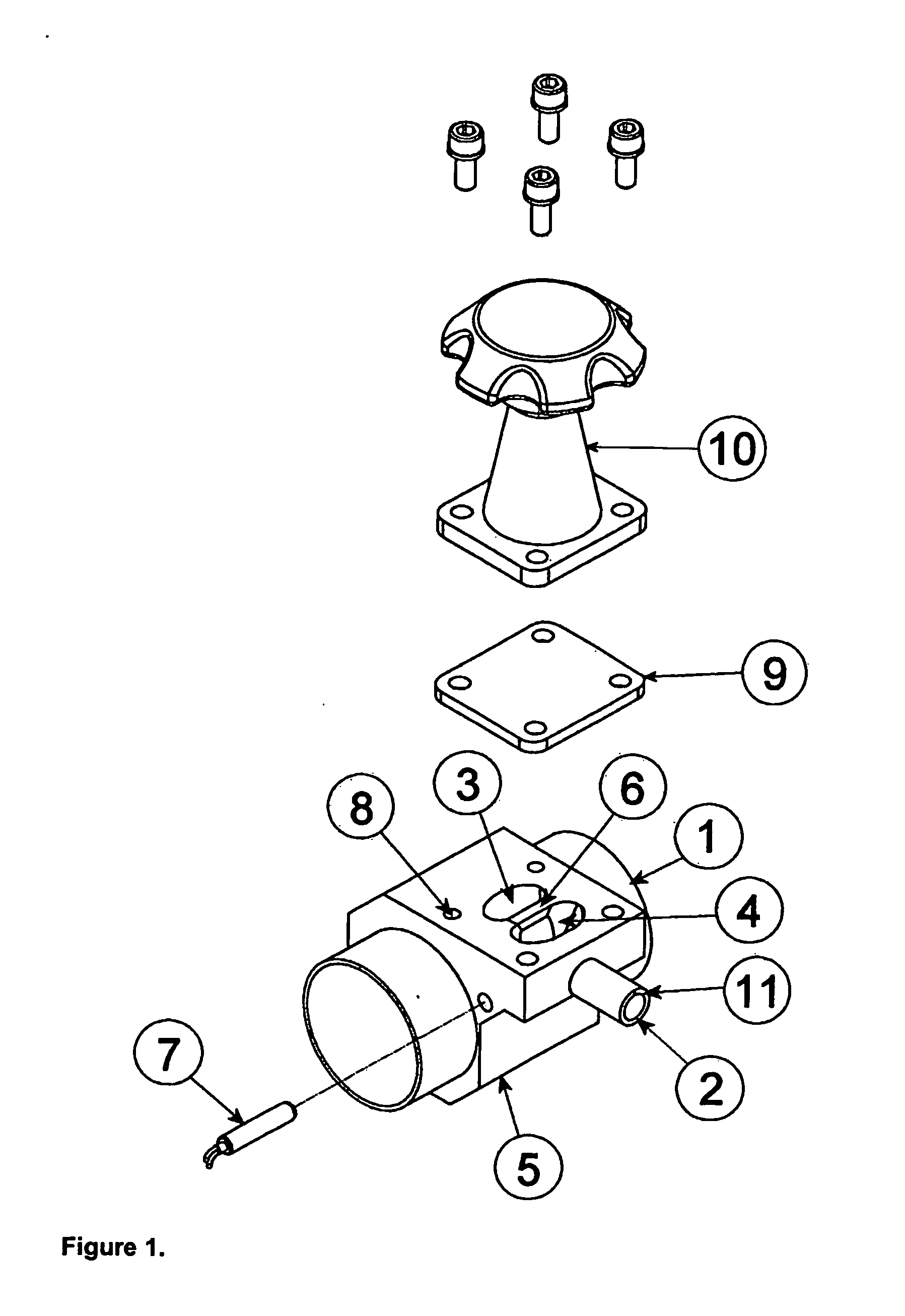

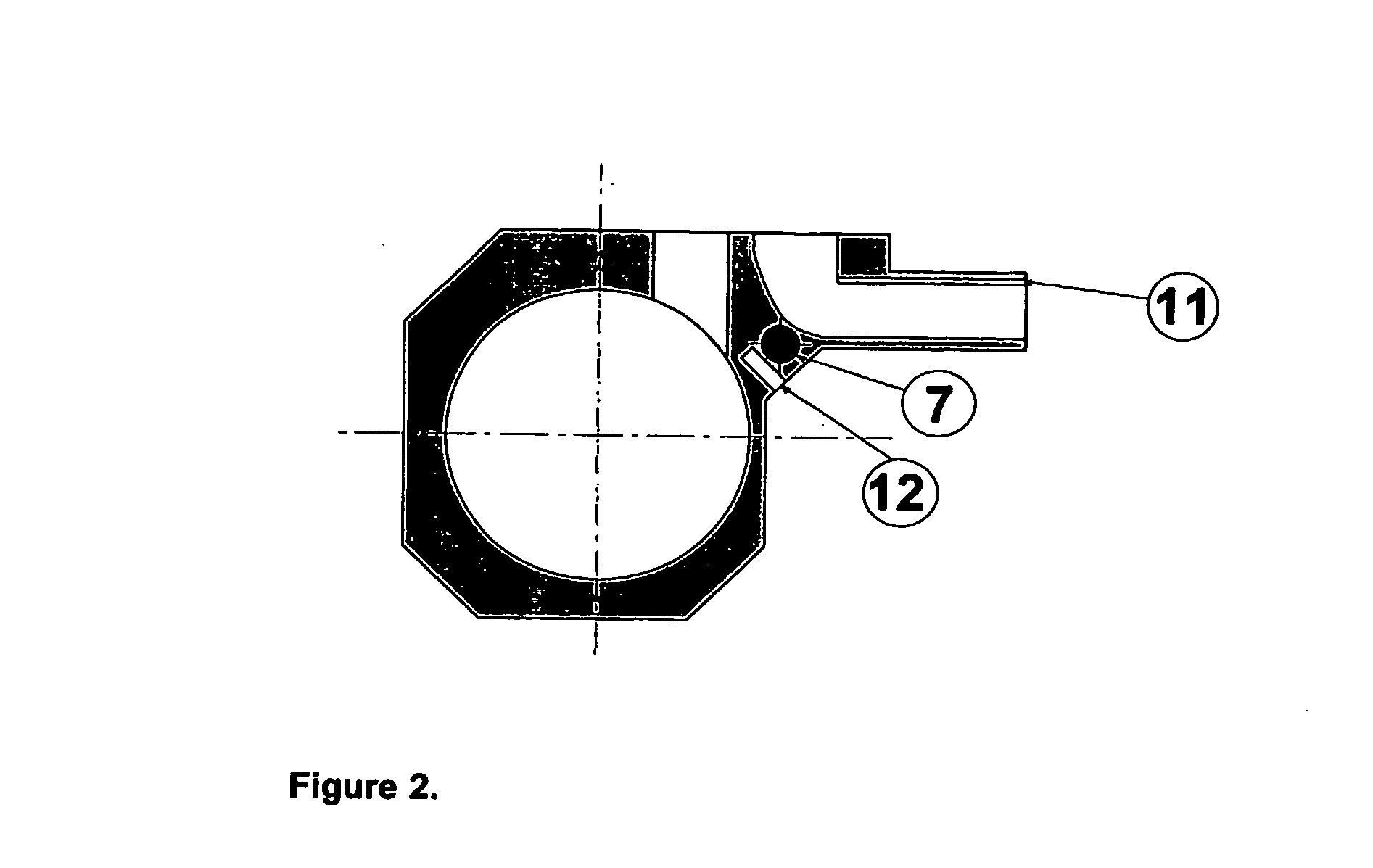

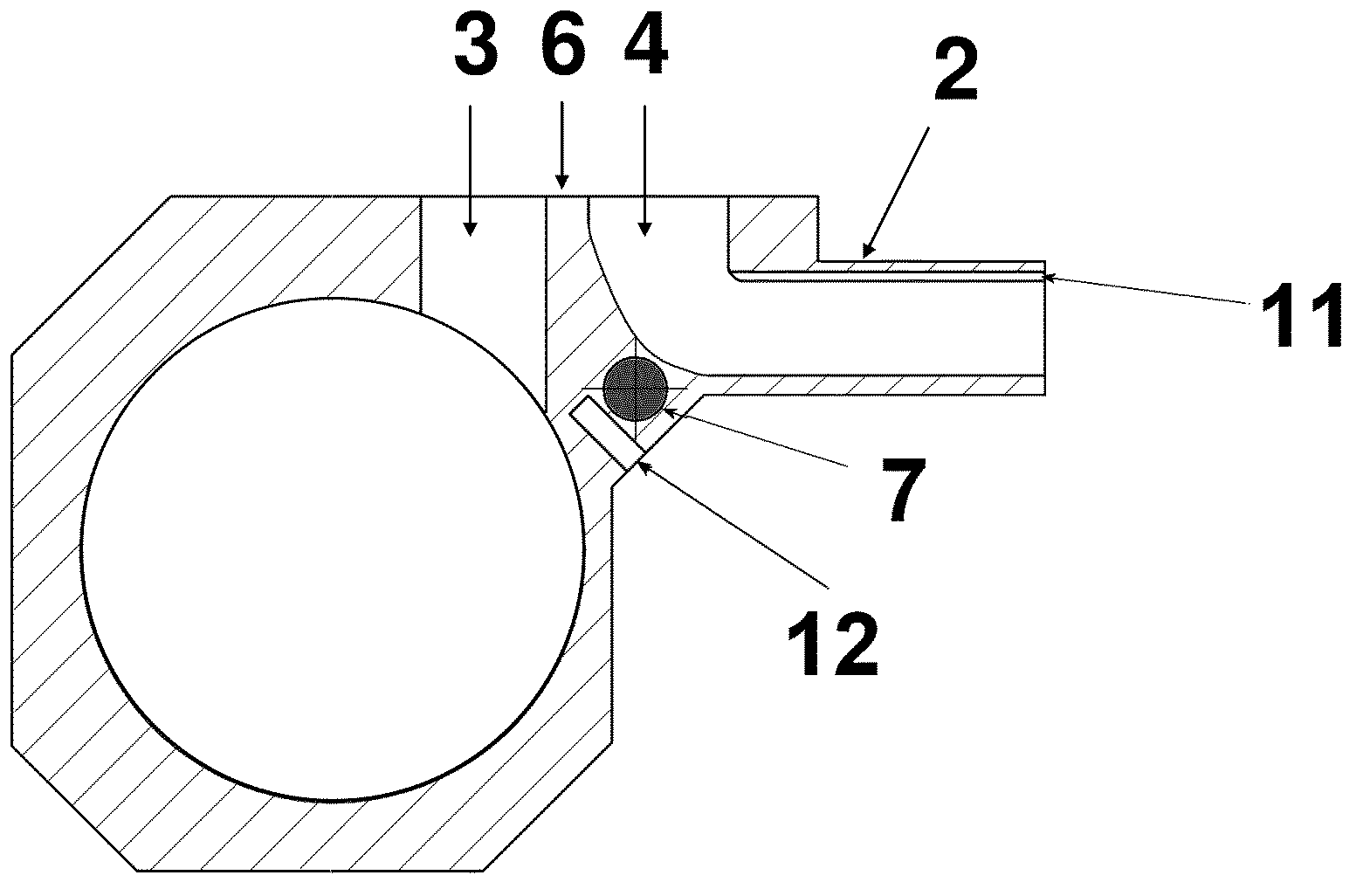

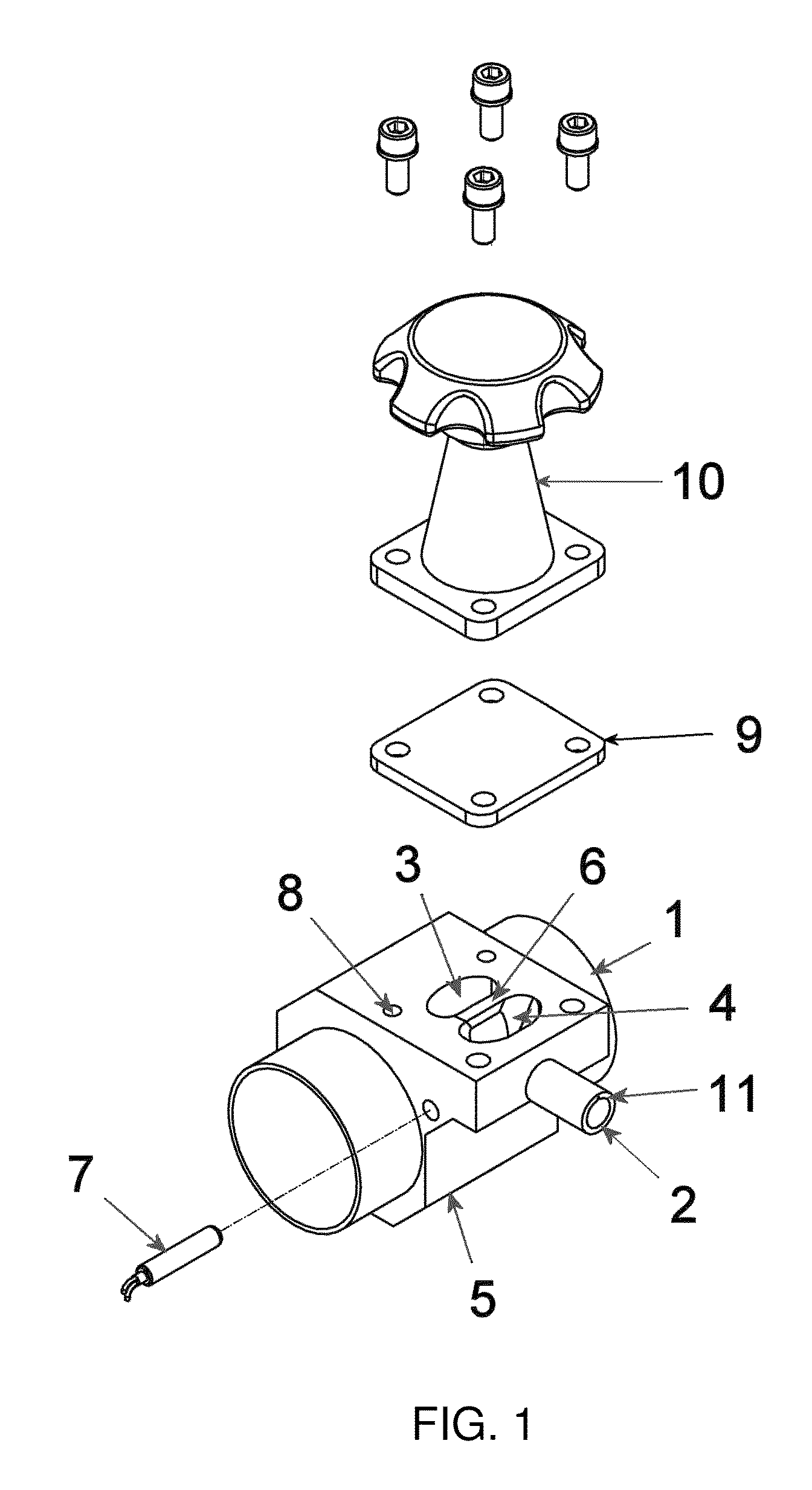

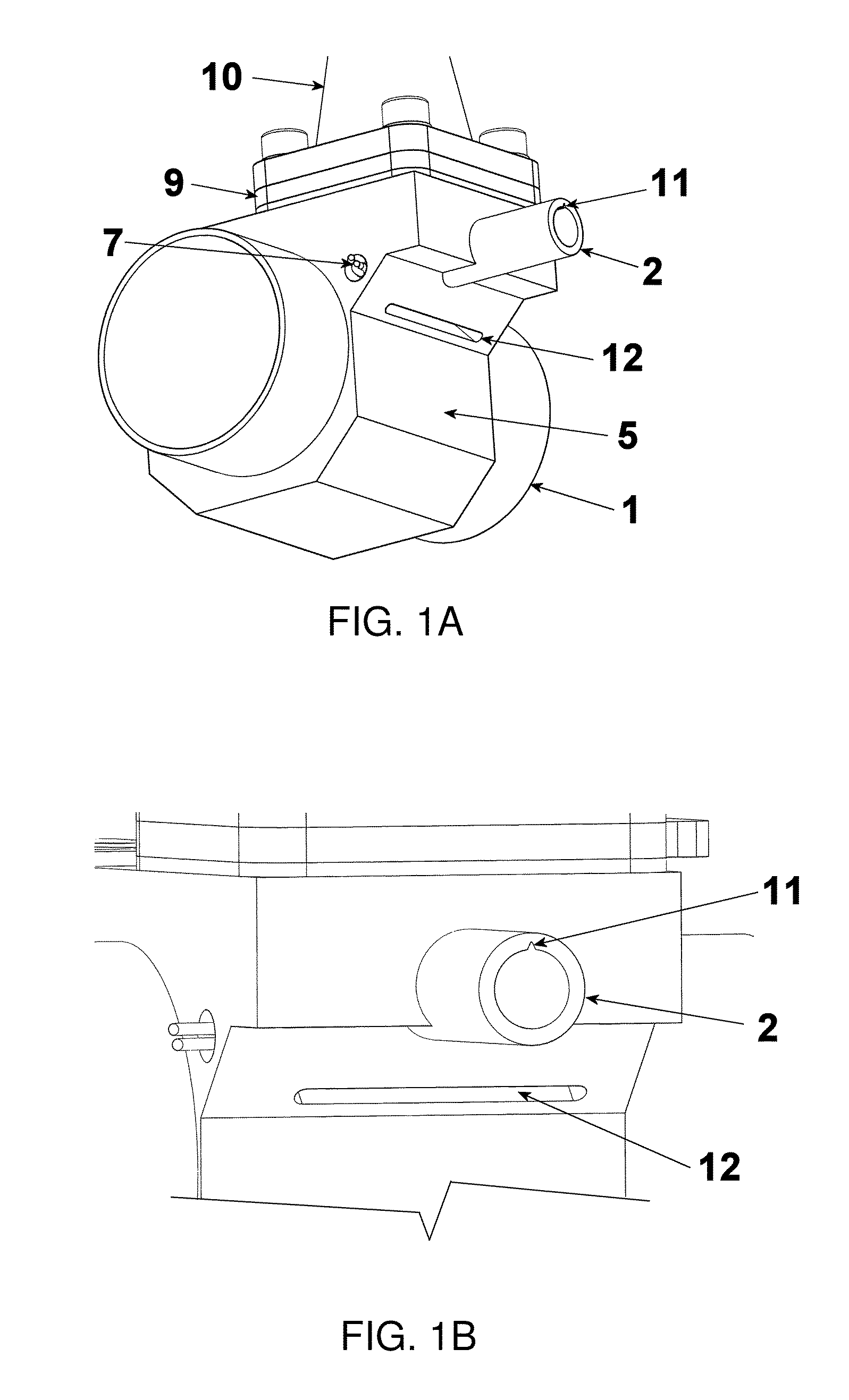

Clean line heated valve

InactiveUS20060144443A1Drying processEasy to useDiaphragm valvesEngine diaphragmsBiomedical engineeringMembrane configuration

Owner:YEWDALL GARY WAYNE +1

Clean line heated valve

InactiveUS7814929B2Drying processEasy to useDiaphragm valvesEngine diaphragmsEngineeringBiomedical engineering

Owner:YEWDALL GARY WAYNE +1

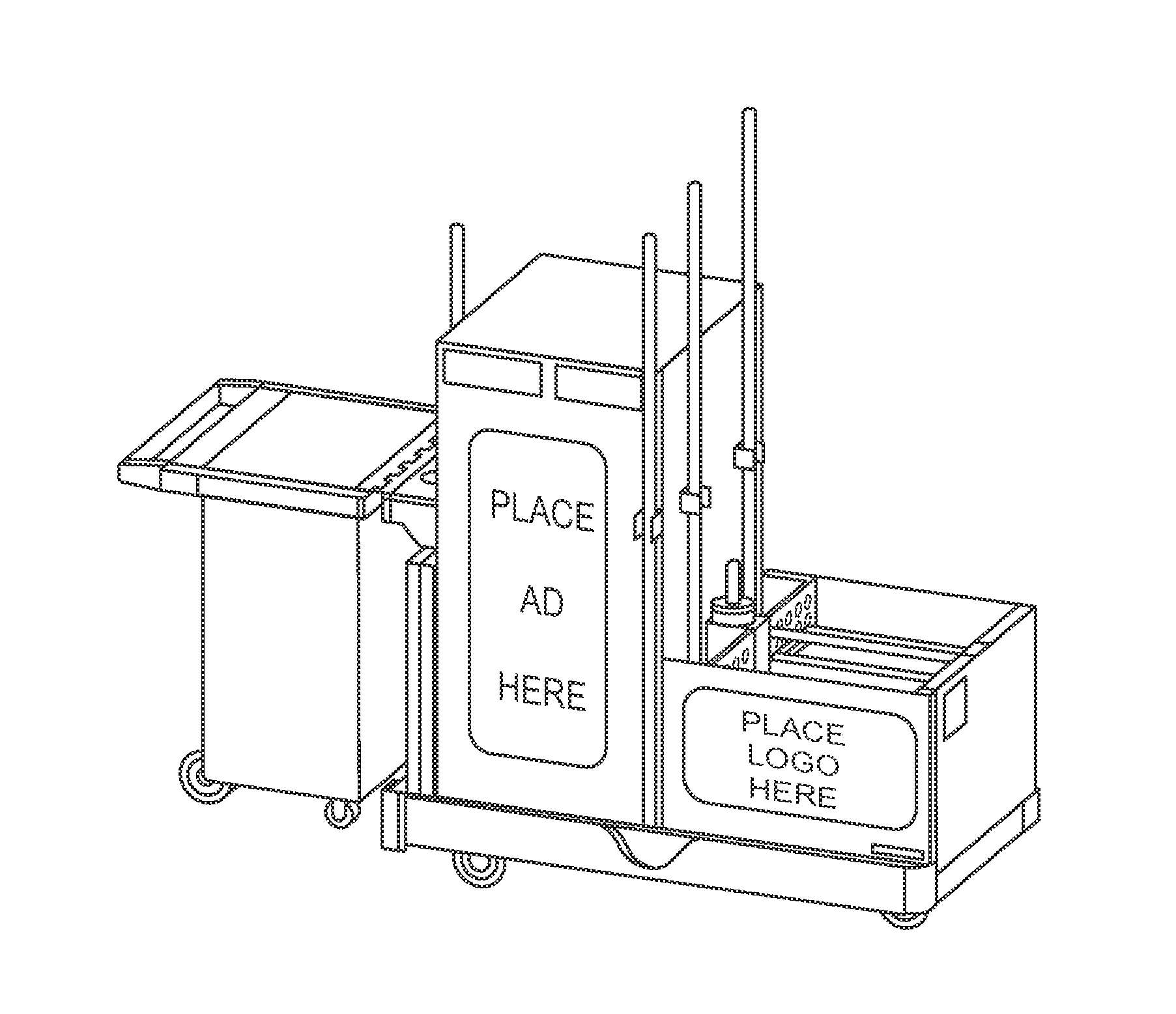

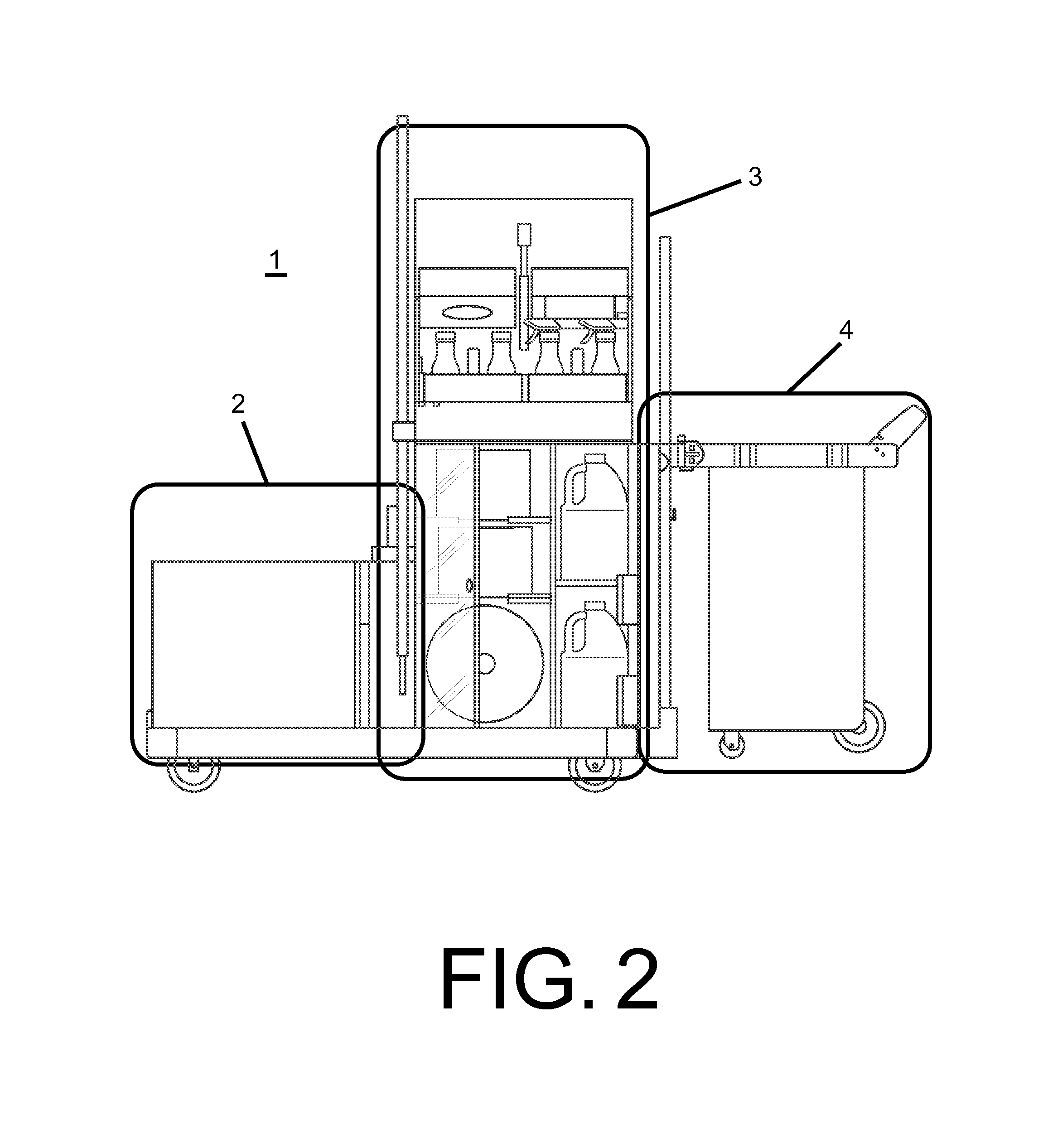

Cleaning cart

InactiveUS8419024B1Avoid cross contaminationDrying processHand carts with one axisChildren carriages/perambulatorsEngineeringCleaning product

The cleaning cart of the invention is a new kind of cleaning cart providing several utilities and designed to provide an efficient and organized solution. The cleaning cart is completely covered preventing People from seeing dirty mops, buckets, dirty wipes or cleaning products. The cleaning cart also has a removable waste container that can be easily separated from the rest of the cleaning cart. The cleaning cart also works as an advertising cart. The cleaning cart provides a new way of cleaning in a more organized, clean and healthier way.

Owner:ARROYO FERRER FERNANDO

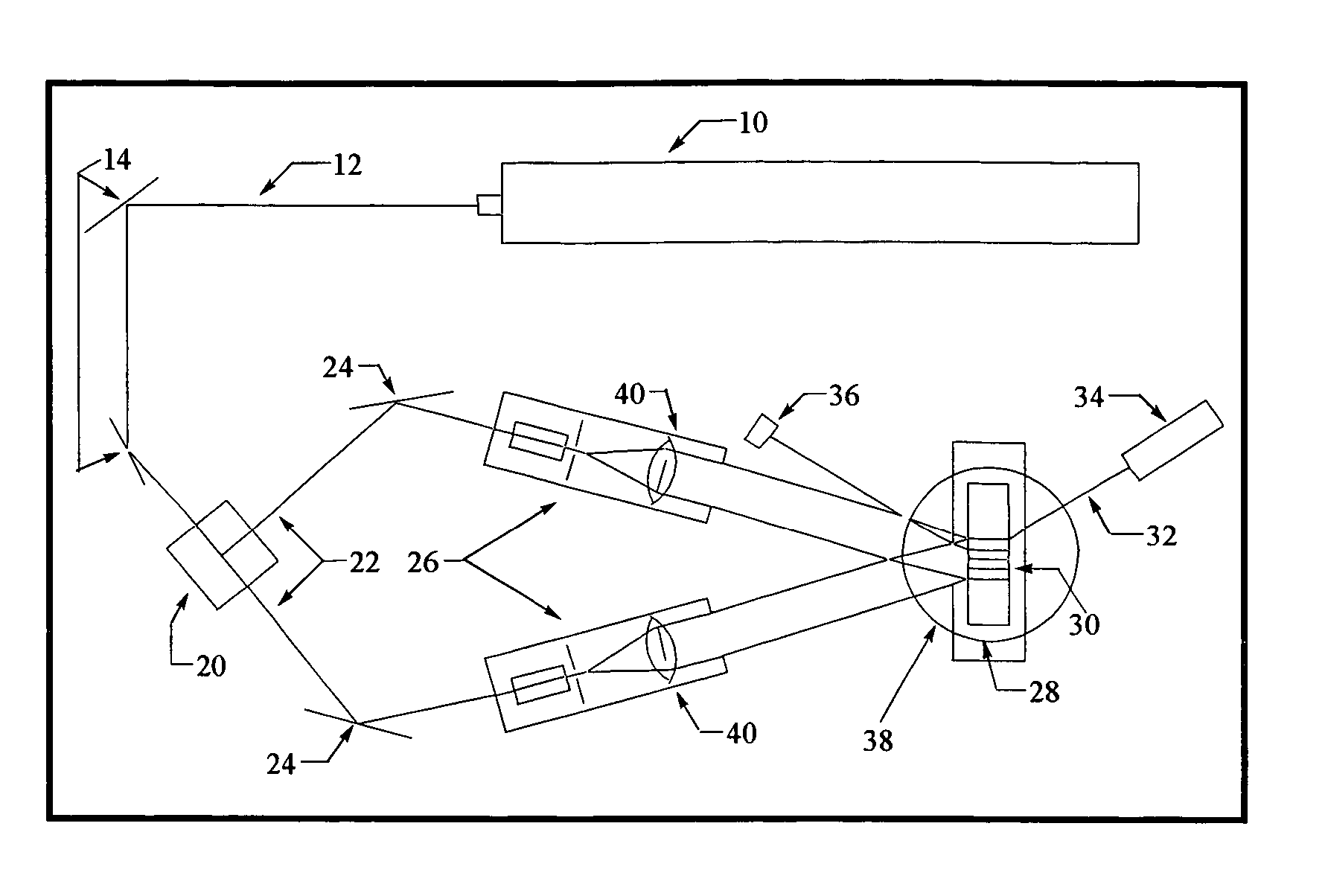

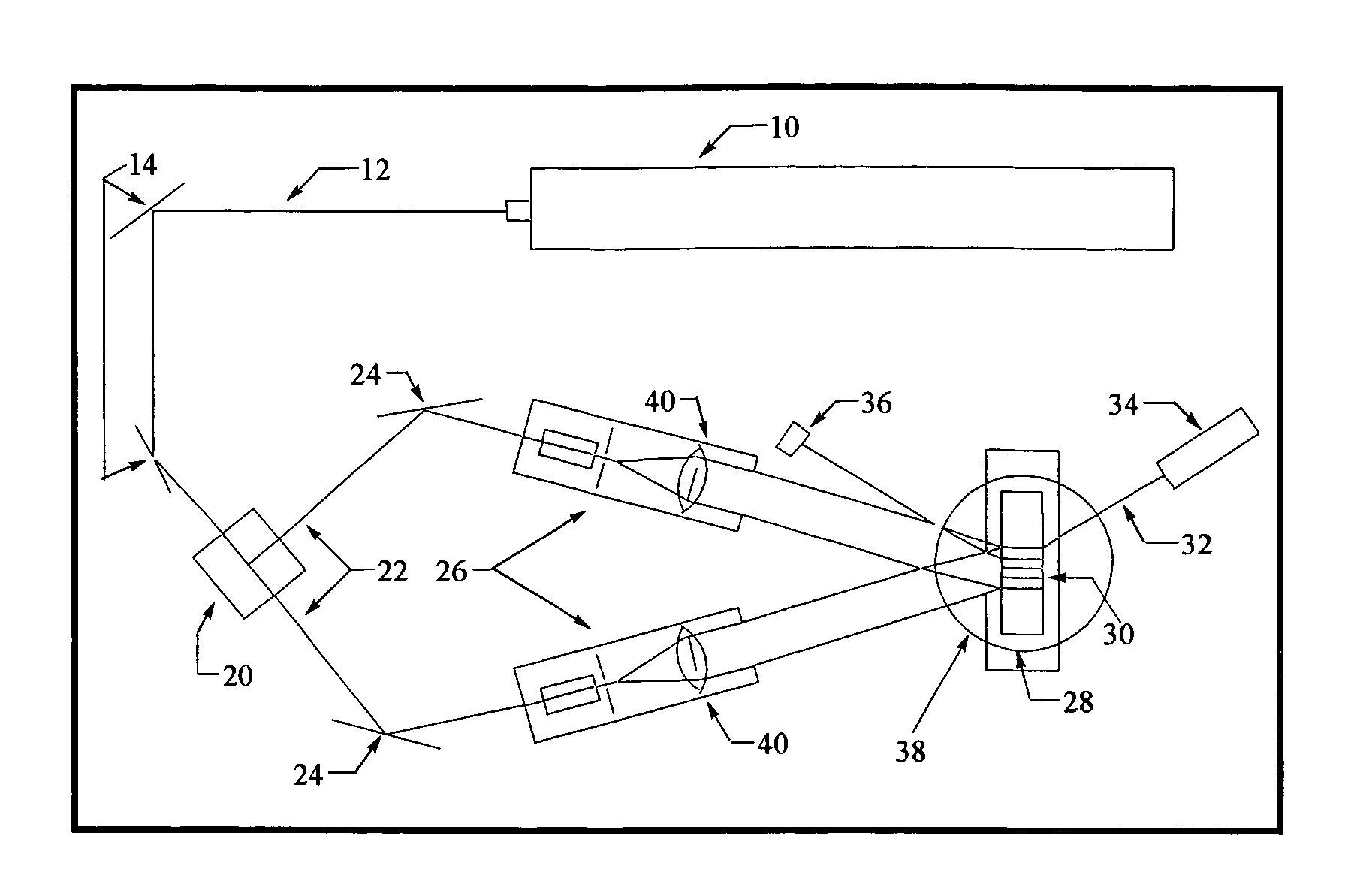

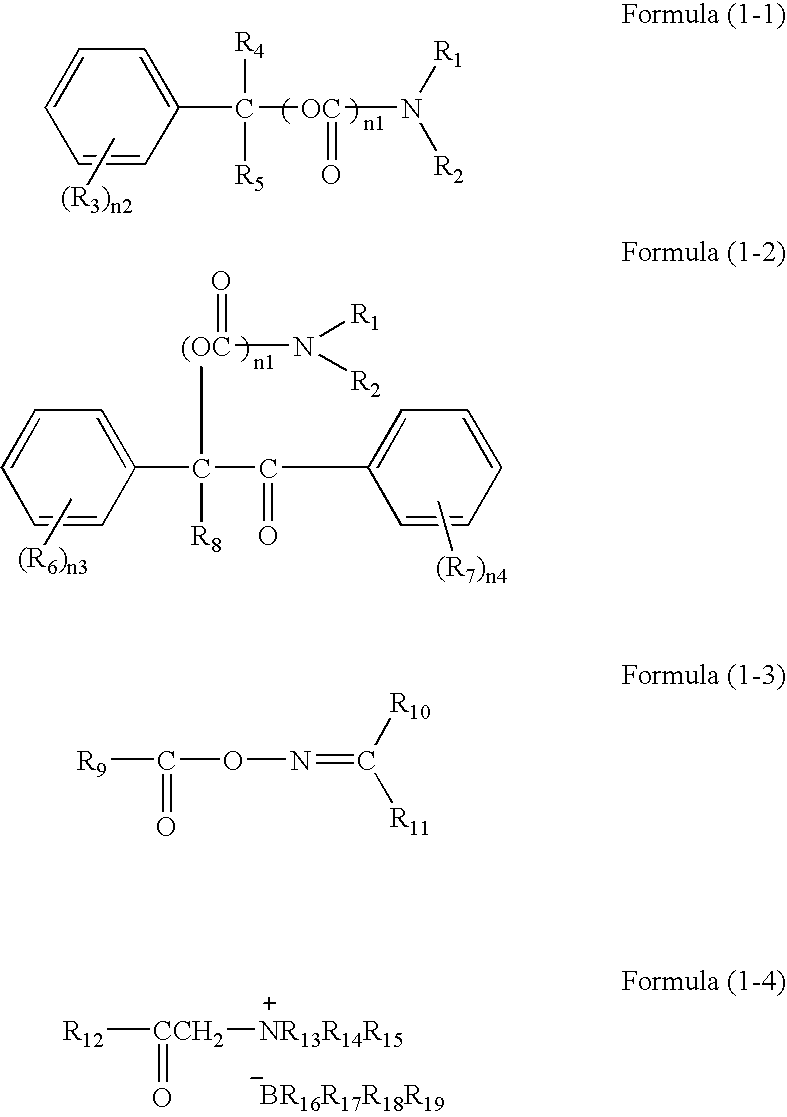

Hologram recording material and hologram recording method

InactiveUS20060057467A1Satisfactory storabilityHigh sensitivityLiquid crystal compositionsPhotosensitive material processingRefractive index modulationChemistry

A hologram recording material and a hologram recording method, capable of attaining a high sensitivity, a high diffraction efficiency, a satisfactory storability and a dry processability at the same time and applicable to a high-density optical recording medium, a three-dimensional display, a holographic optical element and the like, are provided. The hologram recording method is characterized in causing a change in an alignment of a compound having a specific birefringence upon holographic exposure and fixing the alignment by a chemical reaction so as to record an unrewritable modulation in refractive index in a unrewritable mode. The hologram recording material is characterized in including a low-molecular liquid crystalline compound having a polymerizable group, a photoreactive compound, and a polymerization initiator, and being of an unrewritable type.

Owner:FUJIFILM CORP +1

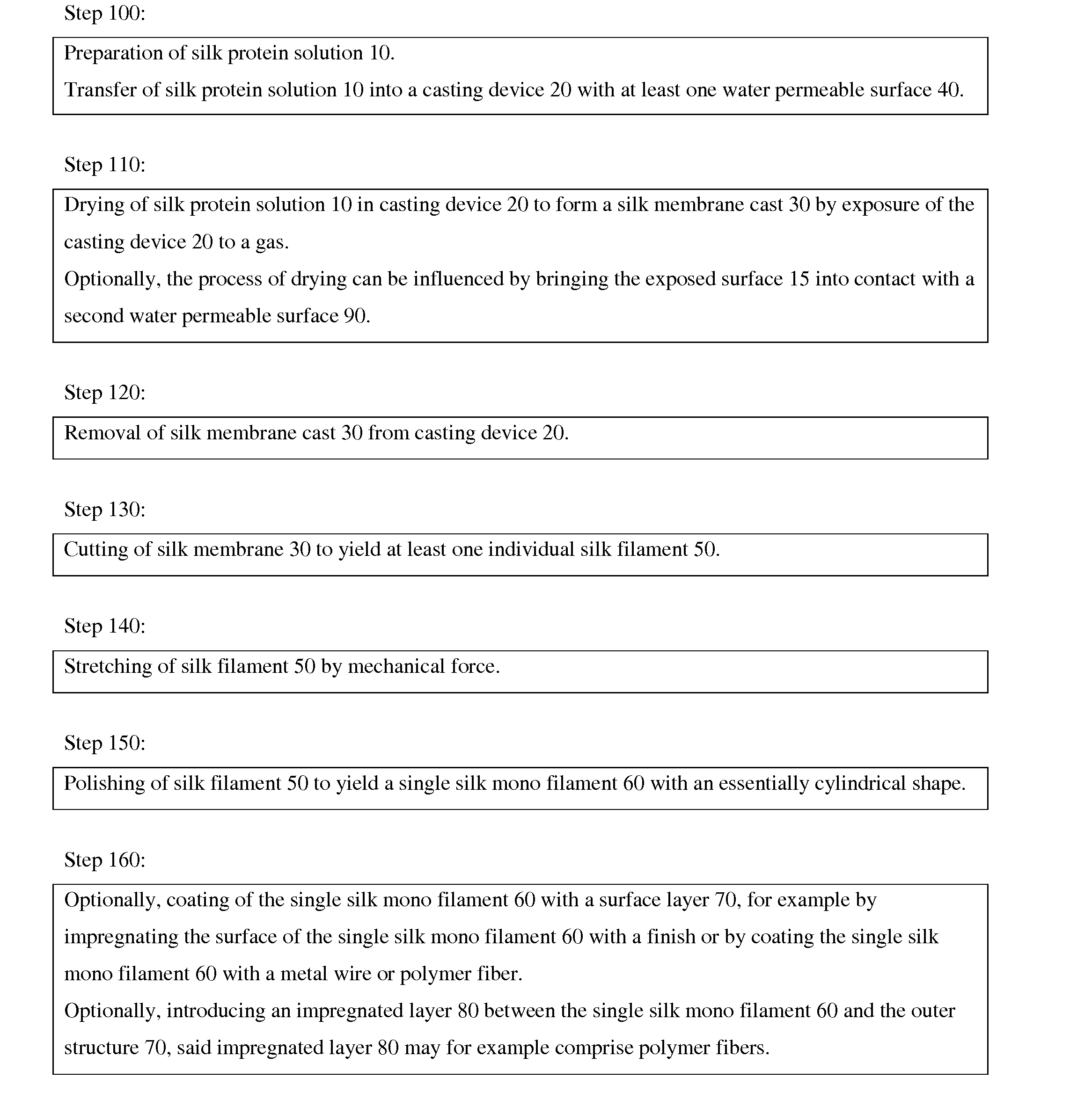

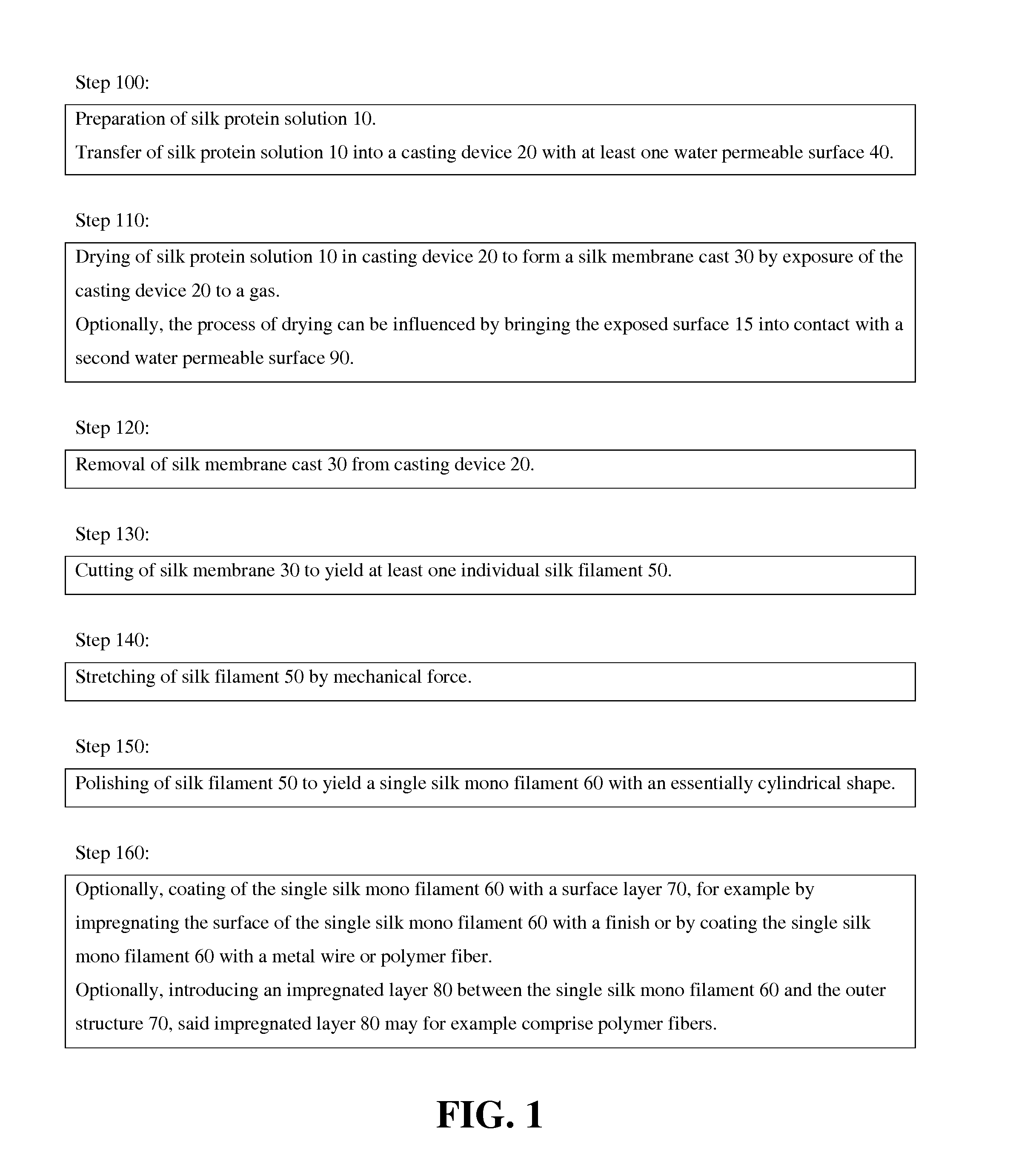

Apparatus and method for the manufacture of a silk mono-filament with a high tensile strength

InactiveUS20100095827A1Expedited drying processAvoid problemsStringed musical instrumentsMonocomponent fibroin artificial filamentUltimate tensile strengthMedical device

A method and an apparatus for the manufacture of a single silk mono-filament. The single silk mono filament has a tensile strength of above 40 Newtons. The single silk mono-filament has applications as a musical string or a medical device.

Owner:SPINTECH ENG

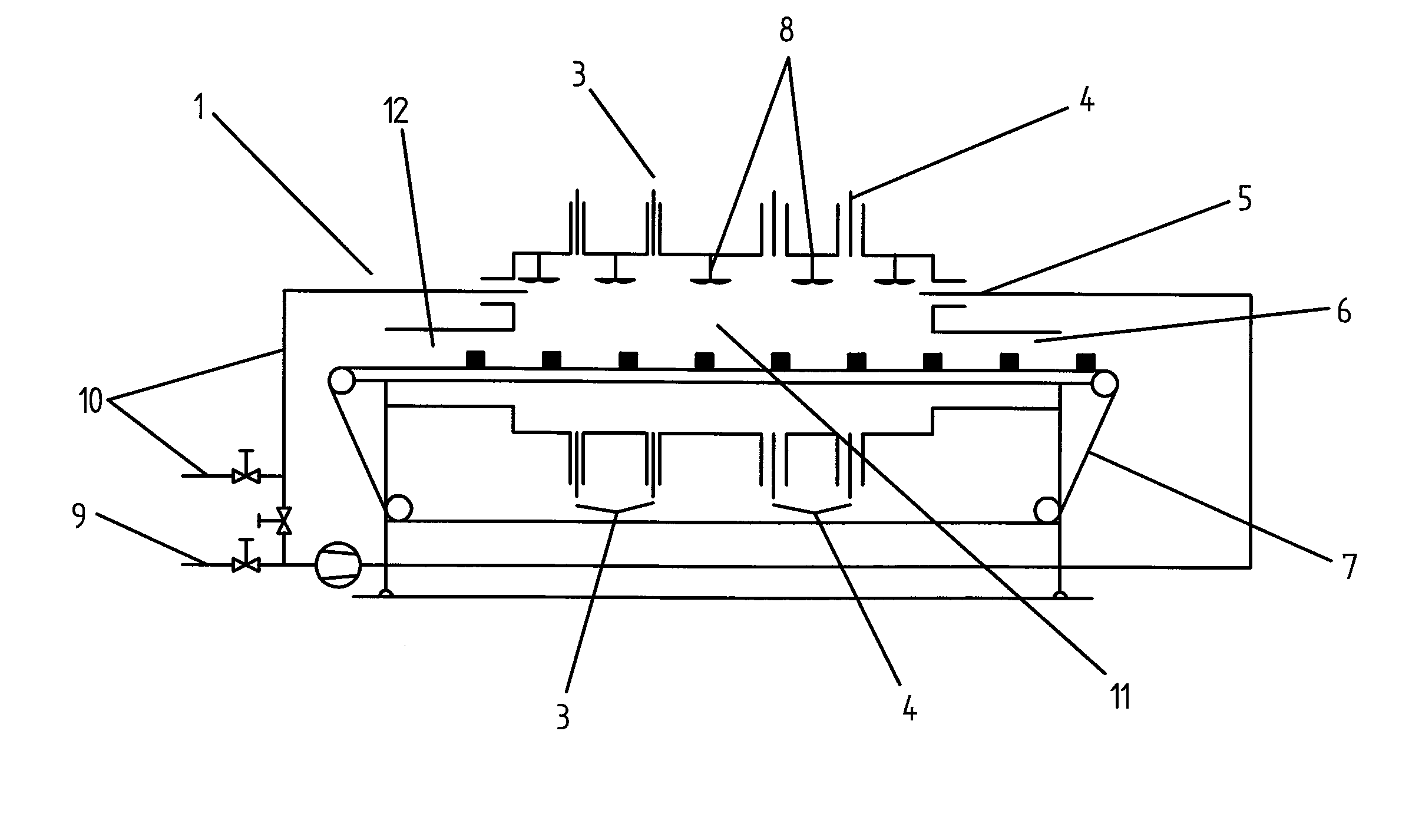

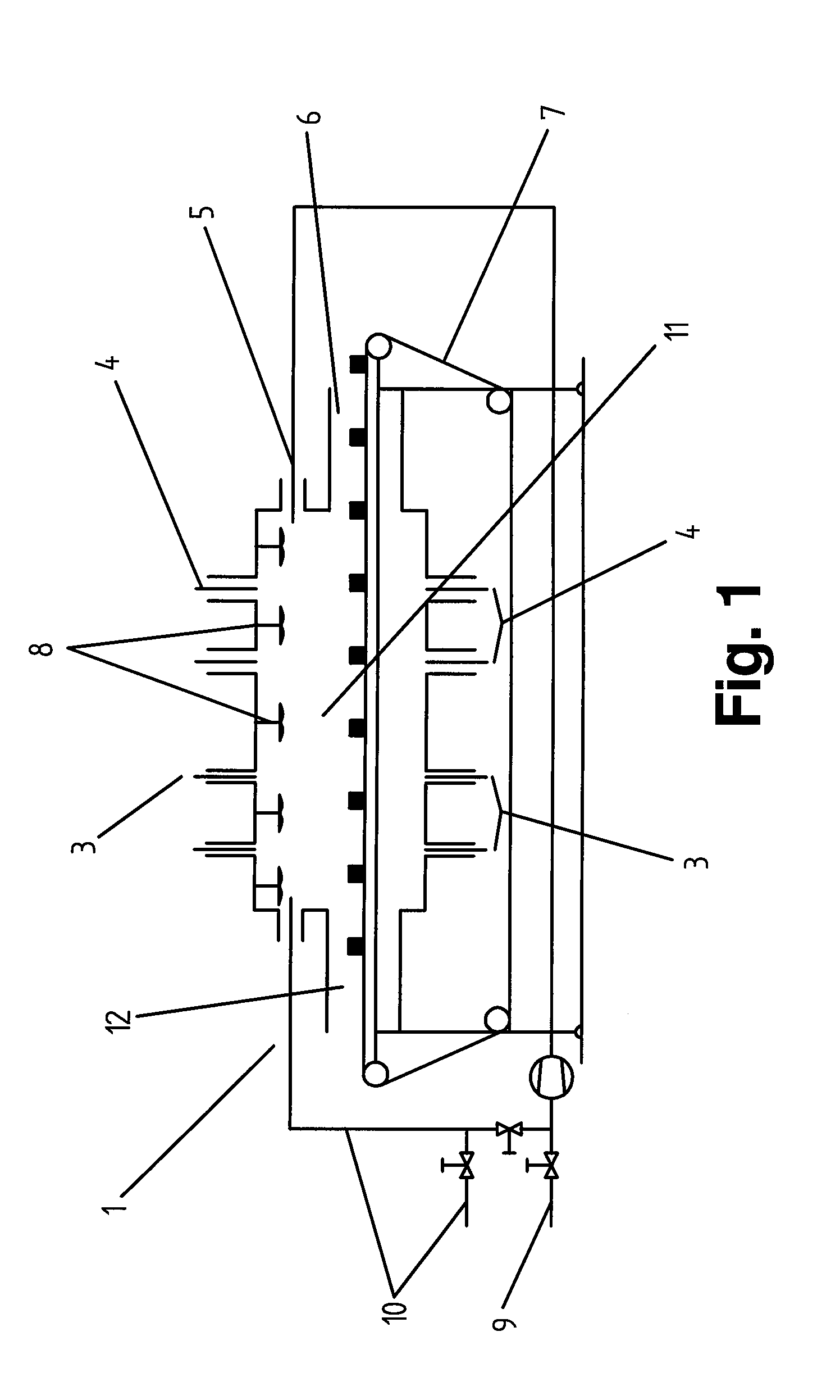

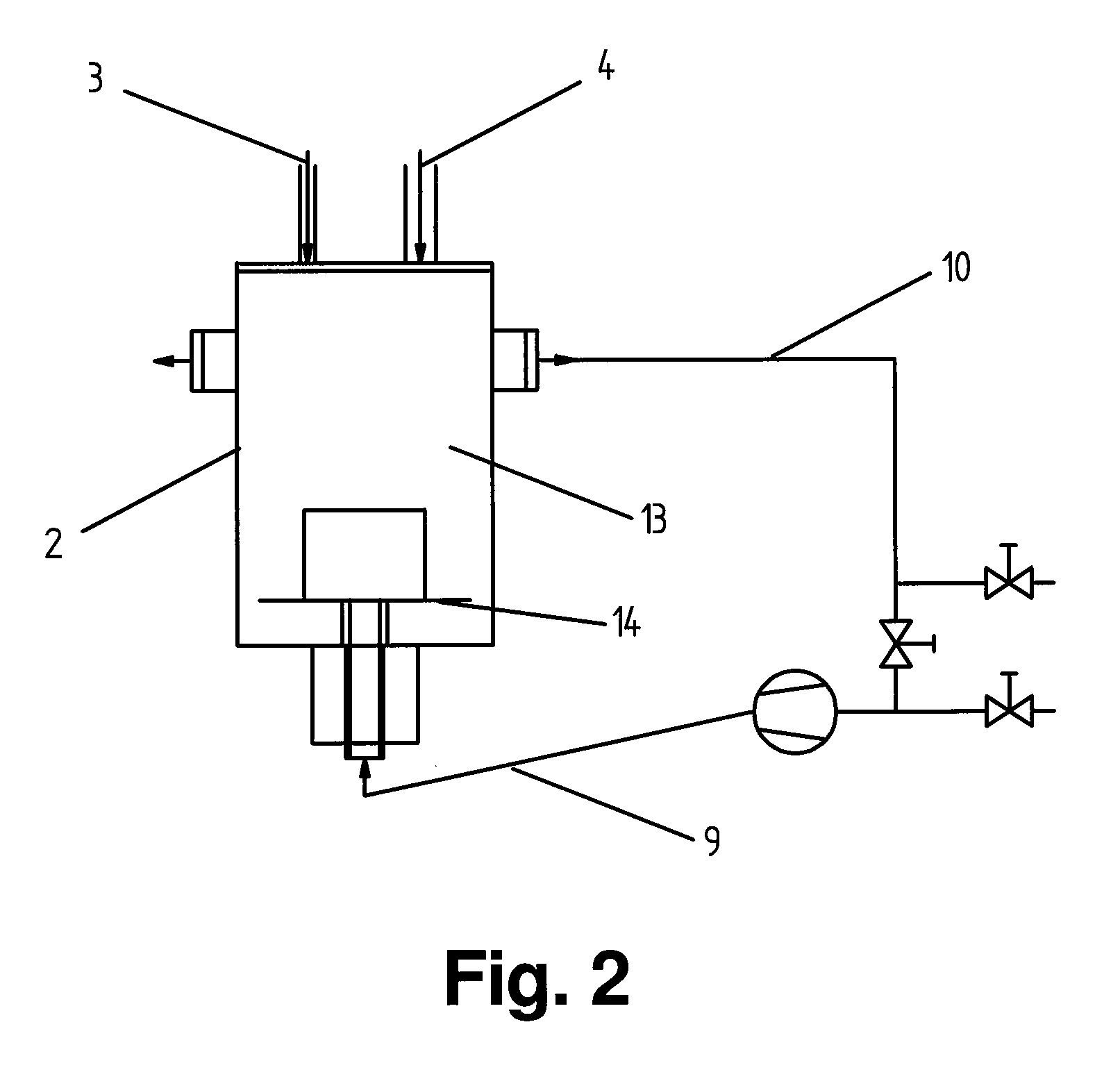

Holder product range and cleaning apparatus for cleaning breathing apparatuses

ActiveUS20150314340A1Improve overall utilizationEasy to processRespiratory masksSuction cleanersMedicineGas cylinder

Proposed is a product range for cleaning breathing apparatuses, including at least two holders, wherein the holders include:a first holder for cleaning breathing masks and breathing valves, including at least one mask holding device for positioning at least one breathing mask, additionally comprising at least one breathing valve holding device for positioning at least one breathing valve and least one pressurizing device with at least one pressure connection, wherein the pressure connection is connectable to the breathing valve and wherein the pressurizing device is set up to apply compressed air to the breathing valve during cleaning; andat least one second holder for cleaning carrying frameworks for pressurized gas cylinders for breather apparatuses, including at least one carrying framework holding device for positioning at least one carrying framework.The holders are dimensioned in such a manner that they can be moved into a cleaning apparatus for cleaning the breathing apparatuses so as to be exchangeable.

Owner:MEIKO MASCHENBAU

Microwave process for porous ceramic filters with passivation and catalyst coatings

InactiveUS20070098914A1Improve washcoating characteristicEasy to disassembleRadiation applicationsLayered productsMicrowavePorous ceramics

A method for base-coating a porous ceramic catalyst support includes coating the support with a passivation coating via vacuum infiltration, and subsequently exposing the support to a microwave field to dry the coating and form a polymerized film. The method further includes coating the support with a catalyst coating or washcoat, and subsequently exposing the support to a second microwave field, thereby removing water from the catalyst coating or washcoat.

Owner:CORNING INC

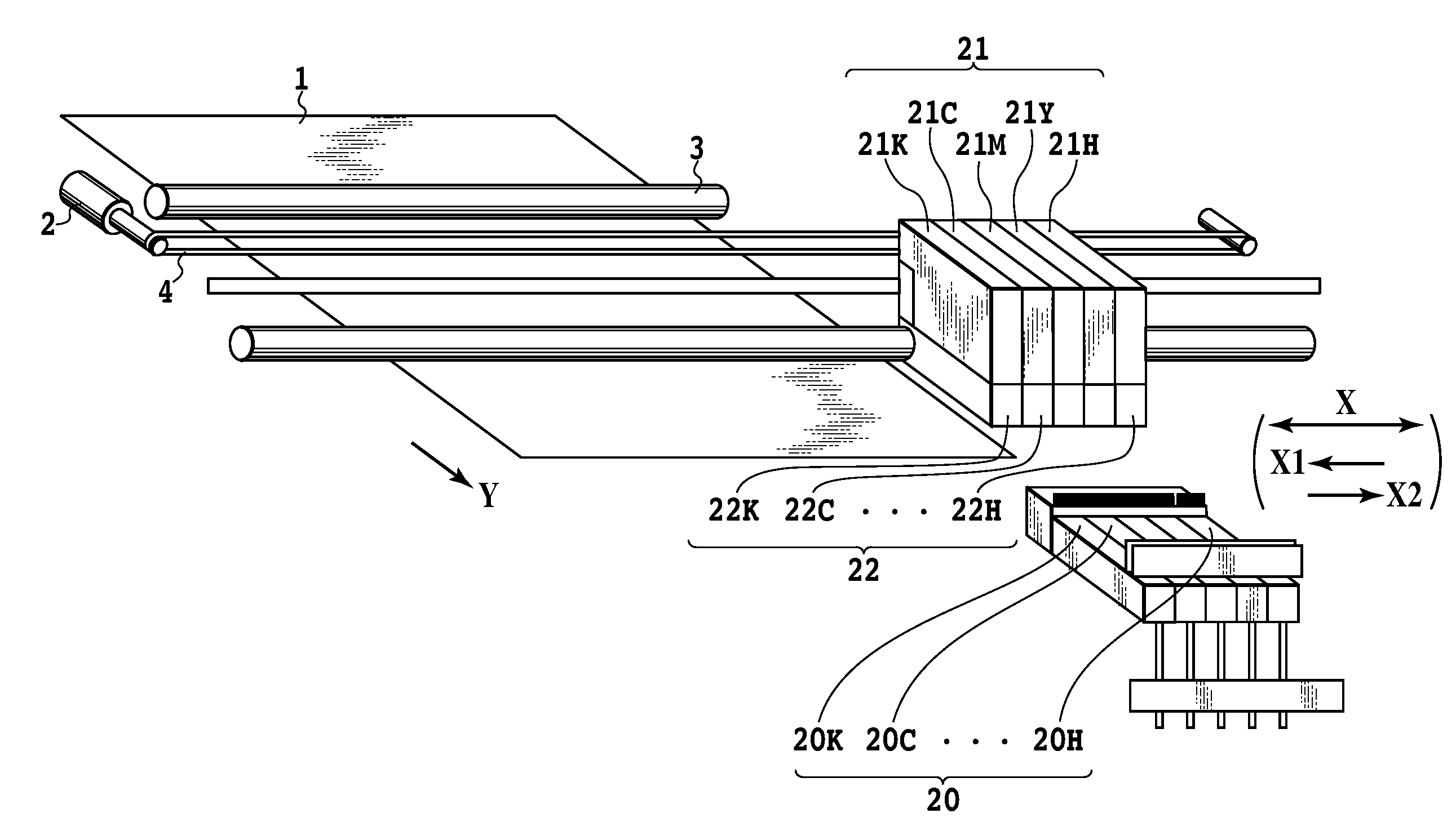

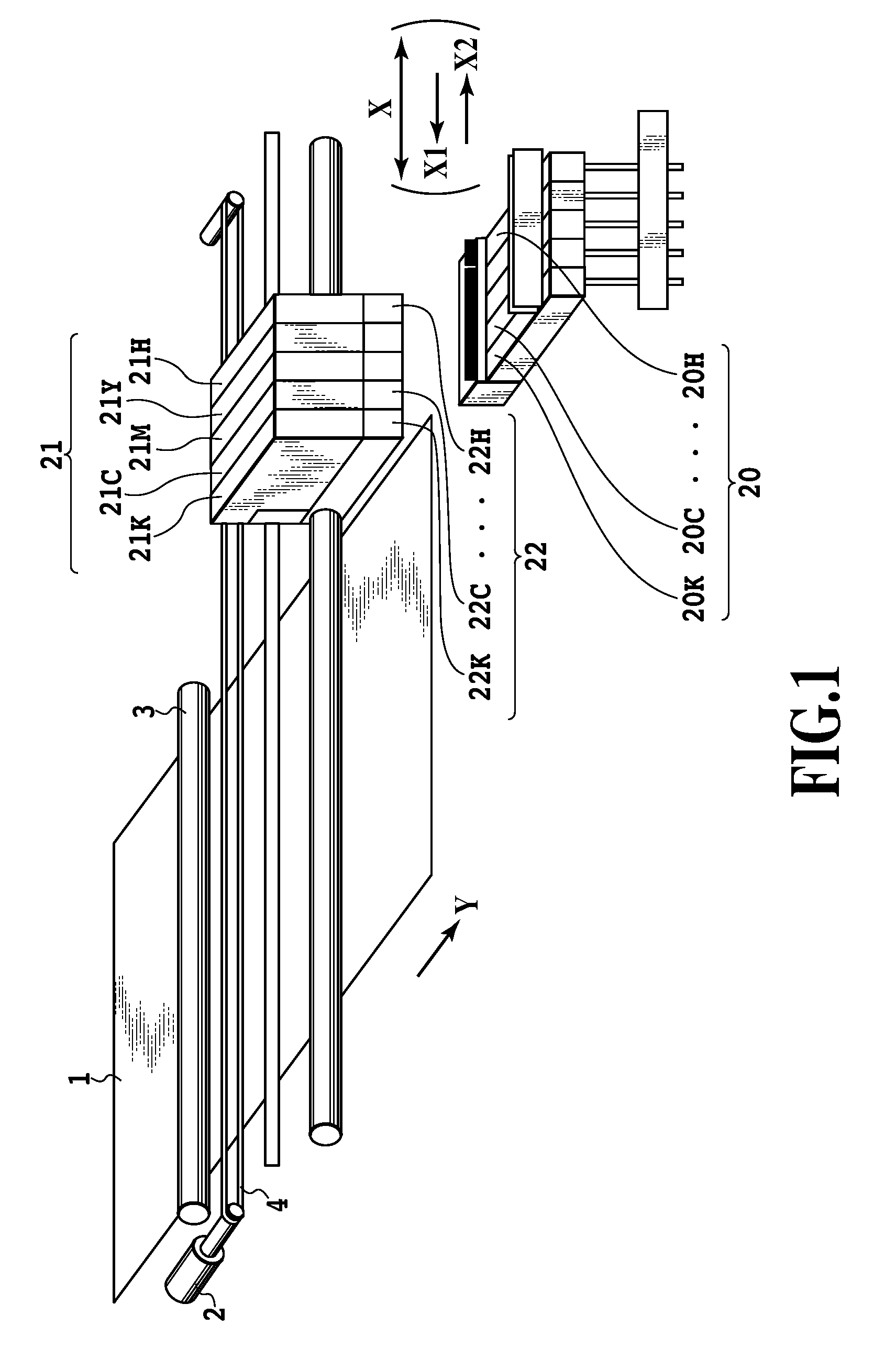

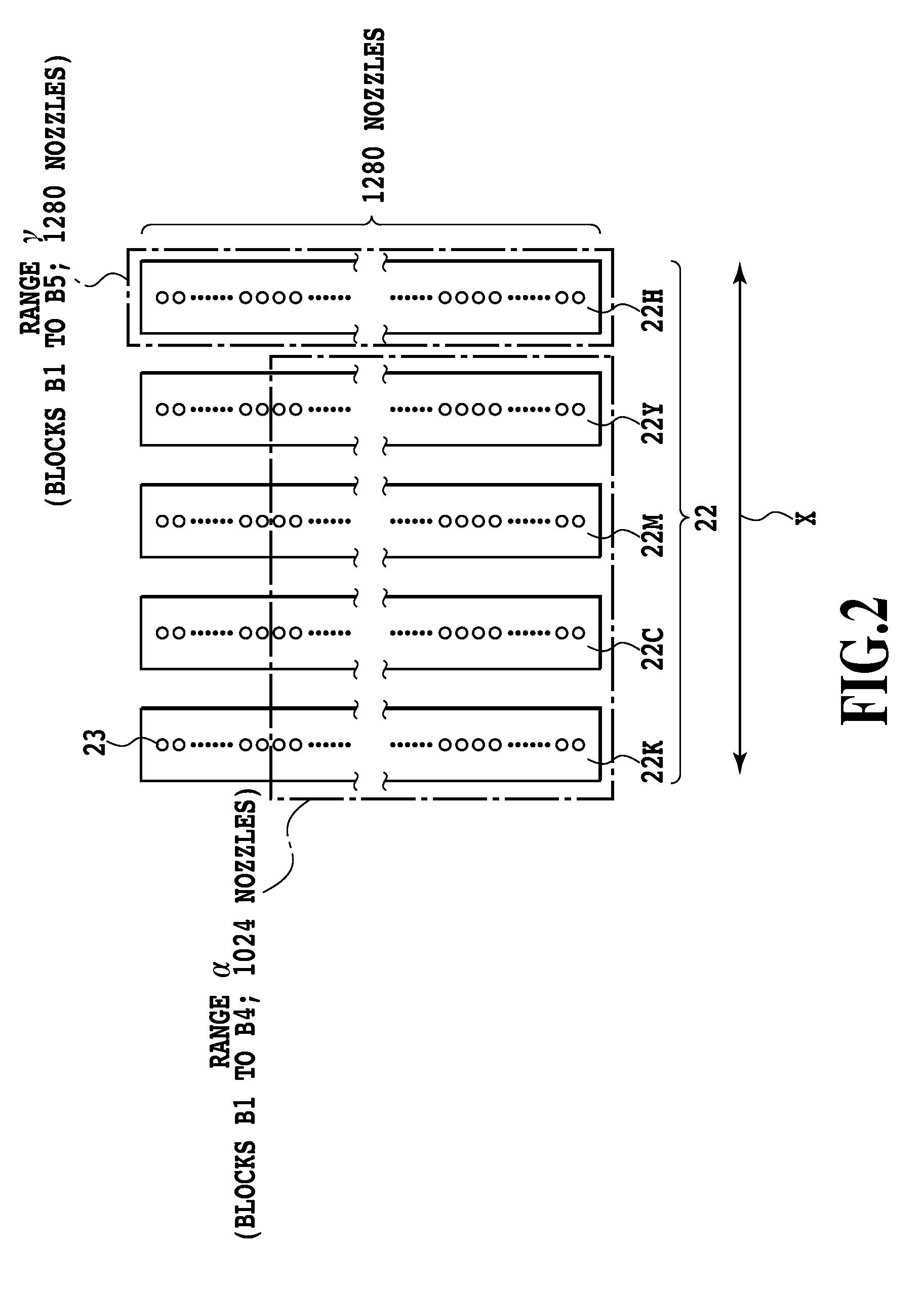

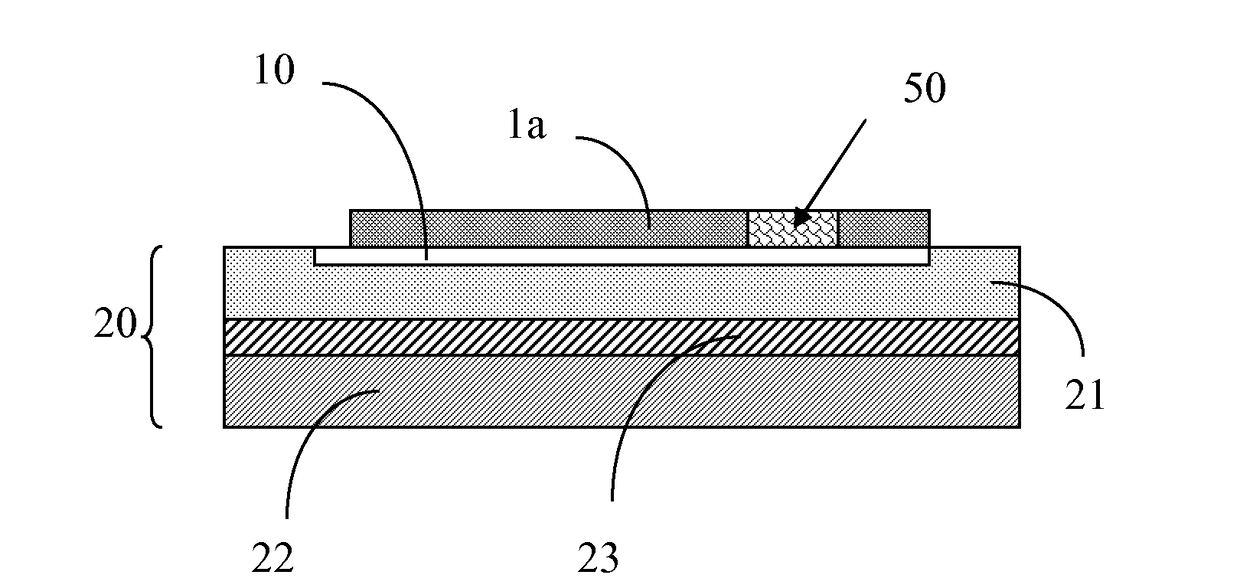

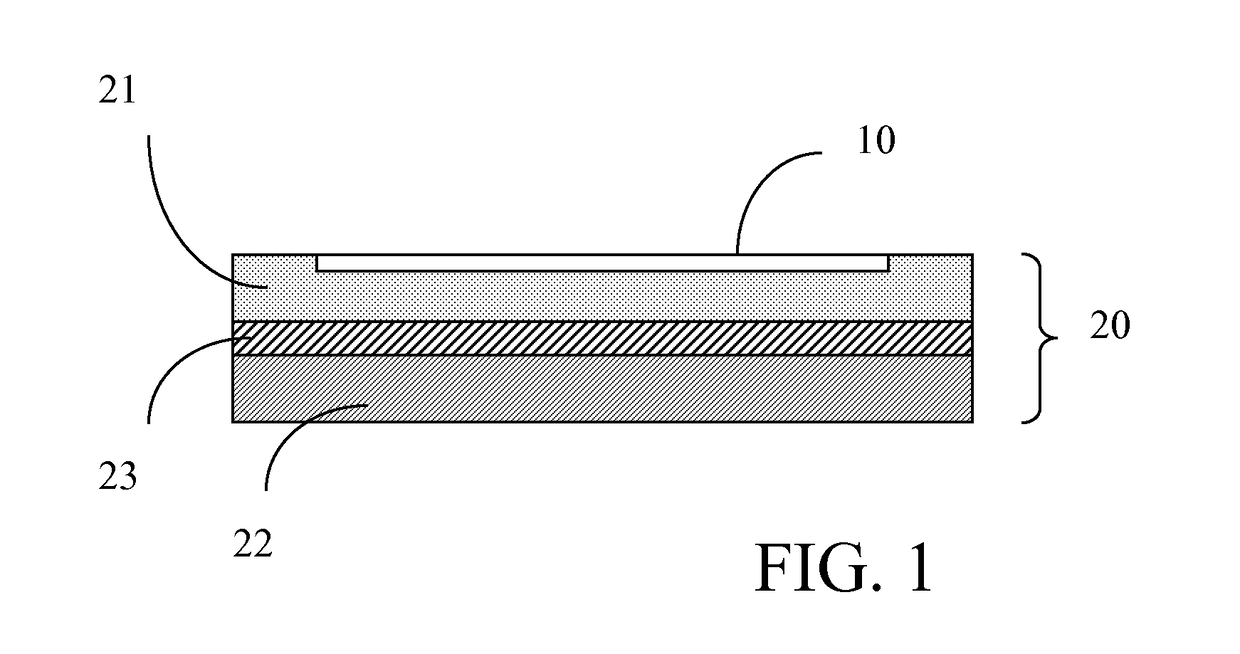

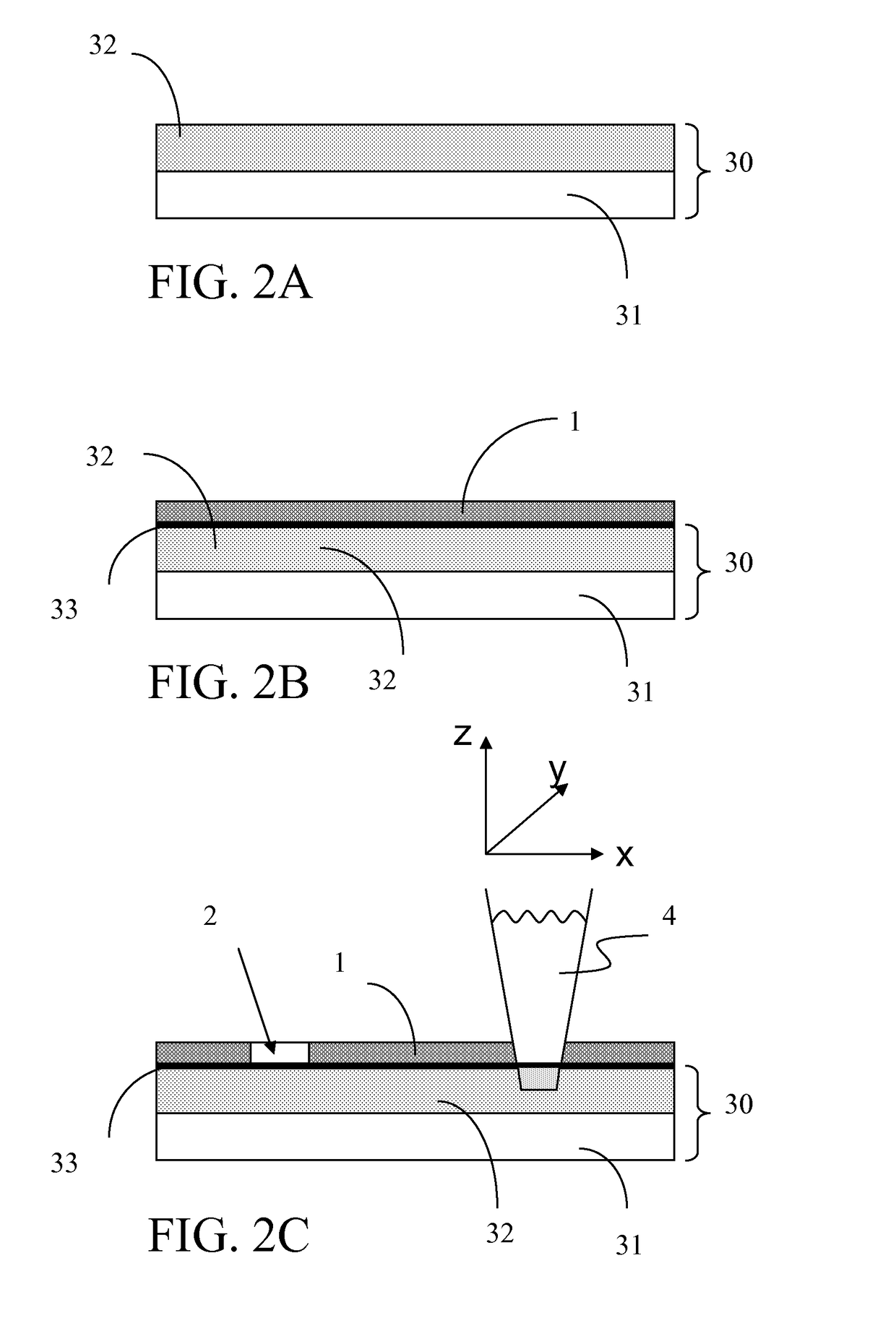

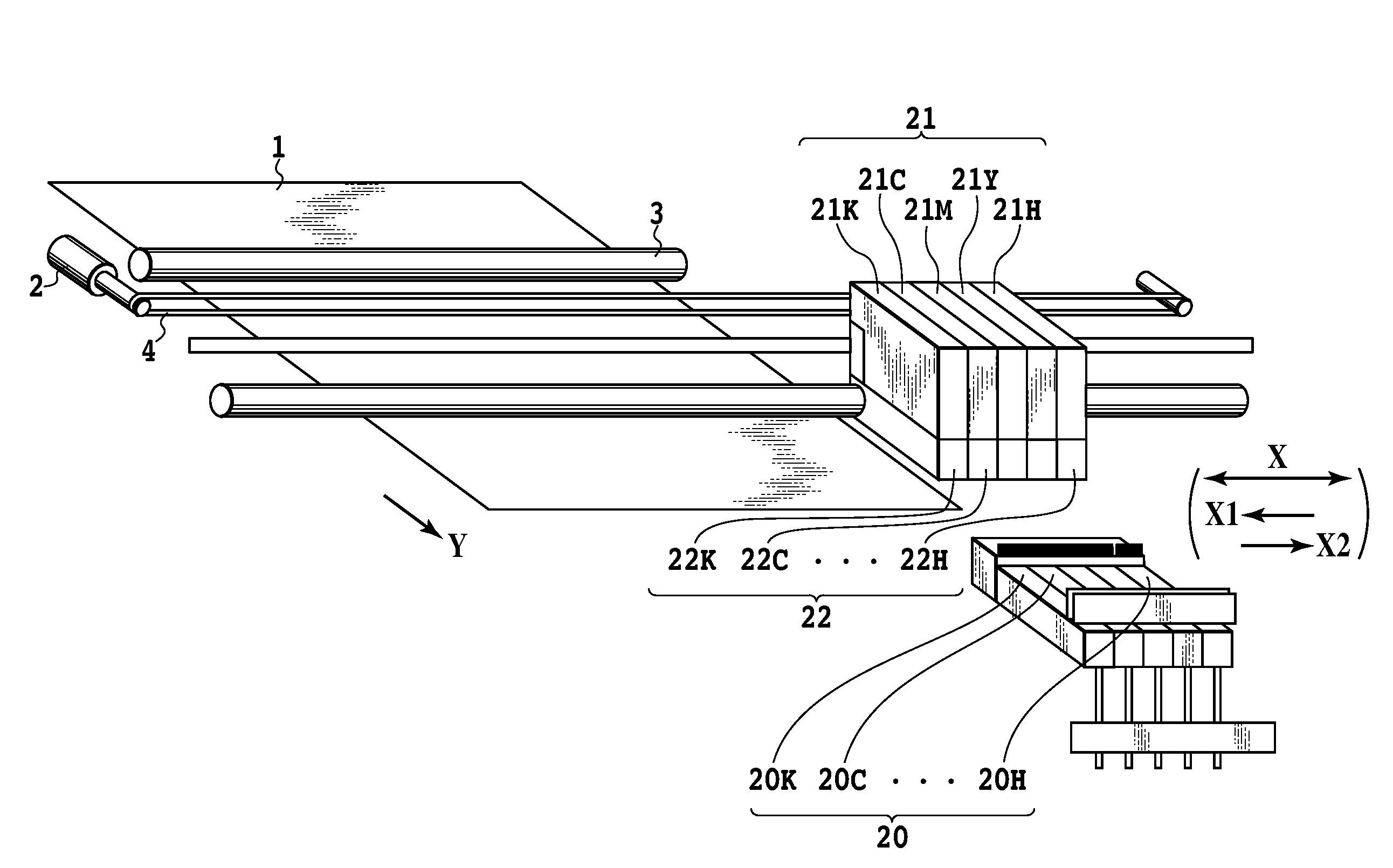

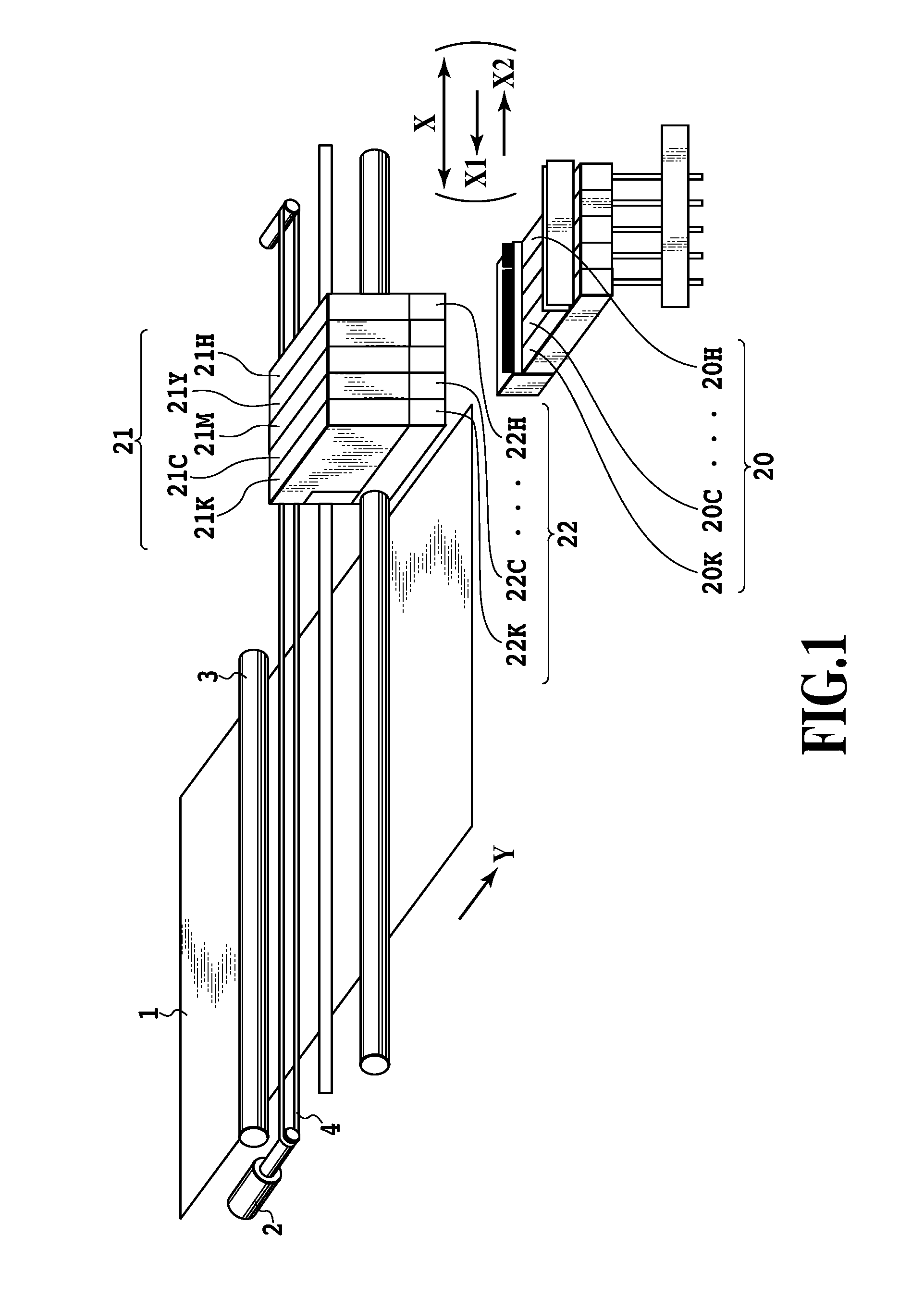

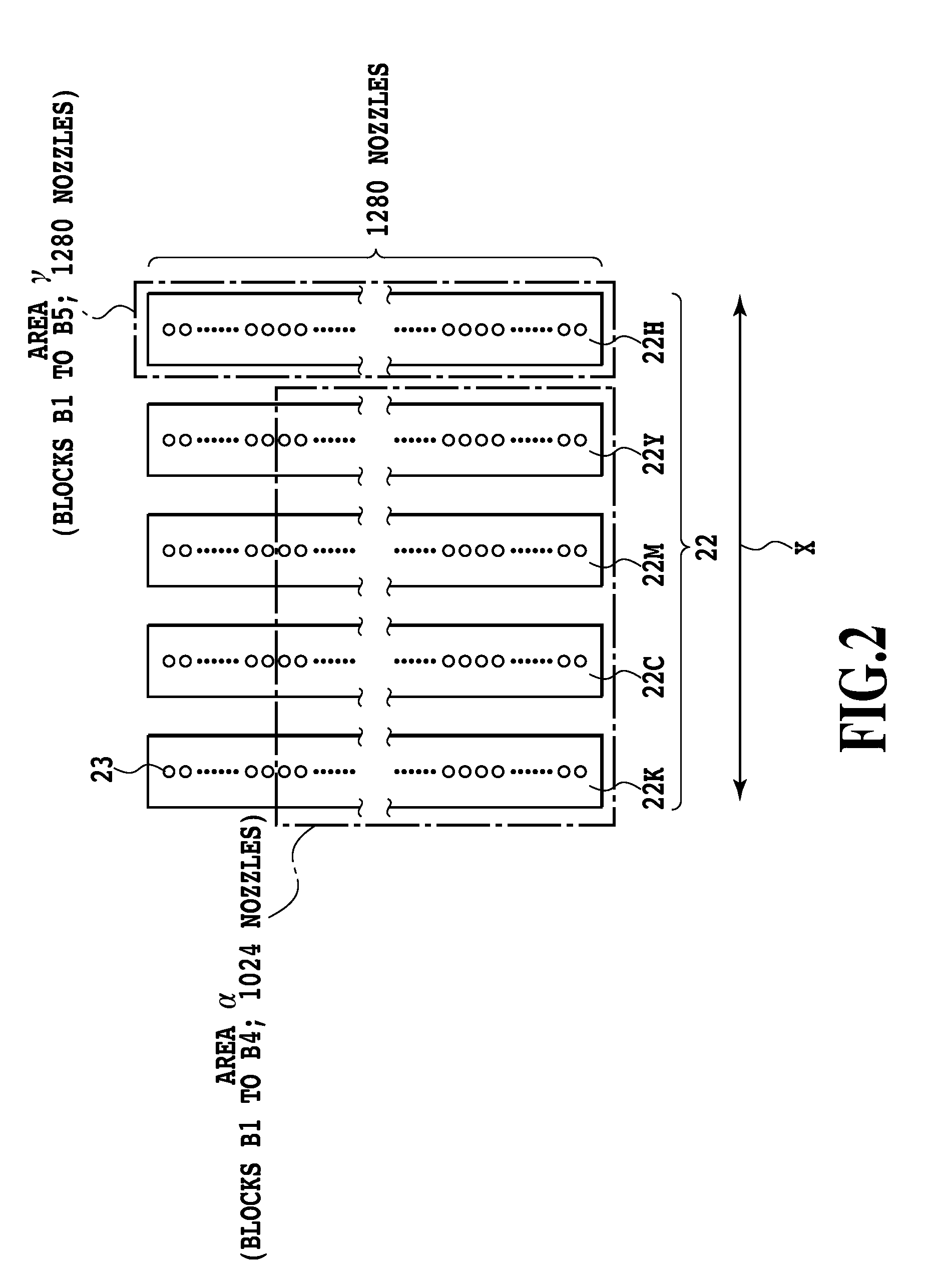

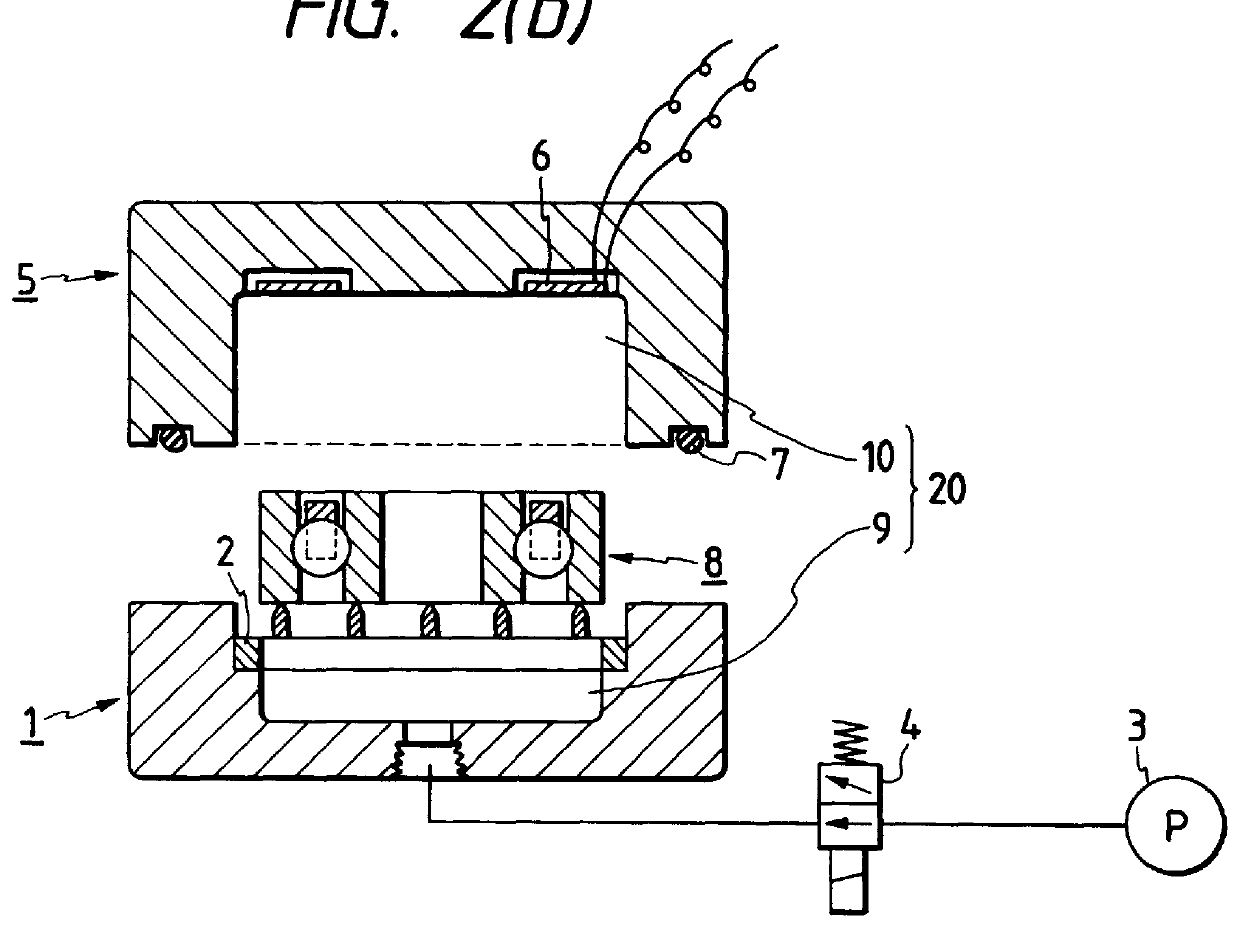

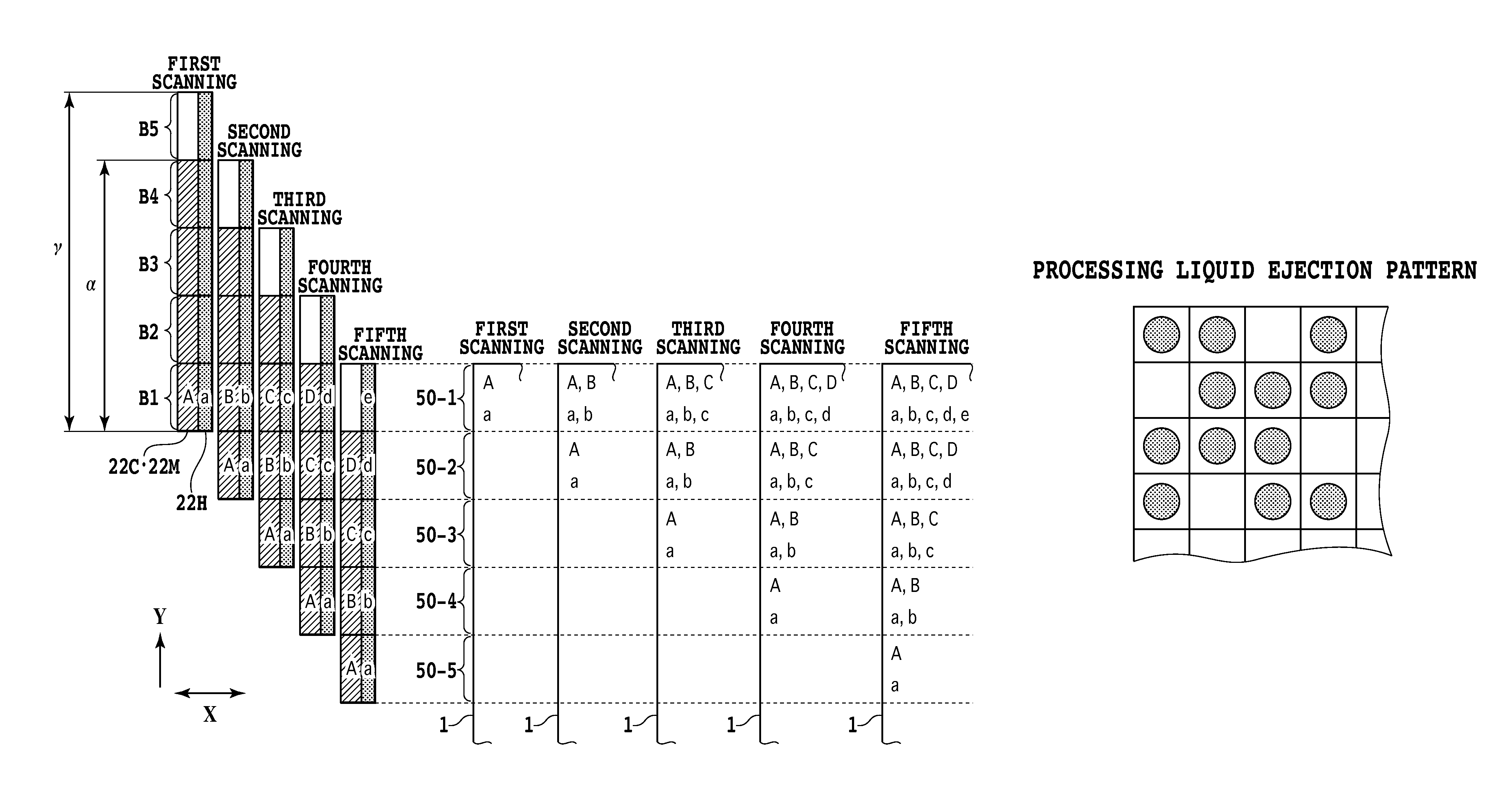

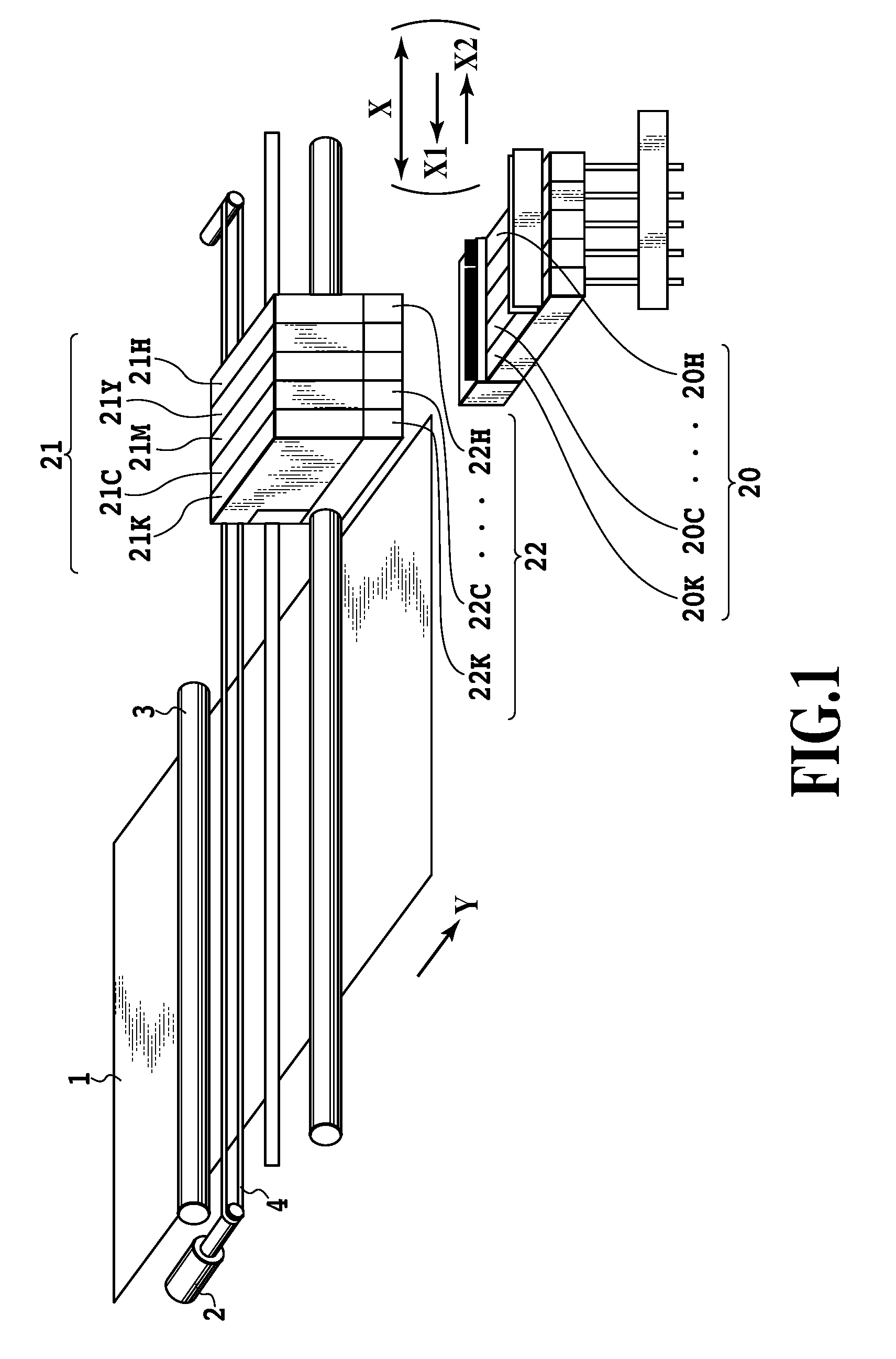

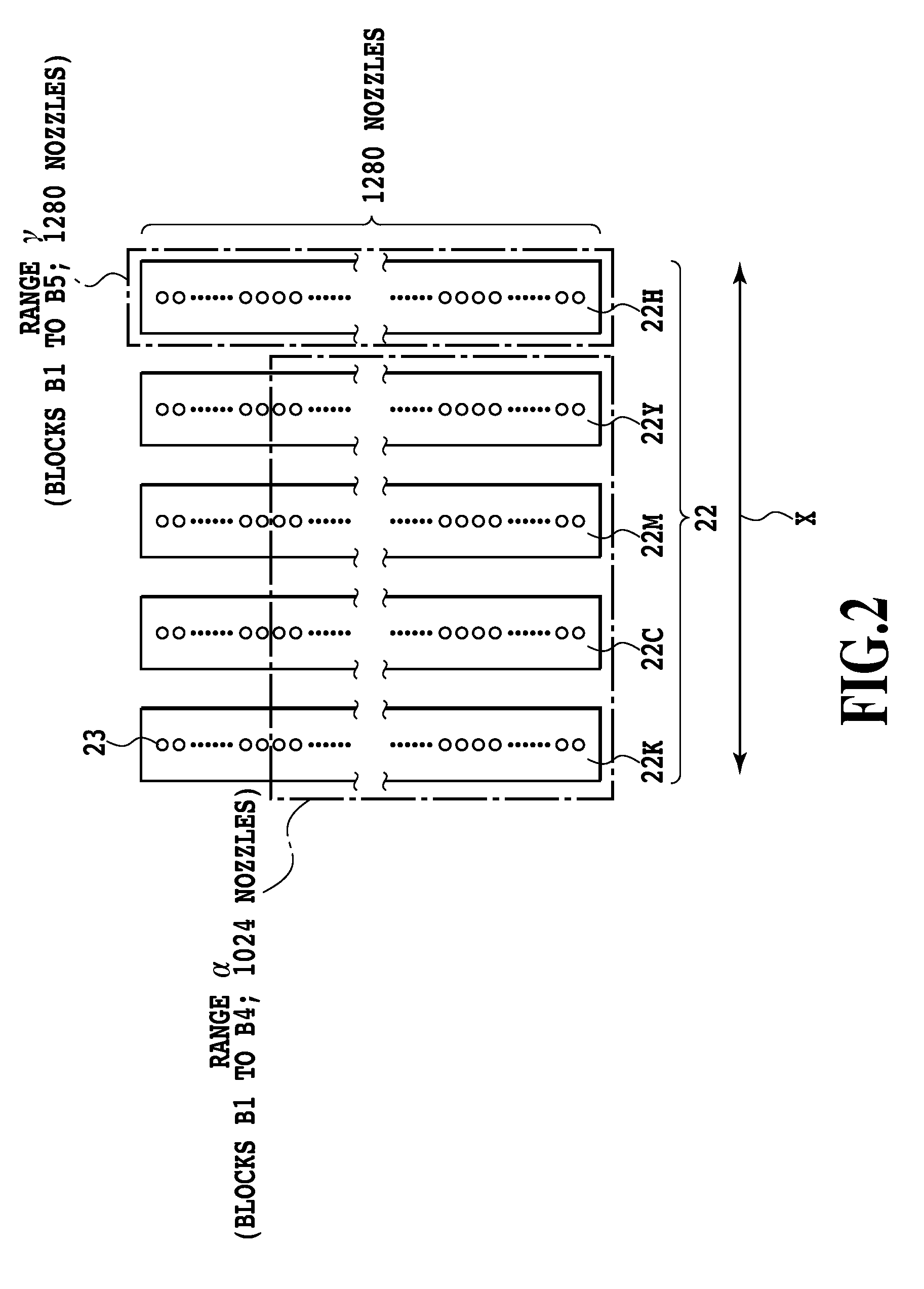

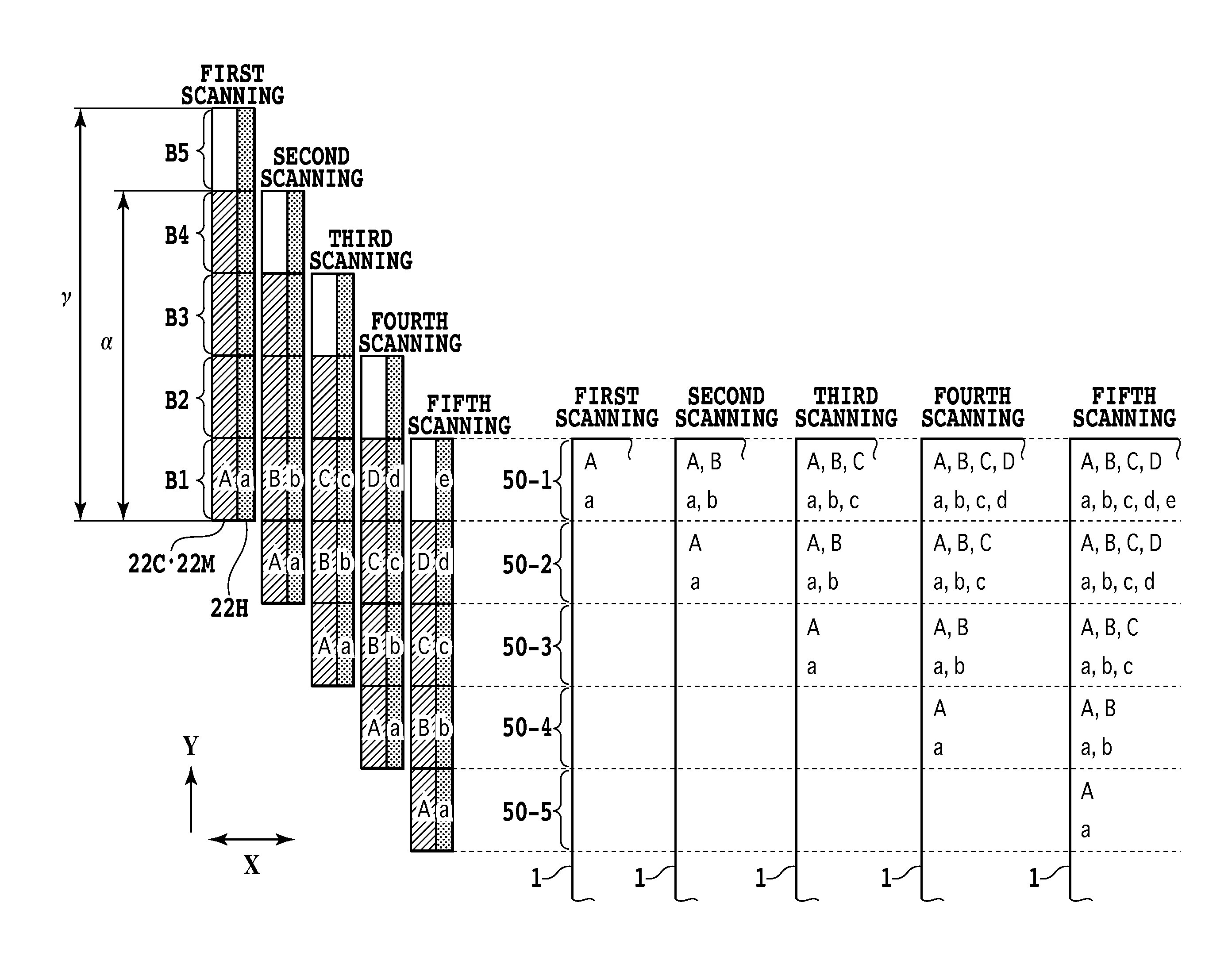

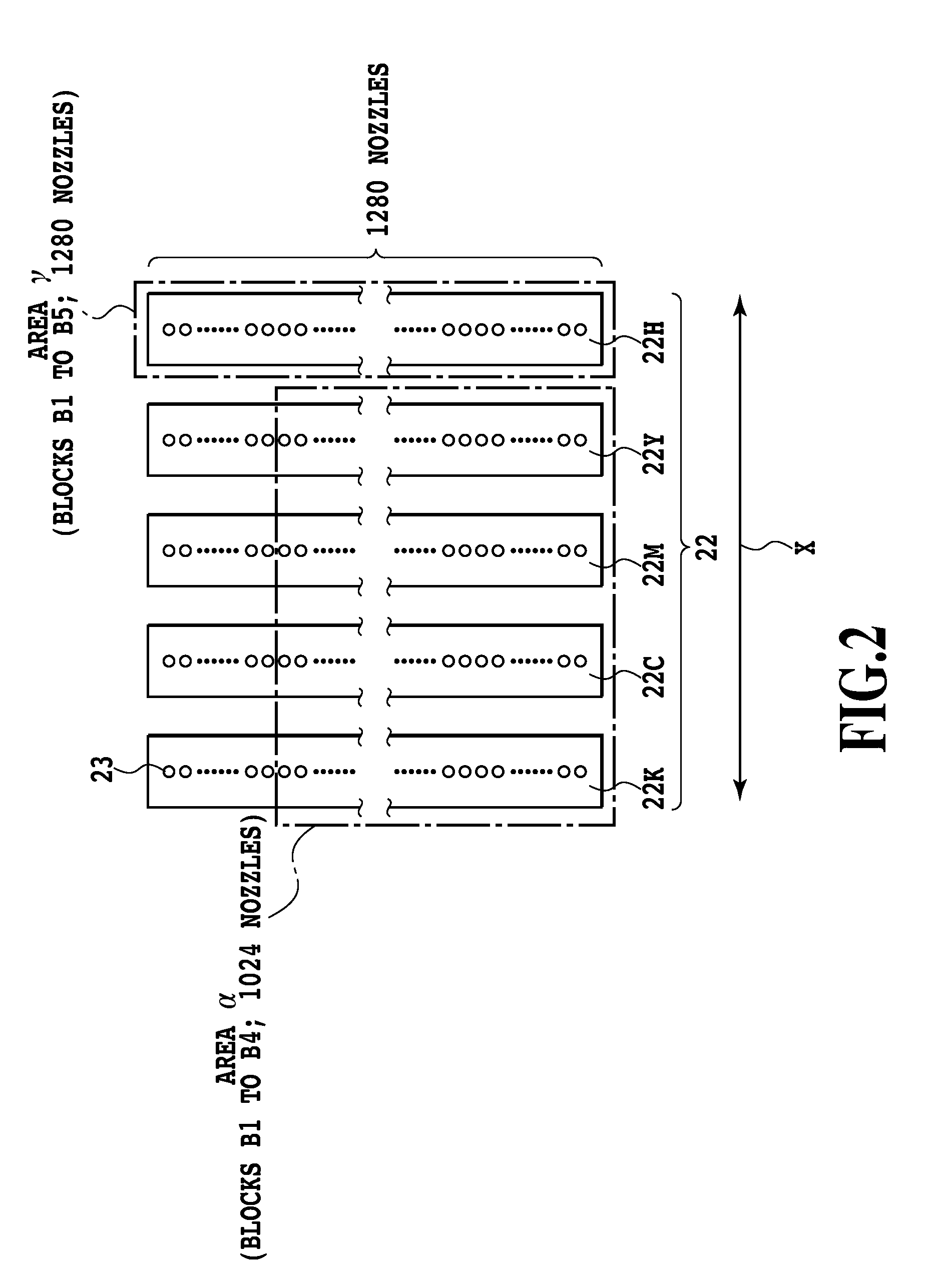

Ink jet printing apparatus, ink jet printing method, and data generating apparatus

InactiveUS20090073203A1Improve imaging effectSolution to short lifeMeasurement apparatus componentsOther printing apparatusWear resistanceElectrical and Electronics engineering

An ink jet printing apparatus, an ink jet printing method, and a data generating apparatus are provided in which an image performance such as an abrasion resistance can be improved and a printing head can have a longer life by ejecting processing liquid at an appropriate time. The processing liquid is ejected, to a predetermined area on a printing medium in which the formation of a image by ink is completed, from a printing head in two or more scannings in five scannings of the printing heads.

Owner:CANON KK

Method for the electrical passivation of electrode arrays and/or conductive paths in general, and a method for producing stretchable electrode arrays and/or stretchable conductive paths in general

ActiveUS20170086301A1Reduce riskLow costSemiconductor/solid-state device detailsSolid-state devicesMicro nanoConductive paste

A method produces a conductive paste comprising 15-20% by weight of PDMS and 80-85% by weight of metallic micro-nano particles, wherein the conductive paste is obtained by repeated addition of singular doses of PDMS to a heptane diluted PDMS low viscosity liquid containing the metallic micro-nano particles, wherein the heptane fraction is allowed to evaporate after addition of each of the singular doses of PDMS. A method forms a conductive path on a support layer, wherein the conductive path is encapsulated by an encapsulation layer comprising at least one via through which at least one portion of the conductive path is exposed, the method comprising filling the at least one via with the conductive paste.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Ink jet printing apparatus, ink jet printing method, data generating apparatus, computer program, and ink jet printing system

InactiveUS20090073204A1Improve imaging effectSolution to short lifeOther printing apparatusEngineeringWear resistance

The present invention provides an ink jet printing apparatus, an ink jet printing method, a data generation apparatus, a computer program, and an ink jet printing system by which a timing for ejecting a processing liquid can be changed to improve image performance of a printed image such as abrasion resistance, to provide the printing head with a longer life, and to improve a throughput. The processing liquid is ejected to a predetermined area on a printing medium, for which a formation of an image by ink is completed, in two or more scannings among five scannings of the printing head. When an amount of ejection data for ejecting the processing liquid in the fifth scanning for ejecting only the processing liquid is equal to or lower than a predetermined amount, the fifth scanning is not carried out.

Owner:CANON KK

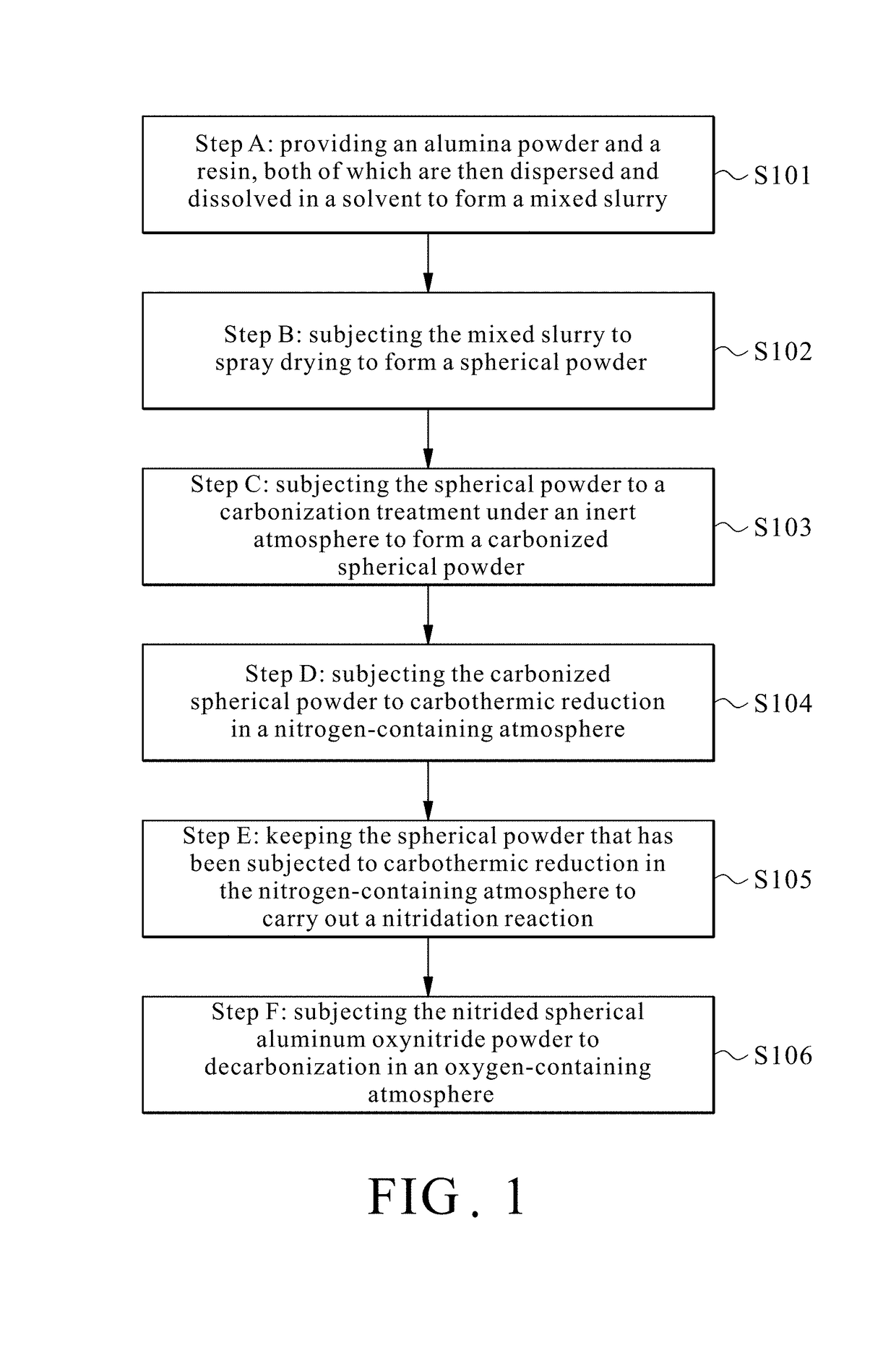

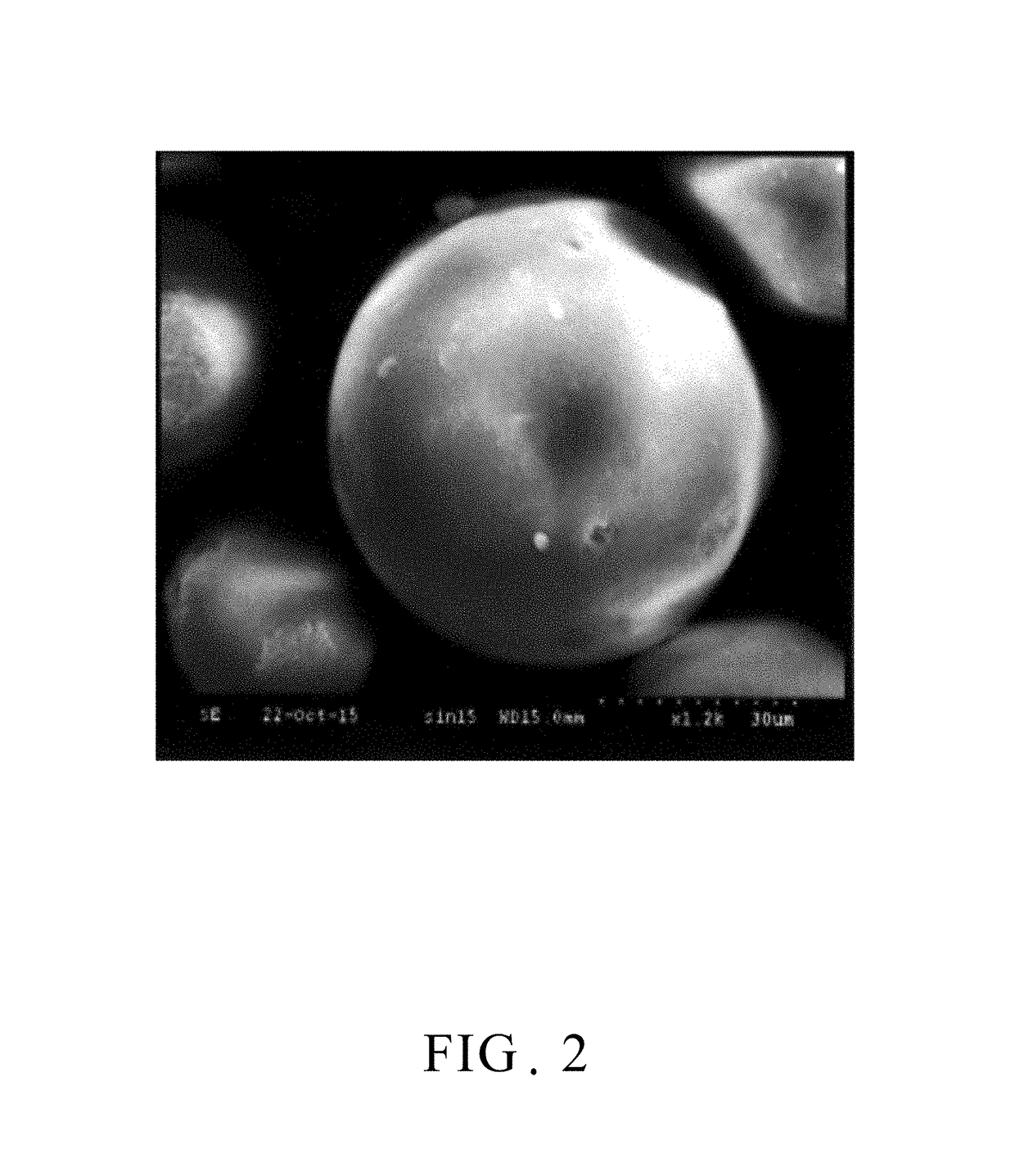

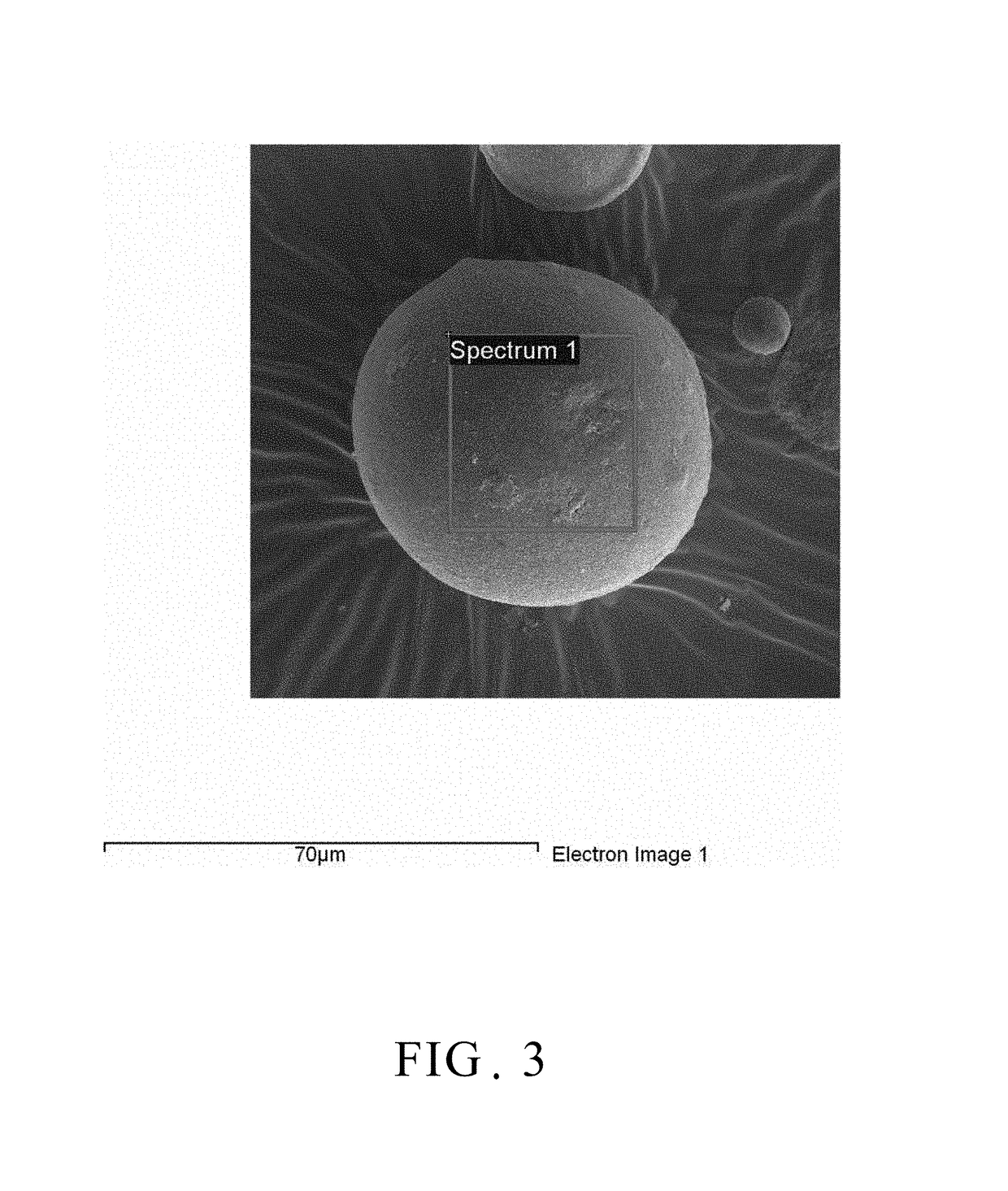

Method for preparing spherical aluminum oxynitride powder

ActiveUS10144645B1Maintain good propertiesRapid productionAluminium oxynitridesCarbonizationNitrogen

A method for preparing spherical aluminum oxynitride powder, comprising the steps of (A) providing an alumina powder and a resin, both of which are then dispersed and dissolved in a solvent to form a mixed slurry; (B) subjecting the mixed slurry to spray drying to form a spherical powder; (C) subjecting the spherical powder to a carbonization treatment under an inert atmosphere to form a carbonized spherical powder; (D) subjecting the carbonized spherical powder to carbothermic reduction in a nitrogen-containing atmosphere at a temperature of 1450° C. to 1550° C.; (E) keeping the spherical powder that has been subjected to carbothermic reduction in the nitrogen-containing atmosphere to carry out a nitridation reaction at a temperature of 1700° C. to 1730° C., forming a nitrided spherical aluminum oxynitride powder; (F) subjecting the nitrided spherical aluminum oxynitride powder to decarbonization in an oxygen-containing atmosphere to form the spherical aluminum oxynitride powder.

Owner:NAT CHUNG SHAN INST SCI & TECH

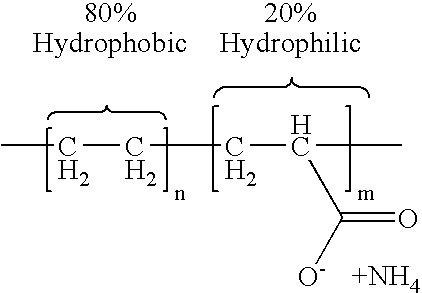

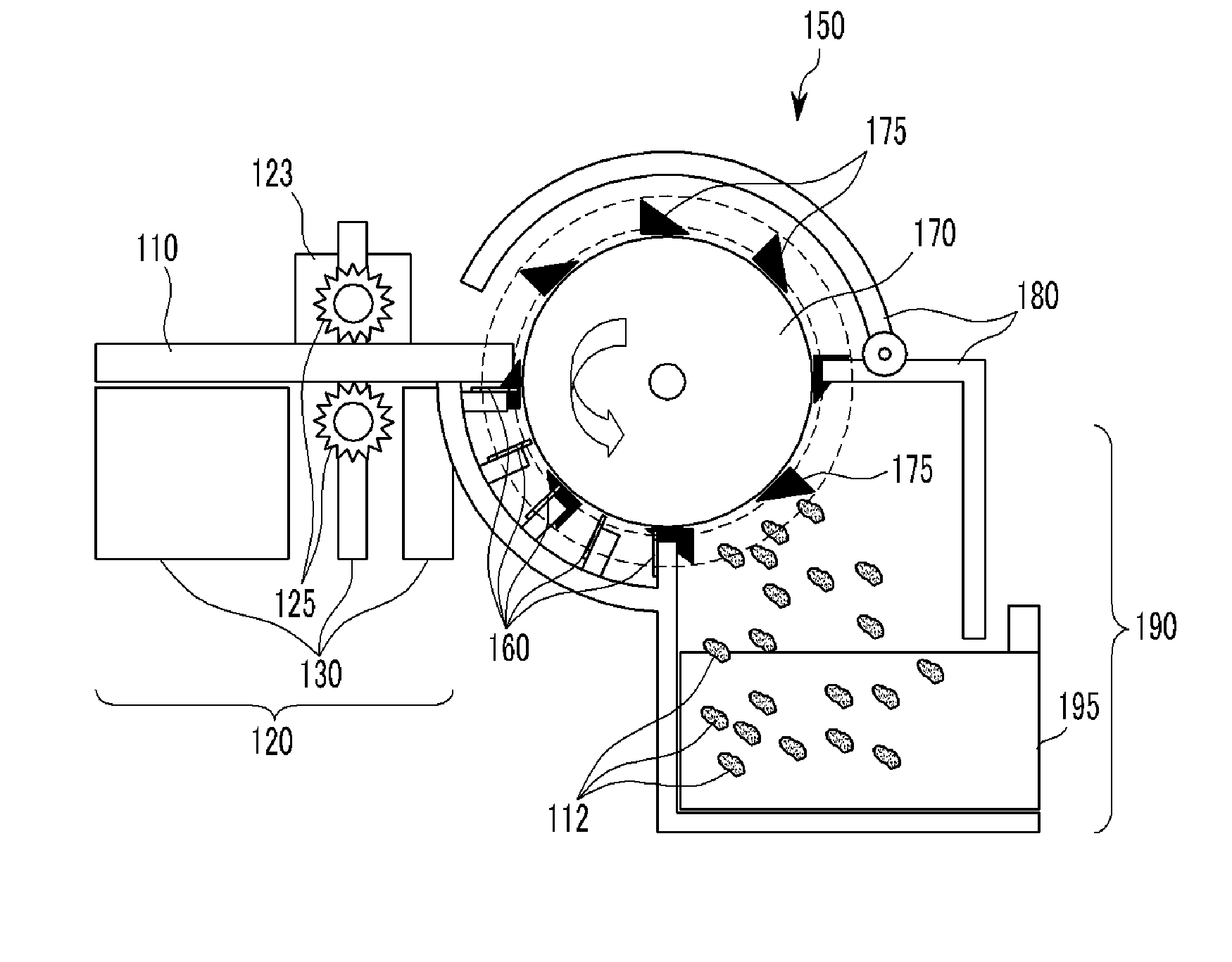

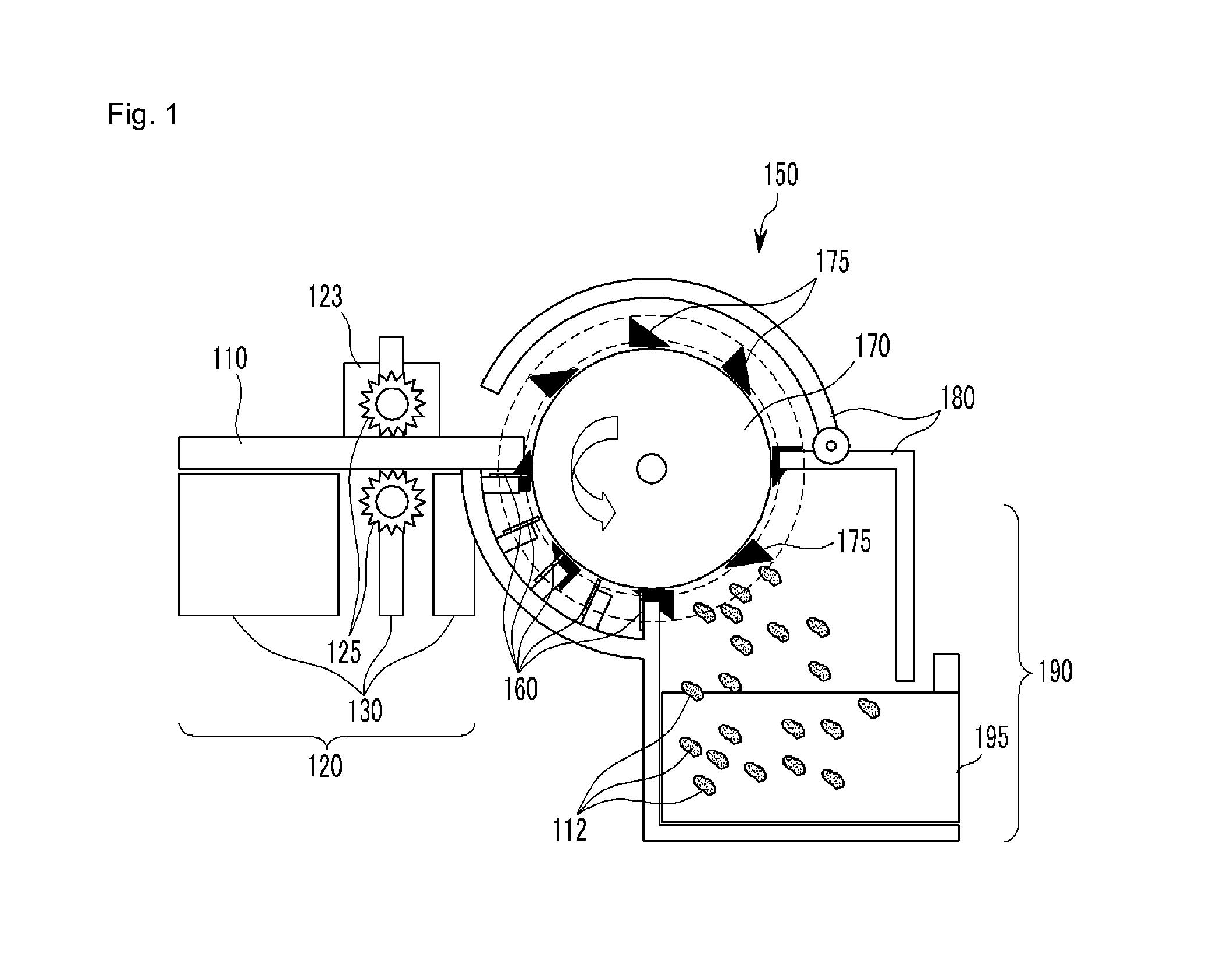

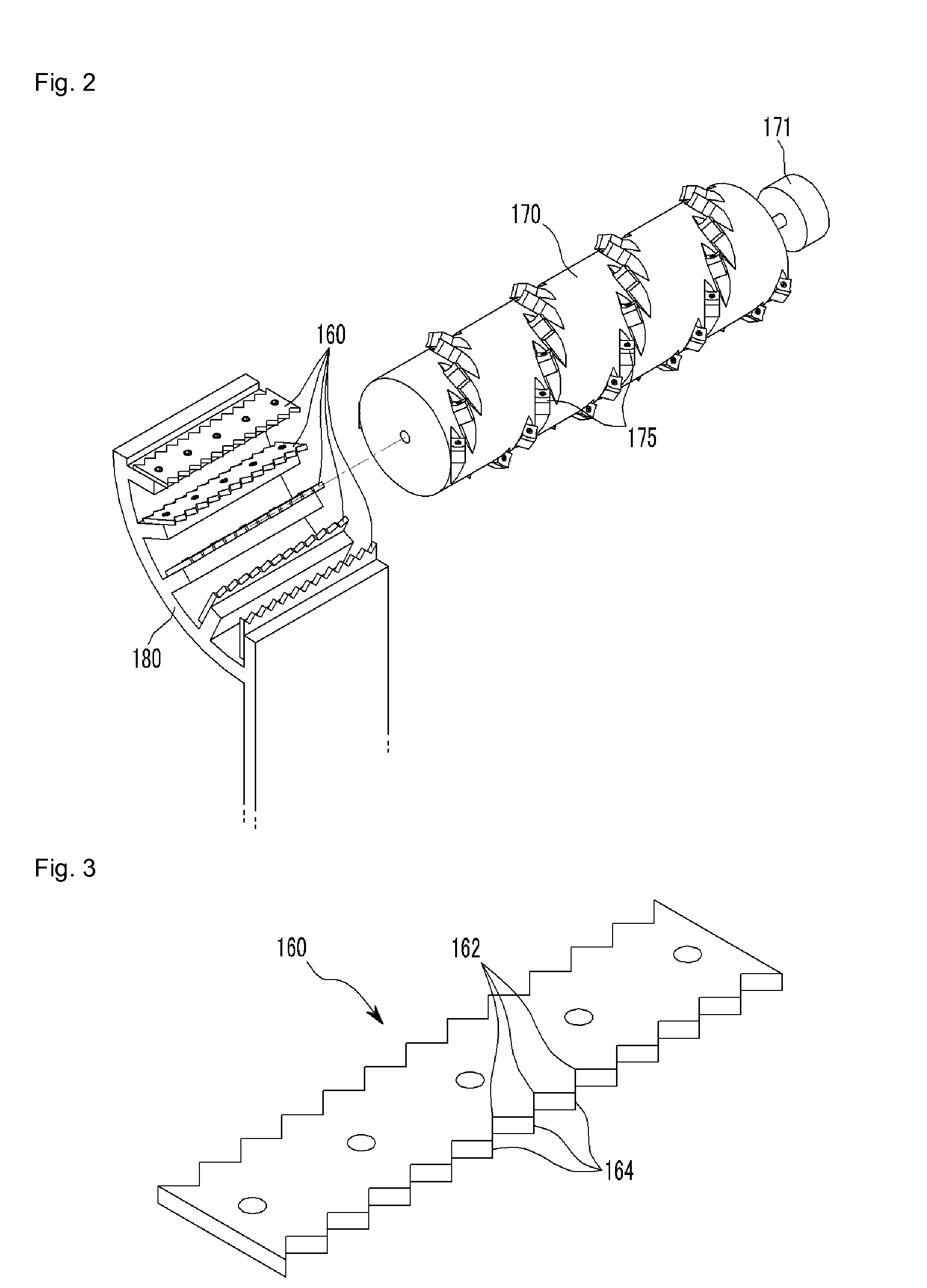

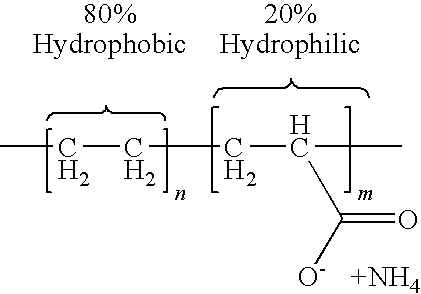

Shredder for super absorbent polymer and preparation method of super absorbent polymer using the same

ActiveUS20140339344A1Efficient crushingImprove propertiesSolid waste disposalGrain treatmentsAcute angleSuper absorbent

The present invention is to provide a shredder for super absorbent polymer that comprises: an inlet portion for feeding a plate-shaped super absorbent polymer; a pulverizing portion for pulverizing the super absorbent polymer fed through the inlet portion; and an outlet portion for discharging the pulverized super absorbent polymer from the pulverizing portion. The pulverizing portion comprises: a rotary drum to which a plurality of rotary blades are attached; at least fixed blade for pulverizing the super absorbent polymer in cooperation with the plural rotary blades; and a housing for holding the rotary drum and the at least one fixed blade. Each rotary blade has a shape of polygon with at least one vertex having an acute angle of at most 45°.The present invention is also to provide a preparation method for super absorbent polymer using the shredder for super absorbent polymer.

Owner:LG CHEM LTD

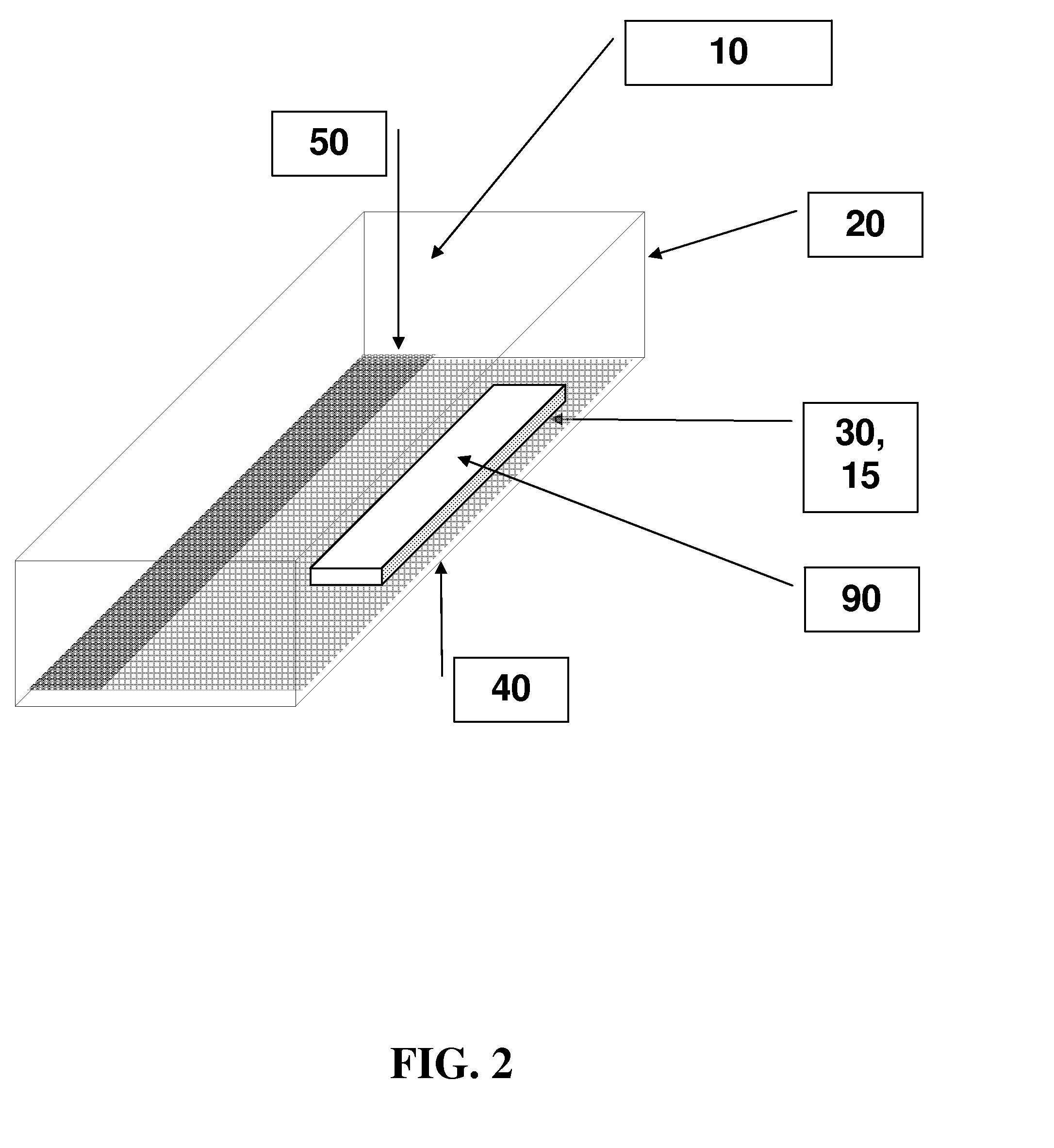

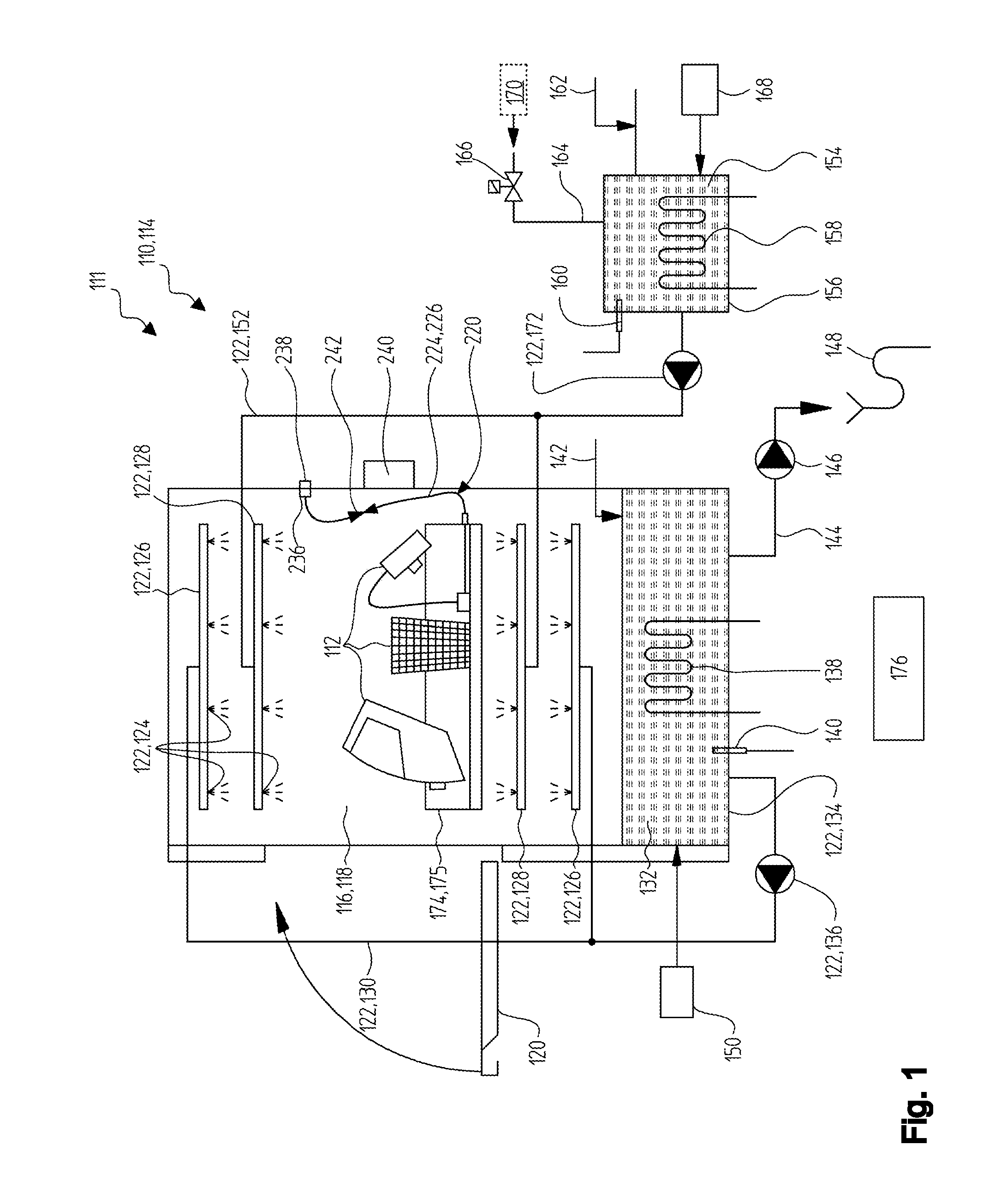

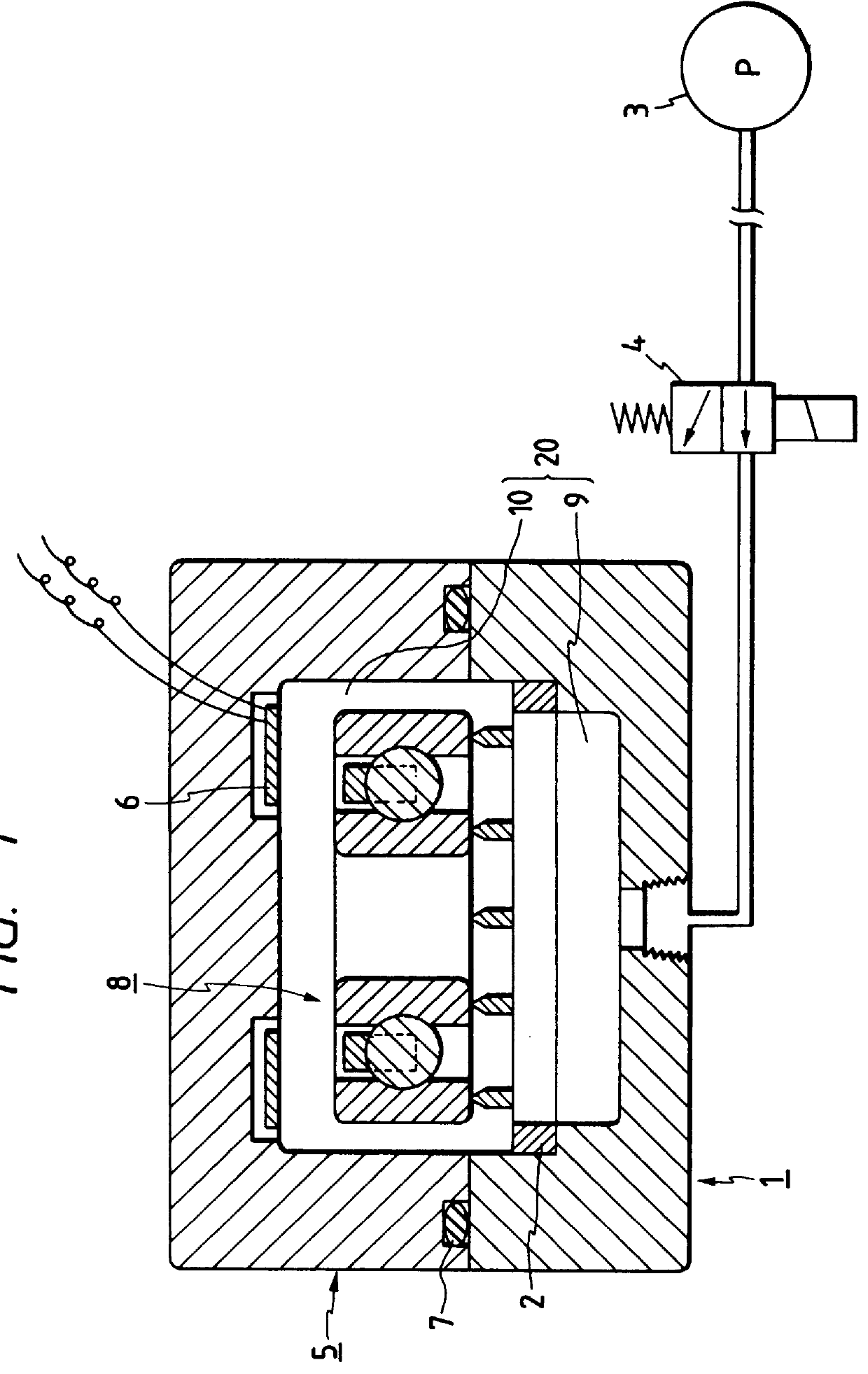

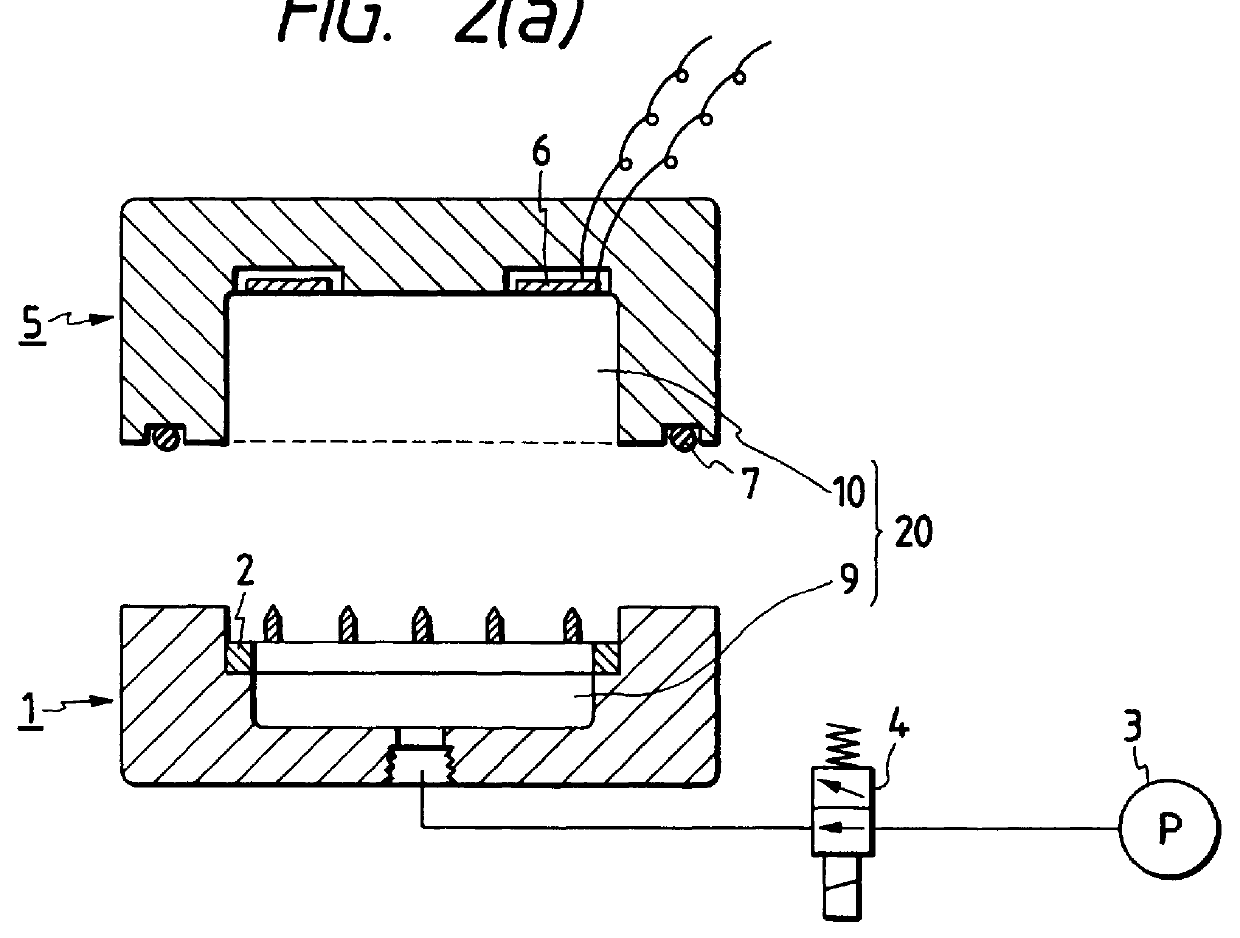

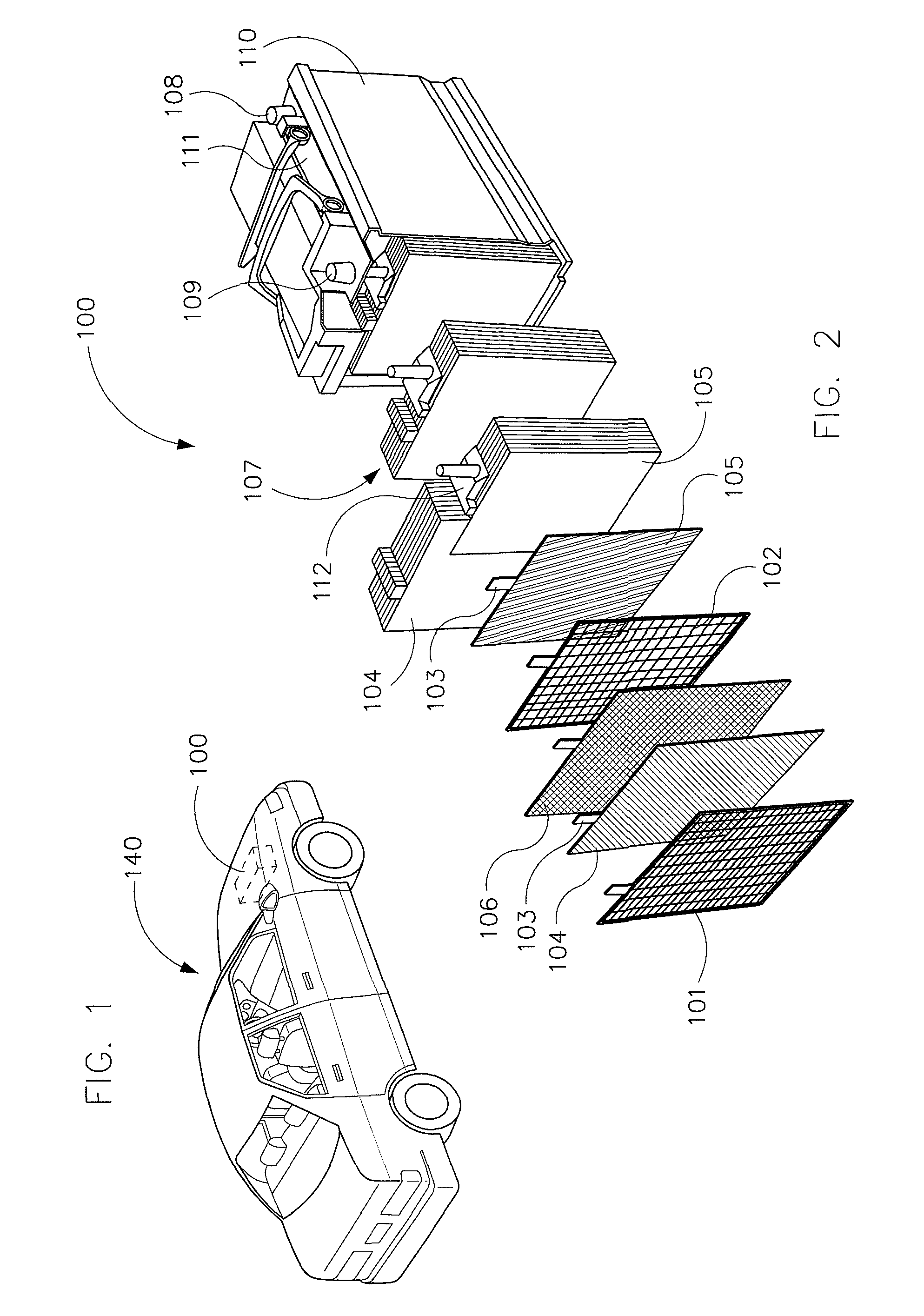

Method and apparatus for drying bearing

InactiveUSRE36796E1Configuration is complicatedSmall sizeDrying solid materials without heatDrying machines with progressive movementsOrganic solventEngineering

In order to provide a vacuum degreasing-drying method by which extremely small, precision metal products can be degreased and dried quickly and completely without using organic solvents, according to the present invention, an object 112 to be rinsed is put in a vacuum drier 110 after being rinsed with a hydrocarbon cleaning agent and then the air in the vacuum drier 110 is evacuated so as to degrease and dry the object thus rinsed.

Owner:NSK LTD

Ink jet printing apparatus, ink jet printing method, and data generating apparatus

InactiveUS8132878B2Solution to short lifeImprove imaging effectMeasurement apparatus componentsOther printing apparatusWear resistanceElectrical and Electronics engineering

An ink jet printing apparatus, an ink jet printing method, and a data generating apparatus are provided in which an image performance such as an abrasion resistance can be improved and a printing head can have a longer life by ejecting processing liquid at an appropriate time. The processing liquid is ejected, to a predetermined area on a printing medium in which the formation of a image by ink is completed, from a printing head in two or more scannings in five scannings of the printing heads.

Owner:CANON KK

Ink jet printing apparatus, ink jet printing method, data generating apparatus, computer program, and ink jet printing system

InactiveUS8083337B2Solution to short lifeImprove imaging effectOther printing apparatusEngineeringWear resistance

The present invention provides an ink jet printing apparatus, an ink jet printing method, a data generation apparatus, a computer program, and an ink jet printing system by which a timing for ejecting a processing liquid can be changed to improve image performance of a printed image such as abrasion resistance, to provide the printing head with a longer life, and to improve a throughput. The processing liquid is ejected to a predetermined area on a printing medium, for which a formation of an image by ink is completed, in two or more scannings among five scannings of the printing head. When an amount of ejection data for ejecting the processing liquid in the fifth scanning for ejecting only the processing liquid is equal to or lower than a predetermined amount, the fifth scanning is not carried out.

Owner:CANON KK

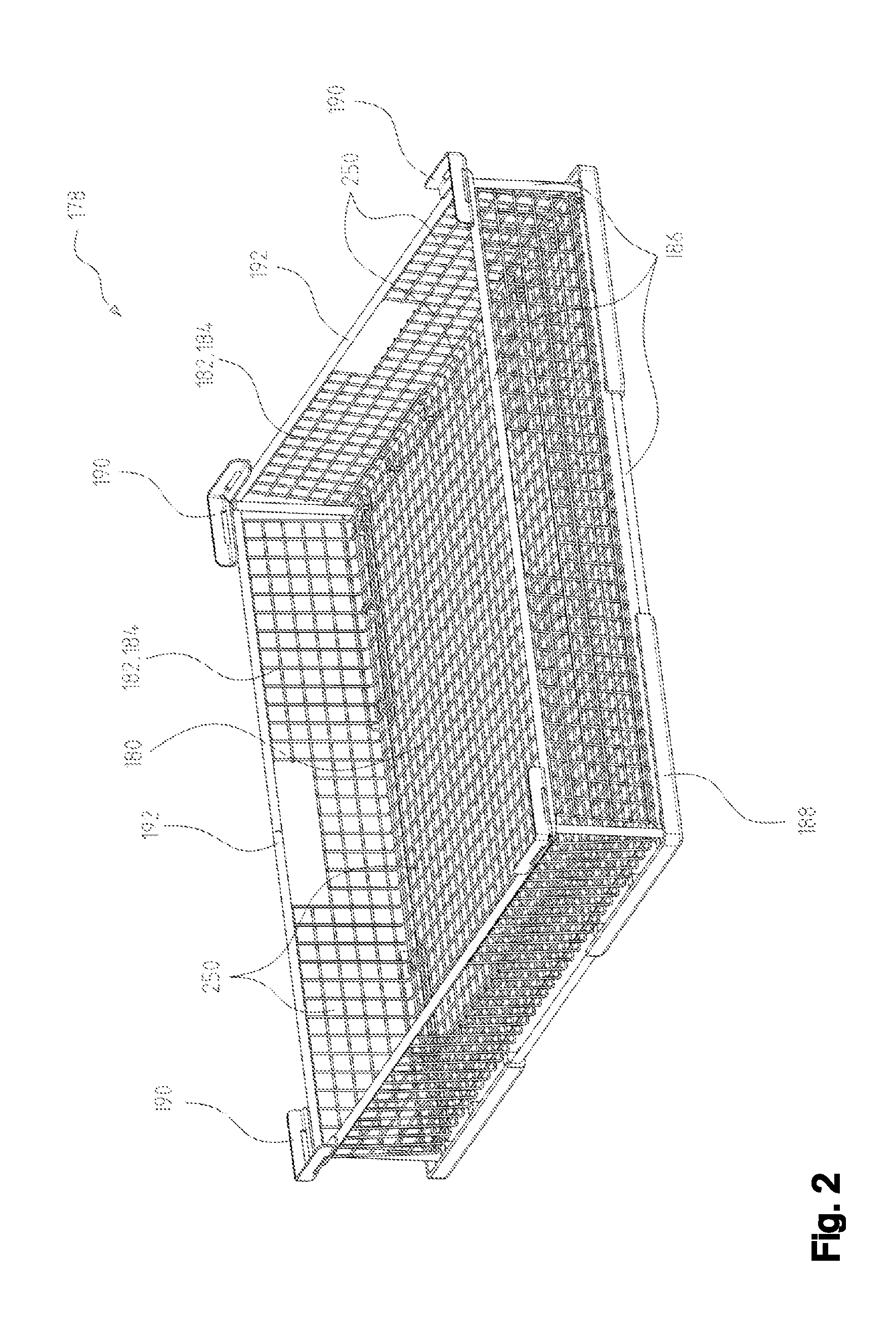

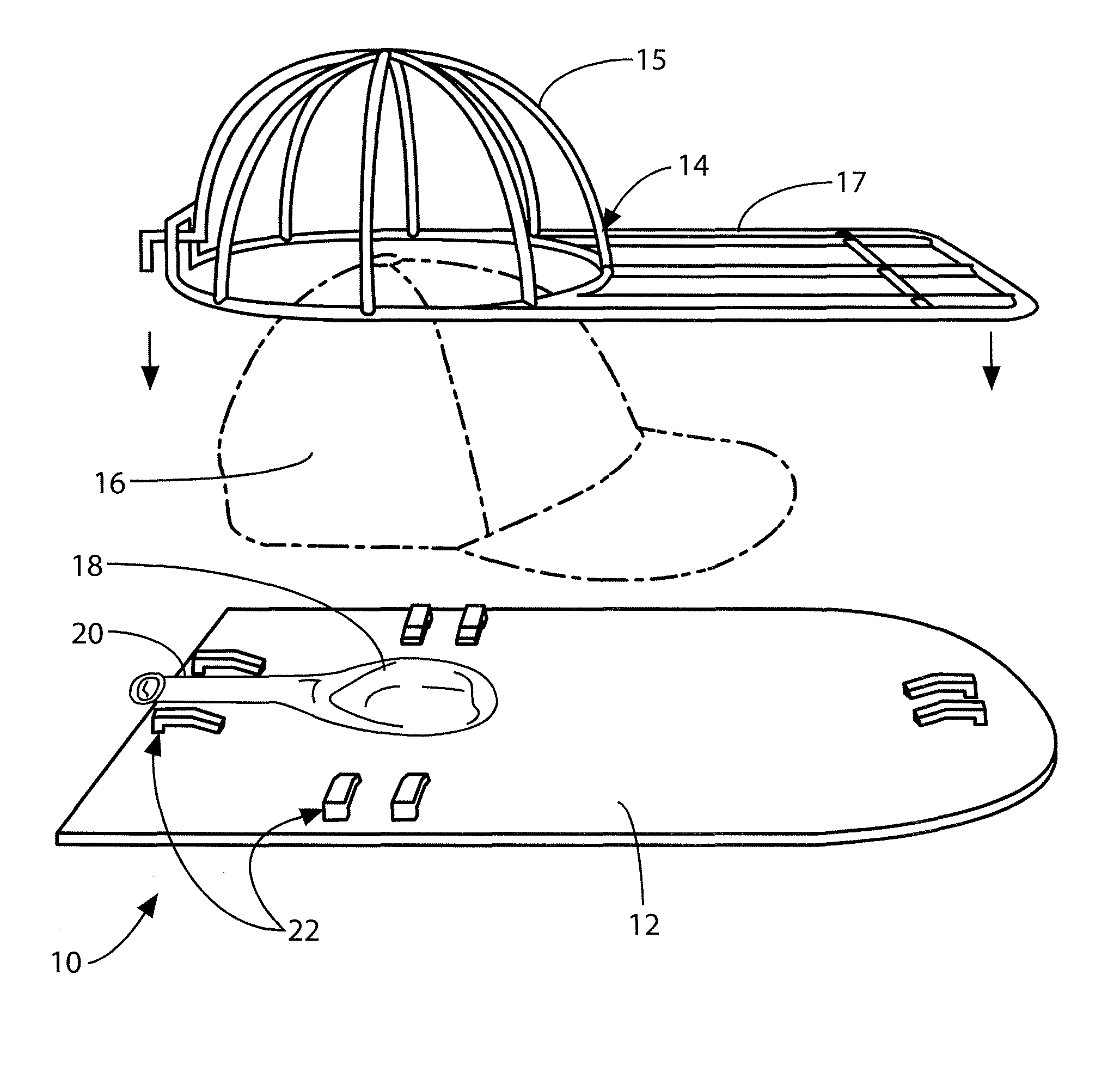

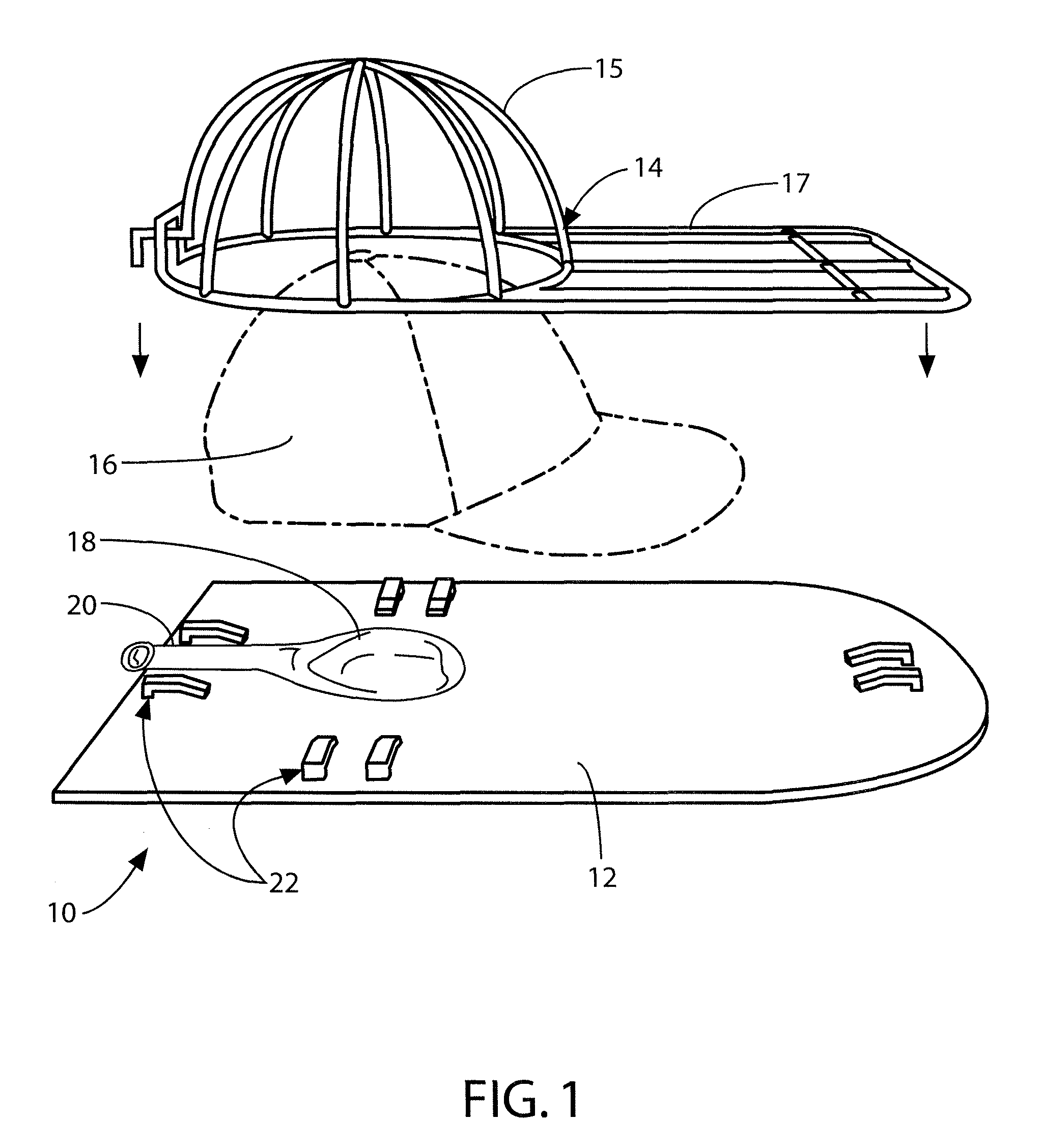

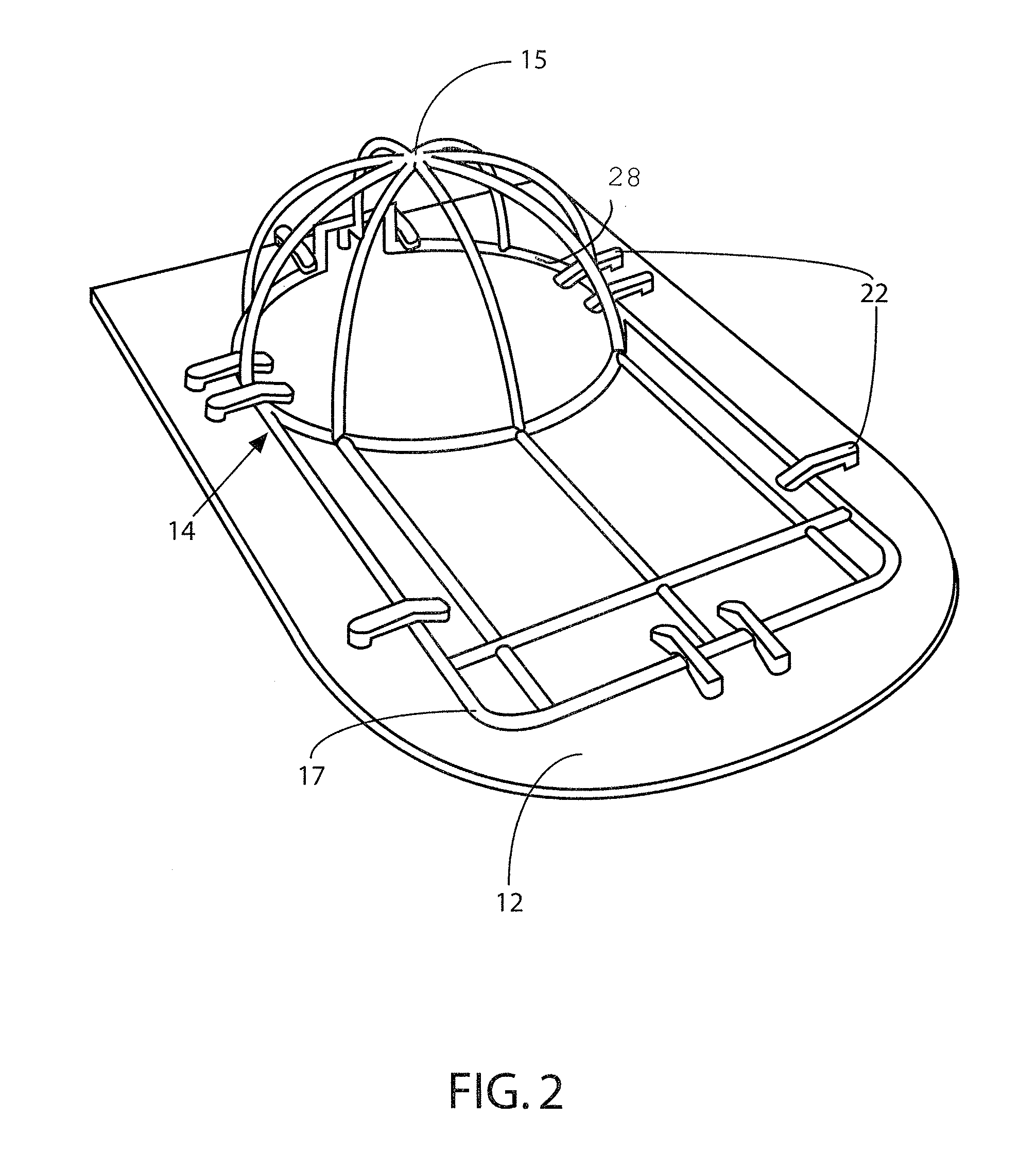

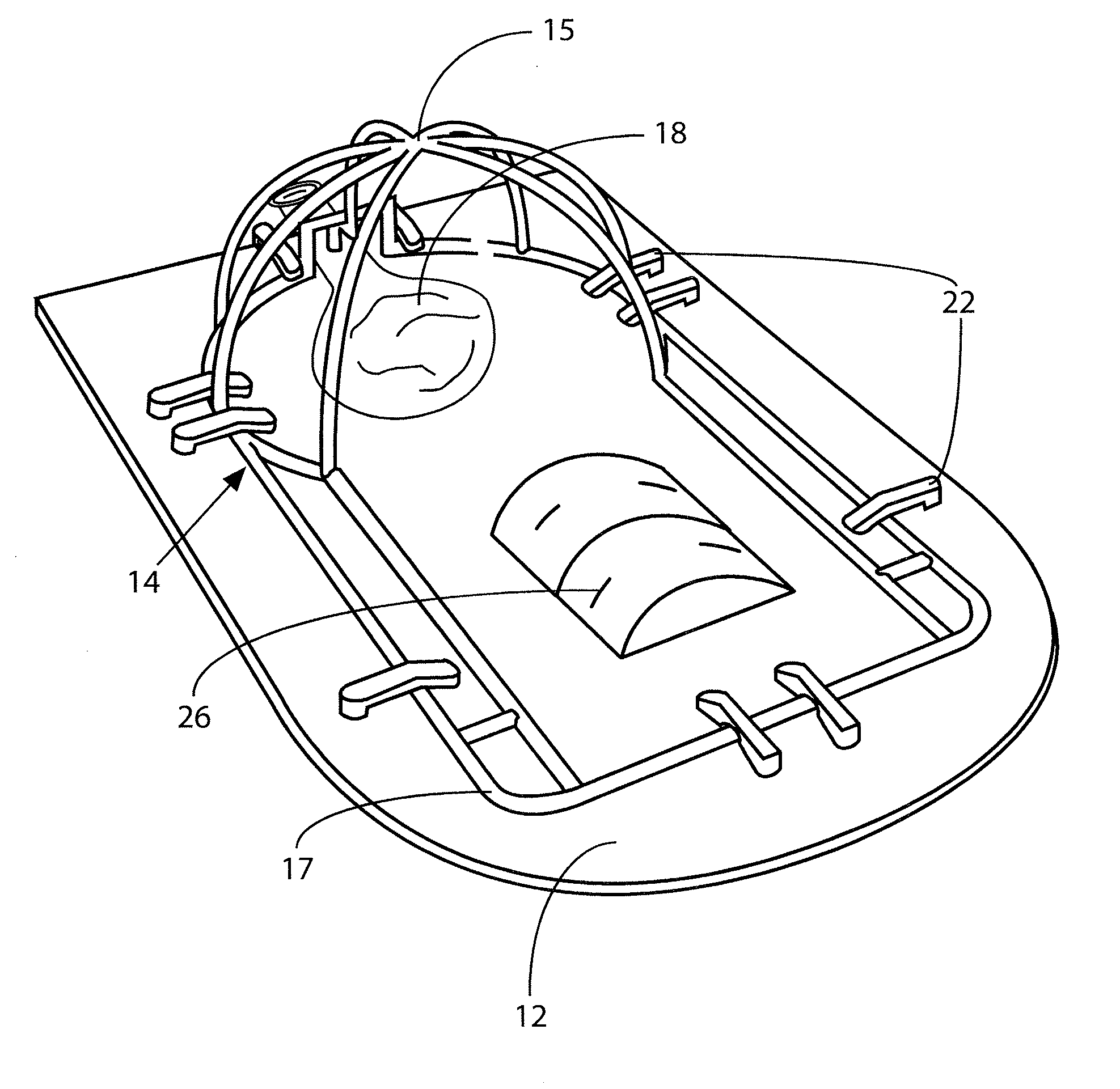

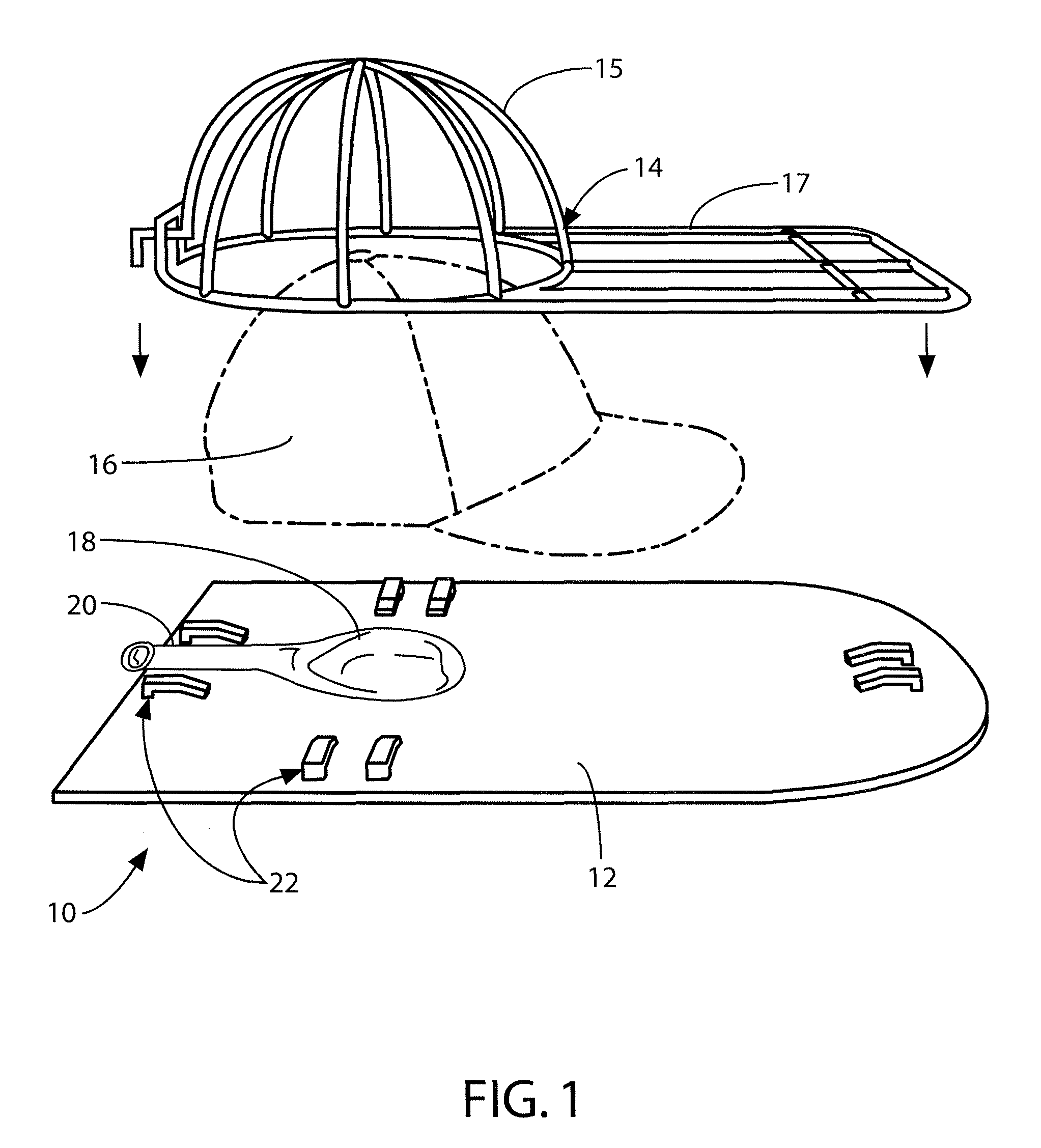

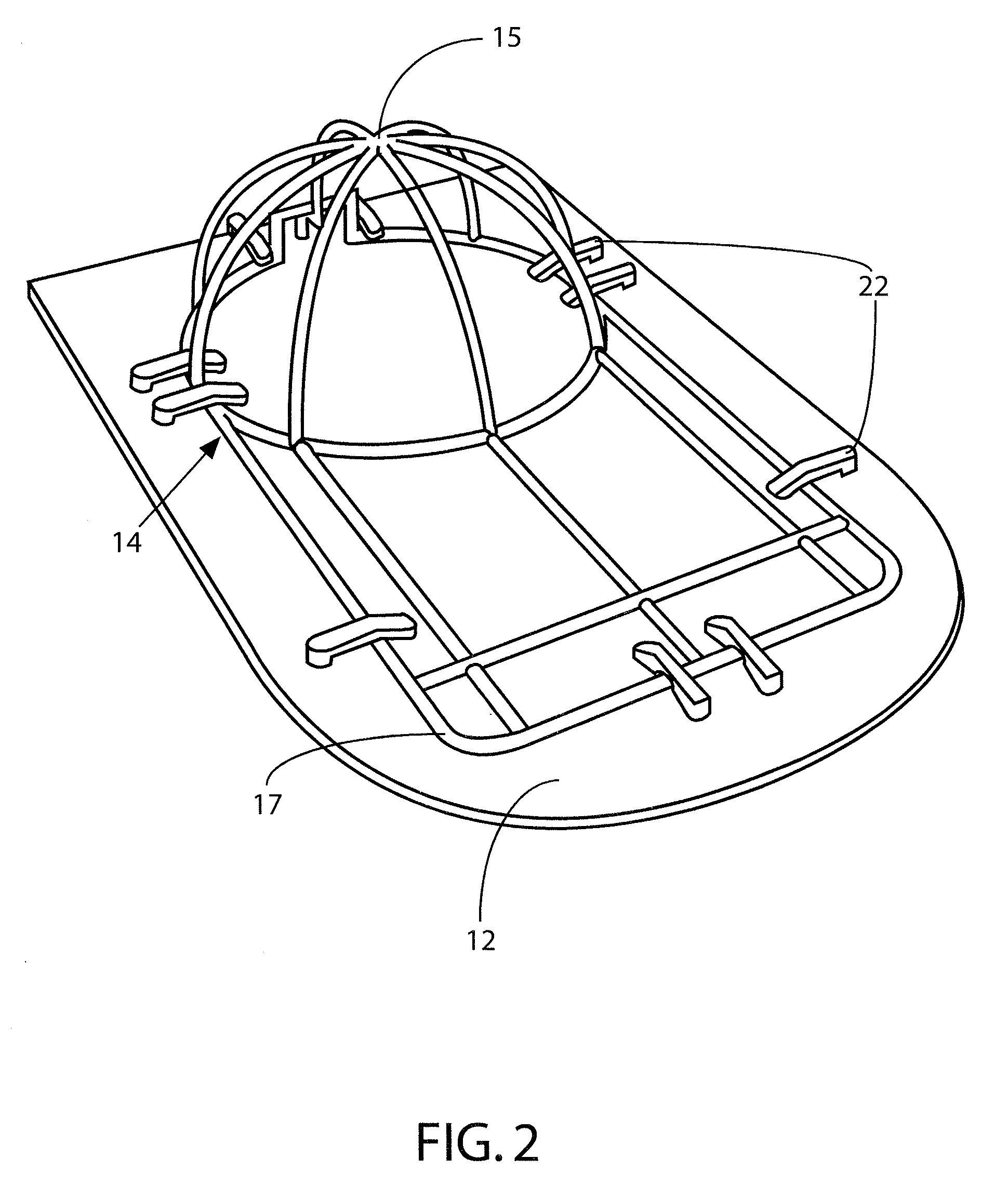

Cap drying apparatus

InactiveUS8177104B2Drying processSimple and inexpensive and adjustableOther drying apparatusHatsEngineeringMechanical engineering

A cap drying and shaping apparatus includes a substantially planar base, an inflatable bladder disposed proximal one end of the planar base, and a ribbed cage member. The ribbed cage member includes a domed portion having a predetermined radius to the apex and a predetermined diameter parallel to the planar base, and a planar portion at least as long and wide as a bill on a typical ball cap. Attachment means are disposed on top of the planar base for removably clamping the ribbed cage member to the planar base.

Owner:BRYANT CARL E

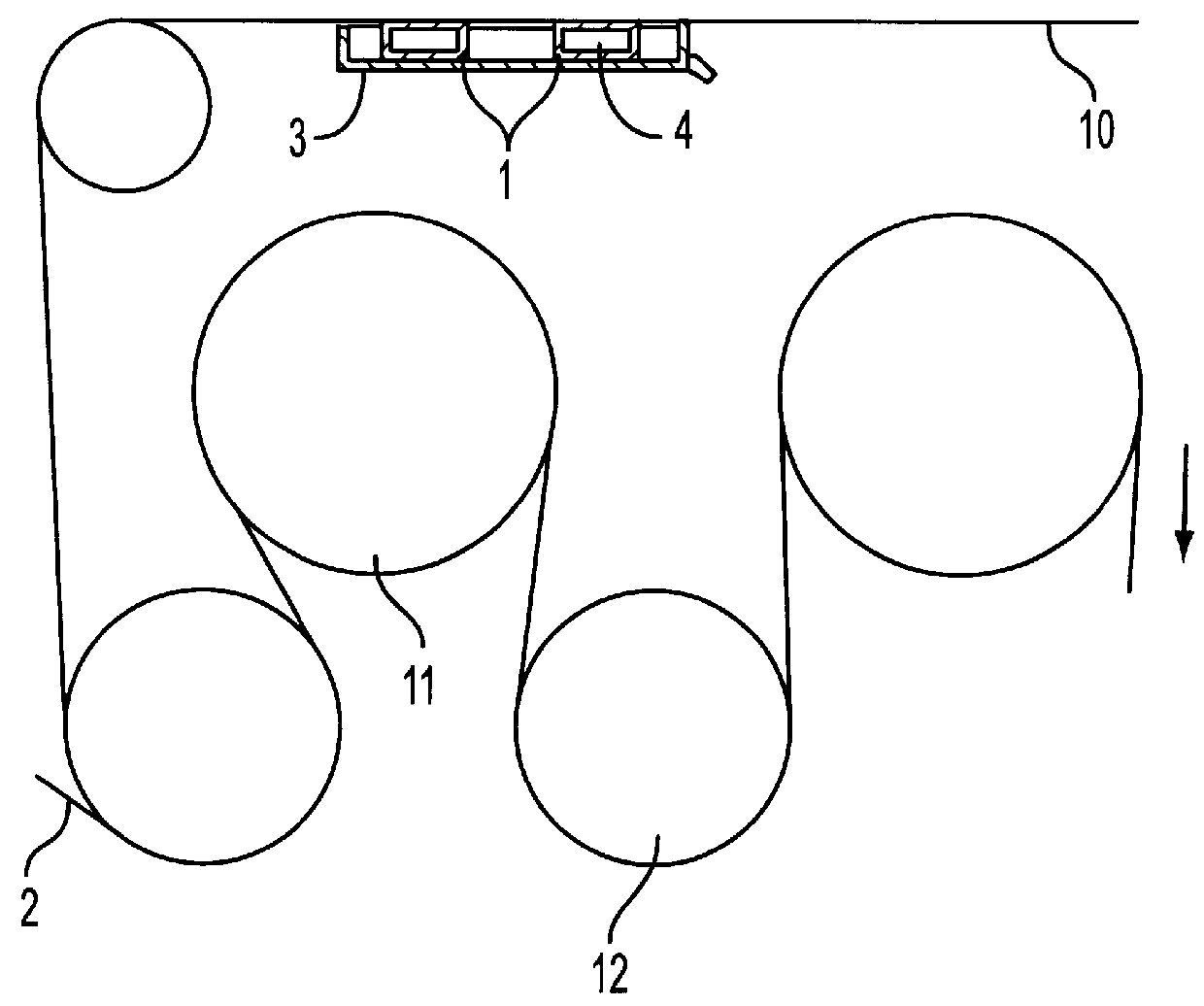

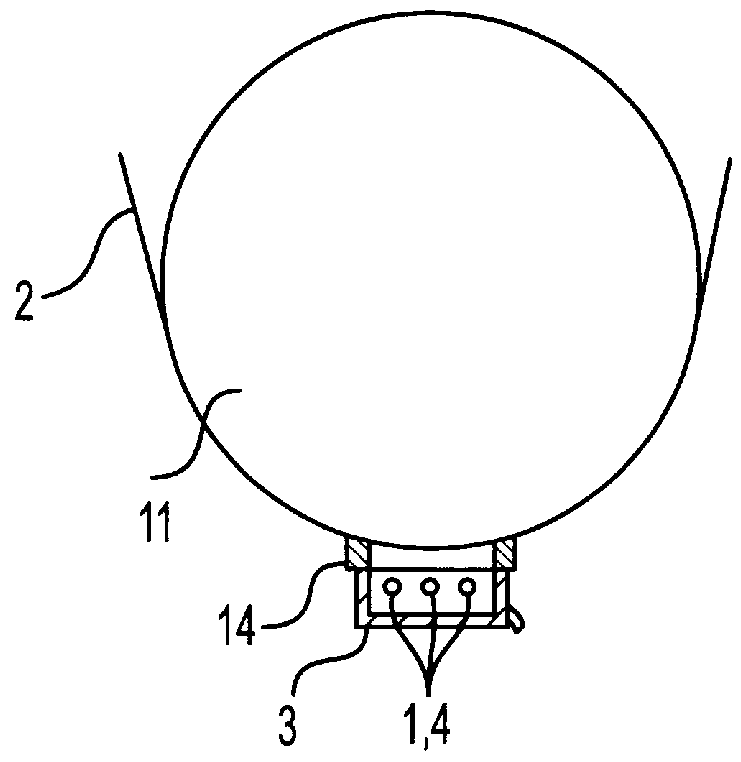

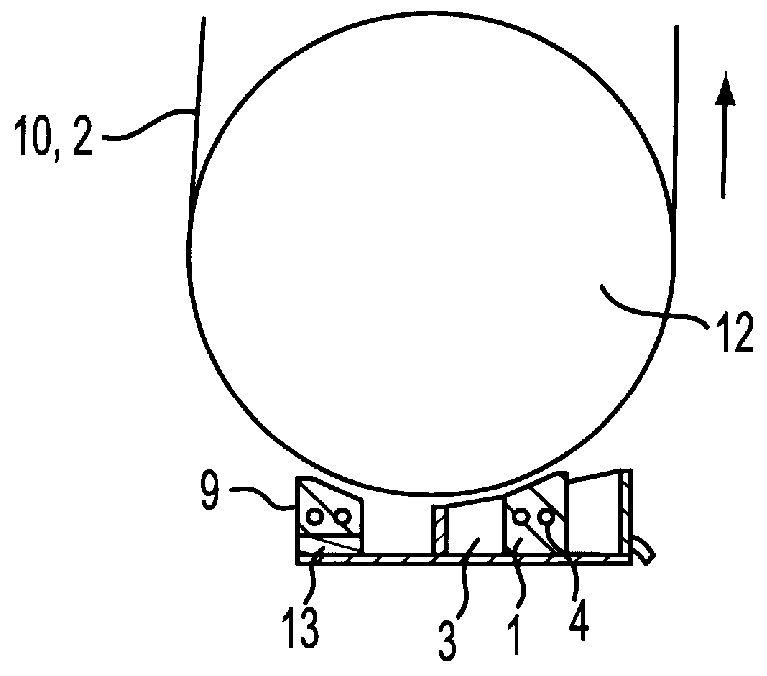

Condensation device and suction element including a condensation device

InactiveUS6148538ASimple structureDiversion simplifiedDrying solid materials with heatDryer sectionFiberEngineering

Owner:VOITH SULZER PAPIERMASCHEN GMBH

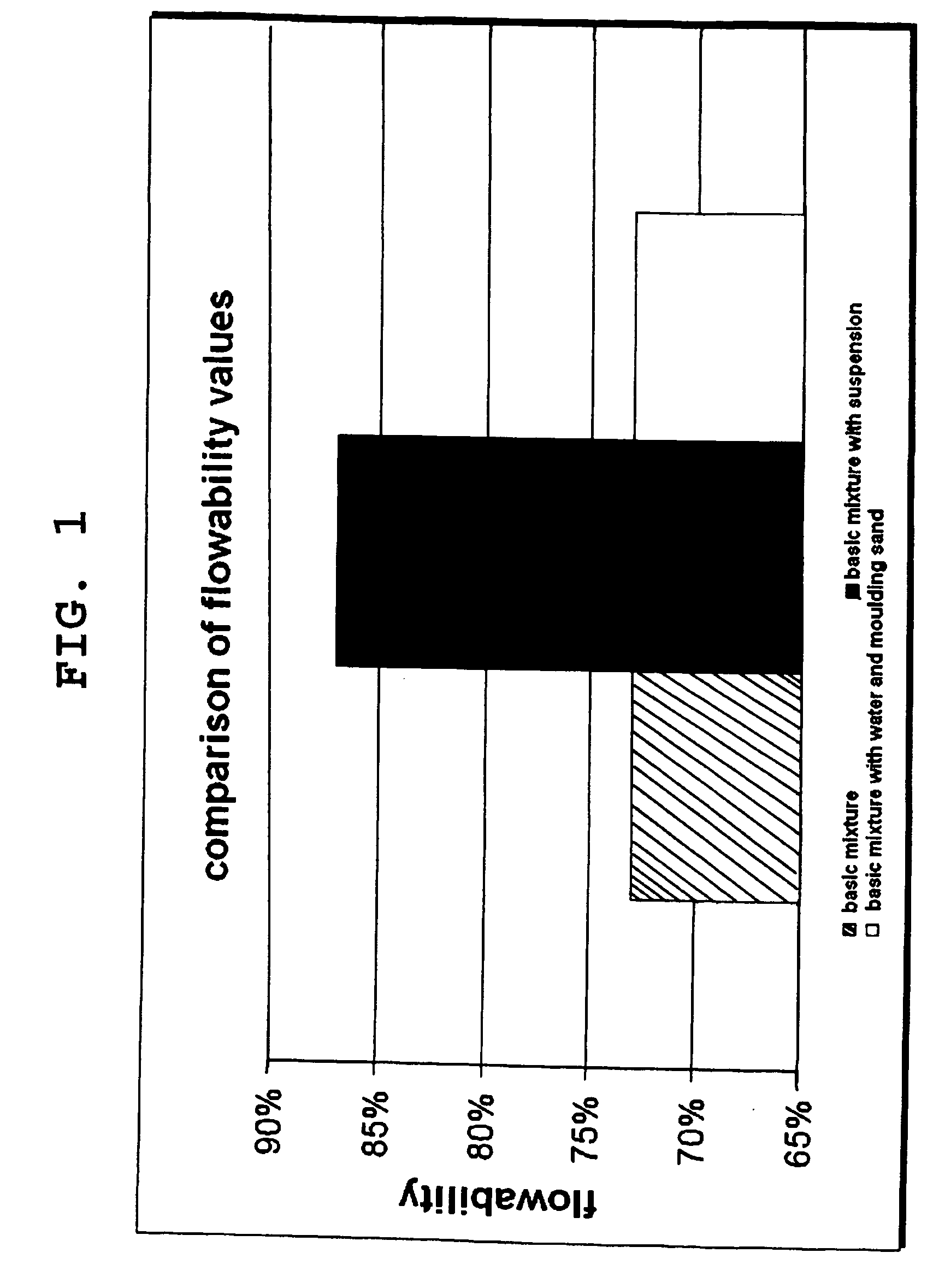

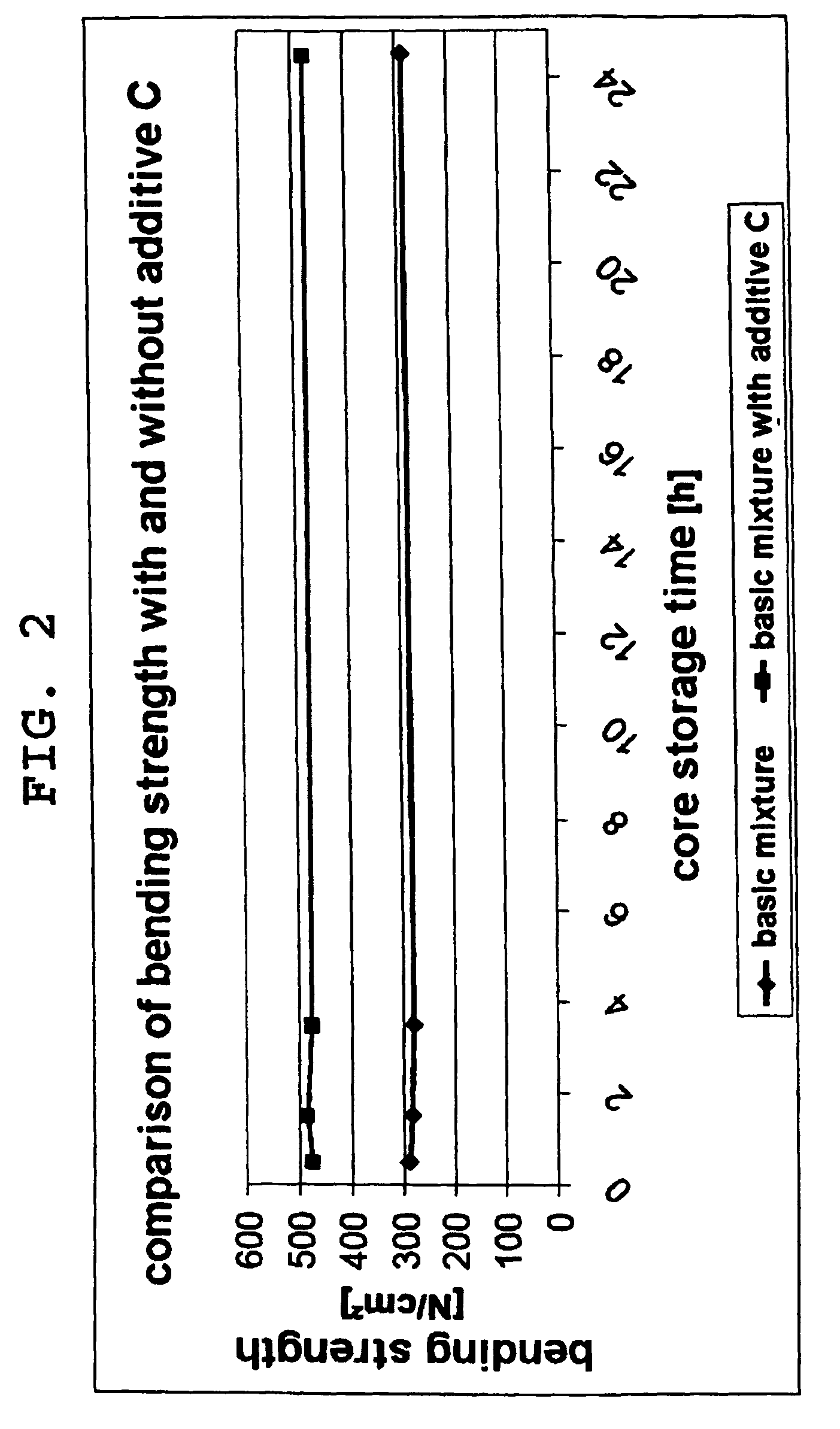

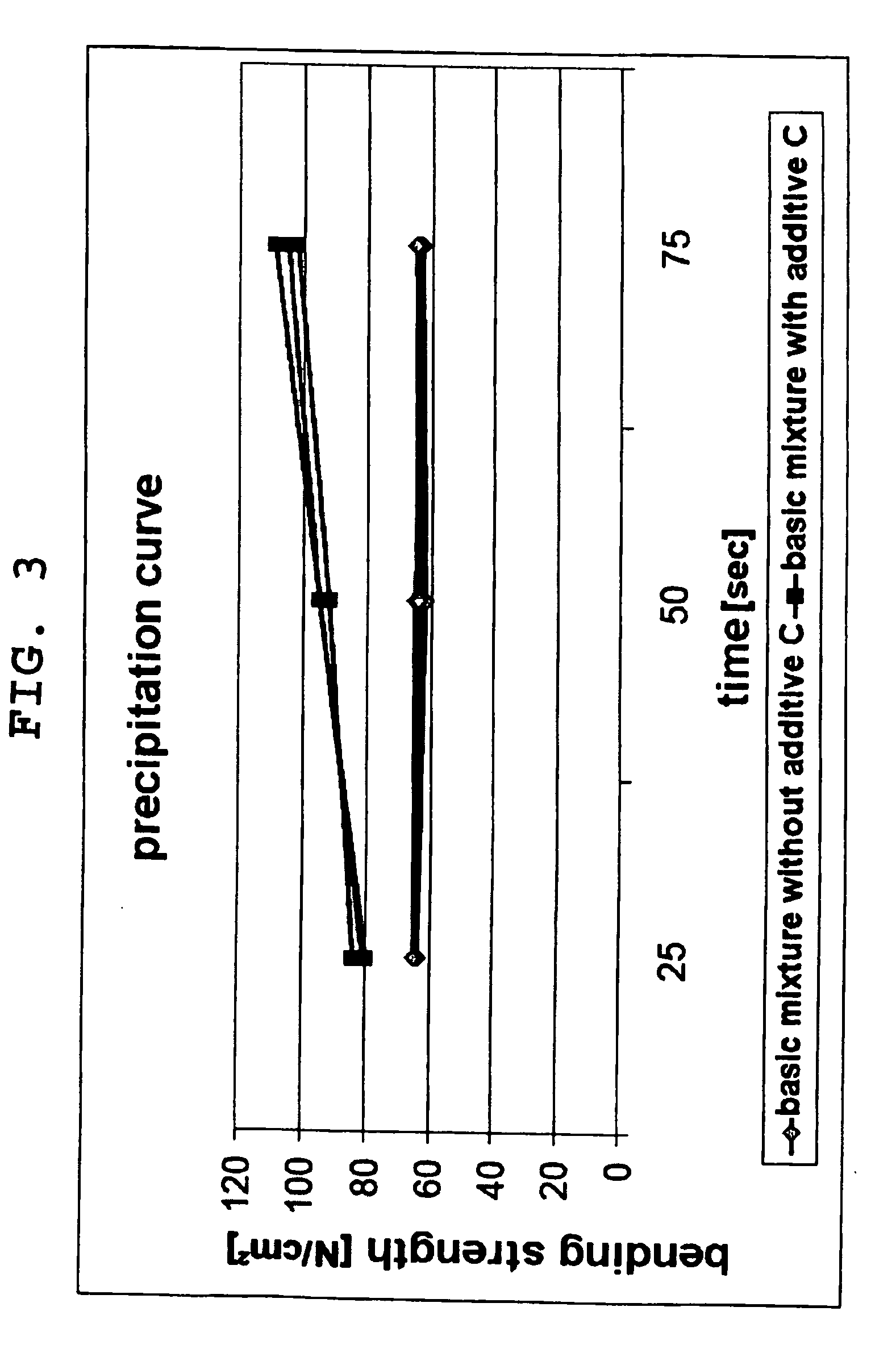

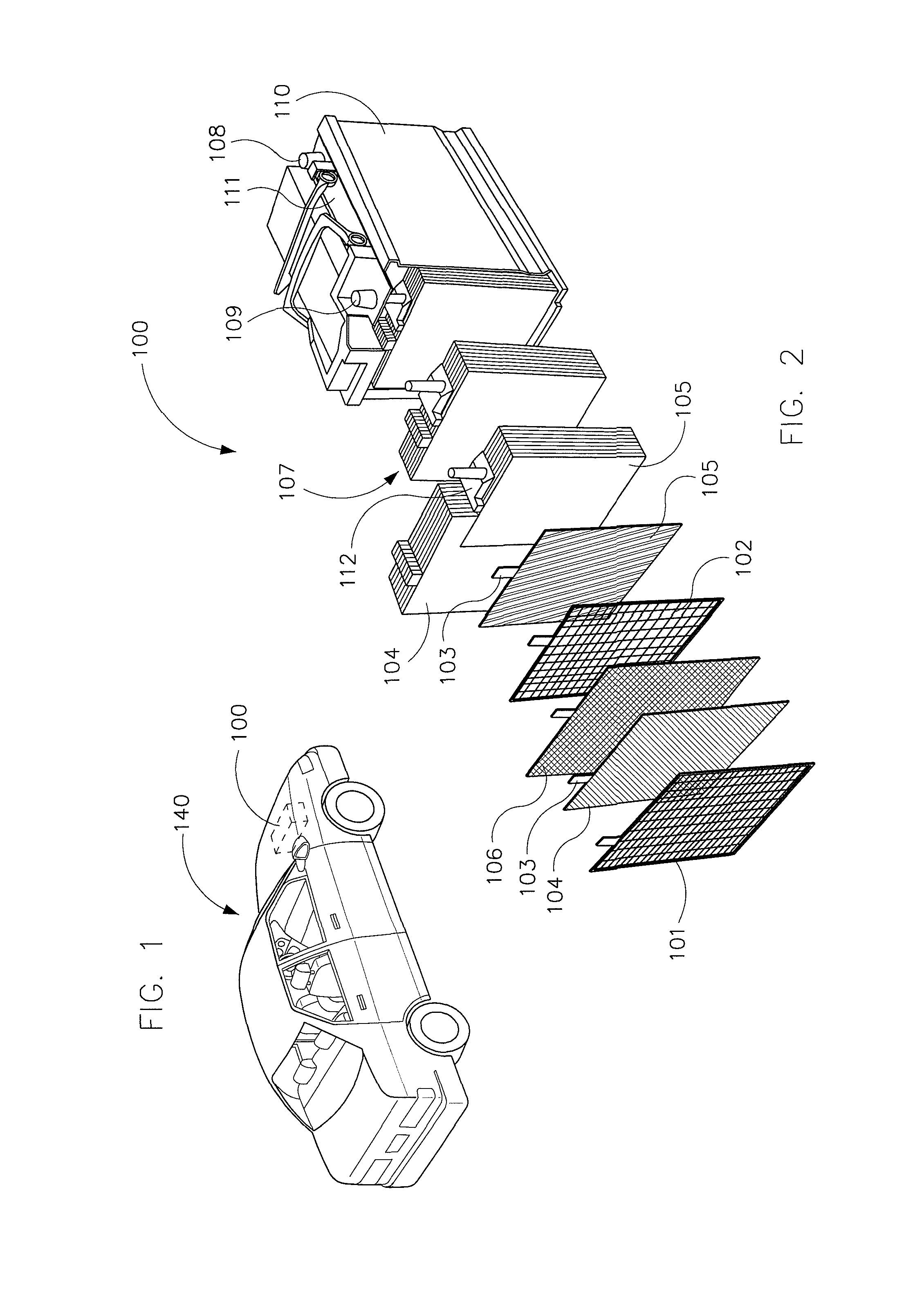

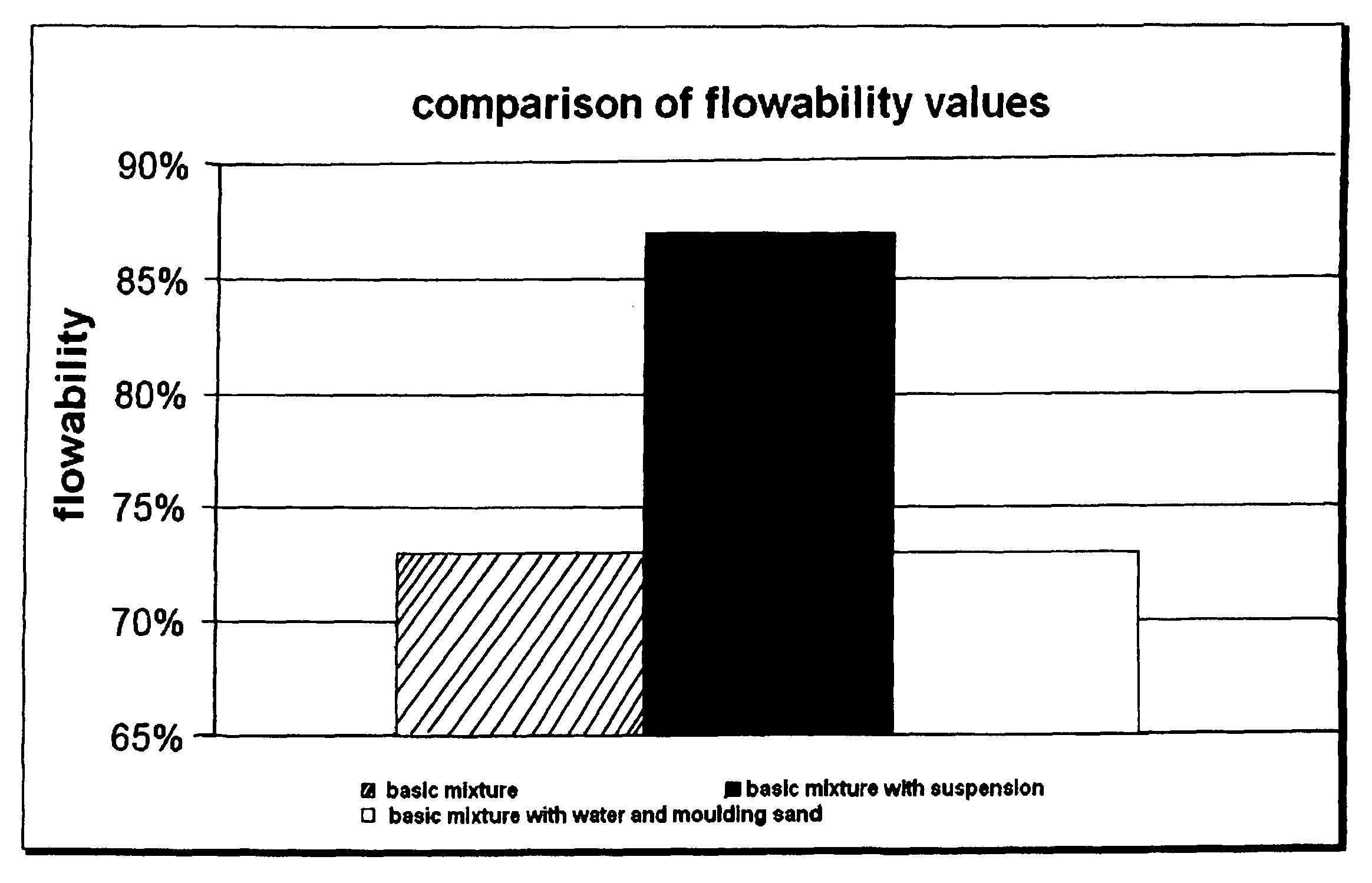

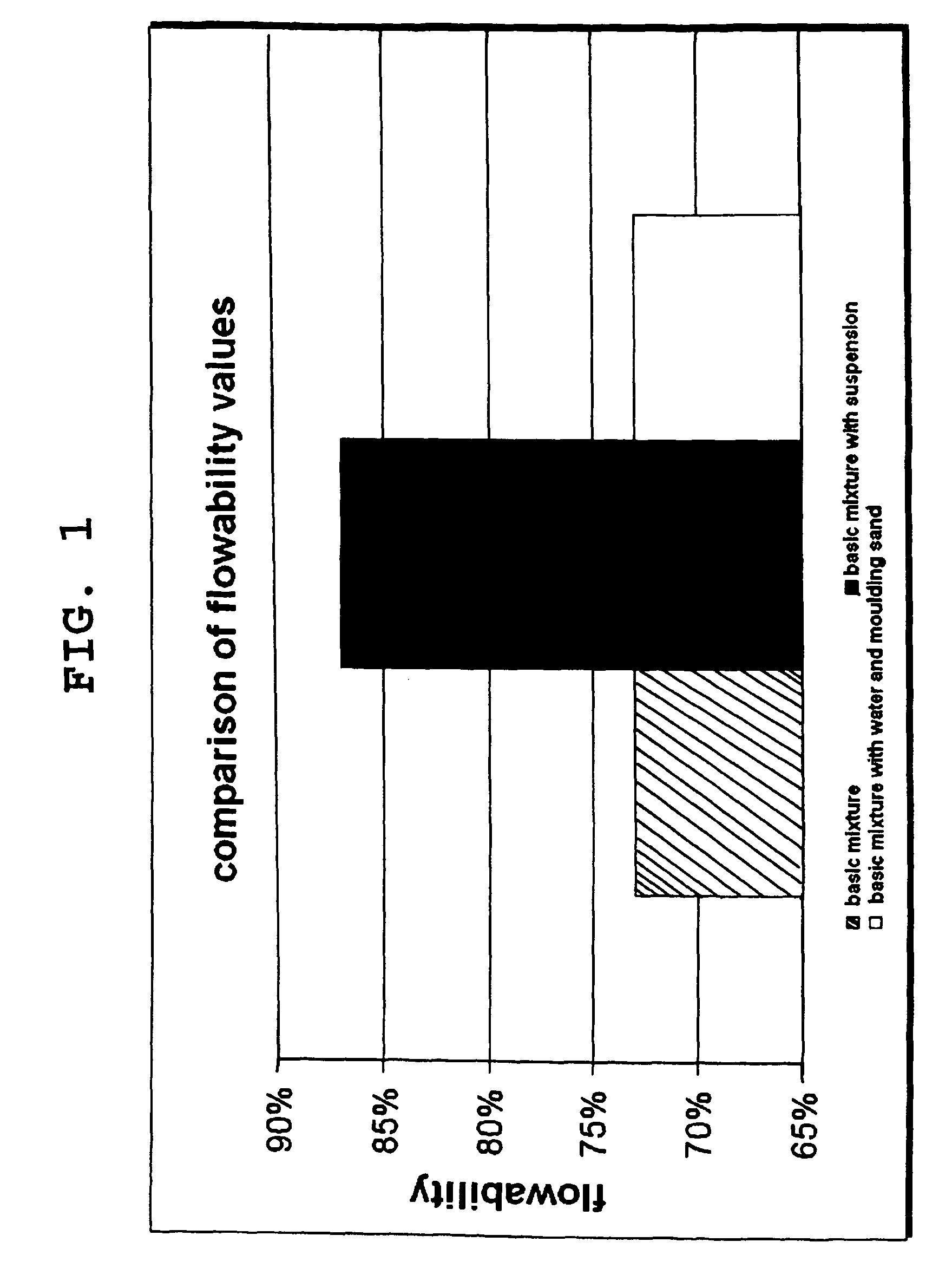

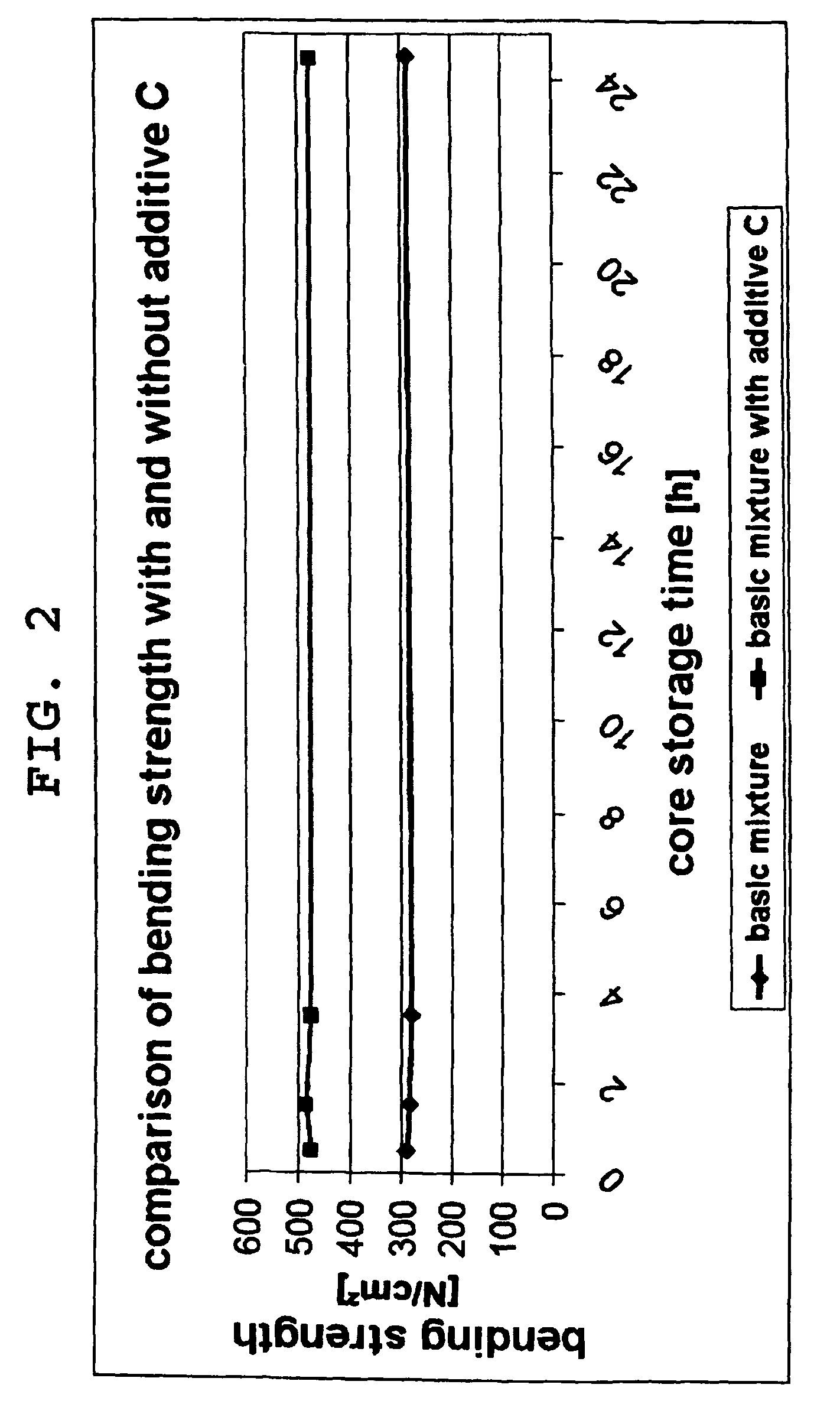

Molding material mixture, molded part for foundry purposes and process of producing a molded part

InactiveUS20080314549A1Evenly distributedImprove flow characteristicsAlkali metal silicate coatingsFoundry mouldsTrademarkShell molding

Molding material mixture, molded part for foundry purposes and process of producing a molded part. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:IMERYS METALCASTING GERMANY GMBH

Microwave process for porous ceramic filters with passivation and catalyst coatings

InactiveUS7700163B2Improve washcoating characteristicEasy to disassembleRadiation applicationsLayered productsMicrowavePorous ceramics

Owner:CORNING INC

Microwave Heater

InactiveUS20090302031A1Drying processImprove uniformityCeramic shaping apparatusOhmic-resistance heatingMicrowaveDepth of penetration

The invention relates to a microwave heater comprising a plurality of microwave generators each emitting microwaves at a frequency in a range of frequencies ranging from 300 MHz to 5.8 GHz which couple into objects to be heated. At least one of the microwave generators emits the microwaves at a first frequency of an upper part of the range of frequencies, the microwaves of the first frequency displaying a first of depth of penetration into the objects to be heated; and at least one other of the microwave generators emits the microwaves at a second frequency of a lower part of the range of frequencies, the microwaves of the second frequency displaying a second depth of penetration into the objects to be heated, the first penetration depth being substantially smaller than the second penetration depth.

Owner:FRICKE & MALLAH MICROWAVE TECH

Cap drying apparatus

InactiveUS20090166388A1Drying processSimple and inexpensive and adjustableOther drying apparatusHatsEngineeringMechanical engineering

A cap drying and shaping apparatus includes a substantially planar base, an inflatable bladder disposed proximal one end of the planar base, and a ribbed cage member. The ribbed cage member includes a domed portion having a predetermined radius to the apex and a predetermined diameter parallel to the planar base, and a planar portion at least as long and wide as a bill on a typical ball cap. Attachment means are disposed on top of the planar base for removably clamping the ribbed cage member to the planar base.

Owner:BRYANT CARL E

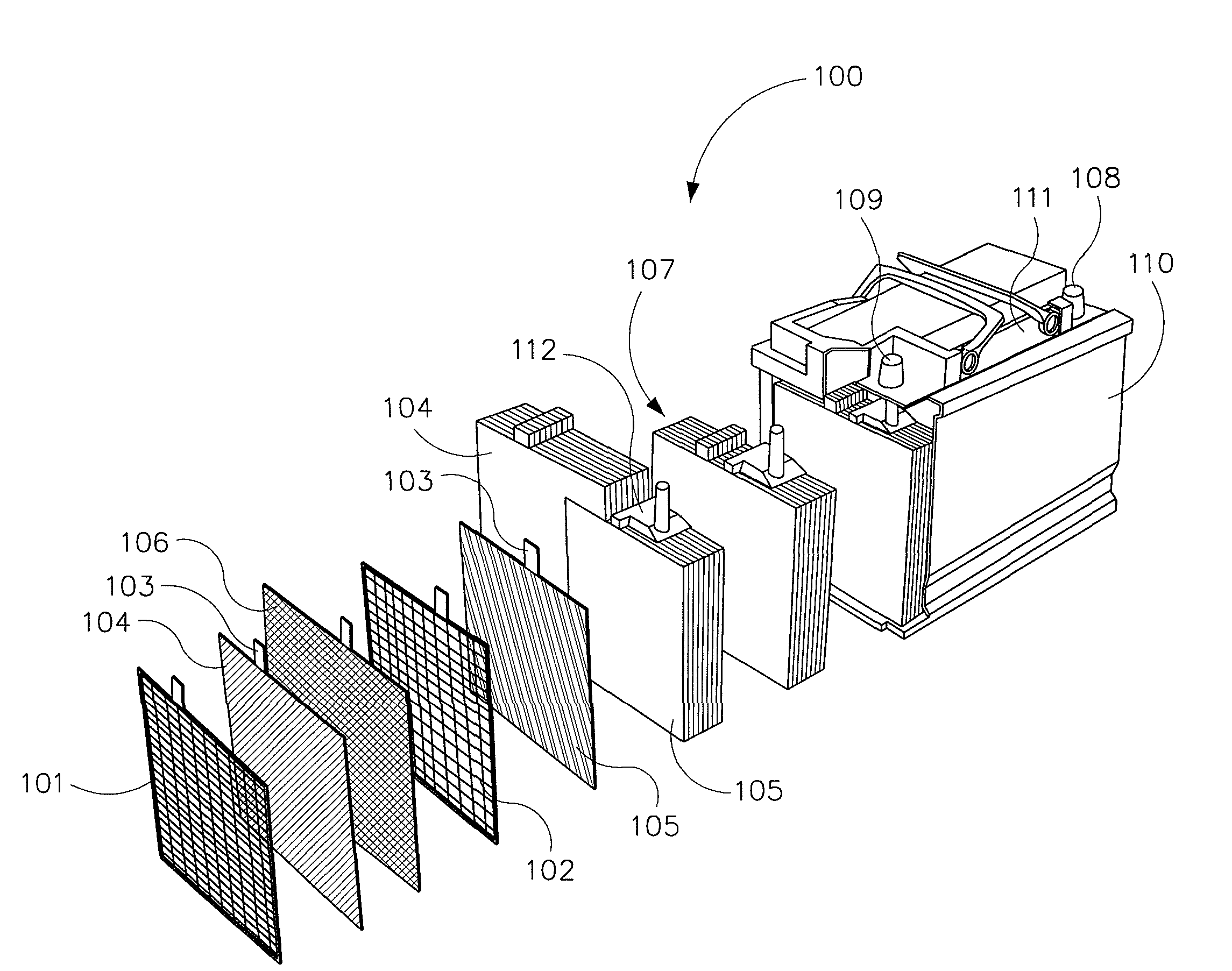

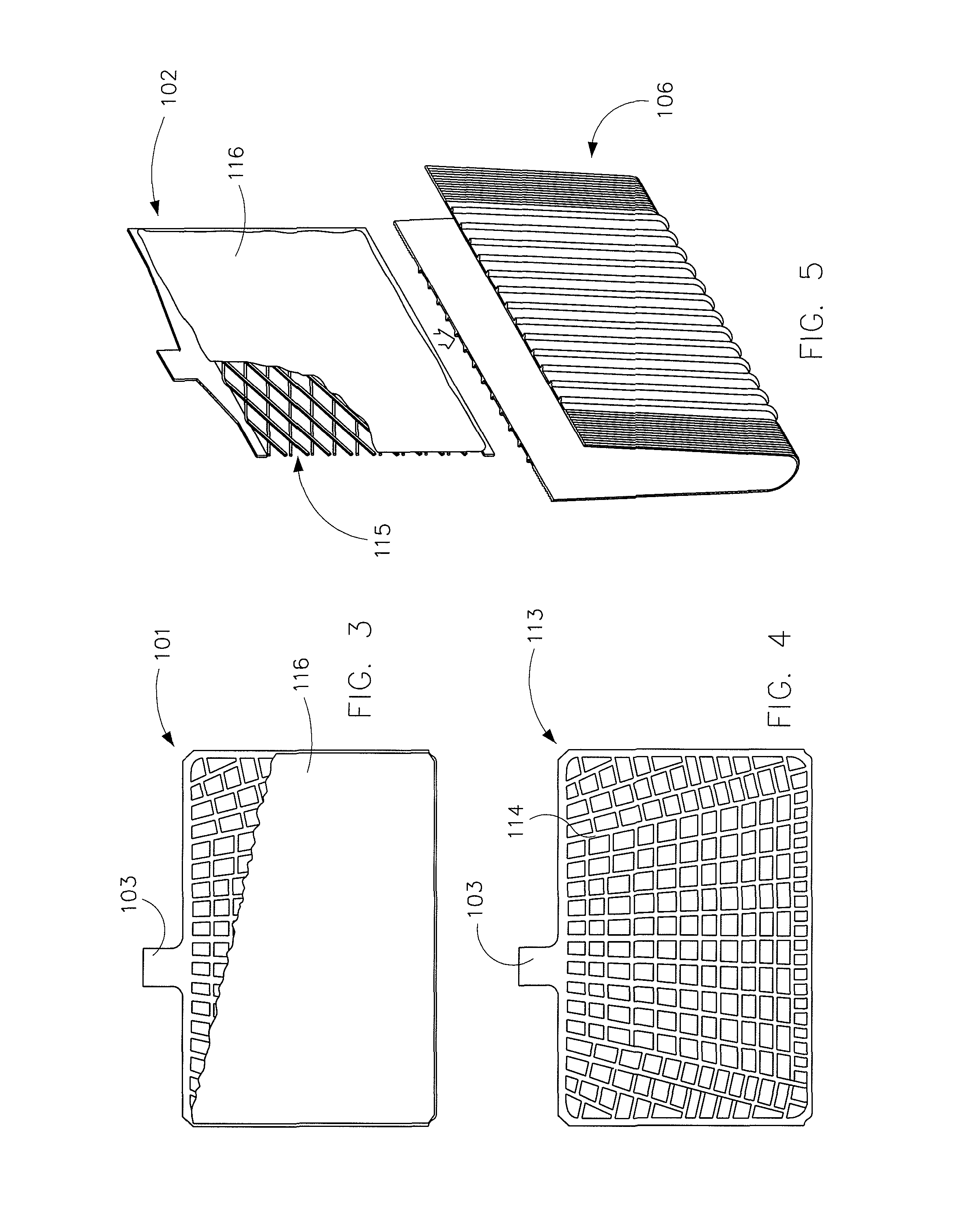

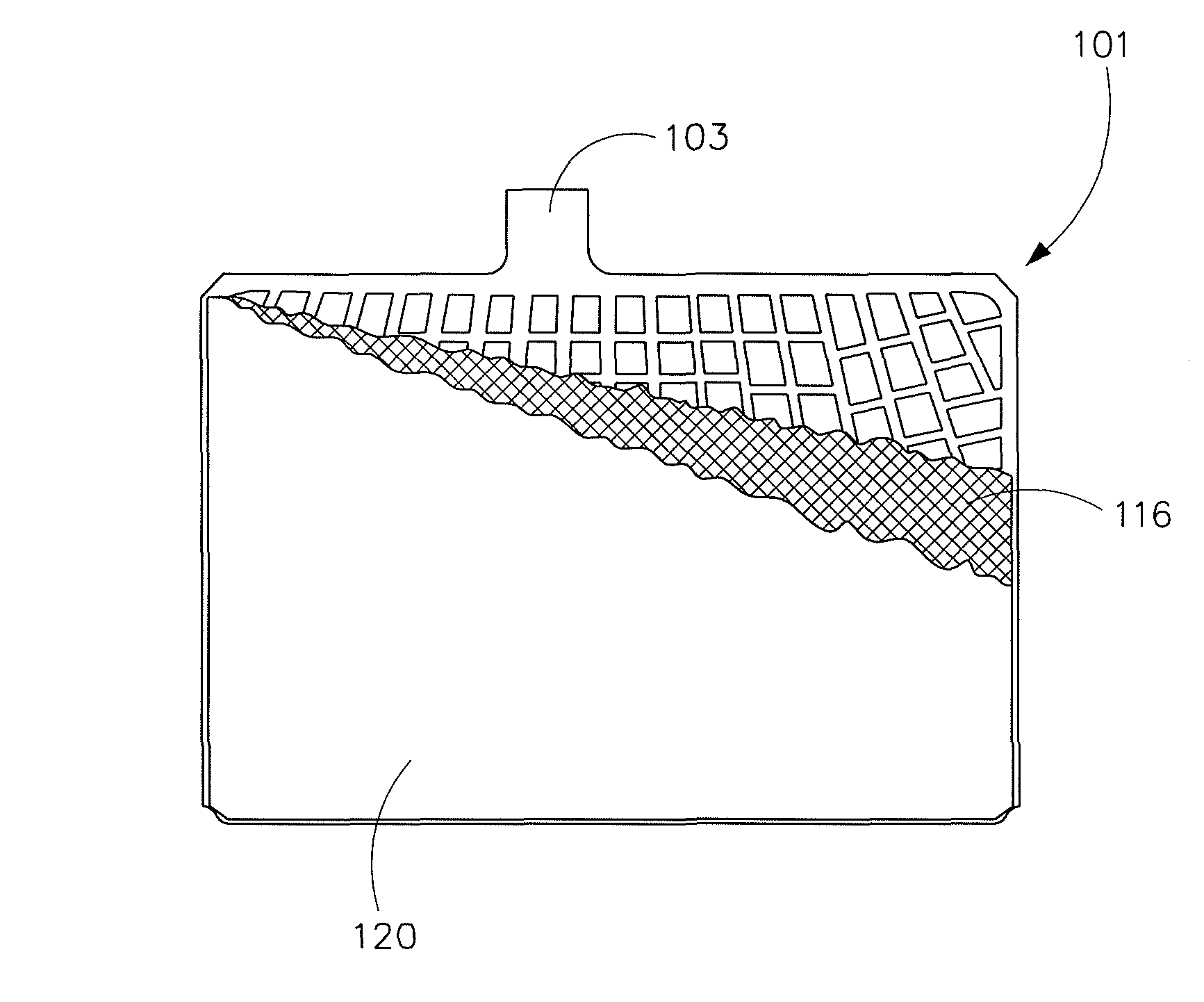

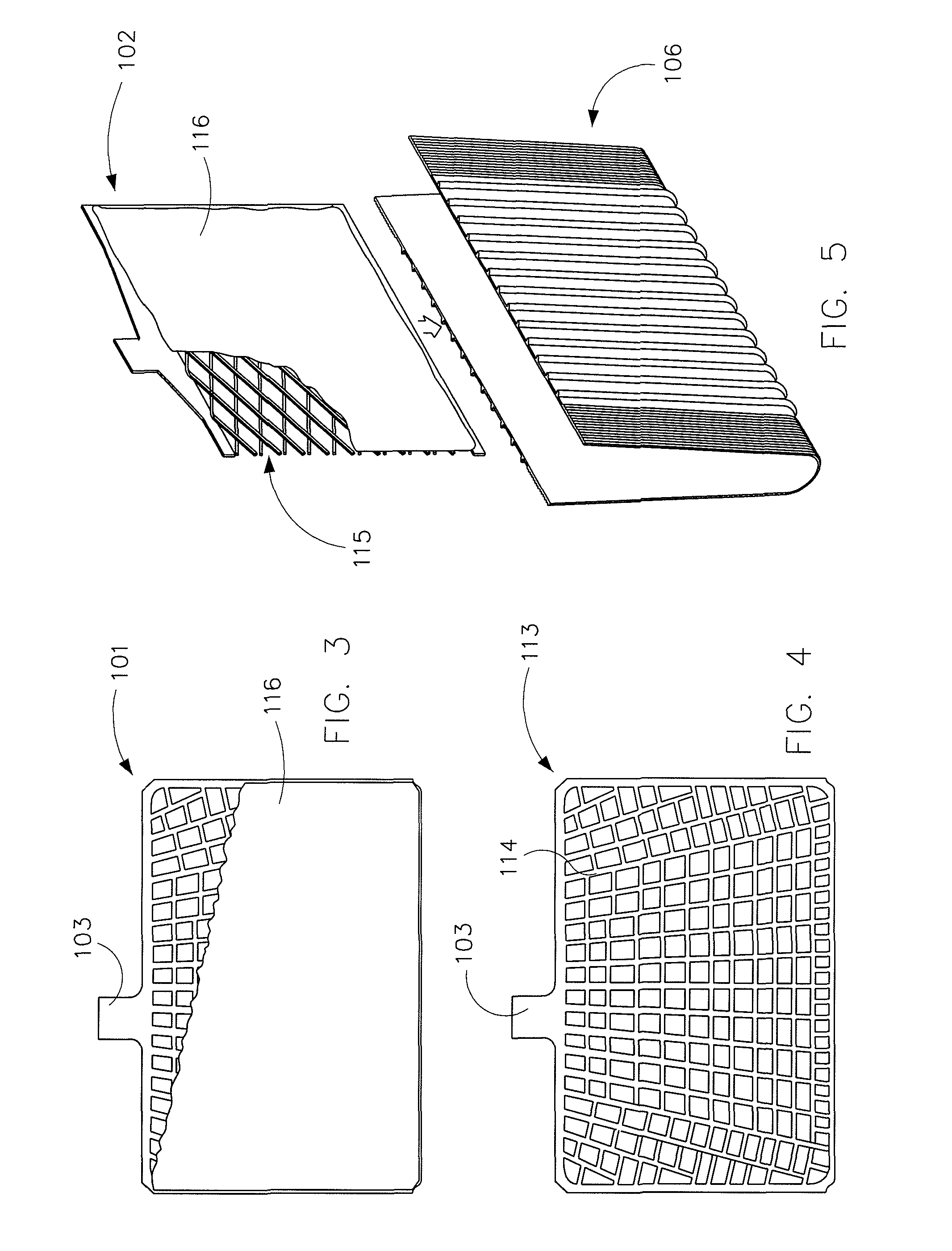

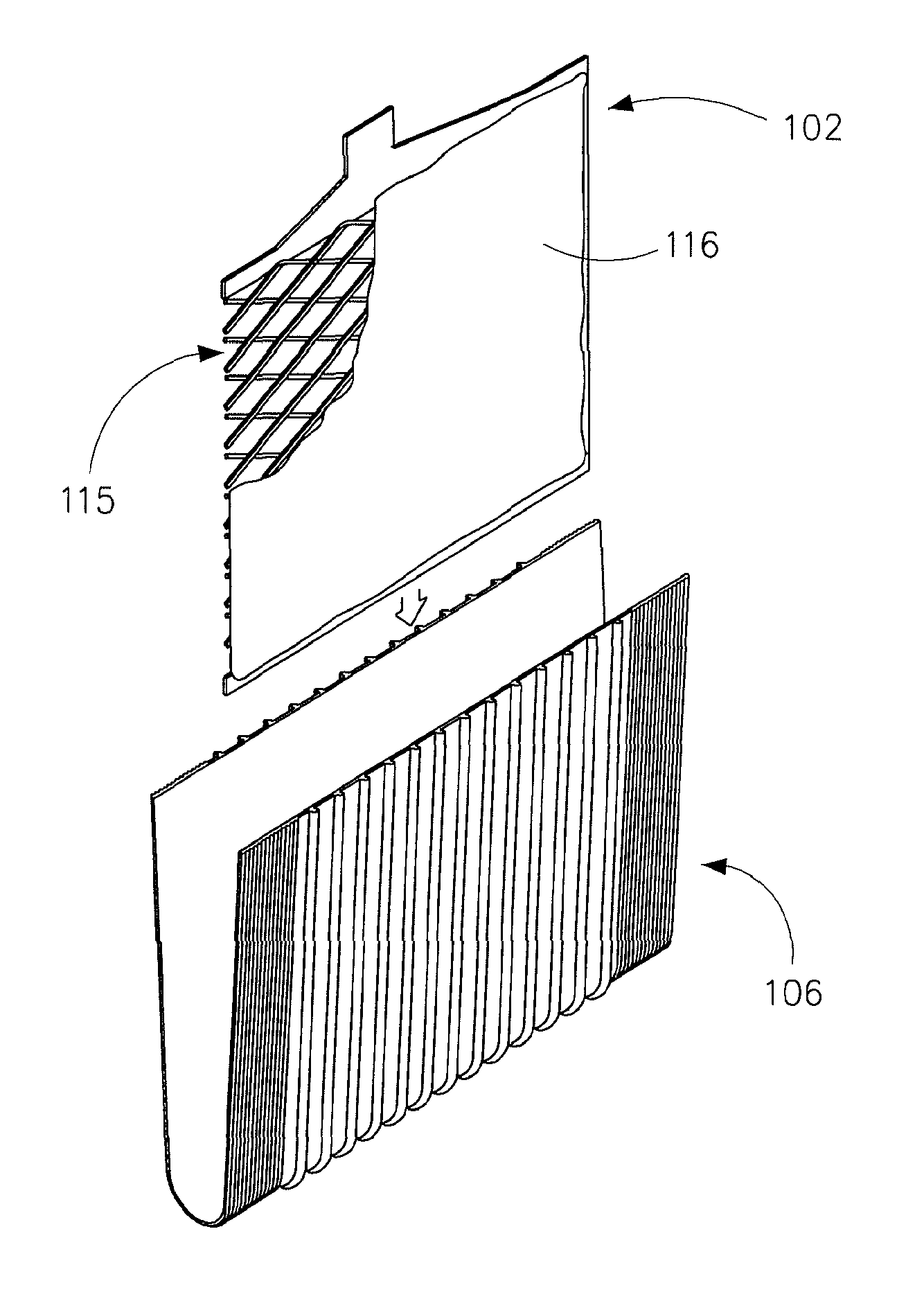

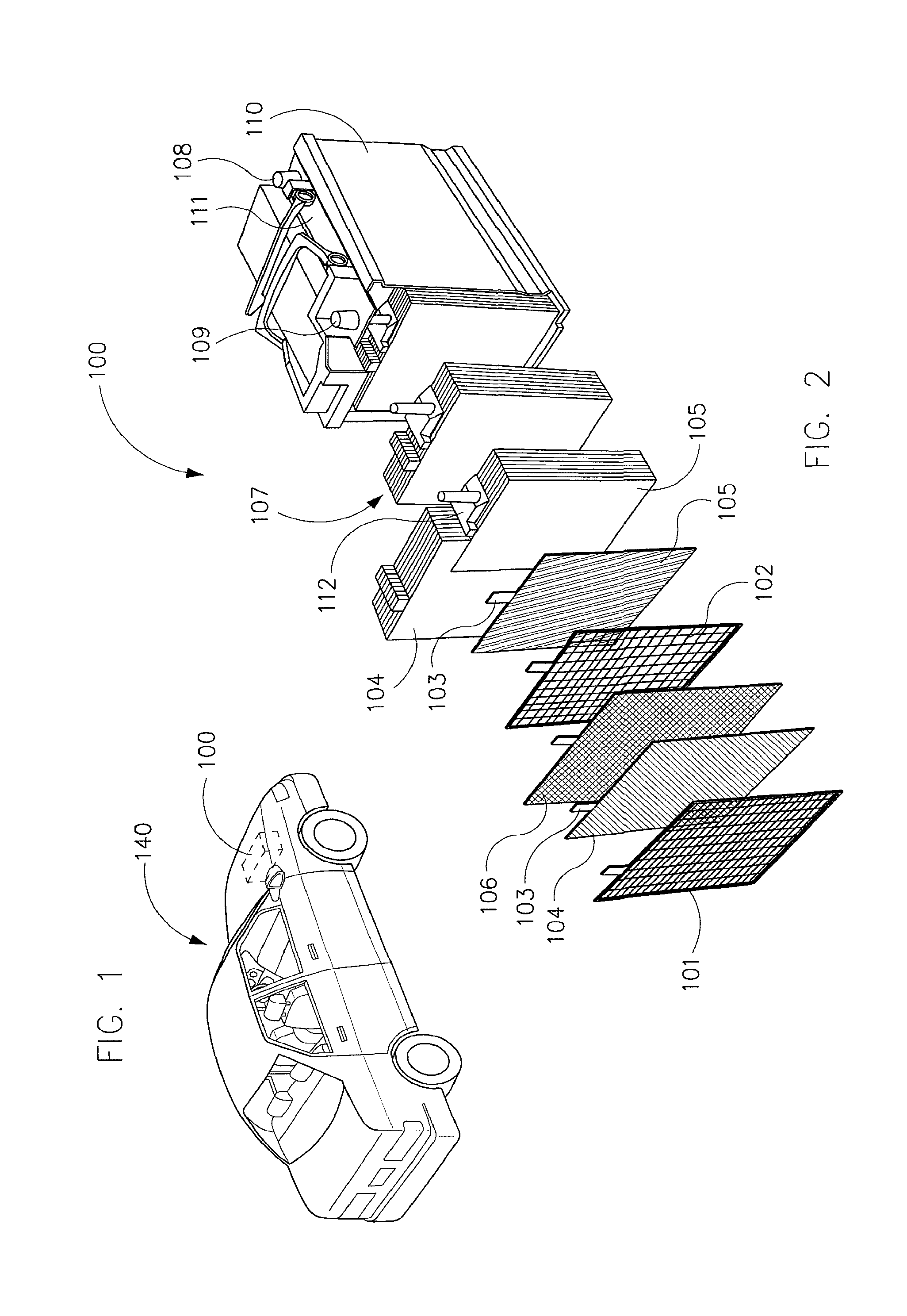

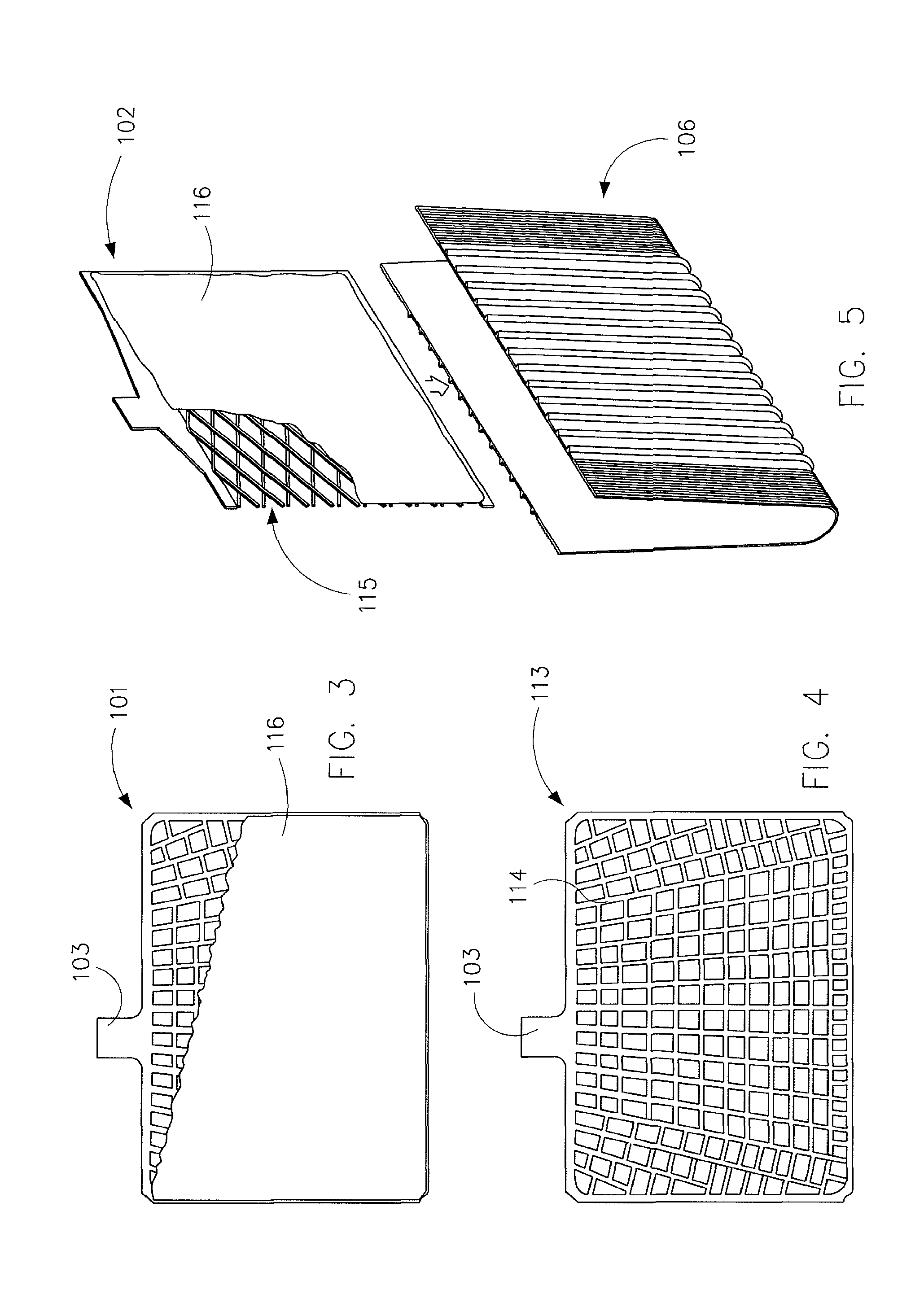

Battery electrode and method for manufacturing same

ActiveUS20120040251A1Low flash-dryingHigh plate manufacturing line speedLead-acid accumulatorsPrimary cellsFiberEngineering

A battery electrode with a pasting textile, fabric, or scrim made with an electrode grid (e.g., a stamped grid or expanded metal grid) coated in battery electrode and covered with pasting textile formed of a bonded, non-woven fiber web. The web is formed from one or more fibers with an average length greater than 20 μm. In various embodiments, the web is formed from one or more spun, continuous fibers. The battery electrode may be made in a continuous process where multiple grids are formed in a single sheet, coated with electrode active material, and the scrim before being cut into individual electrodes.

Owner:CPS TECH HLDG LLC

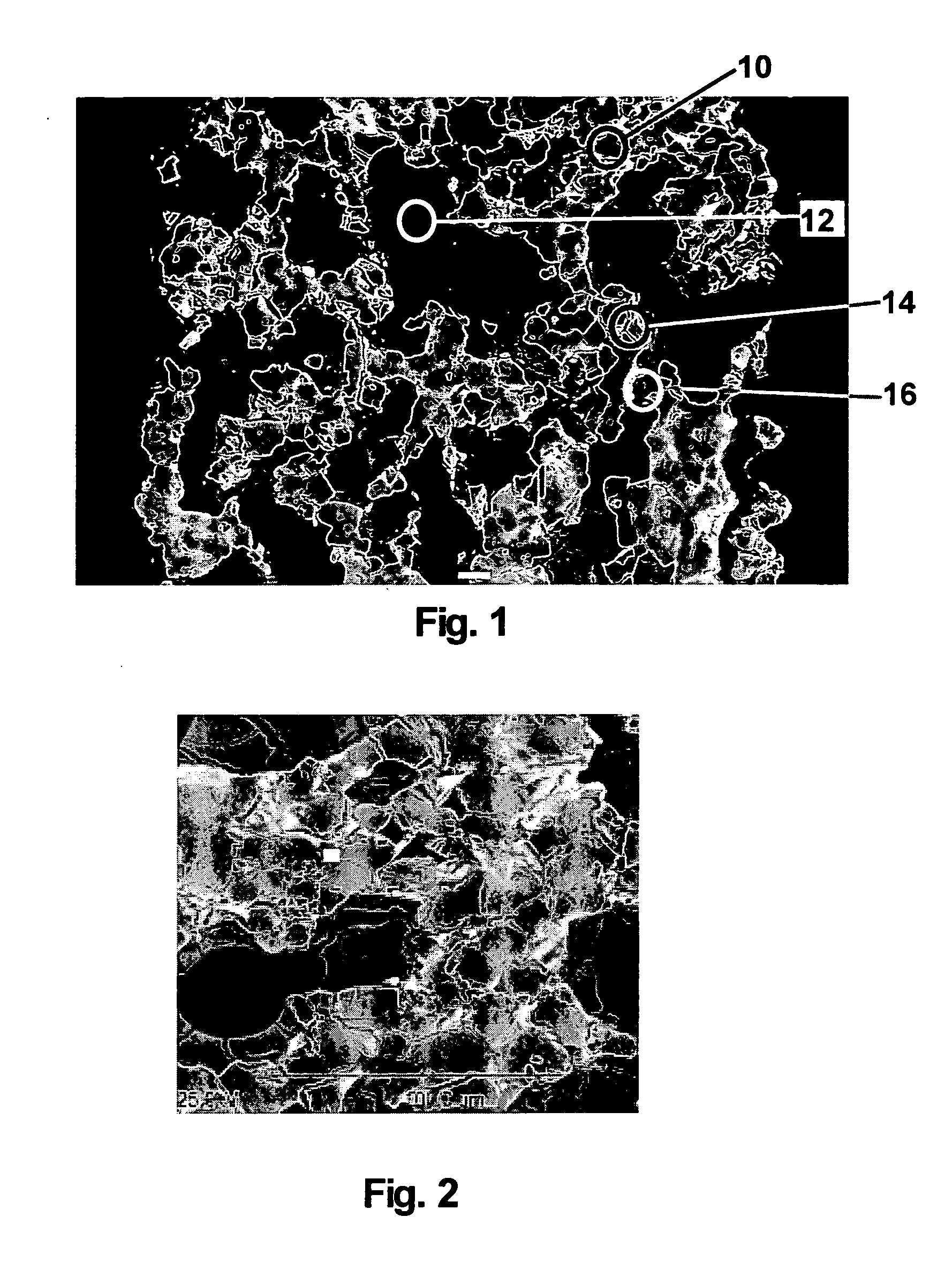

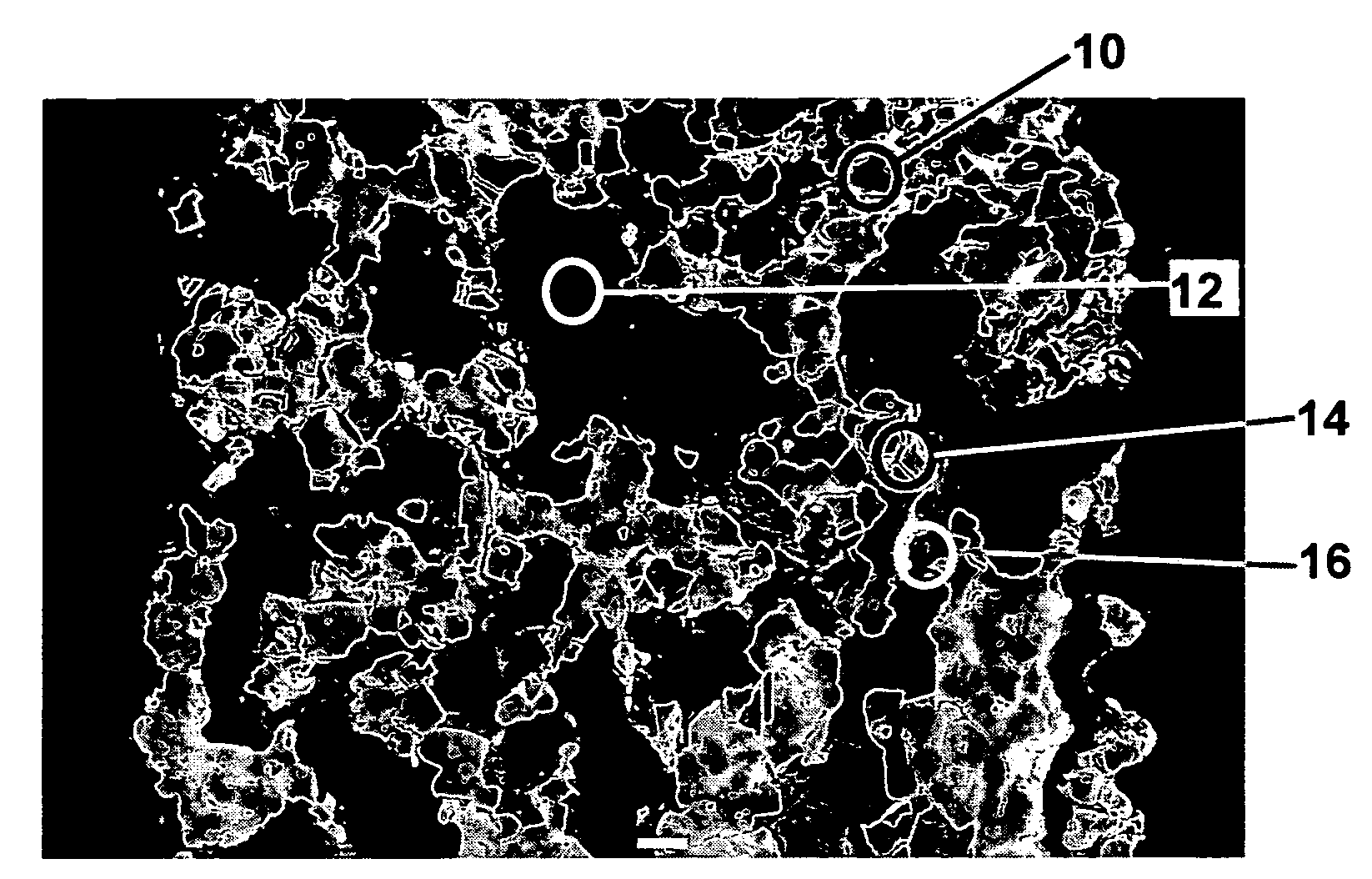

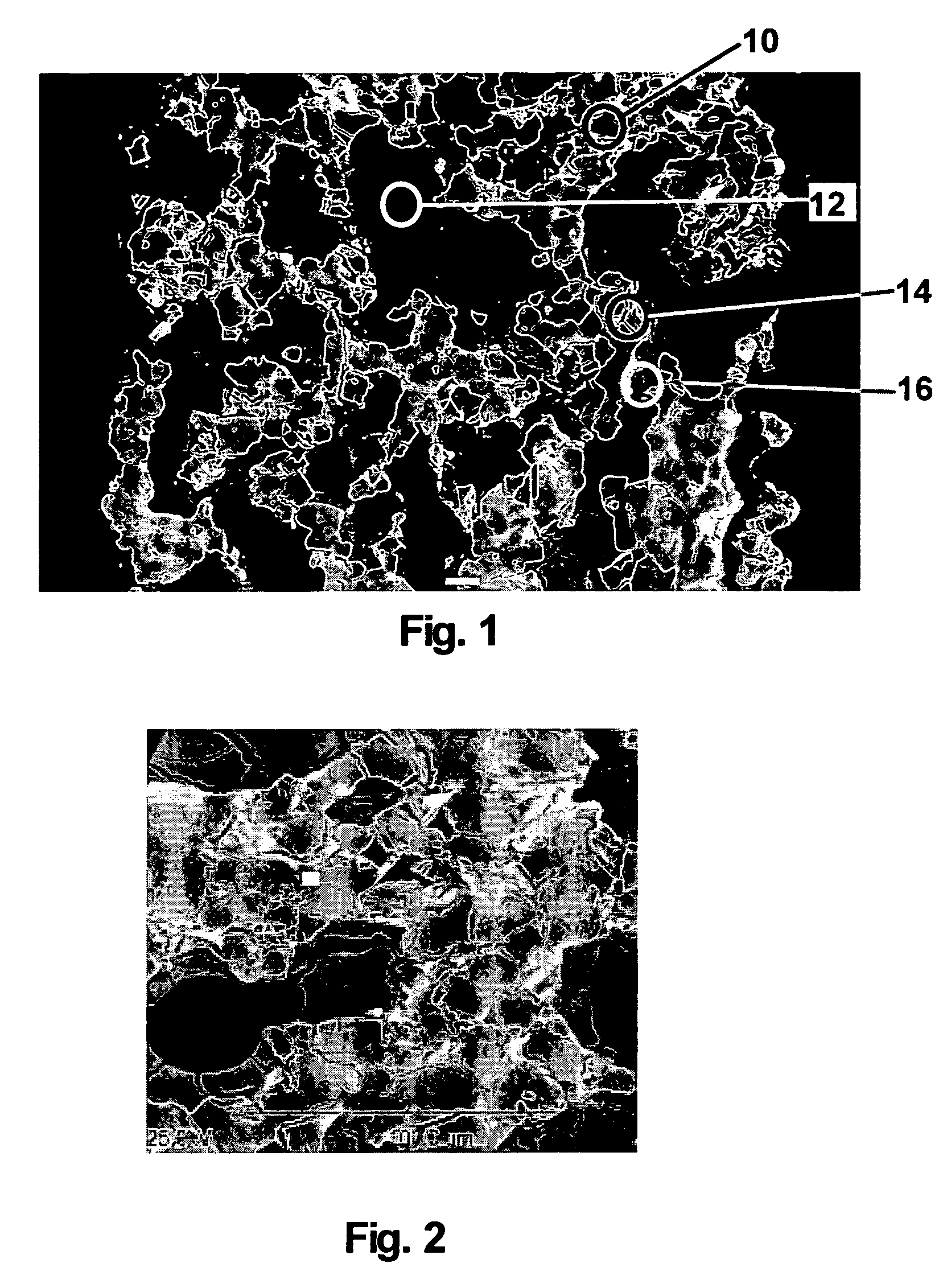

Molding material mixture, molded part for foundry purposes and process of producing a molded part

InactiveUS8006745B2Improve flow characteristicsImprove bending strengthFoundry mouldsFoundry coresShell moldingMicrometer

A molding material mixture for foundry purposes, comprising a mold sand, a sodium hydroxide solution, an alkali-silicate binding agent, and an additive suspension. The molding material mixture contains 0.1 to 10% by weight of sodium hydroxide solution with reference to the weight of the sand, 0.1 to 5% of binding agent with a solid matter percentage of 20 to 70%, and 0.1 to 3% by weight of the additive suspension. The additive suspension comprises 30 to 70% by volume of an amorphous, spherical SiO2 particles, which have a first grain size in the range of 1 to 5 micrometers, and a second grain size in the range of 0.01 to 0.05 micrometers.

Owner:IMERYS METALCASTING GERMANY GMBH

Particle containing a hydrophobic region and a hydrophilic region and methods to make same

InactiveUS20120020106A1Prevents permanent shrinkageLow densitySilicon organic compoundsPigmenting treatmentGlass fiberWaveguide

A particle containing a hydrophobic region and a hydrophilic region, products containing the same, a process of making the same, and uses thereof are described. A process of making the particle is also described wherein UV / Ozone techniques can be used to control the depth of organics removal from a porous hydrophobic particle such as an aerogel. The particles can be used in a variety of applications, such as a monolith, a building block, an optical waveguide, a blanket, a matting agent, a structural composite panel, a glass-fiber reinforced panel, a window, a separation wall, a composite wall, a temperature insulation panel, a sound insulation panel, a moisture resistant article, a syntactic foam, or any product of manufacture containing the particles.

Owner:CABOT CORP

Battery electrode and method for manufacturing same

ActiveUS8846252B2Low flash-dryingHigh plate manufacturing line speedLead-acid accumulatorsPrimary cellsFiberEngineering

A battery electrode with a pasting textile, fabric, or scrim made with an electrode grid (e.g., a stamped grid or expanded metal grid) coated in battery electrode and covered with pasting textile formed of a bonded, non-woven fiber web. The web is formed from one or more fibers with an average length greater than 20 μm. In various embodiments, the web is formed from one or more spun, continuous fibers. The battery electrode may be made in a continuous process where multiple grids are formed in a single sheet, coated with electrode active material, and the scrim before being cut into individual electrodes.

Owner:CPS TECH HLDG LLC

Method for producing chlorotris(triphenylphosphine) rhodium (i)

InactiveUS7145027B2High yieldReduce solubilityRhodium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholCooling down

A process is described for the manufacture of chlorotris(triphenylphosphine)-rhodium(1) by means of causing a reaction of RhCl3 solution with triphenylphosphin in mixtures of C2–C5 alcohols with watersubsequently cooling down and filtering the crystalline precipitate obtained characterized in that the mixture of the reactants is handled in such a way thatB is warmed up to 75° C., andC is maintained at 80 to 110° C.The technique leads to improvements in the yield and quality of the crystals obtained.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Fiber scrim, battery electrode and method for manufacturing same

ActiveUS20140363742A1Low flash-dryingHigh plate manufacturing line speedLead-acid accumulatorsPrimary cellsFiberEngineering

A battery electrode with a pasting textile, fabric, or scrim made with an electrode grid (e.g., a stamped grid or expanded metal grid) coated in battery electrode and covered with pasting textile formed of a bonded, non-woven fiber web. The web is formed from one or more fibers with an average length greater than 20 μm. In various embodiments, the web is formed from one or more spun, continuous fibers. The battery electrode may be made in a continuous process where multiple grids are formed in a single sheet, coated with electrode active material and the scrim before being cut into individual electrodes.

Owner:CPS TECH HLDG LLC

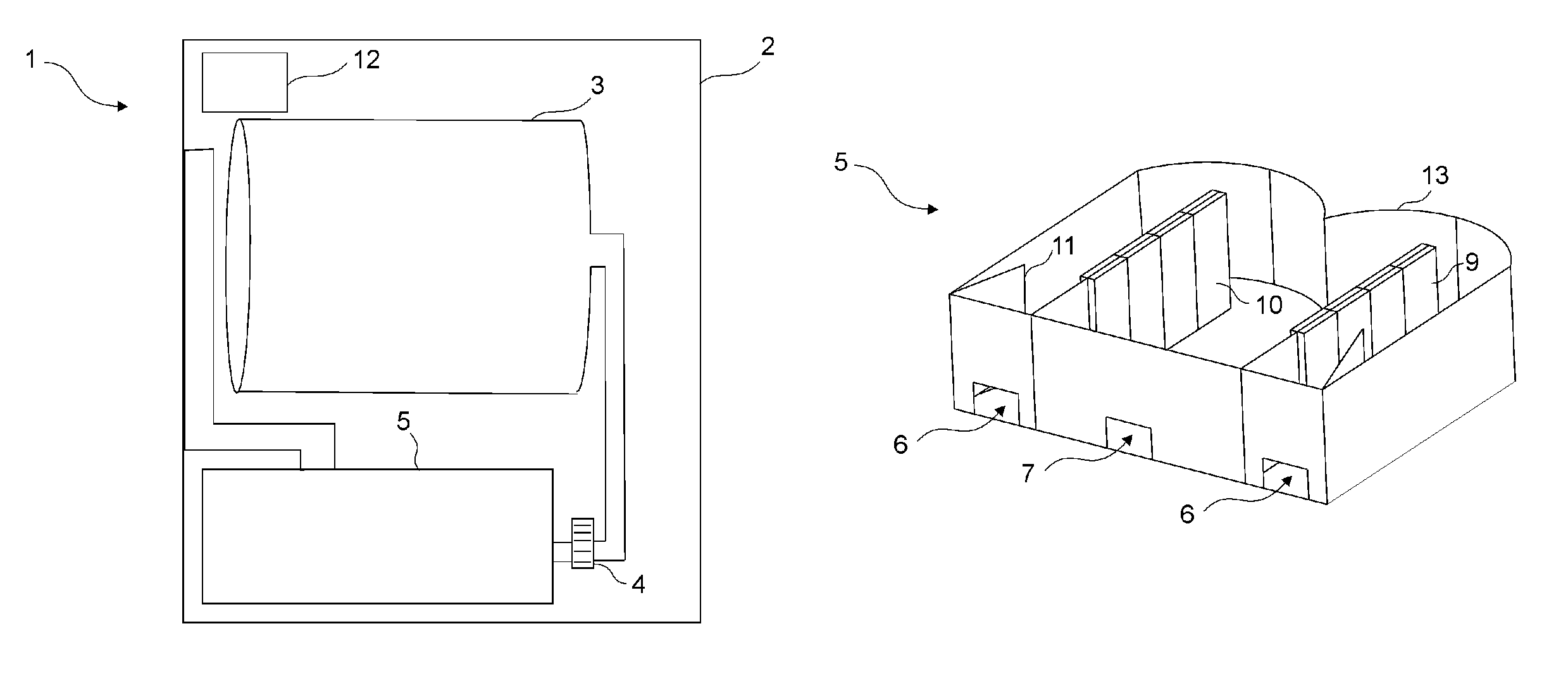

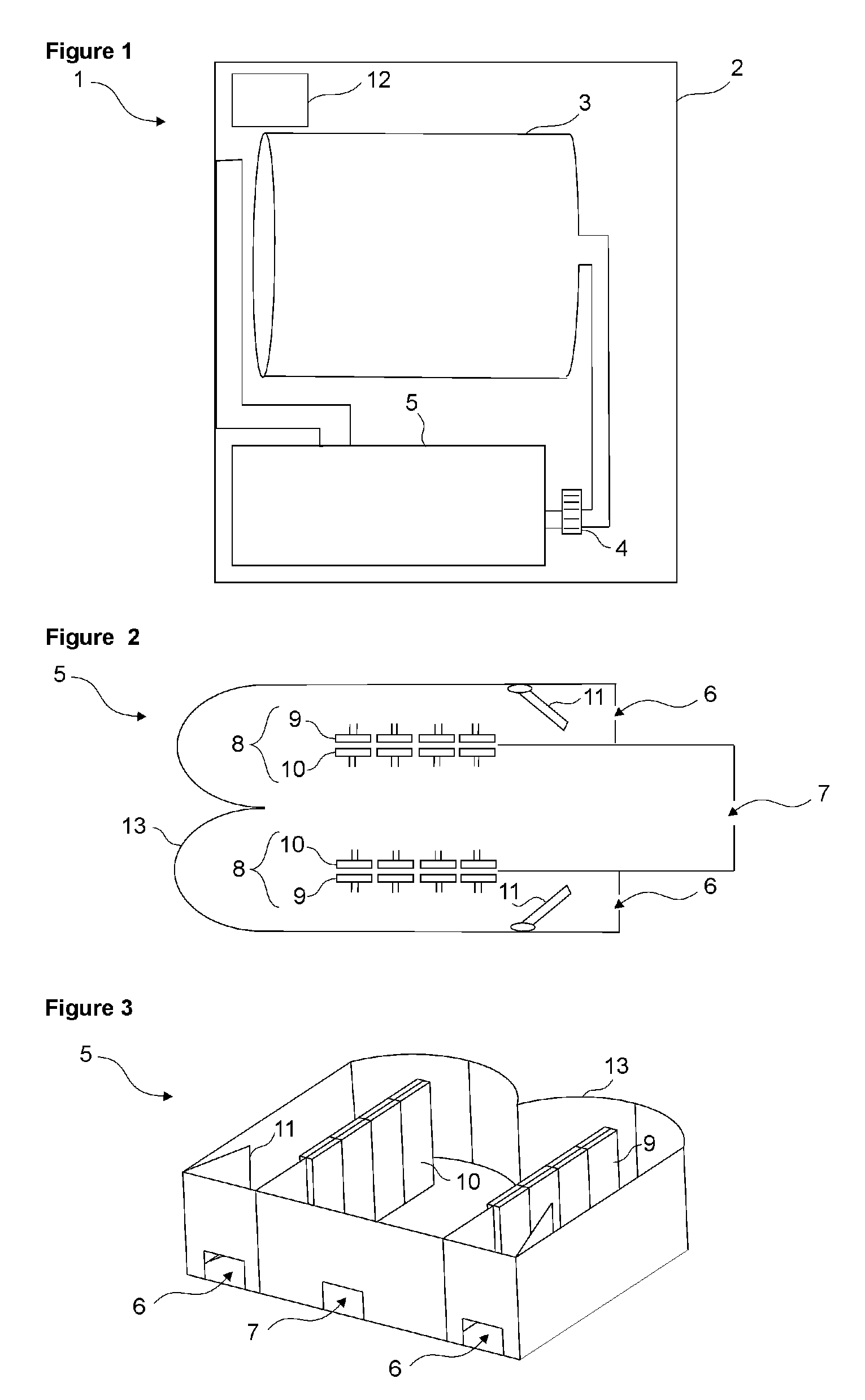

Washer/dryer

InactiveUS9279212B2Effective control of dryingNoiseless and efficient dryingDrying gas arrangementsMachines using electric/magnetic effectsLaundryMechanical engineering

Owner:ARCELIK AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com