Method for constructing superhydrophobic aluminum surface with high stability

A super-hydrophobic, high-stability technology, applied in the field of materials science, can solve the problems of poor super-hydrophobic stability and easy shedding of substances, and achieve the effects of improving anti-corrosion performance, easy operation, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

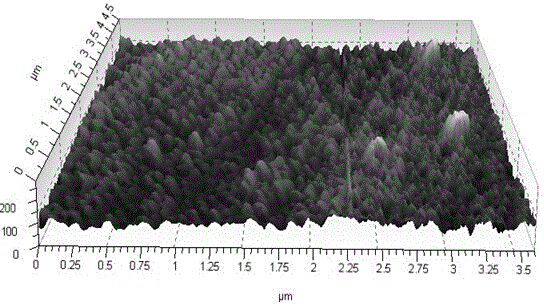

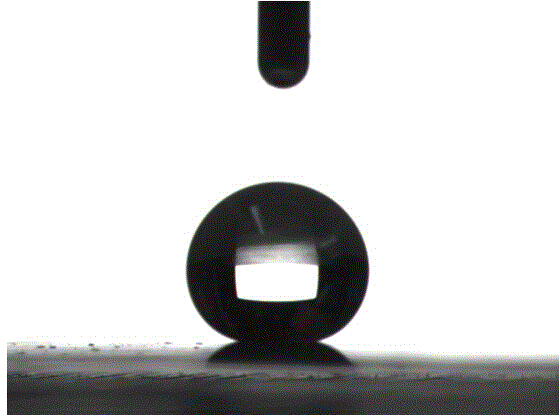

Image

Examples

Embodiment 1

[0020] First, the aluminum sheet (the aluminum element content is 99,99%) is ultrasonically cleaned with acetone and ethanol in sequence, and rinsed with deionized water and dried. Then immerse in 1mol / L sodium hydroxide aqueous solution for 60s, take it out, rinse it with deionized water, and blow dry, then immerse it in 10% nitric acid solution for 60s, take it out and rinse it with deionized water , blow dry. Prepare a 3mol / L phosphoric acid solution as the electrolyte, then use the aluminum plate as the anode and the lead plate as the cathode to carry out the reaction. The reaction temperature was controlled at 0°C, the constant voltage was 40V, and the reaction time was 15 minutes. Wash the reacted aluminum sheet with deionized water and dry it; soak it in ammonia water with a mass fraction of 35% for 3 hours, take it out and rinse it with deionized water and dry it; finally, immerse the aluminum sheet in 3mM / L stearin Aluminum flakes with superhydrophobicity can b...

Embodiment 2

[0022] First, the aluminum sheet (the aluminum element content is 99,99%) is ultrasonically cleaned with acetone and ethanol in sequence, and rinsed with deionized water and dried. Then immerse in 1mol / L sodium hydroxide aqueous solution for 60s, take it out, rinse it with deionized water, and blow dry, then immerse it in 10% nitric acid solution for 60s, take it out and rinse it with deionized water , blow dry. Prepare a 2.6mol / L phosphoric acid solution as the electrolyte, then use the aluminum plate as the anode and the lead plate as the cathode to carry out the reaction. The reaction temperature was controlled at 0°C, the constant voltage was 38V, and the reaction time was 15 minutes. Wash the reacted aluminum sheet with deionized water and dry it; soak it in ammonia water with a mass fraction of 35% for 3.5 hours, take it out and rinse it with deionized water and dry it; finally, immerse the aluminum sheet in 3mM / L hard The superhydrophobic aluminum flakes can be p...

Embodiment 3

[0024] First, the aluminum sheet (the aluminum element content is 99,99%) is ultrasonically cleaned with acetone and ethanol in sequence, and rinsed with deionized water and dried. Then immerse in 1mol / L sodium hydroxide aqueous solution for 60s, take it out, rinse it with deionized water, and blow dry, then immerse it in 10% nitric acid solution for 60s, take it out and rinse it with deionized water , blow dry. Prepare a 2.6mol / L phosphoric acid solution as the electrolyte, then use the aluminum plate as the anode and the lead plate as the cathode to carry out the reaction. The reaction temperature was controlled at 0°C, the constant voltage was 40V, and the reaction time was 30min. Wash the reacted aluminum sheet with deionized water and dry it; soak it in ammonia water with a mass fraction of 35% for 3 hours, take it out and rinse it with deionized water and dry it; finally, immerse the aluminum sheet in 3mM / L stearin Aluminum flakes with superhydrophobicity can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com