Method and apparatus for producing steel-plastic composite pipe

A technology of steel-plastic composite pipe and production method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., and can solve the problems of high, no measures, compounding together, affecting the reliability and strength of mutual melting and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

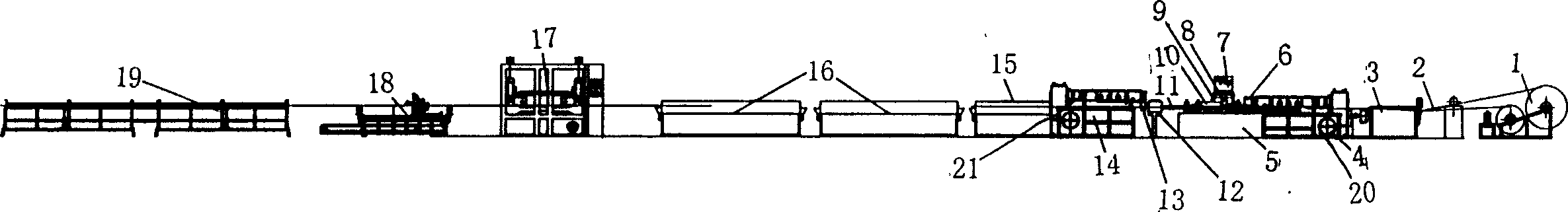

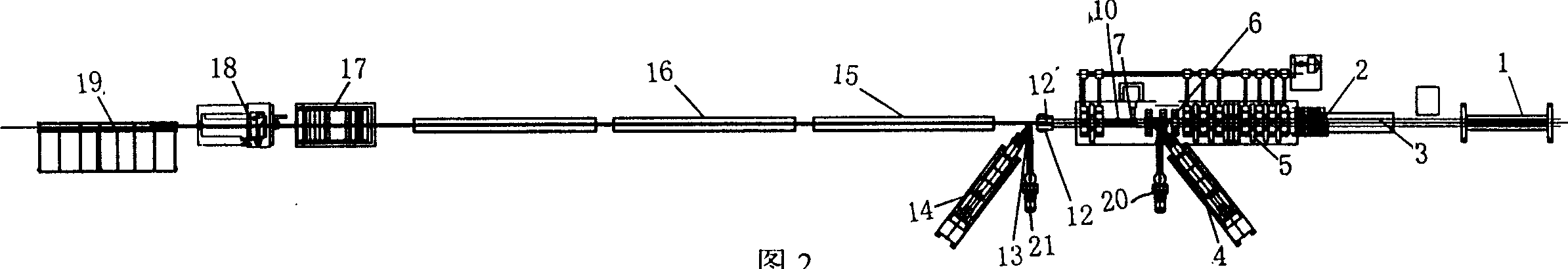

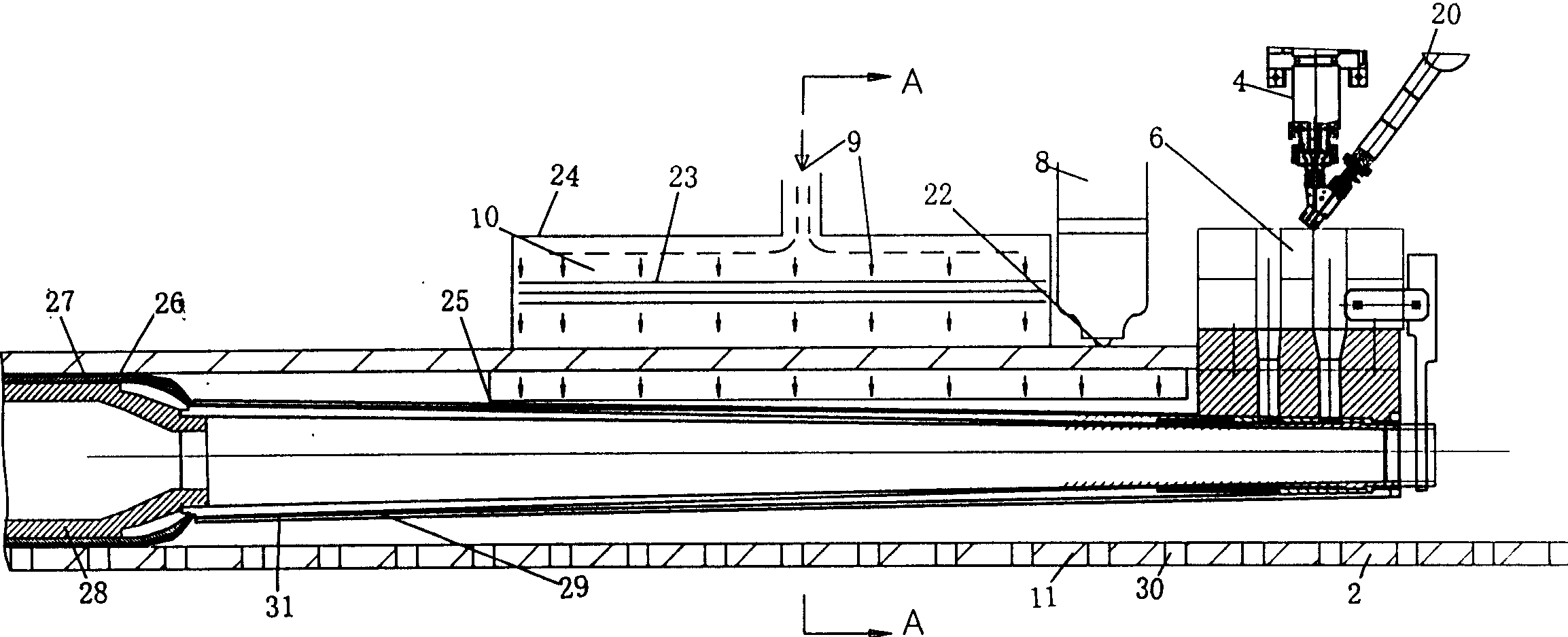

[0039] figure 1 - Figure 4, which shows a diagram of Embodiment 1 of the present invention. see figure 1 , Figure 2, according to the sequence of the composite pipe forming process, an unwinding machine 1 with a perforated steel strip 2, a continuous butt welding mechanism for the perforated steel strip 3, a core tube extruder 4, and an adhesive extruder 20 are arranged , Cylindrical perforated steel framework forming mechanism 5, core layer tube and core tube surface adhesive co-extrusion die head 6, cylindrical perforated steel framework welding mechanism 7, welding nozzle 8, filling weld seam protection device 10 Inert gas 9, welded cylindrical perforated steel frame 11, cylindrical perforated steel frame heater 12, co-extrusion die head 13 of the outer layer tube with adhesive layer on the inner surface, outer layer Pipe extruder 14, outer layer binder extruder 21, composite pipe cooling calibrating box 15, composite pipe spray cooling water tank 16, composite pipe tract...

Embodiment 2

[0042] figure 1 , Fig. 2, Fig. 5 have provided embodiment 2 figure of the present invention. Embodiment 2 is basically the same as Embodiment 1. The difference is that an inflatable tube 32 is installed on the co-extrusion die 6 as shown in FIG. , the inflated airbag will cling to the core tube on the inner surface of the metal skeleton.

Embodiment 3

[0044] figure 1 ,figure 2, Image 6 Figure 3 of Embodiment 3 of the present invention is given. Embodiment 3 is basically the same as Embodiment 1. The difference is as Image 6 In the extrusion die head 35 shown in the cylindrical metal skeleton 11 that has been welded and formed, there are respectively a core layer pipe extrusion flow channel 37 and an adhesive layer extrusion flow channel 36. In the repair ring 34 (or Under the action of scraper), the first extruded adhesive layer 26 is closely attached to the inner surface of the metal skeleton, and then the core layer tube 27 is extruded, and under the action of the inner sizing rod 28 (or plugging), the core layer tube 27 is compounded on the inner surface of the metal skeleton through the adhesive layer 26. The step-by-step method is used to extrude the adhesive layer separately on the inner surface of the metal skeleton, and then extrude the core layer tube on the adhesive layer, which is beneficial to separately a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com