Anti-shattering adhesive composition for glass, glass product and application

A technology of glass products and compositions, applied in the direction of coating, etc., can solve the problems of complex application steps of glass coating production process, increase production efficiency, disadvantages, etc., achieve good appearance and light extraction efficiency, simple production process, and good surface leveling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the glass anti-shattering adhesive composition of the present invention, firstly mix the components (A), (D) and silazane in an internal mixer for 2 hours, then discharge the material after vacuuming at 170°C for 2 hours, and mix in other Components (each component is counted in parts by mass), and if necessary, add components (F) and (G) and other additives such as inorganic fillers, pigments, flame retardants and heat-resistant agents, etc., thereby preparing curable glass Anti-fragmentation composition.

[0061] In the present invention, a glass product is provided, including a glass body, and the glass body is coated with a cured product of the glass anti-shattering adhesive composition of the present invention.

[0062] The application of the glass anti-shatter adhesive composition of the present invention on glass products includes: diluting the above-mentioned mixed composition in an organic solvent, the type of the organic solvent is no...

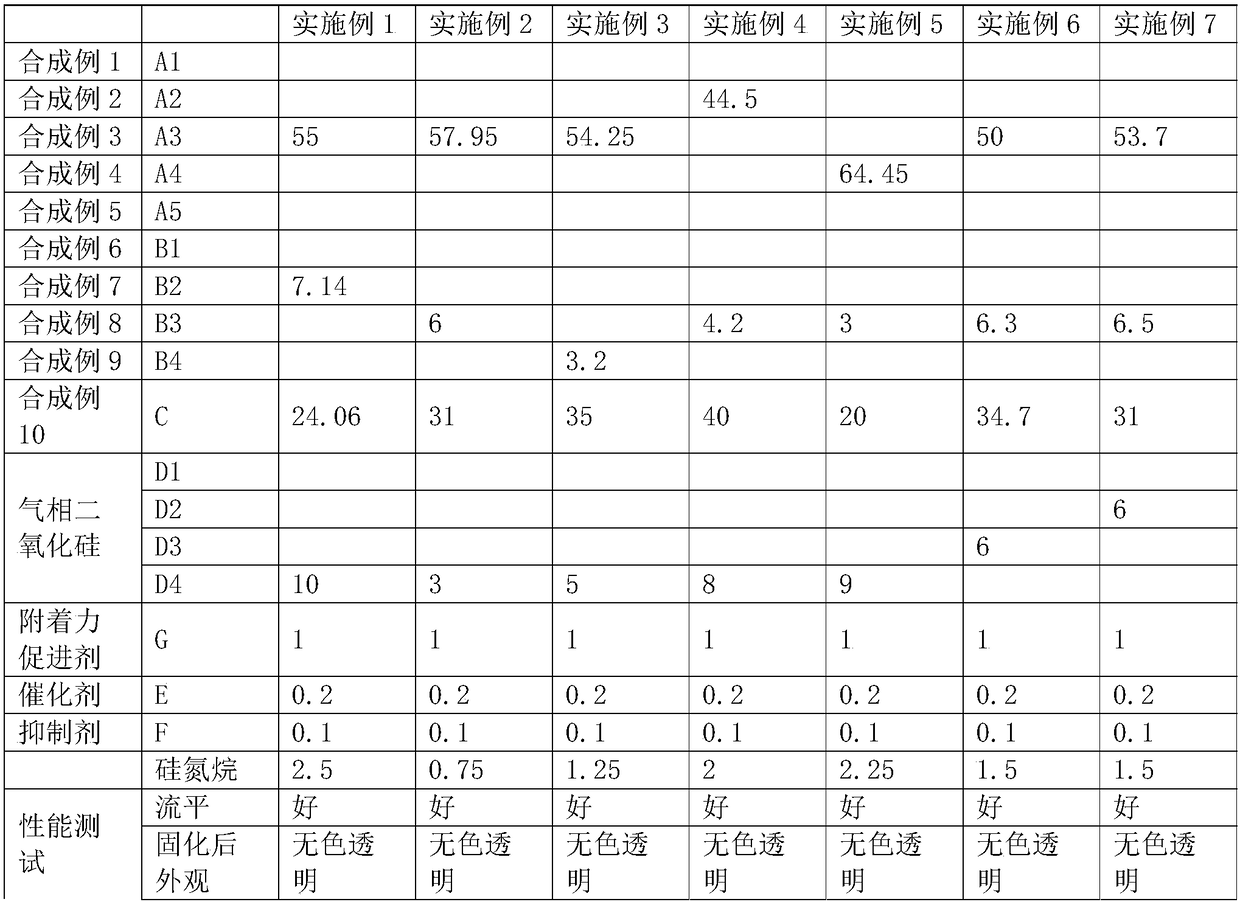

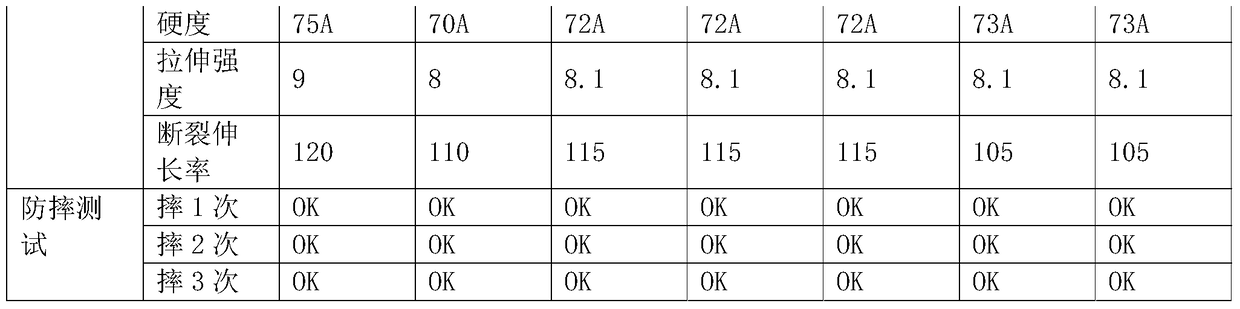

Embodiment 1~7 and comparative example 1~9

[0116] First mix the resins (A), (D) and silazane prepared in the synthesis example in an internal mixer for 2 hours, then vacuumize at 170° C. for 2 hours and discharge, and mix in other components according to the combination shown in Table 1 ( Each component is in parts by mass) to obtain the composition of the present invention.

[0117] The physicochemical properties of the obtained compositions were evaluated by the following methods. Record the results in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com