Glass shot blasting device for optimizing surface of small-wire-diameter spring

A technology of shot blasting device, glass shot, applied in the direction of used abrasive processing device, abrasive material, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

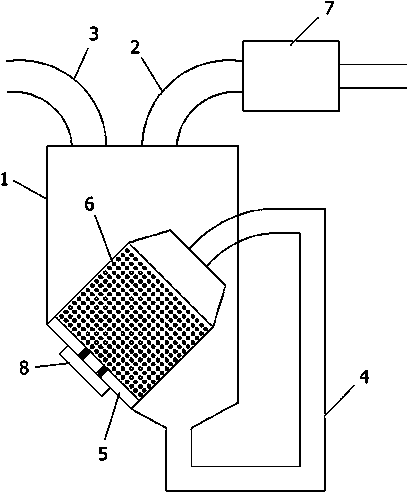

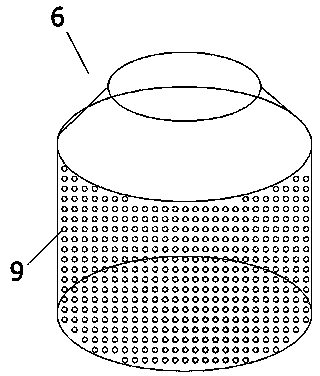

[0016] The invention provides a shot blasting device, which is used for optimizing the surface of a spring with a small wire diameter, and the adopted shot is glass shot. Such as figure 1 As shown, the shot blasting device includes a sealed shot blasting chamber 1, and the two sides of the top of the shot blasting chamber are respectively communicated with an air delivery pipeline 2 for feeding compressed air and an air outlet pipeline 3 for discharging impurities, wherein the air delivery A solenoid valve 7 is provided at the entrance of the pipeline. The bottom of the shot blasting chamber is communicated with a conveying pipeline 4 for transporting glass pellets. One end of the conveying pipeline communicates with the bottom of the blasting chamber, and the other end extends into the blasting chamber. The bottom of the shot blasting cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com