Processing device for by-product hydrochloric acid of industrial potassium sulfate

A technology for by-producing hydrochloric acid and processing equipment, which is applied in the fields of halogen/halogen acid, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve the problems of yellowing color, restriction on the use of hydrochloric acid, etc., and achieves low processing cost, low investment, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

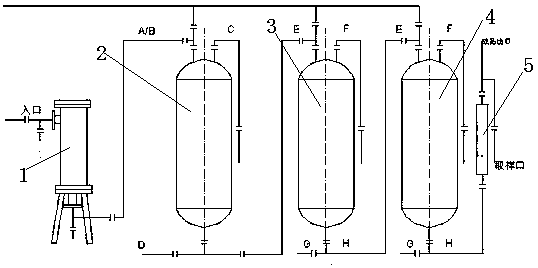

[0020] A kind of treatment equipment of industrial potassium sulfate by-product hydrochloric acid, comprises filter 1 and resin column, and described resin column comprises first resin column 2, second resin column 3 and the 3rd resin column 4, and one end of filter 1 and inlet The air pipe is connected, the other end of the filter 1 is connected with the first resin column 2, the other end of the first resin column 2 is connected with the second resin column 3, and the second resin column 3 is connected with the third resin column 4, The other end of the third resin column 4 communicates with the finished product outlet and the sampling port respectively. A flow meter 5 is arranged between the third resin column 4 and the finished product outlet, which is convenient for controlling output. The filter 1 adopts a bag filter, which is small in size, easy and flexible in operation, energy-saving and strong in applicability. The first resin column 2 and the second resin column 3 ...

Embodiment 2

[0022] A kind of treatment equipment of industrial potassium sulfate by-product hydrochloric acid, comprises filter 1 and resin column, and described resin column comprises first resin column 2, second resin column 3 and the 3rd resin column 4, and one end of filter 1 and inlet The air pipe is connected, the other end of the filter 1 is connected with the first resin column 2, the other end of the first resin column 2 is connected with the second resin column 3, and the second resin column 3 is connected with the third resin column 4, The other end of the third resin column 4 communicates with the finished product outlet and the sampling port respectively. A graphite condenser is installed between the filter and the first resin column. A graphite condenser is installed between the filter 1 and the first resin column 2 to lower the temperature of the gas to facilitate the next step. Cyclone dust removal equipment is installed between the graphite condenser and the first resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com